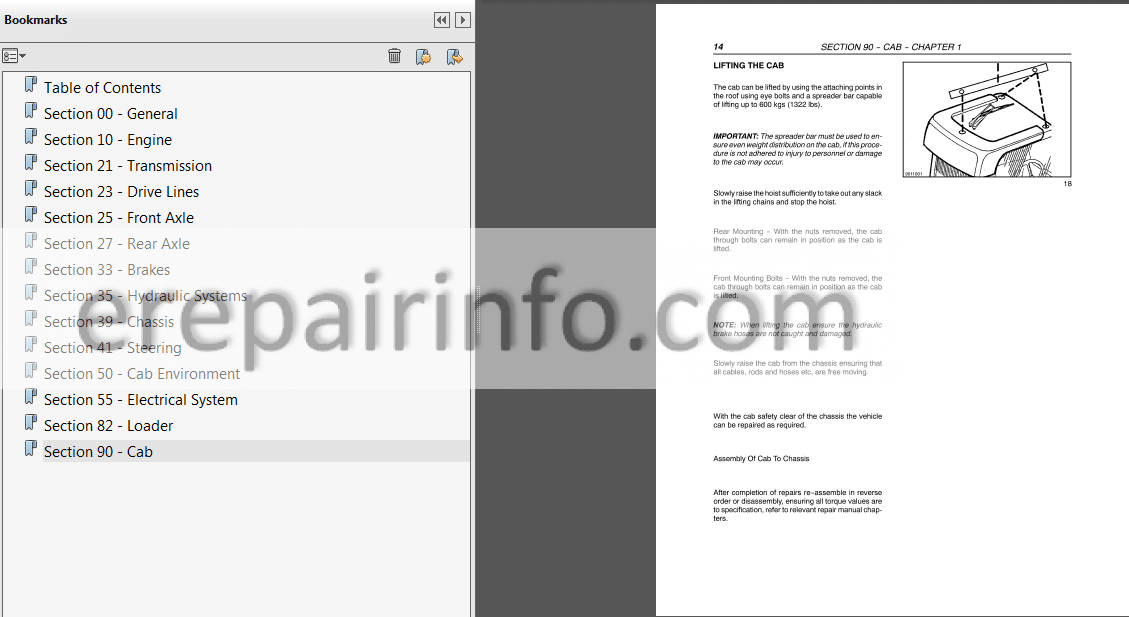

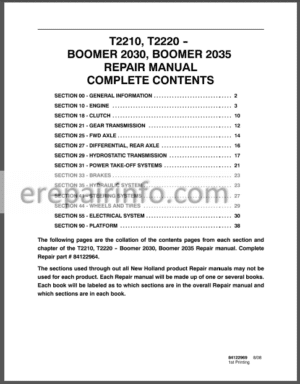

Repair Manual For New Holland LM415A, LM425A, LM435A, LM445A Telehandlers.

Manual includes step by step instructions, illustrations, diagrams. Remove, Install, disassemble, assemble, repair procedures, troubleshooting, and other servicing procedures. This repair manual provides the technical information needed to properly service the New Holland Telehandlers.

Format: PDF

Language: English

Pages:944

Bookmarks: Yes

Searchable: Yes

Number: 87751937

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland LM415A, LM425A, LM435A, LM445A

