Factory Repair Manual For New Holland E18SR Compact Crawler Excavator; Mitsubishi L3E Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 682

Number: 87630256NA

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Crawler EXcavator

E18SR

Mitsubishi Diesel Engine

L3E

Contents

1.NEW HOLLAND E18SR SERVICE MANUAL COMPACT CRAWLER EXCAVATOR

2.MITSUBISHI DIESEL ENGINE L3E-W231KBS SERVICE MANUAL

1.NEW HOLLAND E18SR SERVICE MANUAL COMPACT CRAWLER EXCAVATOR

SAFETY

-OUTLINE

General Precautions For Repairs

International Unit Conversion System

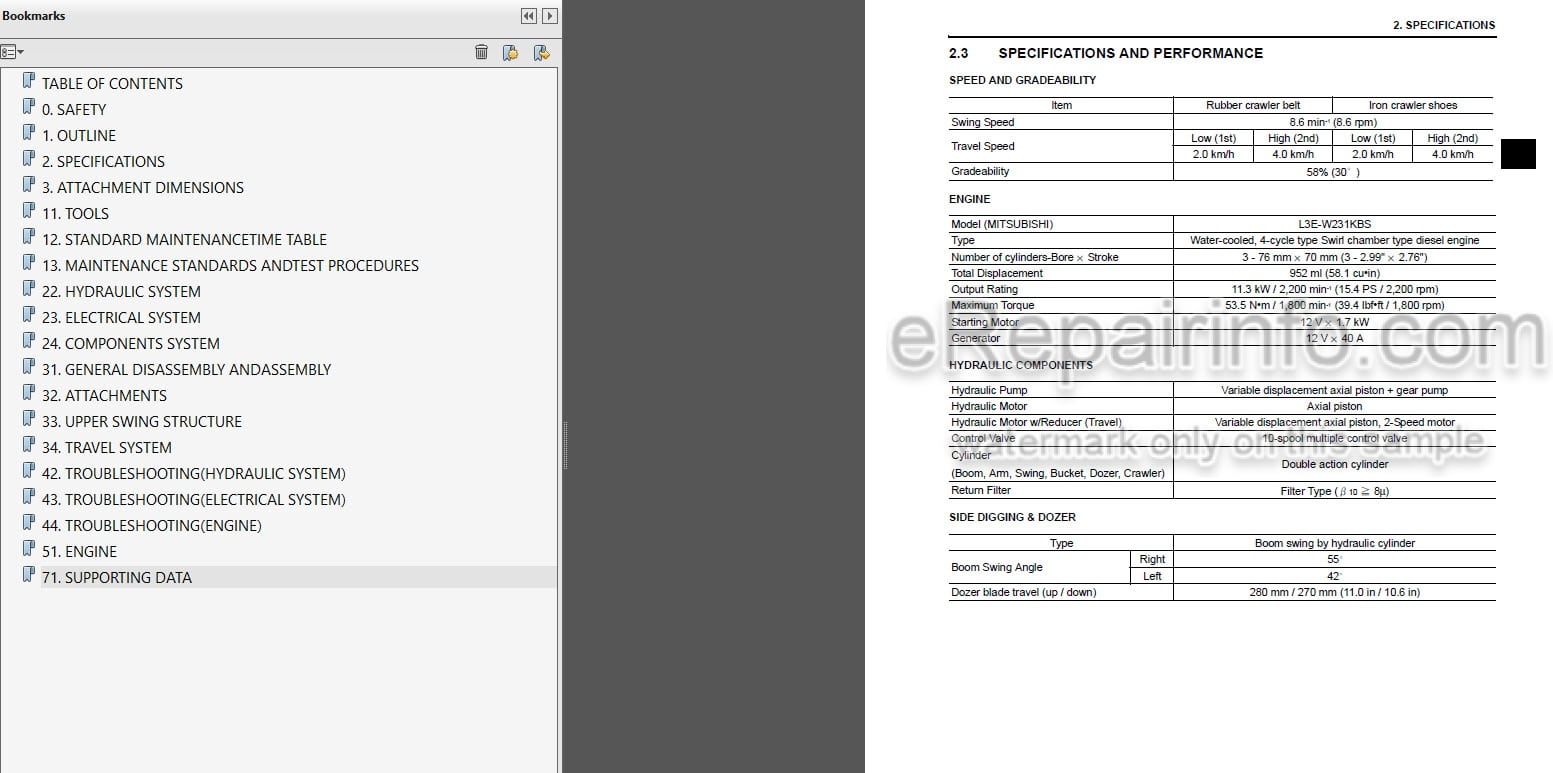

-SPECIFICATIONS

Components Name

Machine Dimensions

Specifications And Performance

Machine & Components Weight

Transportation

Type Of Crawler Shoes

Type Of Bucket

Engine Specifications

-ATTACHMENT DIMENSIONS

Boom

Arm

Bucket

Dozer

Swing

-TOOLS

Torque Specifications For Capscrews & Nuts

Screw And Tool Sizes

Torque Specifications For Joints And Hoses

Torque Specifications For Sleeve Type Tube Fittings

Plugs

Special Spanners For Tubes

Special Tools

Application Of Screw Locking And Sealing Compounds

Counterweight Lifting Jig

-STANDARD MAINTENANCETIME TABLE

