Factory Service Manual For New Holland E27B Compact Hydraulic Excavator; Yanmar 3TNV, 4TNV Industrial Diesel Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 765

Number: S5PV0023E02

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland Compact Hydraulic EXcavator

E27B

PIN number PV13 – and higher

Yanmar Industrial Diesel Engine

3TNV

4TNV

Contents

1.NEW HOLLAND E27B COMPACT HYDRAULIC EXCAVATOR

2.YANMAR 3TNV; 4TNV SERVICE MANUAL INDUSTRIAL ENGINE

1.NEW HOLLAND E27B COMPACT HYDRAULIC EXCAVATOR

-OUTLINE

General Repair Safety

International Unit Conversion System

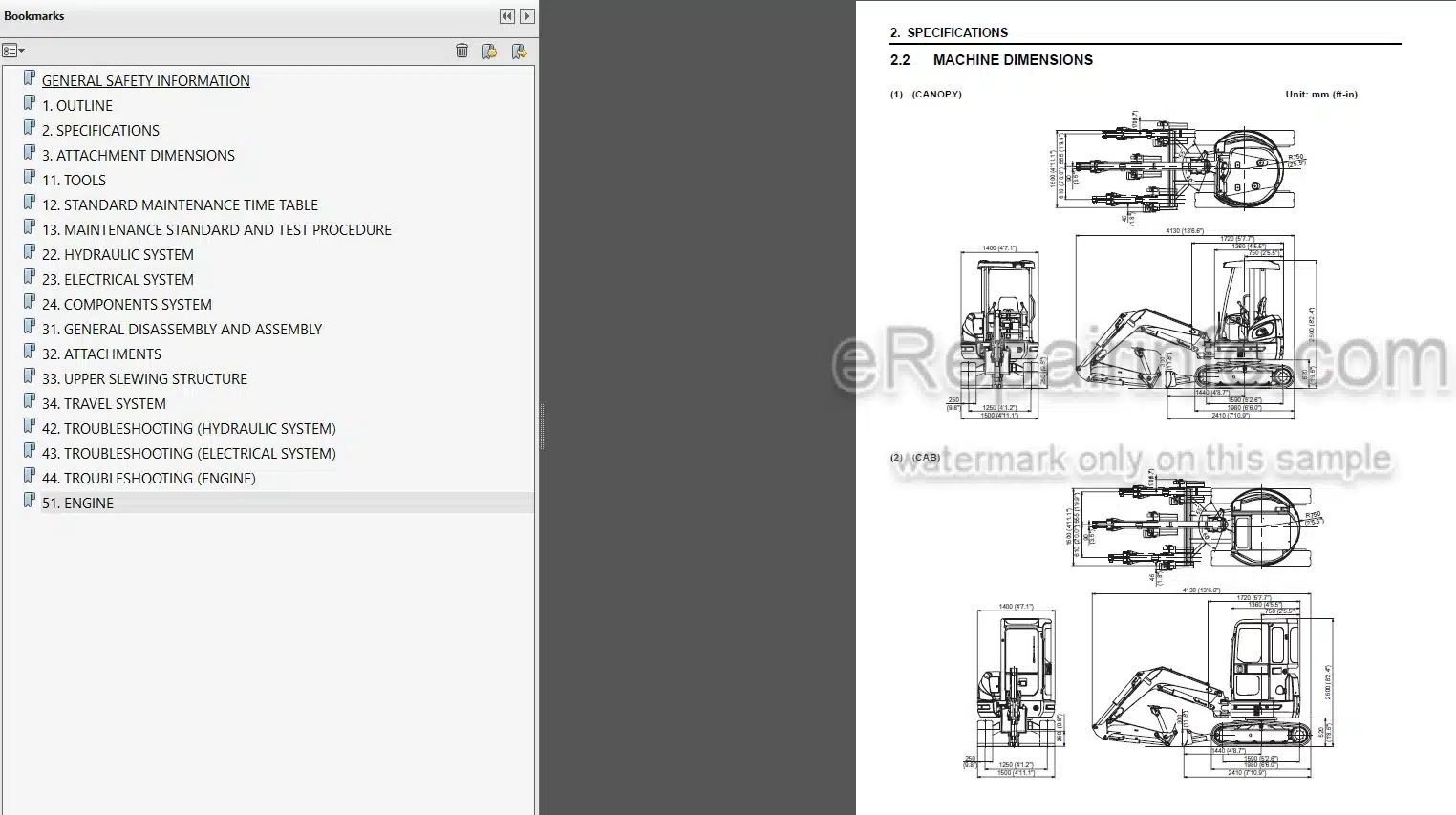

-SPECIFICATIONS

Component Location

Machine Dimensions

Specifications And Performance

Machine & Components Weight (DRY)

