Factory Repair Manual For New Holland CR920, CR940, CR960, CR970 Combine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 4344

Number: 87600552

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Combine

CR920

CR940

CR960

CR970

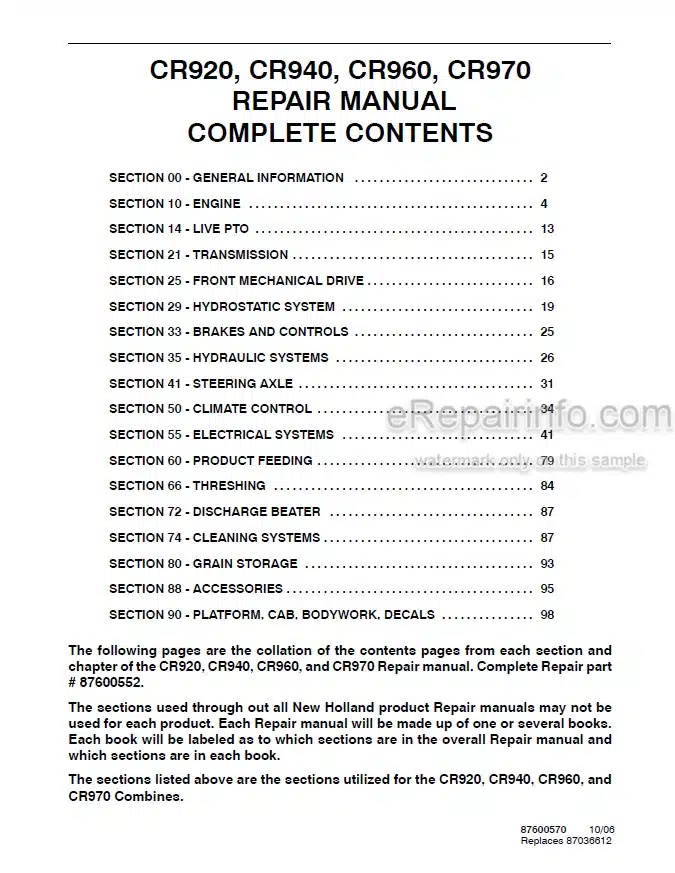