Standard Working Time Table For The Maintenance Of Excavator

-MAINTENANCE STANDARDS ANDTEST PROCEDURES

How To Use Maintenance Standards And Precautions

Performance Inspection Standard Table

Measuring Engine Speed

Measuring Hydraulic Oil Pressure

Measuring Travel Performances

Measuring Swing Performances

Measuring Attachment Operating Performances

Measuring Swing Bearing Performances

Measuring Crawler Tension

-HYDRAULIC SYSTEM

Summary

Hydraulic Circuits And Component Models

Hydraulic Circuit Operation

Schematic Piping For Hydraulic System

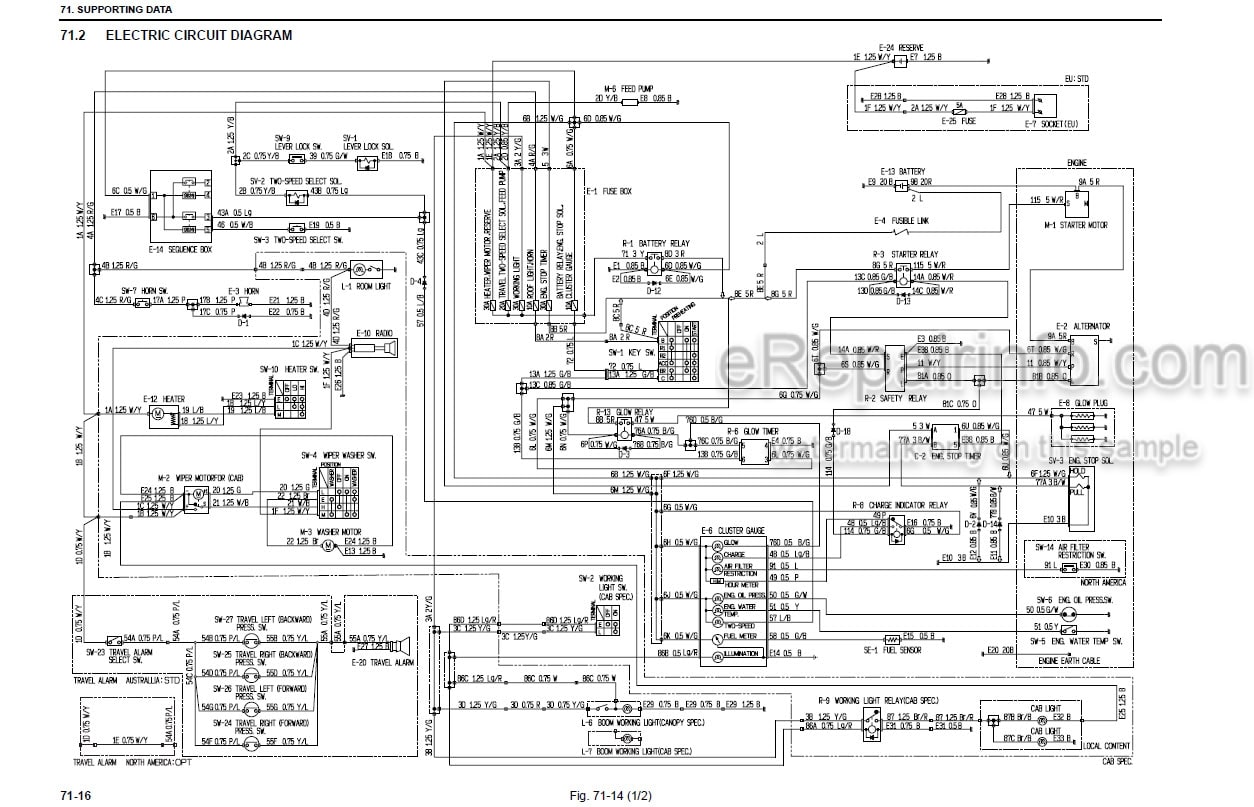

-ELECTRICAL SYSTEM

How To Read Circuit Diagram And Harness Connection

Electrical Equipment & Harness

-COMPONENTS SYSTEM

Hydraulic Components

Electrical Equipment

-GENERAL DISASSEMBLY ANDASSEMBLY

General Disassembly And Assembly

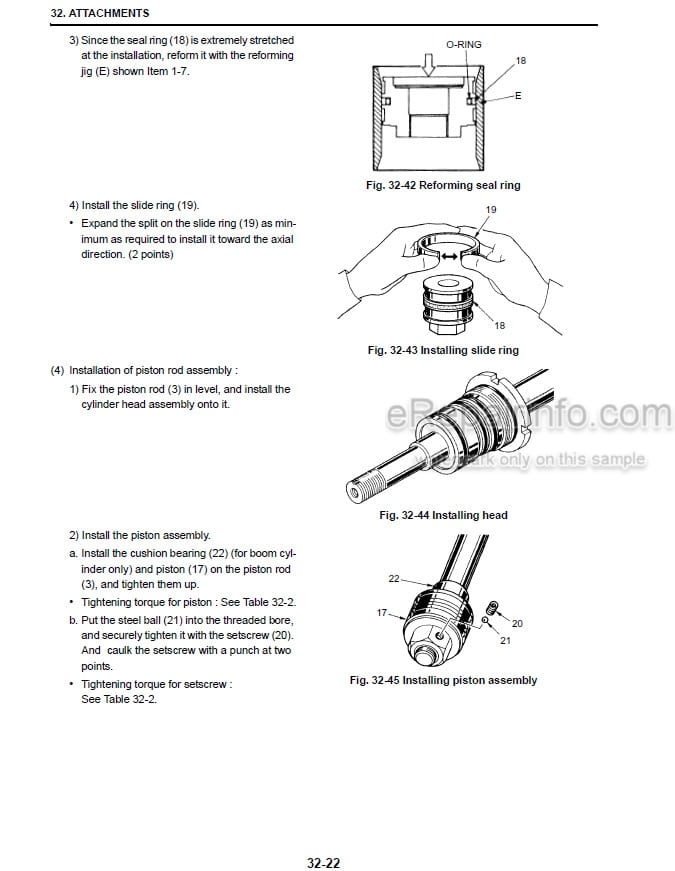

-ATTACHMENTS

Removing And Installing

Disassembling And Assembling

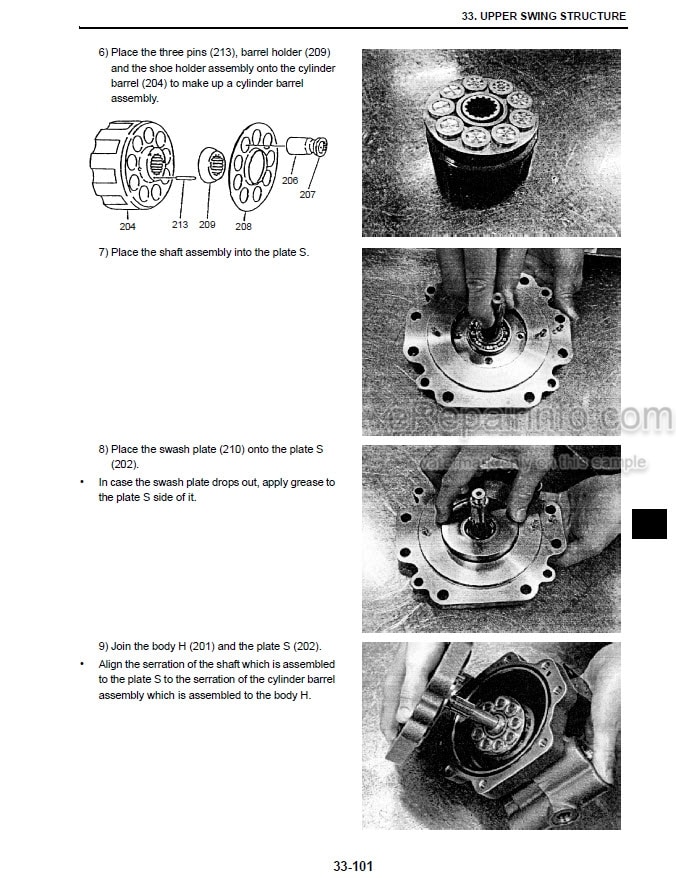

-UPPER SWING STRUCTURE

Removing And Installing

Disassembling And Assembling

-TRAVEL SYSTEM

Removing And Installing

Disassembling And Assembling

-TROUBLESHOOTING(HYDRAULIC SYSTEM)

