Factory Service Manual For New Holland AD300 Dump Truck. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 603

Number: 6045615101

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

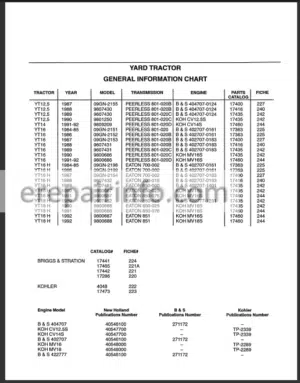

Model

New Holland Articulated Dump Trucks

AD300

Contents

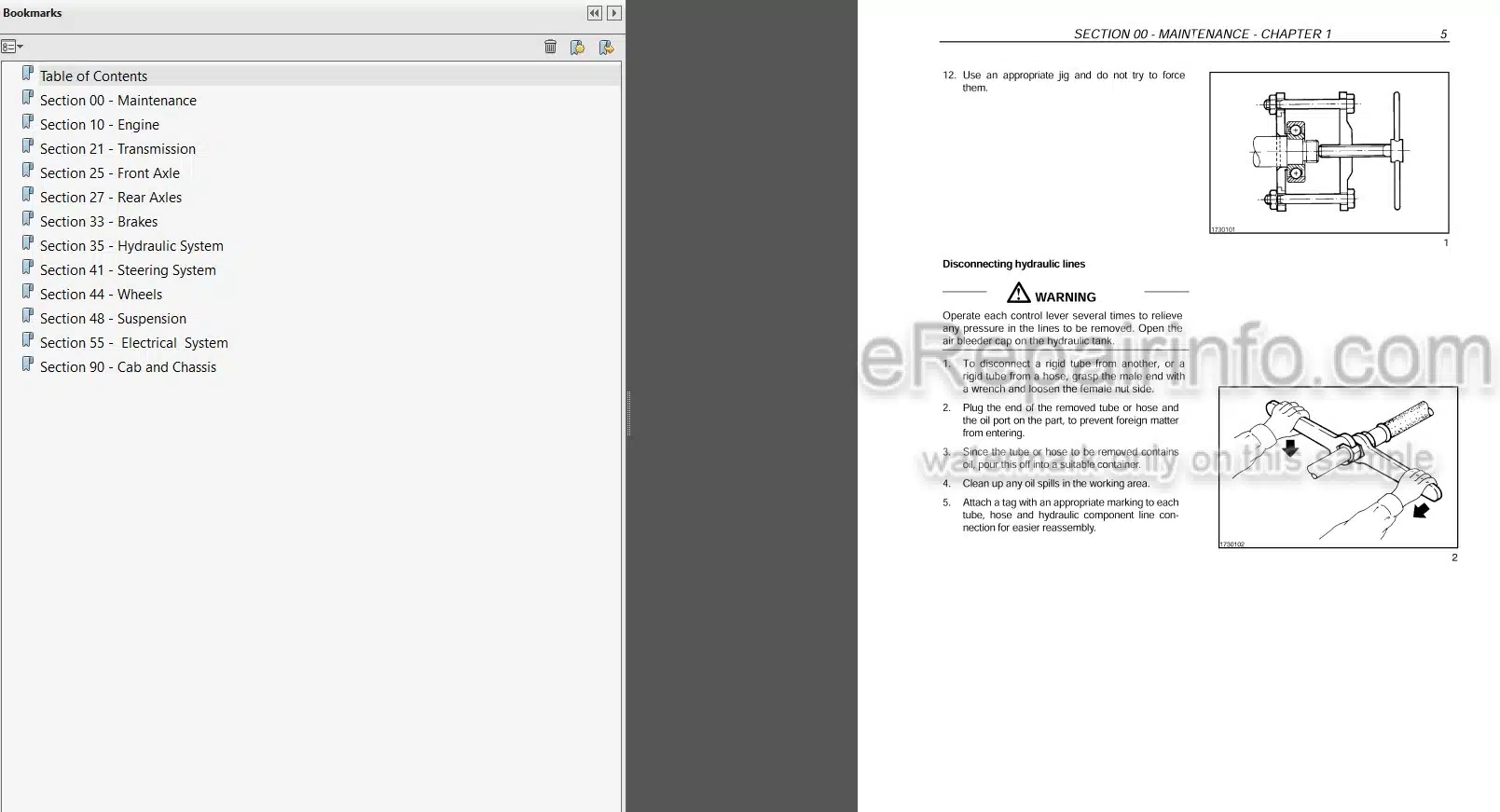

-MAINTENANCE

General Instructions

Specifications

Tooling

Convers

Safety Instruction

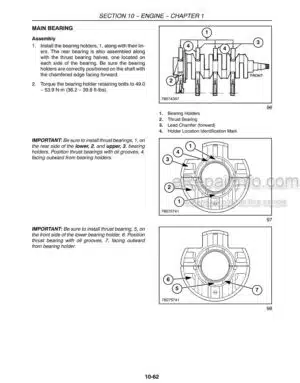

-ENGINE-ENGINE OVERHAUL

External View Of Engine

Engine Lubrication Circuit

Engine Air Intake System

Engine Exhaust System

Engine Fuel Feed System

Engine Cooling System

Coolant Circulation Inside The Engine

Specifications And Data

Diagnostic

Tightening Torques

Special Tools

Engine Removal-Refit

Radiator Removal-Refit

Water-Lubricant Exchanger Removal-Refit On Automatic Transmission

Engine-Periodical Replacement

Engine-Adjustments

Engine – Partial Removals-Refits

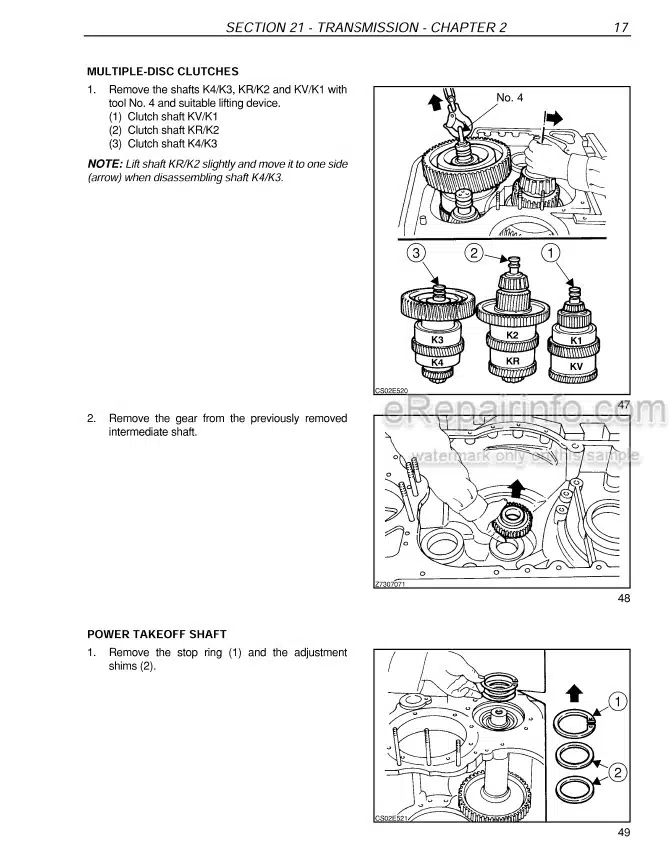

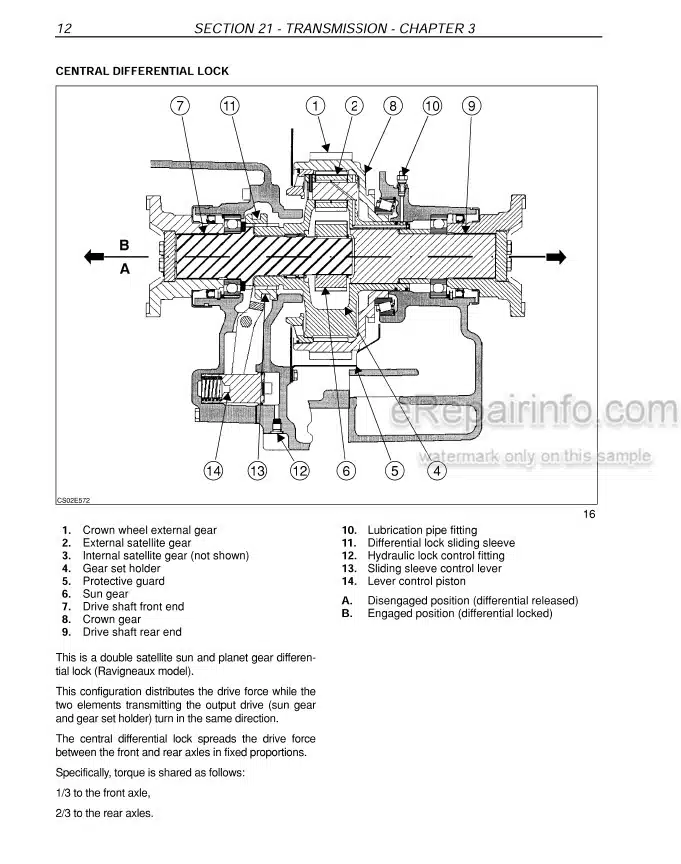

-TRANSMISSION-AUTOMATIC TRANSMISSION

Drive Shaft

Gearbox

Pressure Check And Troubleshooting

Transmission Control Valve

-FRONT AXLE-OVERHAUL

Description

First Reduction: Bevel Gear Pair

Second Reduction: Hub And Epicyclic Train

Specifications And Data