Transportation

Type Of Crawler Shoes

Type Of Bucket

Engine Specifications

-ATTACHMENT DIMENSIONS

Boom

Arm

Bucket

Dozer

Swing

-TOOLS

Torque Specifications For Cap Screws & Nuts

Screw And Tool Sizes

Torque Specifications For Joints And Hoses

Torque Specifications For Sleeve Type Tube Fittings

Plugs

Special Spanners For Tubes

Special Tools

Application Of Screw Locking And Sealing Compounds

Counterweight Lifting Jig

Upper Frame Lifting Jig

-STANDARD MAINTENANCE TIME TABLE

Standard Working Time Table

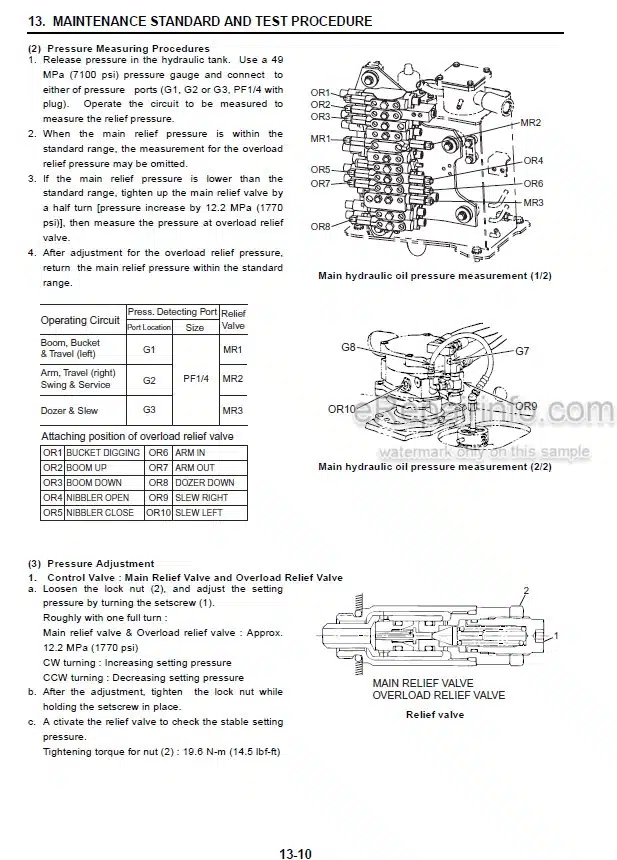

-MAINTENANCE STANDARD AND TEST PROCEDURE

How To Use Maintenance Standards And Precautions

Performance Inspection Standard Table

Measuring Engine Speed

Measuring Hydraulic Oil Pressure

Measuring Travel Performances

Measuring Swing Performances

Measuring Attachment Operating Performances

Measuring Swing Bearing Performances