General Precautions

Trouble Diagnosis: Hydraulic

Troubleshooting

-TROUBLESHOOTING(ELECTRICAL SYSTEM)

Trouble Diagnosis: Electric System

Troubleshooting

-TROUBLESHOOTING(ENGINE)

Trouble Diagnosis: Engine

Troubleshooting

-ENGINE

-SUPPORTING DATA

Hydraulic Circuit Diagram

Electric Circuit Diagram

2.MITSUBISHI DIESEL ENGINE L3E-W231KBS SERVICE MANUAL

-GENERAL

Outline

Specifications

Tips On Disassembling And Reassembling

-SERVICE DATA

Maintenance Service Data

Tightening Torque Table

-BASIC AND SPECIAL TOOLS

Basic Tools

Special Tool

-OVERHAUL DETERMINATION

Determining Overhaul Timing

Testing Compression Pressure

-DISASSEMBLING ENGINE MAIN PARTS

Disassembling And Inspecting Cylinder Head And Valve Mechanism

Disassembling And Inspecting Flywheel

Disassembling And Inspecting Gear Case, Timing Gears And Camshaft

Disassembling And Inspecting Cylinder Block, Crankshaft, Piston And Oil Pan

-INSPECTION AND REPAIRING ENGINE MAIN PARTS

Inspecting And Repairing Cylinder Head And Valve Mechanism

Inspecting And Repairing Flywheel

Inspecting And Repairing Gear Case, Timing Gears And Camshaft