Diagnostic

Tightening Torques

Axle

Epicyclical Reduction Gears

Differential

Tools

Epicyclical Reduction Gears

Axle Removal – Refit

Knuckle Hinge Strip Down

Axle-Hinge Strip Down

Specific Maintenance

Checking Axle / Transfer Case Oil Level

Changing Axle / Transfer Case Oil

Epicyclical Reduction Gear

Checking The Dismantled Parts

Checking The Dismantled Parts

Break-Down Drawing Of Self-Locking Differential

Break-Down Drawing Of Pinion

-REAR AXLES-INTERMEDIATE AXLE

Description

First Reduction: Bevel Gear Pair

Second Reduction: Hub And Epicyclic Train

Transfer Unit

Diagnostic

Tightening Torques

Axle

Epicyclical Reduction Gears

Differential

Tools

Epicyclical Reduction Gears

Differential

Axle Removal – Refit

Axle-Rocker Arm Support – Parking Brake Strip Down

Specific Maintenance

Checking Axle / Transfer Case Oil Level

Changing Axle / Transfer Case Oil

Epicyclical Reduction Gear

Checking The Dismantled Parts

Differential And Splitter

Checking The Dismantled Parts

Lockable Splitter

Self-Locking Differential

Location Of Spacers / Adjustment Ring Nuts And Relative Bearings

Finding The Thickness Of Spacer S1 For Pinion Axial Position

Pinion Bearing Axial Pre-Load: Nil

Shape And Position Of Contact Area

-REAR AXLE

Description