Contents

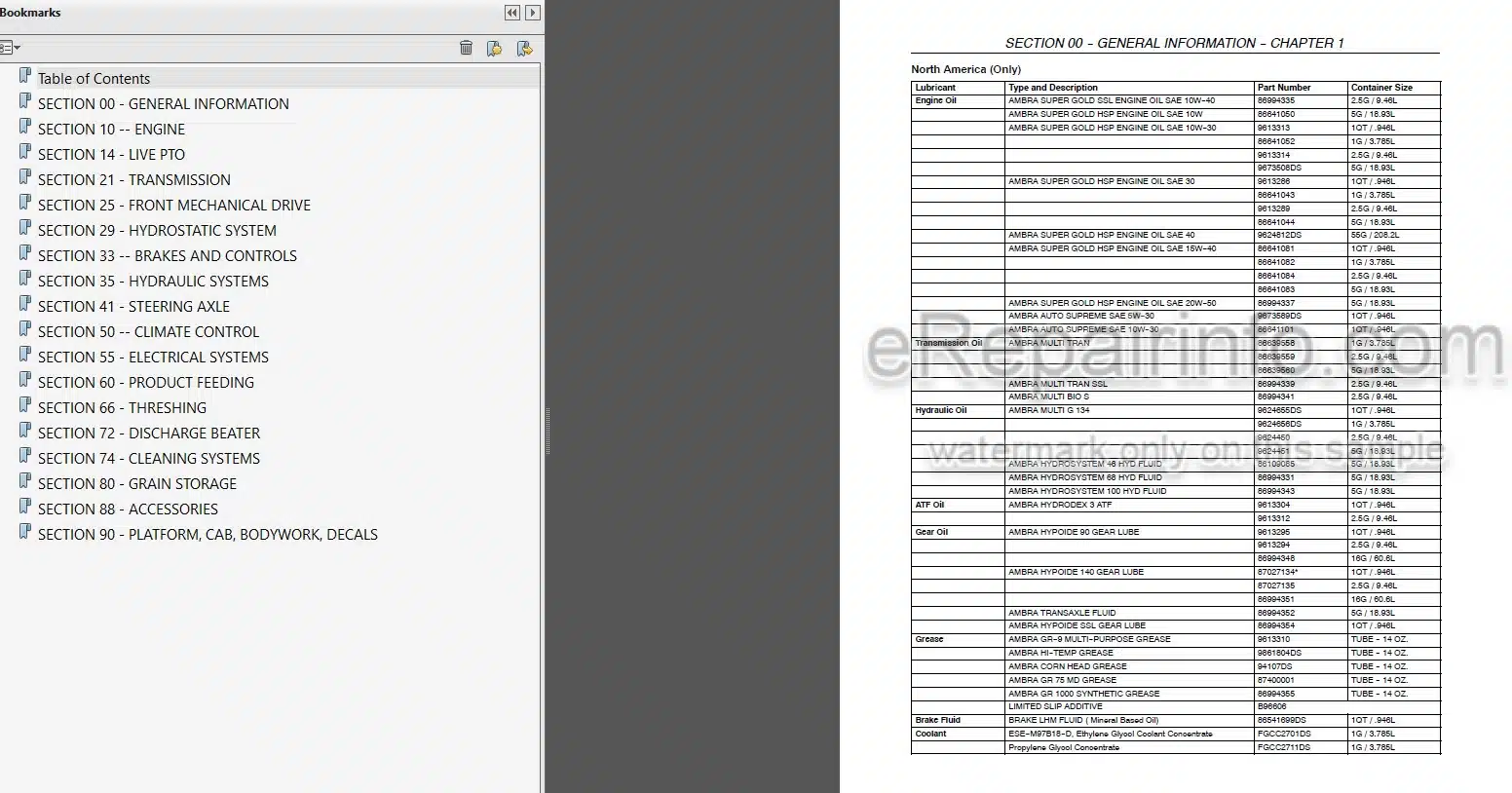

– GENERAL INFORMATION

Foreword

Precautionary Statements

Service Techniques

Product Identification

Minimum Hardware Tightening Torques

Recommended Lubricants And Coolants (North America Only)

