Factory Repair Manual For New Holland E235B Excavator; Case 667TA/EEG, 667TA/EEC, 667TA/EBF, 667TA/EED, 667TA/EBJ, 667TA/EDJ Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 896

Number: 87495895A

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Excavator

E265B

Case Engine

667TA/EEG

667TA/EEC

667TA/EBF

667TA/EED

667TA/EBJ

667TA/EDJ

Contents

1.NEW HOLLAND E235B REPAIR MANUAL EXCAVATOR.

2.CASE 667TA/EEG, 667TA/EEC, 667TA/EBF, 667TA/EED, 667TA/EBJ, 667TA/EDJ REPAIR MANUAL ENGINE.

1.NEW HOLLAND E235B REPAIR MANUAL EXCAVATOR.

-SAFETY

General Safety Information

Safety Precautions

-OUTLINE

General Precautions For Making Repairs

International Unit System

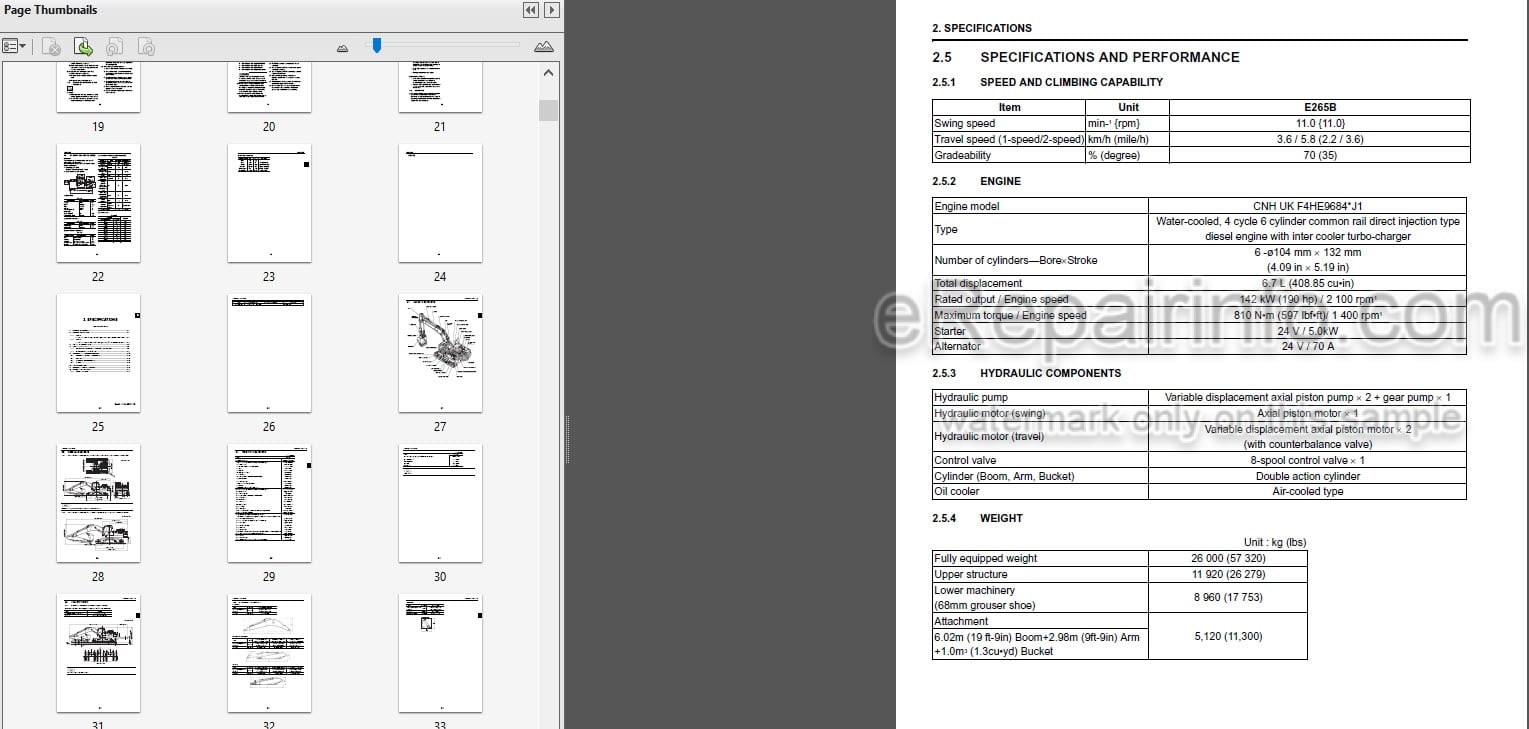

-SPECIFICATIONS

Name Of Components

General Dimensions

Weight Of Components

Transportation

Specifications And Performance

Type Of Crawler

Combinations Of Attachment

Engine Specifications

-ATTACHMENT DIMENSIONS

Boom

Arm

Bucket And Pin

-TOOLS

Standard Torque Specifications For Capscrews And Nuts

Screw Size

Torque Specifications For Hose And Fittings

Torque Specifications For Nuts And Sleeves

Plug

Special Spanner For Tube

Special Tools