First Reduction: Bevel Gear Pair

Second Reduction: Hub And Epicyclic Train

Specifications And Data

Axle

Epicyclical Reduction Gears

Epicyclical Reduction Gears

Axle Removal – Refit

Axle – Knuckle Hinge Strip Down

Specific Maintenance

Checking Axle / Transfer Case Oil Level

Changing Axle / Transfer Case Oil

Epicyclical Reduction Gear

Checking The Dismantled Parts

Checking The Dismantled Parts

Break-Down Drawing Of Self-Locking Differential

Break-Down Drawing Of Pinion

-BRAKES-BRAKE OVERHAUL

Specifications

Torque Specifications

Special Tools

Description

Troubleshooting

Overhaul

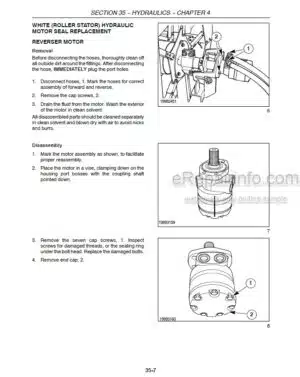

-HYDRAULIC SYSTEM-HYDRAYLIC CIRCUITS AND COMPONENTS

Hydraulic System

Main Hydraulic System

Front Layout

Steering – Tipping (Version Without Retarder)

Steering – Tipping (Version With Retarder)

Main Hydraulic System

Rear Layout

Steering Tipping

Description Of Components

Main Hydraulic System

General Lay-Out

Brakes

Main Hydraulic Pump

Brake Hydraulic Pump

Steering Emergency Electro-Pump

Tipper Cylinders

Tipper Control Distributor

Power Steering

Counterbalancing Valve

Flow Amplifier

Hydraulic System Diagram

Maintenance

Changing Hydraulic Oil

Replacing Pressurised Oil Filter (Pump Outlet)

Replacing Inner Hydraulic Oil Filter (Intake)