Contents

- – General

General Instructions

Important Notice

Shimming

Rotating Shaft Seals

‘O’ Rings

Sealers

Bearings

Spring Pins

Notes For Spare Parts

Notes For Equipment

Notices

How to Move the Vehicle with the Battery Removed

Safety Rules

To Prevent Accidents

Safety Rules

Generalities

Start Up

Engine

Electrical Systems

Hydraulic Systems

Wheels and Tires

Removal and Installation

Product Identification

Vehicle Product Identification Number

Vehicle Identification Plate

Engine Identification

Front Axle Identification

Transmission Identification x Power Shuttle

Transmission Identification x Power Shift

Rear Axle Identification

Identification Plates in the Cab

Important Ecological Considerations

Precautions

Service Techniques

General

Hoses and Tubes

‘O’ Ring Flat Face Seal Fittings

Sealer Specifications - – Engine

Specifications

Of Bosch Injection Pump

Calibration Test Conditions

Assembly

Calibration Test Conditions

Tightening Torques

Troubleshooting

Coding Of Source EnginesFGeCFGeG

Engine

Checks, Measurements And Repairs

Crankcase

Crankshaft

Connecting Rods

Pistons

Valves

Camshaft

Cylinder Head

Oil Filter - – Transmission

Description And Operation

Transmission Control

Transmission Disconnect Switches

Torque Converter

Gear Train

Gear Shift Mechanism

Co Axial Drive Vehicle Hydraulic Pump

Transmission Hydraulic Pump Oil Supply

Oil Flow

Transmission Oil Supply Ports

Transmission Oil Flow Through Solenoid Valve

Oil Flow Solenoid Control Valve Operation (Forward Drive Only Shown)