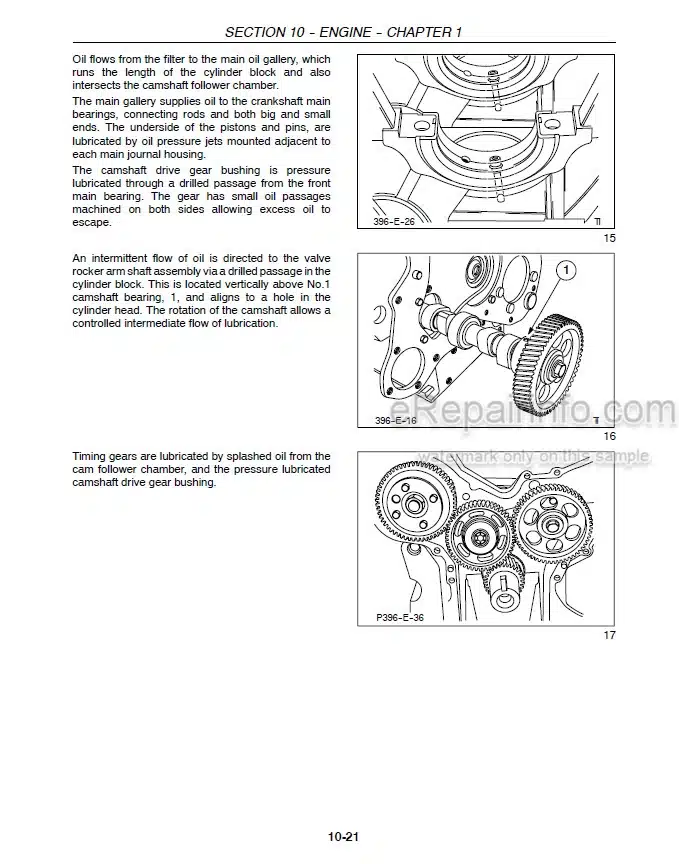

– ENGINE

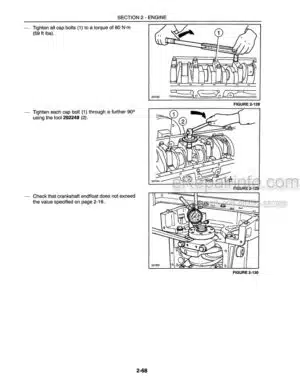

7.5L Engine Block

7.5L Cooling

7.5L Complete Engine, Remove and Replace

7.5L Fuel System

7.8L, 10.3L Description of Operation

7.8L, 10.3L Complete Engine, Remove and Replace

7.8L, 10.3L Engine Block

Common Engine Compartment Components

– LIVE PTO

Engine Gearbox, Clutch Pack Removal/Installation

Engine Gearbox, Clutch Pack Rebuild

Engine Gearbox Removal/Installation

Engine Gearbox Rebuild

– TRANSMISSION

Specifications

Tightening Torques

Special Tools

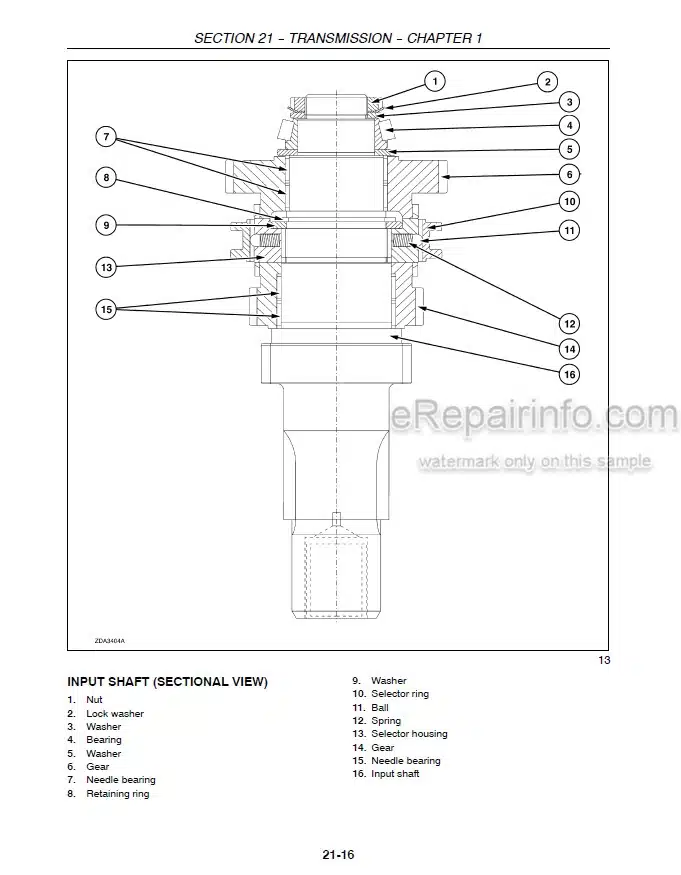

Sectional/Exploded Views

Overhaul

– FRONT MECHANICAL DRIVE

Planetary Final Drive

11/111 Final Drives

– HYDROSTATIC SYSTEM

Hydrostatic Drive System Introduction

Hydrostatic System Operation

Filling the Hydrostatic System and Start-up Procedure

Powered Rear Axle

Pressure Testing and Troubleshooting

Hydrostatic Pump and Motor Repair

– BRAKES AND CONTROLS

Specifications

Tightening Torques

Minimum Hardware Tightening Torques

Overhaul

– HYDRAULIC SYSTEMS

Introduction

Description of Operation

Pressure Testing and Fault Finding The High and Low Pressure Hydraulic Systems

Hydraulic Pump

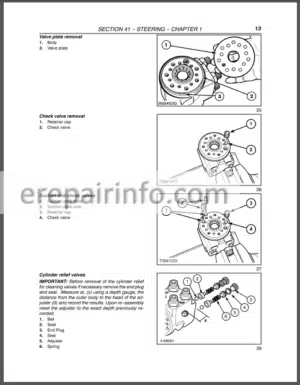

Stack Valves Overhaul

– STEERING AXLE

Axle, General

Wheel Bearings (HDASA)

