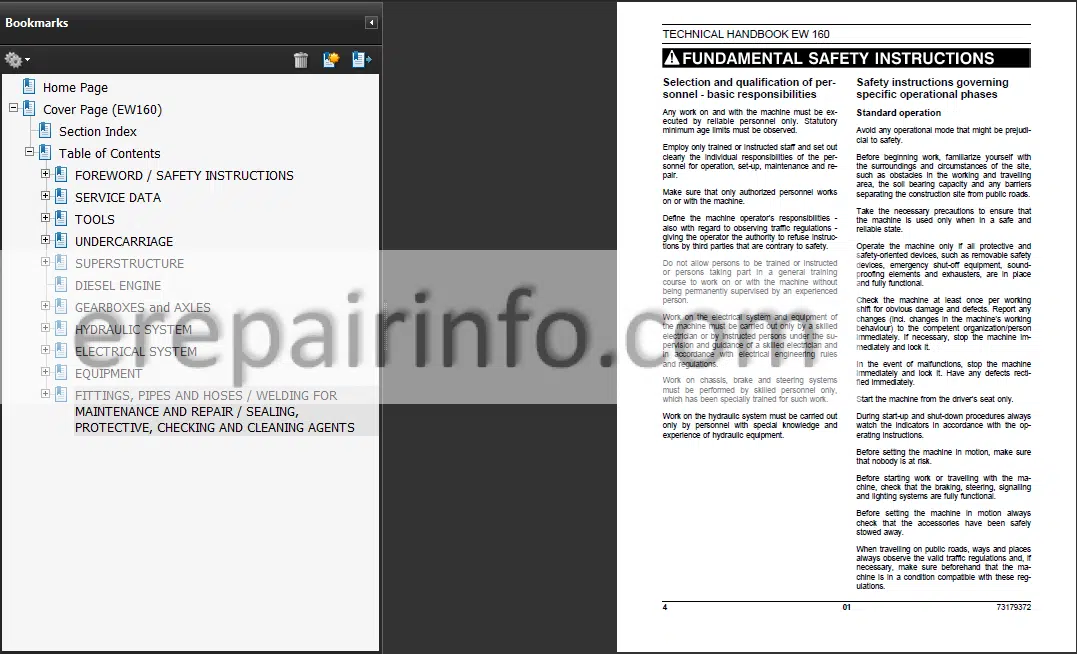

Technical Handbook Repair Manual For New Holland EW160. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up. This Technical Handbook (THB) has been written with the servicing mechanic in mind and contains important information required to carry out repair and servicing procedures.

