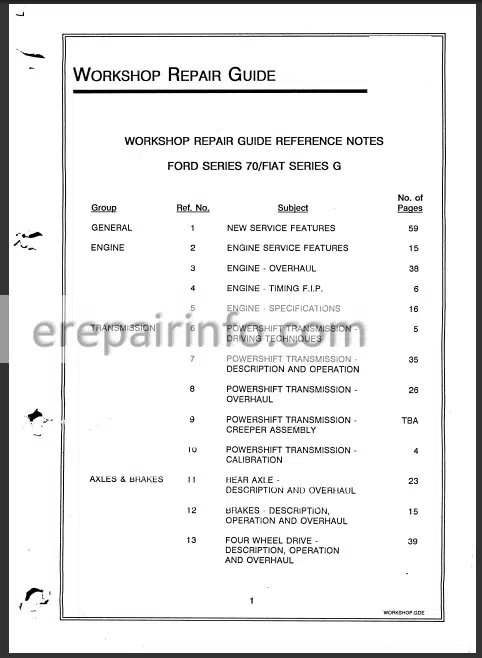

Workshop Repair Manual For New Holland Ford 70, Fiat Series G. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 903

Bookmarks: Yes

Searchable: Yes

Number:

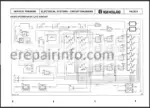

Wiring Diagrams: Yes

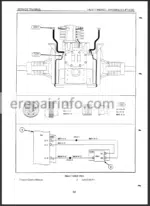

Hydraulic Diagrams: Yes

Model

New Holland

Ford Series 70

Fiat Series G

170, 190, 210 and 240 HP range of tractors

Contents

- – Service Features

Engines

Transmission

Rear Axle

Differential Lock

Brakes

Front Wheel Drive

Hydraulic Pumps

Remote Control Valves

Electronic Draft Control

Power Take O F F

Trailer Brakes

Electrical And Electronic System - – Engine Service Features

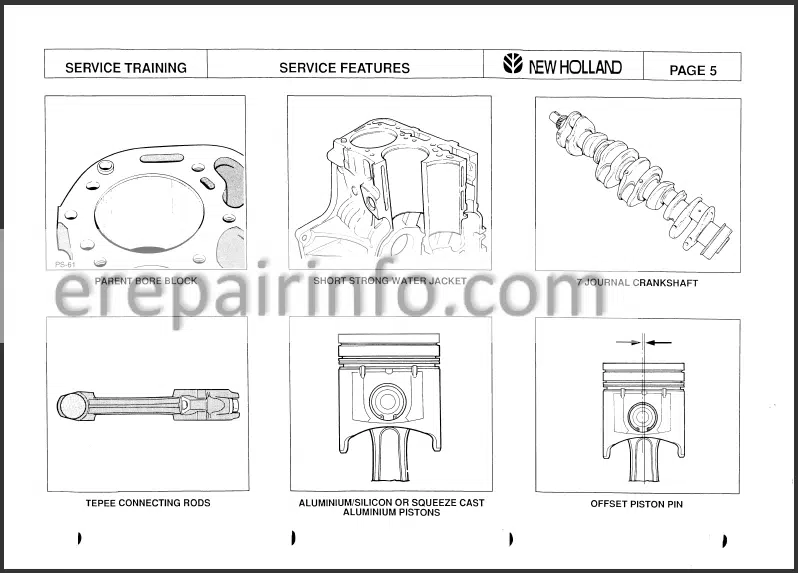

Specification

Performance

Cylinder Block

Crankshaft

Pistons

Connecting Rods

Cylinder Head

Inlet And Exhaust Valves

Camshaft

Rocker Arms And Shaft

Intake And Exhaust Manifolds

Lubrication System

Cooling System

Fuel System

Turbochargers And After Coolers - – Engine Overhaul

Engine Installation

Cylinder Block

Crankshaft

Pistons and Con R Rods

Camshaft

Lubrication

Cylinder Head and Valves

Turbocharger and Aftercooler

Cooling System - – Engine Timing

- – Engine Specifications

Introduction

Cylinder Block

Cylinder Head

Exhaust Valves

Intake Valves

Valve Springs

Valve Timing

Camshaft Lobe Lift

Installed Valve Recession

Valve Inserts

Valve Seats

Camshaft Idler Gear

Camshaft Gear

Rocker Arm Shaft

Rocker Arm

Tappets

Camshaft

Connecting Rods

Piston Pin

Pistons

Piston Rings

Crankshaft

Crankshaft Drive Gear

Main Bearing

Crankpin Bearings

Torsional Vibration Damper

Crankshaft Regrinding

Undersize Bearings Available

Flywheel

Oil Pump

Oil Pressure with Engine at Operating Temperature

Engine Oil Specifications

Selecting the Right Viscosity

Engine Oil Capacity

Thermostat

Water Pump

Fan Belt

Cooling System Capacities

Cooling F lu id

Torque Values - – Transmission Driving Techniques

- – Transmission Description And Operation

Clutches

Drive Lines

Vibration Damper

PTO Drive Line

Low Pressure Supply

Control Valve

Electronic Controls - – Transmission Overhaul

Valve Chest Removal

Transmission Overhaul Special Tools

Transmission Disassembly

Clutch Disassembly and Components

Clutch Piston Travel Check

Transmission Reassembly

Valve Chest Overhaul

Torque Specification - – Transmission Calibration

- – Rear Axle Description And Overhaul

Overhaul Special Tools

Disassembly, Centre Housing

Differential Assembly

Differential Lock Operation

Disassembly Axle Housing

Rear Axle Adjustments - – Brakes Description & Operation

Braking System Schematic Diagram

Power brake Valve Operation

Brake Valve Removal

Brake Valve Disassembly

Brake Assembly Axle Housing

Brake Plate Inspection

Handbrake Removal

Handbrake Installation

Handbrake Adjustment - – Four Wheel Drive Axle Description

Introduction

Super Steer

FWD Operation (Electrical)