Transmission Hydraulic Valves And Pressure Test Points

Transmission Power Flows

Fault Finding

Stall Procedure

Stall Speed

Overhaul

Forward / Reverse Control Solenoid Valve

Solenoid Valve

Resistance Checking Of Coils

Oil Pump

Transmission Overview

Transmission Overhaul - – Drive Lines

Tightening Torque

Description of Operation

Drive Line Power Flow

Drive Shaft Removal

Rear Lower Driveshaft

Upper Driveshaft

Front Lower Driveshaft

Driveshaft Installation

Center Bearing

Driveshaft Components - – Front Axle

Sealants

Torque Specification

Description Of Operation

Front Axle

Housing

Transfer Gear Box

Hubs

Component Overhaul

Axle In Place

Axle Removed

Axle Removal Procedure

Overhaul

Planetary Reduction Assembly And Wheel Hubs

Disassembly

Steering Rod End Ball Joint Removal

Swivel Pin Removal

Swivel Housing Removal

Handbrake Lock

Shaft Retaining Lock Nuts

Axle Shaft Removal

Swivel Hub Seal Removal

Swivel Pin Bearing Removal

Removal Of Lower Swivel Pin Bearing Cone

Removal Of Shaft Bearing And Seal Housing

Reduction Hub, Swivel Housing And Axle Shaft Reassemble

Hub Oil Seal Installation

Swivel Housing Seal Installation

Swivel Pin Bearing Cone Installation

Lower Swivel Pin Bearing Cone Installation

Steering Cylinder Removal

Steering Cylinder Disassembly

Transfer Gearbox Disassembly

Axle Trumpet Housing Removal

Differential Assembly Removal

Differential Disassembly

Pinion

Bearing Preload

Differential Preload

Crown Wheel To Pinion Backlash - – Rear Axle

Torque Specification

Description of Operation

Load Sensor

Component Overhaul

Axle In Place

Axle Removed

Axle Removal Procedure

Overhaul

Pivot Bushes

Load Sensor Installation - – Brakes

Brake Master Cylinder

Brakes Released

Brakes Applying

Brakes Applied

Fault Finding and Pressure Testing

Brake Bleeding Procedure

Machine Preparation

Servo Circuit Pressure Testing

Overhaul

Brake Master Cylinder

Removal

Installation

Master Cylinder Overhaul

Assembly

Ports

Push Rod Components

Servo Housing

Brake Piston

Return Spring & Feed Valve Assembly

Fluid Feed Valve Replacement

Front Axle Brake Disassembly

Brake Piston Assembly

Rear Axle Brake Disassembly

Brake Piston Assembly

Parking Brake Operation

Handbrake Adjustment

Handbrake Lever

Front Axle

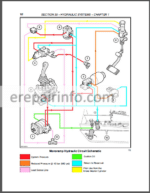

Adjustment Procedure - – Hydraulic Systems

Introduction

Gear Type Hydraulic Pump

Brake Circuit Accumulator And Pressure Reducing Valve

Hydraulic Control Valves

Telescopic Loader Controls

Hydraulic Cylinders

Counterbalance Valves

Hydraulic Circuit

Basic Circuit Operation

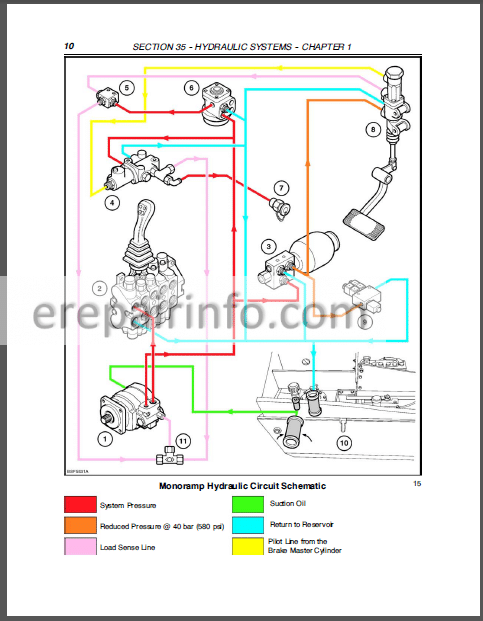

Monoramp Hydraulic Circuit Schematic

Component Operation

Hydraulic Pump

Flow Divider Valve

Pressure Reducing Valve And Accumulator

Pressure Reducing Valve Operation

Hydraulic Control Valves

Control Valve Oil Flow

Circuit Relief Valves

Direct Acting System Relief Valve

Circuit Relief Valves

Monoramp Control System

Control Buttons Released

Control Button Depressed

Fault Finding And Pressure Testing

Fault Finding

Flow And Pressure Testing

Preparation

Flow Testing (Using Auxiliary Test Hydraulic Ports)

Pump Cavitation Test

Performance Test

Alternative Method

Pressure Testing (Using Auxiliary Test Hydraulic Ports)

Using Auxiliary Test Hydraulic Ports

System Pressure Test

Telescopic Circuit Relief Valve Pressure Test

Tilt Cylinder Pressure TeSt

Piston End Circuit Relief Valve

Lift Cylinder Circuit Relief Valves Pressure Test

Pressure Testing (Using Control Valve Test Port)