Format: PDF

Language: English

Pages: 792

Bookmarks: Yes

Searchable: Yes

Number: 73179372

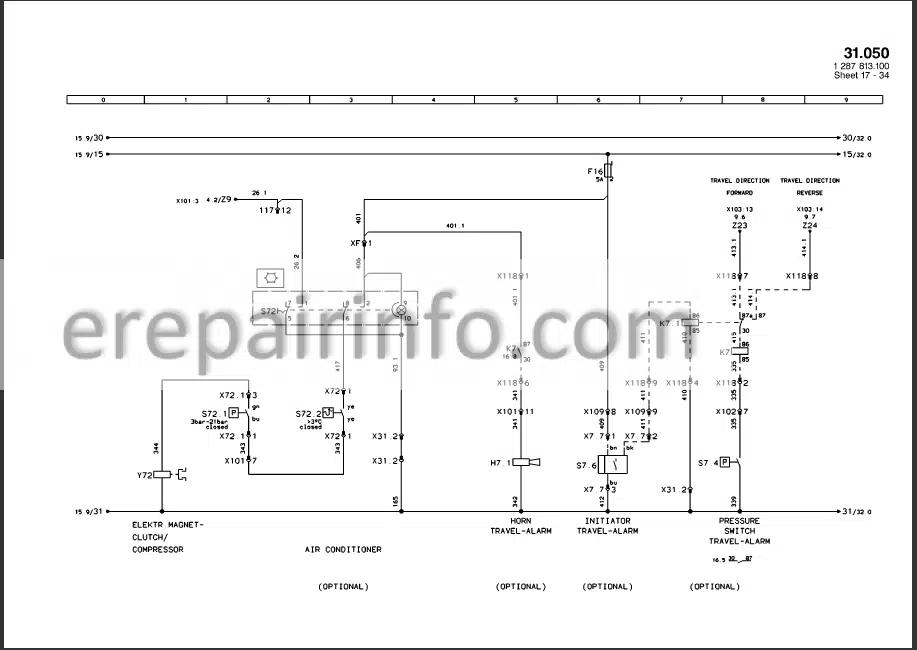

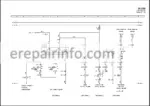

Wiring Diagrams: Yes

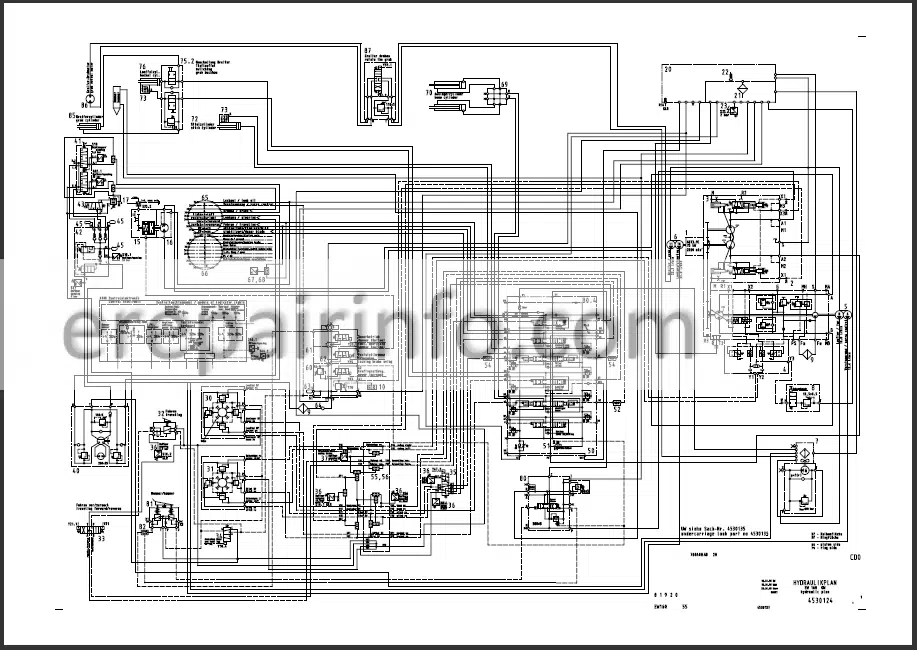

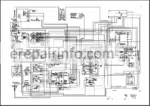

Hydraulic Diagrams: Yes

Model

New Holland EW160

Contents

- – Foreword / Safety Instructions

Using The Technical Handbook

Servicing And Repair

Warnings And Symbols

Danger In The Event Of NonObserVance Of The Safety Instructions

Organizational Measures

Selection And Qualification Of PersonnelBasic Responsibilities

Safety Instructions Governing Specific Operational Phases

Standard Operation

Special Work In Conjunction With Utilization Of The MachineMaintenance And Repairs During Operation Disposal Of Parts And Consumables