Inspecting And Repairing Cylinder Block, Crankshaft, Piston And Oil Pan

-REASSEMBLING ENGINE MAIN PARTS

Reassembling Cylinder Block, Crankshaft, Piston And Oil Pan

Reassembling Gear Case, Timing Gear And Camshaft

Reassembling Flywheel

Reassembling Cylinder Head And Valve Mechanism

-FUEL SYSTEM

Removing Fuel System

Disassembling, Inspecting And Reassembling Fuel System

Installing Fuel System

-LUBRICATION SYSTEM

Removing Lubrication System

Disassembling, Inspecting And Reassembling Lubrication System

Installing Lubrication System

-COOLING SYSTEM

Removing Cooling System

Disassembling, Inspecting And Reassembling Cooling System

Installing Cooling System

-INLET AND EXHAUST SYSTEMS

Removing Inlet And Exhaust

Disassembling, Inspecting And Reassembling Inlet And Exhaust Systems

Installing Inlet And Exhaust Systems

-ELECTRICAL SYSTEM

Removing Electrical System

Disassembling, Inspecting And Reassembling Electrical System

Installing Electrical System

-ENGINE ADJUSTMENT, BREAK-IN OPERATION AND PERFORMANCE TESTS

Inspecting And Adjusting Engine

Break-In Operation

Performance Test (JIS Standard)

-TROUBLESHOOTING

Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.