Steering Pivot (HDASA)

Center Section

Powered Rear Steering Axle BSN HAJ100101

Hydrostatic Motor ASN HAJ100101

– CLIMATE CONTROL

Heating, Ventilation and Air-Conditioning

Air Filters

Blower Fans

Compressor

Condenser

Cool Box

Evaporator

Heater Core

High/Low Pressure Cutout Switch

Receiver/Dryer

Thermal Expansion Valve

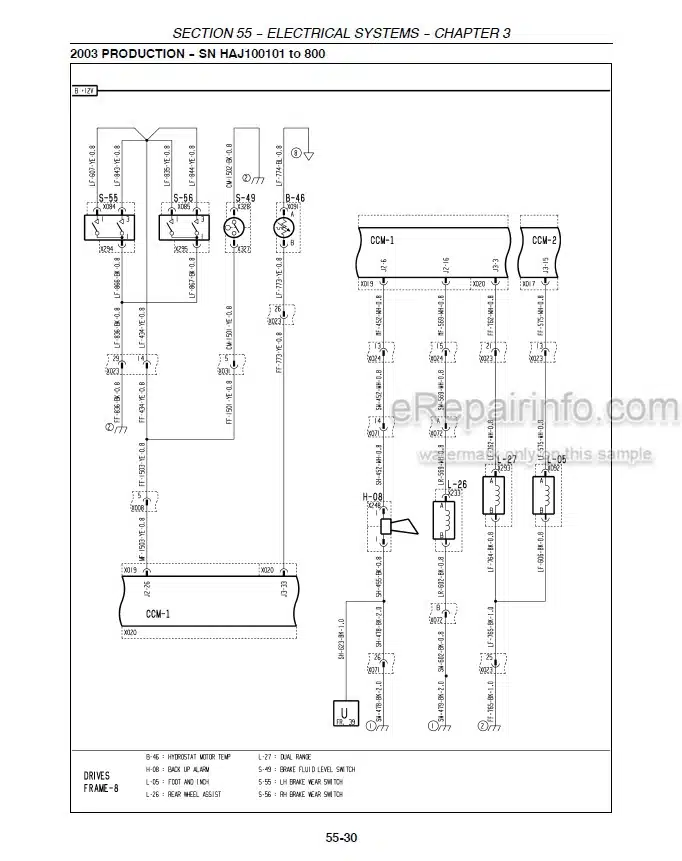

– ELECTRICAL SYSTEMS

General Information

Infoview Monitor Diagnostic Functions

Electrical Schematics

CAN Data Bus Network

Engine Systems

Power Distribution and Lighting

Cab Systems

Hydraulic Systems

Driveline Systems

Header Systems

Feeder Systems

Threshing Systems

Cleaning Systems

Clean Grain Systems

Crop Residue

Precision Farming

Electrical Connectors

CCM1 Error Codes

CCM2 Error Codes

CCM3 Error Codes

Engine Fault Codes

HHC Diagnostic Codes

ASP Fault Codes

RHM Fault Codes

– PRODUCT FEEDING

Feeder House

Feeder Drives

Stone Ejection System

– THRESHING

Rotor Chamber

Rotors

Main Threshing Drives

– DISCHARGE BEATER

Specifications

Introduction

Overhaul

– CLEANING SYSTEMS

Cleaning Shoe Frame

Cleaning Shoe Drive

Cleaning Fan and Drives

Returns System

– GRAIN STORAGE

Clean Grain Transport

Unloading System

– ACCESSORIES

Straw Chopper

Chaff/Corn Spreader

Positive Straw Discharge (PSD)

– PLATFORM, CAB, BODYWORK, DECALS

Cab

Shielding

Blow Off System

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.