Warning Of Special Dangers

Electric Energy

Gas, Dust, Steam And Smoke

Hydraulic And Pneumatic Equipment

Noise

Oil, Grease And Other Chemical Substances

Transporting And TowingRecommissioning

Repair Work, Safety Instructions

Accumulators, Safety Instructions

Engine

Engine, Repair Instructions

Assisted Starting (With JumpLeads)Safety Instructions

Welding Operations

Welding OperationsSafety Instructions - – Service Data

RaumUnd MassegroЁЯen

Quantities Of Space And Mass

Zeitgrogen

TimeRelated Quantities

Kraft, Energie Und LeistungsgroЁЯen

Quantities Of Force, Energy And Power

Umrechnungstabellen

Conversions Tables

Umrechnung Von LaЁngenMaЯen

Conversion For Units Of Length

Umrechnung Von FlaЁchenmaЯen

Conversion For Units Of Area

Umrechnung Von Foot (Fuss) Und Inch (Zoll) In Meter

Conversion From Foot (Fuss) And Inch (Zoll) To Metric Measures

Umrechnung Von Newtonmeter “Nm” In Foot Pounds “FtLb”

Conversion From Newtonmeter “Nm” Into Foot Pounds “FtLb”

Umrechnungstabelle FuЁ R Druckeinheiten Von Gasen, DaЁmpfen Und FluЁssigkeiten

Conversion Table For Units Of Pressure In Gases, Steam And Fluids

Umrechnungstabelle FuЁ R Einheiten Von Energie, Arbeit Und WaЁ Rmemenge

Conversion Table For Units Of Power, Energy And Heat Quantity

Umrechnungstabelle FuЁ R Einheiten Der Mechanischen Spannung (Festigkeit)

Conversion Table For Units Of Mechanical Stress (Strength)

Praktisch Gleichwertige Einheiten FuЁ R Druck Und Mechanische Spannung (Festigkeit)

Practically Equivalent Units For Pressure And Mechanical Stress (Strength)

TemperaturEinheiten Und Umrechungsformeln

Units Of Temperature And Conversion Formulas

Leistung, Energiestrom, WaЁ Rmestrom

Power, Energy And Heat Flow

Geschwindigkeiten

Speed

Masseeinheiten (Gewichte)

Units Of Mass (Weight)

Volumeneinheiten, DurchfluЯmenge

Units Of Volume, Flow Rates

Kraftstoffverbrauch

Fuel Consumption

Berechnungsbeispiele

Calculation Examples

Steigungswinkel

Angles Of Slope

Fahrgeschwindigkeiten

Travel Speeds

Hydraulische Leistungen (Pumpen/Motoren)

Hydraulic Outputs (Pumps/Motors)