FWD Engagement

Drive Line Ratios

Wheel Slip Calculations

Service Tools

Front Axle Disassembly

Differential Overhaul

Differential Adjustments & Reassembly

Drive Shaft Overhaul

Swivel Bearings

Swivel Housing Overhaul

Hub Overhaul

Planetary Reduction Overhaul

Axle Reassembly

FWD Clutch Unit Overhaul - – Hydraulic Pumps

Hydraulic Circuit Description

Hydraulic Pump Installation

Hydraulic Pump Drive Line

Variable Flow Pump Operation

Piston Pump Overhaul

Gear Type Pump Overhaul

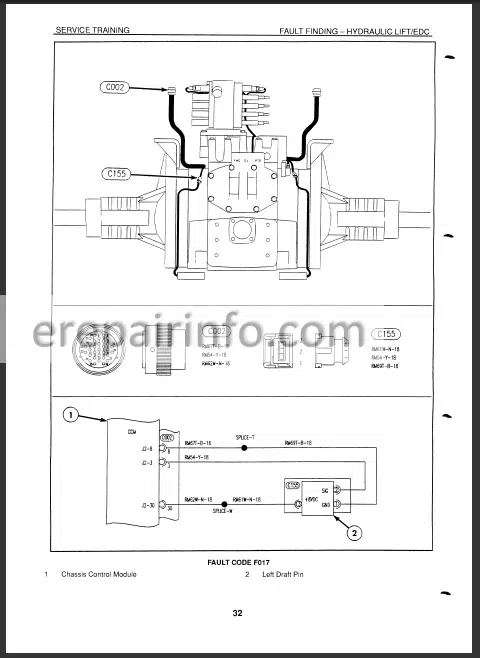

Pump Drive Gear Housing Bearing Adjustment - – Electronic Draft Control System

Components

System Operation and Oil Flows

Overhaul

Electronic Draft Control Menu Modes

Hydraulic Lift Calibration

Electronic Draft Control Memory Reset

Adjustment to Speed of Response of EDC Valve

Fault Codes - – Into And Low Pressure Hydraulic System

Low-Pressure Hydraulic CIRCuit

Controls

PTO Schematic

PTO Components

PTO Clutch Oil Flow Diagrams

PTO Housing Removal

Disassembly

Inspection and Reassembly

Installation

PTO Output Shaft Removal ( rpm PTO Tractors)

PTO Output Shaft Seal Replacement

Pressure Testing - – Hydrostatic Steering Description & Overhaul

Components Location

Steering Motor

Priority Valve

Oil Flows

Steering Motor Disassembly

Steering Motor Reassembly

Steering Cylinder

Toein Adjustment

Steering Stop Adjustment - – Remote Control Valves

Features

Control Valve Identification

Remote Control Valve Oil Flows

Overhaul - – Trailer Brakes Description

Trailer Brake System

Trailer Brake Valve Pilot Head Operation

Trailer Brake Valve Operation

Trailer Brake Valve Disassembly

Bleeding the Brakes

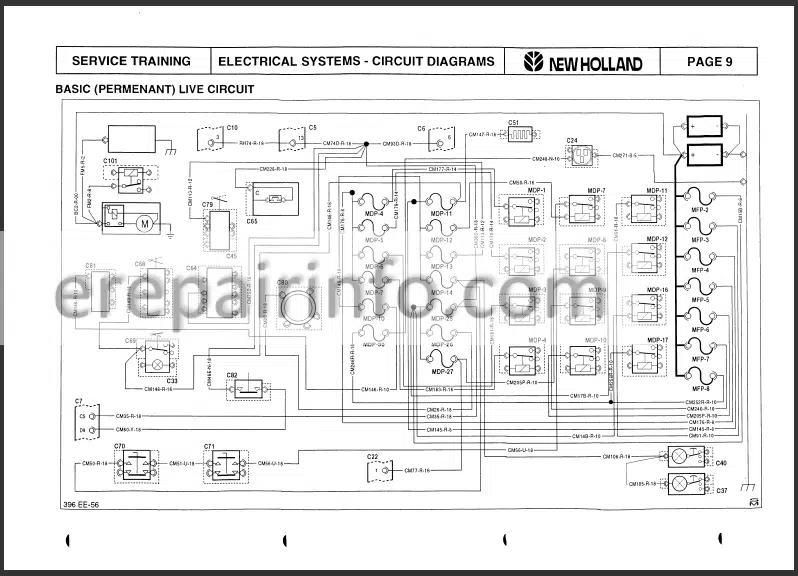

Trailer Brake Pressure Test - – Electrical System Description

Instrumentation and Controls

Fuses, Relay and Diagnostic Connector

Harnesses and Connectors - – Electrical System Wiring Diagrams

Harness Identification

Symbols

Fuses

Connectors

Circuits

Basic (Permanent) Live Circuits

Accessory ‘on’

Engine Starting

Lighting

Work Lamps

Hazard Warning Lights

Pto Operation

Brake Lights

Diff Lock Operation

Front Wheel Drive Operation - – Electronic Instrument Cluster

Introduction and Component Location

Electronic Instrument Cluster Warning Lamps

Data Displays

Alarms

Service Diagnostic Modes - – Fault Finding And Diagnostics Procedure

- – Fault Finding Hydraulic Lift/Edc

- – Fault Finding Right Hand Controls

- – Fault Finding Electronic Instrument Cluster

- – Fault Finding Electronic Transmission Control

- – Fault Finding Engine Control

- – Hydraulic Pressure Testing

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.