Application Of Screw Locking Compound And Sealing Compound

Suction Stopper

Counter Weight Lifting Jig

Engine Turnover Stand

Track Spring Set Jig

-STANDARD MAINTENANCE TIMETABLE

Standard Working Time Table For The Maintenance Of Excavator

-MAINTENANCE STANDARD AND TEST PROCEDURE

How To Use The Maintenance Standard

Performance Inspection Standard Table

Measurement Of Engine Speed

Measurement Of Hydraulic Pressure

Measuring Travel Performances

Measuring Swing Performances

Measuring Attachment Operating Performances

Measuring Performances Of Swing Bearing

Mechatro Controller

-MECHATRO CONTROL SYSTEM

Summary Of Mechatro Control System

Mechatro Controller

-HYDRAULIC SYSTEM

Summary

Hydraulic Circuits And Components

Color Coding Standard For Hydraulic Circuits

Neutral Circuit

Travel Circuit

Bucket Circuit

Boom Circuit

Swing Circuit

Arm Circuit

Combined Circuit

Pressure Draining (Releasing) Circuit

-ELECTRICAL SYSTEM

Electric Circuit Diagram

Electrical Equipment List

Harness

-COMPONENTS SYSTEM

Hydraulic Components

Electric Equipment

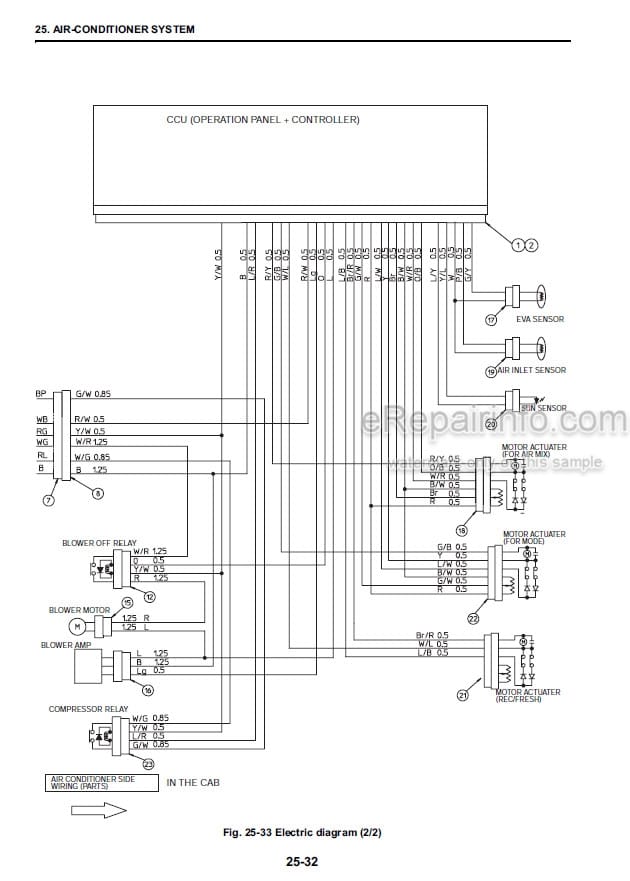

-AIR CONDITIONER SYSTEM

Basic Air Conditioner System (HVAC Air Conditioner)