ZylinderHubzeiten

Stroking Times Of Cylinders

Drehzahlen Von Hydraulikmotoren

Speeds Of Hydraulic Motors

Anziehdrehmomente

Allgemeine Hinweise

Tightening Torques

General Information

Schrauben Mit Regelgewinde Nach Din

Bolts With Standard Thread Din

Schrauben Mit Metrischem Feingewinde Din

Bolts With Metric Fine Thread Din

Anziehdrehmomente FuЁ R Sae Flanschsystem

Tightening Torques For Sae flange system

Anzugswinkel

Tightening Angles - – Tools

Big Leather Test Case With Contents

Solenoid Valve Tester

Measuring Adapter

Vacuum Pump

environment protection Plugs

Pressure Gauge

StrokeMeasuring Device

Cylinder Tools

Fitting Suspension

Protective Sleeve

Protective Sleeve

Fitting Device

Axle And Gearbox Tools

Axle

Hydraulic Pump

Fitting Punch

Fitting Punch

Stud

Fitting Device

Thickness Gauge

Swing Gearbox

Vacuum Pump

Connecting The Vacuum Pump - – Undercarriage

Safety Instructions

Danger In The Event Of NonObservance Of The Safety Instructions

Rules For Safety At Work

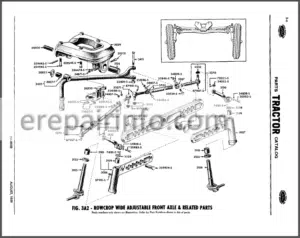

Undercarriage Components

Chassis

Steering Swing Axle

Rigid Axle

Cardan Shaft

Removal And Fitting Of Cardan Shaft

Wheels And Tyres

Tyre Inflation Pressure Safety Instructions

Checking The Tyre Inflation Pressure Refilling The Tyre

Table Of Tyre Inflation Pressures

Tyres And Wheels Safety Instructions

Wheel Components

Changing A Wheel

Wheels Tread Pattern Arrangement

Support

Outrigger Stabilizers

Levelling Blade

Steps

RightHand Steps / Toolbox Components

LeftHand Steps - – Superstructure

Safety Instructions

Danger In The Event Of NonObserVance Of The Safety Instructions

Rules For Safety At Work

BallBearing Swing Bearing

General Information

Dismantling / Installing The BallBearing Swing Ring

Tools And Aids

Dismantling The Swing Bearing

Installing The Swing Bearing

Swing Gearbox Pinion / Checking The Tooth Flank Clearance On The Swing Ring

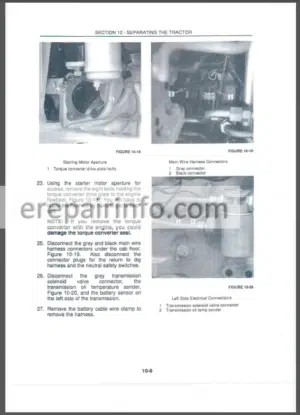

Engine, Installation

Removing And Installing The Diesel Engine

Removing The Diesel Engine

Installing The Diesel Engine

Engine, Coupling

General Information

Removing The Coupling

Installing The Coupling - – Gearboxes And Axles

Dismantling And Reassembling The Swing Gearbox

Dismantling The Swing Gearbox

Reassembling The Swing Gearbox

Technical Handbook “Swing Gearbox”

Technical Handbook “Axles” - – Hydraulic System

Venting The Hydraulic System

Reason For Venting

Venting

Hydraulic Tank

Top Servo Control Caps

Hydraulic Pumps And Hydraulic Motors

Hydraulic Cylinder

Brake System

After Venting

Flushing The Hydraulic System

Description Of The Hydraulic System

Technical Data

Hydraulic Circuit Diagram

Survey Of Components In The Hydraulic Circuit Diagram

Hydraulic Components

Drive Engine (Item )