Measuring Crawler Tension

-HYDRAULIC SYSTEM

Summary

Hydraulic Circuits And Component Models

Hydraulic Circuit Operation

Schematic Piping For Hydraulic System

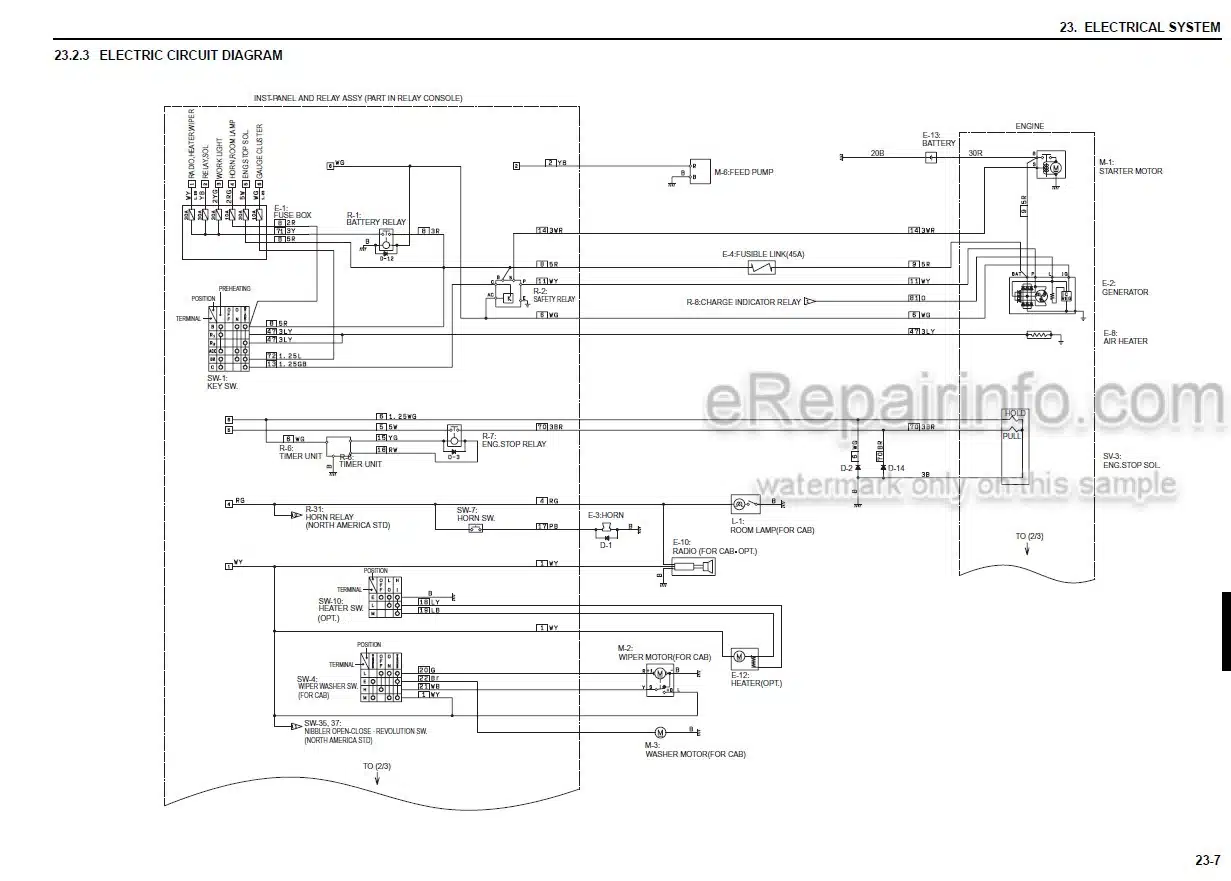

-ELECTRICAL SYSTEM

How To Read Circuit Diagram And Harness Connection

Electrical Equipments Harness

-COMPONENTS SYSTEM

Hydraulic Components

Electrical Equipment

-GENERAL DISASSEMBLY AND ASSEMBLY

General Disassembly And Assembly

-ATTACHMENTS

Removing And Installing

Disassembling And Assembling

-UPPER SLEWING STRUCTURE

Removing And Installing

Disassembling And Assembling

-TRAVEL SYSTEM

Removing And Installing

Disassembling And Assembling

-TROUBLESHOOTING (HYDRAULIC SYSTEM)

General Precautions

Trouble Diagnosis : Hydraulic

Troubleshooting

-TROUBLESHOOTING (ELECTRICAL SYSTEM)

Trouble Diagnosis : Electric System

Troubleshooting

-TROUBLESHOOTING (ENGINE)