Component And Construction

Piping

Function

Disassembly And Assembly

Charging Refrigerant

-ELECTRIC CIRCUIT

Wiring Diagram And Connectors

Structure And Operation Of Each Part And Inspection

Troubleshooting

Self Diagnosis Function On Display Of Panel

-DISASSEMBLY AND ASSEMBLING

Disassembly & Assembly Overview

-ATTACHMENT

Removing And Installing

Disassembling And Assembling

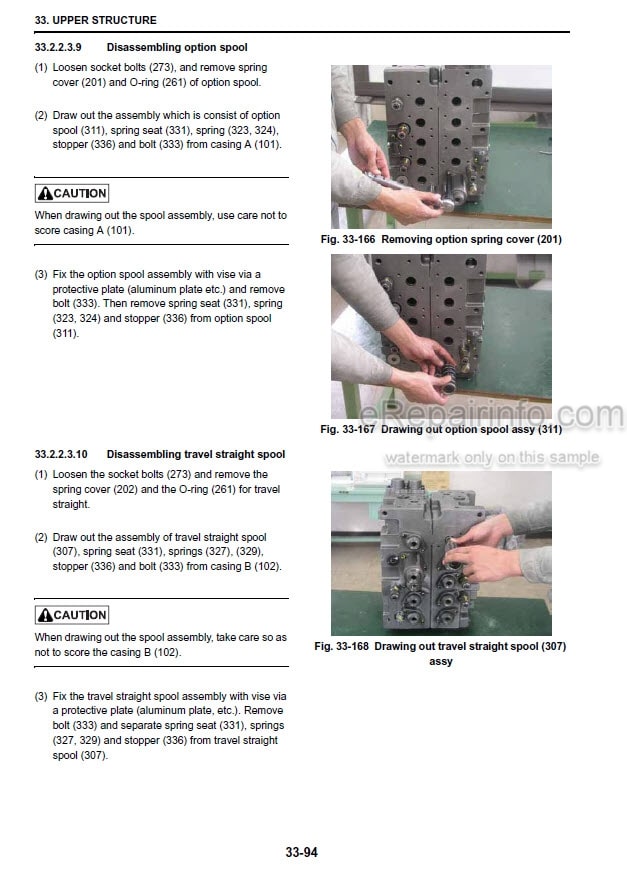

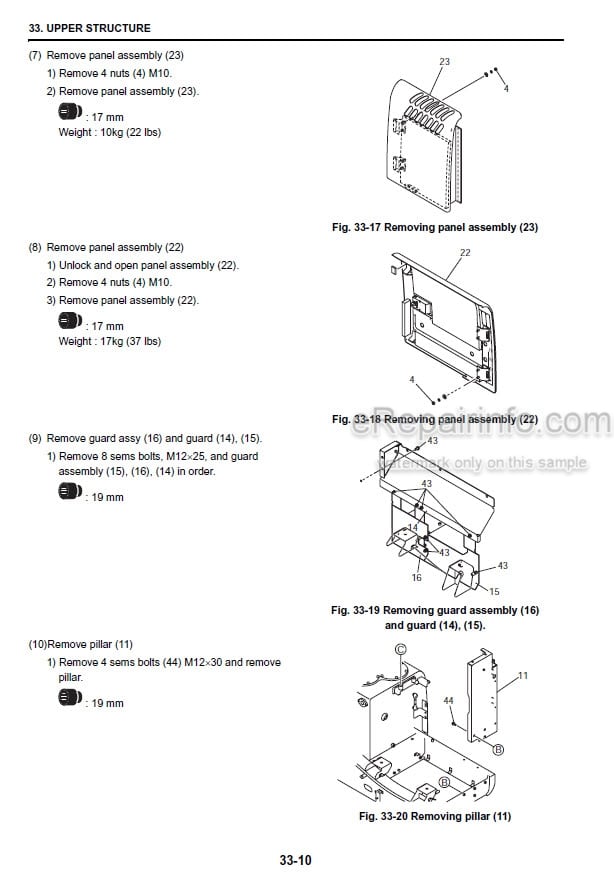

-UPPER STRUCTURE

Removing And Installing

Disassembling And Assembling

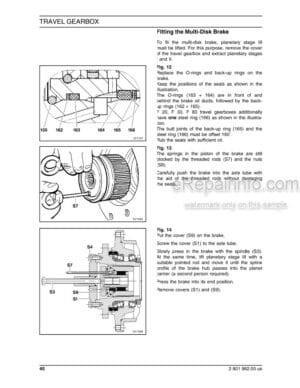

-TRAVEL SYSTEM

Removing And Installing

Removal And Installation Of Travel Motor Unit

-TROUBLESHOOTING (BY ERROR CODES)

Evaluation Of Actual Problem At The Site

Classification Of Failure And Troubleshooting

Mechatro Controller Blown Fuse

Troubleshooting By Error Code

-TROUBLESHOOTING (BY SYMPTOM)

Hydraulic System

Electric Systems

Engine Related Troubleshooting

-TROUBLESHOOTING (BY DIAGNOSIS MODE)

Trouble Diagnosis Mode

-ENGINE

2.CASE 667TA/EEG, 667TA/EEC, 667TA/EBF, 667TA/EED, 667TA/EBJ, 667TAEDJ REPAIR MANUAL ENGINE.

-DIAGNOSTICS

CNH- EST Diagnostic Tool

Troubleshooting

-667TA ENGINE OVERHAUL

Engines

Coding Of Source Engines

Engine Properties

General Engine Features

Crank Gear Components And Cylinder Assembly

Valve Gear – Cylinder Assembly

Torque Specifications

Special Tools

667TA Engines

Description Of Main Engine Components

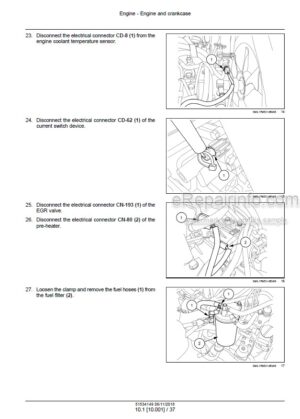

EGR Exhaust Gas Recirculation System

ENGINE LUBRICATION

ENGINE COOLING

High Pressure Electronic Injection System (Common Rail)

EDC7UC31 -Electronic Control Unit Operation

Fuel Supply System

Common Rail

Common Rail Pressure Relief Valve

Electro-Injector

Location Of The Main Electrical Components

Checking The Fuel System

Engine Overhaul On The Bench

Checks And Specifications On Engine Crankcase

Crankshaft

Engine Flywheel

Cylinder Head

Valves

Valve Guide

Valve Seats

Valve Springs

Cylinder Head

Rods And Tappets

-CHARGING AND START-UP

Starter Motor

Alternator

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.