Twin Variable Displacement Pump

Demand Control

Power Control

Load Limit Regulator

Swing Pump

Twin Gear Pump

Oil Cooler With Fan Drive

Swing Mode Valve

Filter

Load Limit Regulator

Swing Gearbox

Swing Motor

Speed Sensor

Hydraulic Reservoir, Complete

ReturnFlow Filter

Bypass Valve

Filter Contamination Switch

Temperature Sensor

Servo Control Valve Right

Servo Control Valve Left

Travel Pedal

Solenoid Valve

Solenoid Valve

Solenoid Valve Stick / Stabilizers

Steering Valve

PedalOperated Brake Valve

Accumulator Charging Valve

Pressure Switch

Pressure Switch

Service Brake Solenoid Valve And PressureRegulating Valve

The DiaphragmType Accumulator

Way Control Block

Arrangement Of Valves In The Control Block

Primary Valve With Pressure CutIn Stage

MiniRate Regulator Or ShockReducing Valve

Shuttle Valve Cascade

Valve Assembly

Solenoid Valve

Sealing Plug

DiaphragmType Accumulator

Rotor For Hydraulic Oil

Rotor For Electric Current

Boom Cylinder

Stick Cylinder

Restrictor Check Valve, Adjustable

SwitchOver Valve Grab/Backhoe

Bucket Cylinder

Auxiliary Control Block

Auxiliary Equipment Servo Control Valve

Grab Cylinder

Grab Rotation Motor

Grab Rotation Solenoid Valve

Rigid Axle (), SpeedChange Gear And Hydraulic Travel Motor

Hydraulic Travel Motor With Travel Braking Valve (

Automatic Regulation

CreepSpeed Function

Secondary Pressure Protection

Travel Braking Valve

Control Block

Steering And Floating Axle

Floating Axle Cylinder

Levelling Blade Cylinders

Stabilizer Cylinders

Levelling Blade/Stabilizer SwitchOver Valve

SwitchOver Valve Right/Left Stabilizer

Description Of System Sections

Load Limit Control System

Unpressurized Oil Circuit Of Pumps

Oil Circuit Pump

Servo Control System

Servo Control Valve Boom/Bucket

Servo Control Valve Stick/Swinging

Servo Control Valve Travel

MiniRate Regulators Or Shock Reducer Valves

Servo Control Valve Hammer/Shears

Working Hydraulic System

Bucket Parallel Connection

Stabilizers

Optional Boom Adjusting Cylinder

Travel Hydraulic System

Auxiliary Hydraulic System Hammer / Shears

Swinging System

Swinging Mode Activated (Led On):

Swinging Mode DeActivated (Led Off):

Neutral Position

Counter Clockwise Swinging

Clockwise Swinging

Braking The Superstructure

Steering And Braking System

Steering System

Dual Circuit Braking System

Grab Rotation Sytem

Checking And Setting Pressures

Safety Instructions

General

Pressure Settings

Tools

Pcs Tester

Big Leather Test Case With

Pressure Gauge

Stroke Measuring Device

Servo Control Pressure

Working Hydraulics With Power Boost Function

Setting Up Primary Valve

Secondary Valves For Cylinders

Measurement Of Stroking Length And Pressure At Control Spool

Secondary Valves Of Travel Motor

Setting/Adjusting Secondary Valves

Travel Motor Regulating Start

Pressure Relief Valves On Auxiliary Control Block

Setting/Adjusting Primary Valves

Pump Control Through Proportional Demand Signals

Output Control Through Proportional Demand Pressure

Pump

Swinging System

Feed Pressure And Zero Point

Swinging Power (Swinging Mode)

High Swinging Pressure And Safety Valves

Safety Valve

Swing Pump Legend:

Changing The Braking Torque

Installing The Hydraulic Pumps

Components

Installing And Dismantling The Hydraulic Pumps

Dismantling A Pump

Installing A Pump

Hydraulic Cylinders

Components For Boom, Stick And Bucket Cylinders

Components For Stick Cylinders

BossType, OnePiece

Pivot Bearings

Piston Rod Guide Boom And Bucket Cylinder

Rod Guide Of Stick Cylinder

Piston Rod And Piston

Floating Axle Supporting Cylinder

Components

Floating Axle Cylinder With Integrated Blocking Valve

Commissioning And Venting

Malfunctions And Rectification Of Faults

Repair Instructions

Steering Cylinder

Dismantling The Steering Cylinder

Assembling The Steering Cylinder

Assembling The Steering CylinderCalculation Examples - – Electrical System

The Atom

Structure Of Atoms

Free Electron

Electromagnetic Field

Alternating Current Diagram

Power Generation

Power Generation In Motor Vehicles

Battery Charging

Claw Pole Alternator

Circuit With Fault Indication On Interruption In The Exciter Circuit

Testing The Charging System

Main Components Of Automotive Electrical System

Battery

Types Of Batteries

MaintenanceFree Starter Battery

low maintenance Batteries

Checking The Battery

Density Values Of Diluted Sulphuric Acid

Mixing Fresh Battery Acid

Mixing Instructions

Maintenance

Troubleshooting

Function Of The Alternator

Alternator

Type Designation

Alternator

ClawPole Alternator

Maintenance

Electric Motors

Principle Of The Electric Motor

Starting Motor (Starter)