Preparation

System Pressure Test

Telescopic Circuit Relief Valve Pressure Test

Tilt Cylinder Pressure Test

Piston End Circuit Relief Valve

Boom Lift Cylinder Circuit Relief Valve Pressure Test

Adjustment Of Circuit Relief Valves

Servo Hydraulic Circuit Pressure Test

Component Overhaul

Hydraulic Control Valve

Accumulator And Pressure Reducing Valve

Solenoid Control Valves - – Chassis

Vehicle Chassis Type

Overhaul

Engine, Torque Convertor and Transmission

Front Axle and Rear Axle

Hydraulic Brake

Hydraulic Loader Valve PackMechanical & Monoramp Controls

Hydraulic Telescopic Boom Controls

Frame Attachments

Hydraulic Steering Control

Loader

Chassis / Cab - – Steering

Component Operation

Hydraulic Pump

Flow Divider

Pressure Testing

Preparation

Pressure Test

Steering Motor Shock Relief Valves

Steering Control Valve Removal

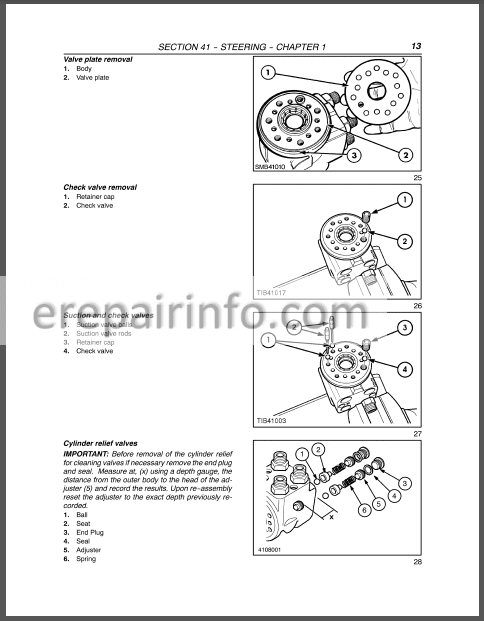

Overhaul

Steering Motor Inspection

Component Inspection

Replace the End Cover

Pressure Testing - – Cab Environment

Sealants

Torque

Description And Operation

Cab Climate Controls

Heater Blower Control

Heater Temperature Control

Air Flow Vents

Windshield Demisting

Heater Radiator

Cab Air Filter

Draining The System

Heater Radiator

Blower Motor

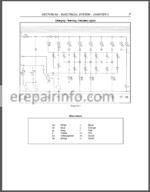

Heater Control Valve - – Electrical System

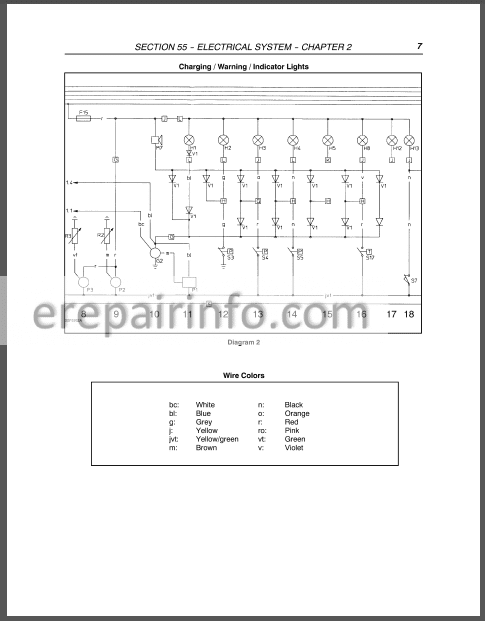

Electrical System And Fuses

Fuses And Relays

Powershuttle Fuses & Relays

Powersoft Fuses & Relays

Controls And Instruments

Mechanical

Mono Ramp

Flow Sharing

Cab Instruments And Controls

Lamps And Operating Lever For Alignment Of The Wheels

Lamp Indicator Panel

Alignment Of The Wheels

Instrument Console

Engine Coolant Temperature Warning Gauge (With Warning Buzzer)

Tachometer And Hour Meter

Fuel Level Gauge

Warning Lights

Load Status Indicator Panel

Led’S (Visual Alarm)

Sound Alarm Switch

Test Switch

Hydraulic Load Automatic Cut Off (Where Fitted)

Lifting From Ground Level

Lowering From A High Position

Hydraulic Load Cut Off (In A Worsening Situation)

MultiFunction Lever

Switches

Interior Light

Bulb Replacement

Work Lamp Bulb Replacement

Headlight And Indicator Bulb Replacement

Loader Mounted Work Lights

Interior Lamp Bulb Replacement

Rear Work Lamps

Rear, Stop And Indicator

Reversing Lamps

Rocker Switch Bulb Replacement

Protecting The Electrical Systems

Charging Or Welding

Starting The Machine With Jump Leads

Temporary Wiring Harness Repair

Troubleshooting - – Loader

Description Of Operation

Telescopic Loader Controls

Mechanical Controls

Mono Ramp System Controls

Flow Sharing System Controls

Loader Boom Wear Pads

Removing The Wear Pads At The Base Of The Loader Boom

Tilt Cylinder And Auxiliary Hoses

Replacement

Section Boom

Tilt Cylinder

Telescopic Boom Cylinder

Telescopic Boom

Loader Boom Assembly - – Cab

Hand And Foot Operating Controls

Mechanical

Mono Ramp

Flow Sharing

Description And Operation

Cab Disassembly

Inside The Cab

Underside Of The Cab

Cab Heater Hoses

Air Conditioning (Where Fitted)

Electrical/Harness Connections

Lifting The Cab

Overhaul

Cab Internal Parts

Seats

Steering Column

Instrument Panel

Inner Roof Panel

Windshield Wipers

Roof Panel

Cab Glass Replacement (Bonded)

Glass Intact

Glass Broken

New Glass

Existing Glass

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.