Changing Hydraulic Brake Oil Filter

Checking Fitting And Pipe Tightness

Bleeding The Hydraulic System

Checks And Verify

Hydraulic Pressure Test Point

Main Pressure Test Point

Steering Pressure Test Point

6WD Pressure Test Point

Main Pump Removal – Refitting

Brake Pump Removal – Refitting

Steering Valve Removal – Refitting

Rate Of Flow Amplifier Removal – Refitting

Tilt Valve Removal – Refitting

Steering Cylinder Removal – Refitting

Tilt Cylinder Removal – Refitting

-STEERING SYSTEM-Steering Circuit

Description

Troubleshooting

Steering Valve

-WHEELS-TIRES AND WHEELS

Specifications

Torque Specifications

Troubleshooting

Description

Replacing A Complete Wheel

Tire And Wheel Checks

-SUSPENSION-SUSPENSION OVERHAUL

Specifications

Torque Specifications

Special Tools

Description

Troubleshooting

Suspension Cylinder

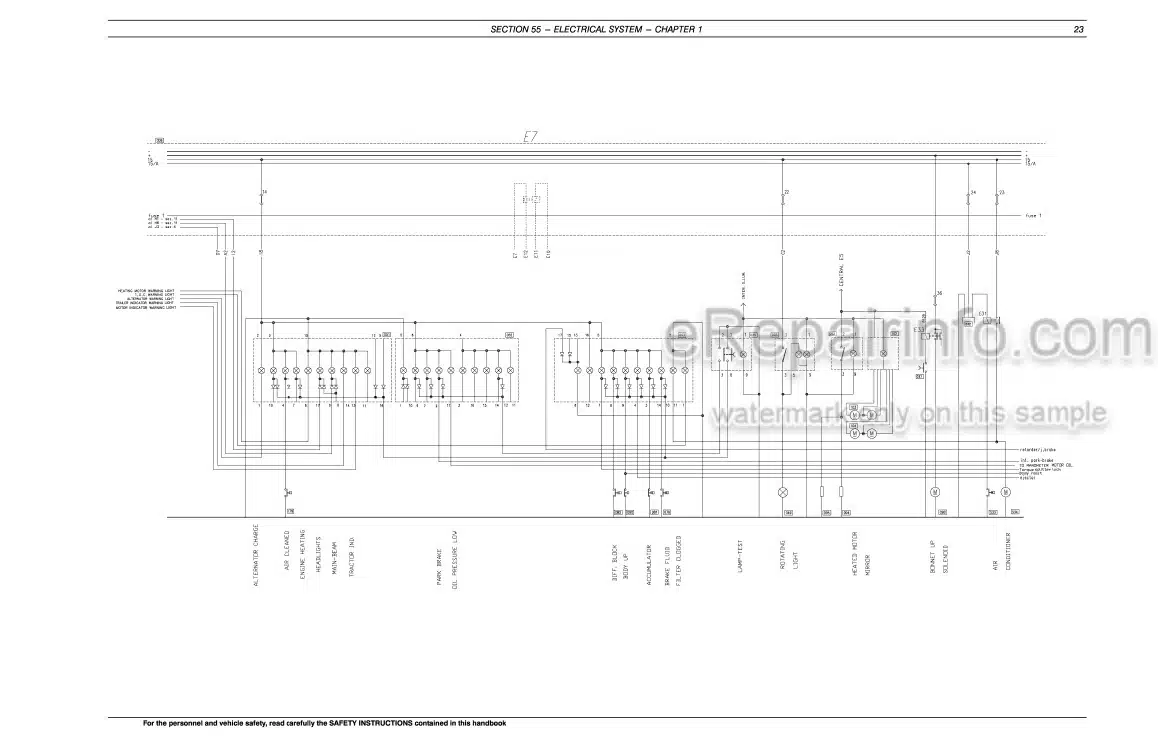

-ELECTRICAL SYSTEM-WIRING DIAGRAM

Technical Data

International System Units (S.L.)

Main Elements – Resistivity And Temperature Coefficient

Resistor Colour Codes

General Instructions

General Precautions

General Precautions For Electronic Components

The Concept Of Earth And Electromagnetic Compatibility

Practical Hints

Cable Colour Codes

Identification Of The Electric Function By The Cable Colour Code

Control Units Location

Transmission Control Unit

Interconnection Control Unit

Fuse

Teleruptors

Layout Electrical System

-CAB AND CHASSIS

Cab And Chassis

Body

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.