Function Of The Starter

Checking The Vehicle Starter System

Starter

Maintenance

Lubrication

Fundamentals Of Automotive Electrical Systems

Current, Voltage, Resistance And Power

Measurements With The Multimeter

Adjustment Of The Multimeter

Measuring Voltage

Measuring Current

Measuring Resistance

Ohmmeter

Series And Parallel Connection Of Electrical Components

Batteries

Resistors

Series Connection

Parallel Connection

Capacitors

Series Connection

Parallel Connection

Electrolytic Capacitors

Voltage Losses And Cables

Calculation Of Lines

Computation

Lines And Wires In Automotive Electrical Systems

Design Example

Lighting

Headlamps Adjustment Hints

Floodlamps

Bulbs

Malfunctions Of The Lighting System And Their Causes

Transition Resistance In Electrical Circuits

Special Circuits In Automotive Electrical Systems

The Diode

The “FreeWheeling” Diode

Varistors

Voltage Rectification In ThreePhase Bridge Circuits

Alternator Regulator

Fuses In Motor Vehicles

Designation Of Individual Components

Standardized Designations Of Terminals

Terminal Designation

Generator And Generator Regulator

TurnSignal Indicator (Flasher Relay)

Symbols Used In Electrical Engineering

Symbols For Directions Of Motion - – Equipment

Assembling Working EquipmentSafety Instructions

Securing The Machine

Corrosion Protection For Pins And Bearings (Bushings And Hubs)

Part Nos For Voler AC

Application Of Voler AC

Detaching / Attaching The Backhoe Bucket

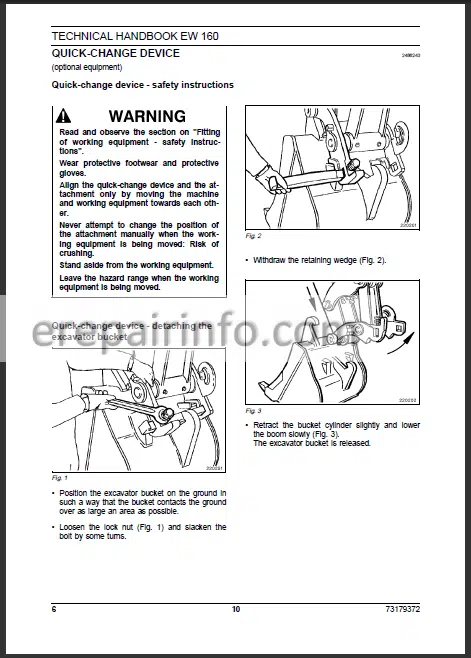

QuickChange

Attaching And Detaching The Grab Equipment

Attaching The Grab

Detaching The Grab - – Fittings, Pipes And Hoses / Welding For Maintenance And Repair / Sealing, Protective, Checking And Cleaning Agents

Warning Of Special Dangers

Electric Energy

Gas, Dust, Steam And Smoke

Hydraulic And Pneumatic Equipment

Noise

Oil, Grease And Other Chemical Substances

Transporting And Towing

Working Equipment

Assembling Working Equipment

Repair Work

Lines For Various Media

Materials For Pipes And Hoses

Conditions And Deviations In The Line System

Steel Pipes

Hoses

Plastic Pipes

Connections

Pipe Couplings

Sealing Pipe Couplings

Bulkhead Couplings

Stud Couplings And Male Nipples

Stircomatic Seal Rings

Swivel Couplings

Swivel Coupling With Straight Male Thread Acc To Din

Swivel Coupling With Long Male Adaptor

Fixed Angle Couplings

Banjo Coupling

Banjo Coupling With Long Male Adaptor

Flange Couplings With Sae Bolt Pattern

Flanged Pipe Couplings

Flanged Hose Couplings

Sealing And Connecting Components

Flanges

Wedge Rings

Seal Rings

Double Hex Bolts

Assembly Aids For Wedge Rings

PreAssembly Device For FRings

Inserter For Z Rings

Inserting The Z Ring

Assembling Flange Couplings

Flange Coupling Pipe / Connection Surface, F System

Zako System

Flange Coupling Hose / Connection Surface

Flange Coupling

Appendix

Seal Rings For Flange Couplings

Double Hex Bolts

Accessories

PreAssembly Aids For Pipe Flange Couplings

Flange

Gauge Connections

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.