Trouble Diagnosis : Engine

Troubleshooting

2.YANMAR 3TNV; 4TNV SERVICE MANUAL INDUSTRIAL ENGINE

-GENERAL

Engine Nomenclature

Specifications

Fuel Oil, Lubricating Oil and Cooling Water

Engine External Views

Structural Description

Exhaust gas emission regulation

-INSPECTION AND ADJUSTMENT

Periodic Maintenance Schedule

Periodic Inspection and Maintenance Procedure

Adjusting The No-Load Maximum Or Minimum Speed

Sensor Inspection

Water Leak Check In Cooling Water System

Radiator Cap Inspection

Thermostat Inspection

Adjusting Operation

Long Storage

-TROUBLESHOOTING

Preparation Before Troubleshooting

Quick Reference Table For Troubleshooting

Troubleshooting By Measuring Compression Pressure

-DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

Complete Disassembly And Reassembly

Cylinder Head: Disassembly, Inspection And Reassembly

Gear Train And Camshaft

Cylinder Block

-LUBRICATION SYSTEM

Lubrication System Diagram

Trochoid Pump Components

Disassembly(Reverse The Procedure Below For Assembly)

Servicing Points

Parts Inspection And Measurement

-COOLING SYSTEM

Cooling Water System

Cooling Water Pump Components

Disassembly (Reverse The Procedure Below For Assembly)

Servicing Points

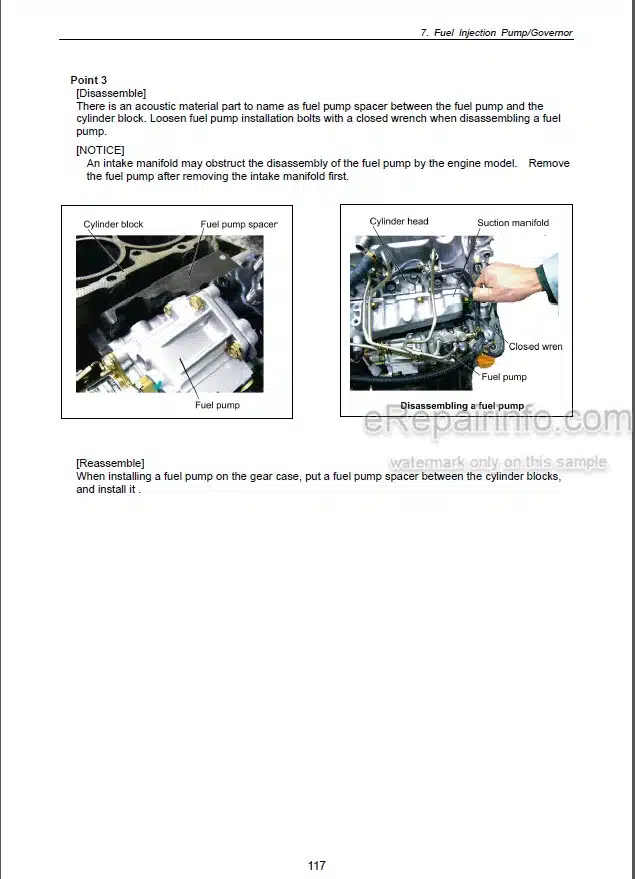

-FUEL INJECTION PUMP/GOVERNOR

Introduction

Fuel Injection Pump

-TURBOCHARGER: DISASSEMBLY, INSPECTION AND REASSEMBLY

Structure and Functions

Service Standards and Tightening Torque

Periodic Inspection Procedure

Disassembly Procedure

Washing and Inspection Procedure

Reassembly Procedure

Handling after Disassembly and Reassembly

Troubleshooting

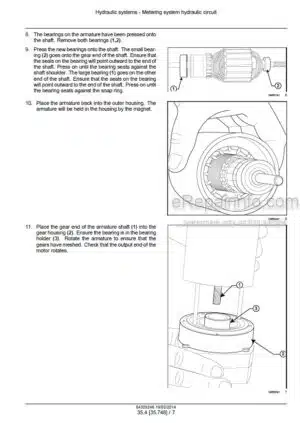

-STARTING MOTOR

For 4TNV94L/ 98

For 4TNV106(T)

-ALTERNATOR

The 40A Alternator for 3TNV84 and other models

Troubleshooting

-ELECTRIC WIRING

Electric Wiring Diagram

Precaution On Electric Wiring

-SERVICE STANDARDS

Engine Tuning

Engine Body

Lubricating Oil System (Trochoid Pump)

-TIGHTENING TORQUE for BOLTS and NUTS

Tightening Torques for Main Bolts and Nuts

Tightening Torques for Standard Bolts and Nuts

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.