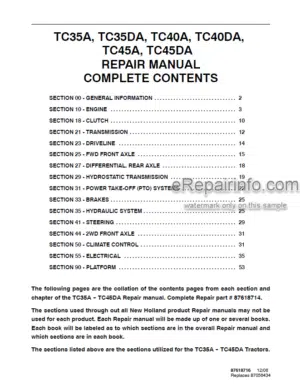

Repair Manual For New Holland TD5 Series Tractors. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 678

Bookmarks: Yes

Searchable: Yes

Number: 47454229

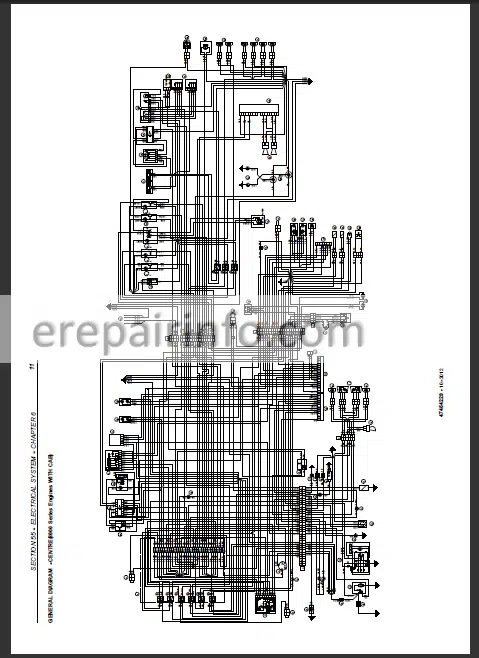

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TD5.65, TD5.75, TD5.80, TD5.90, TD5.100, TD5.110

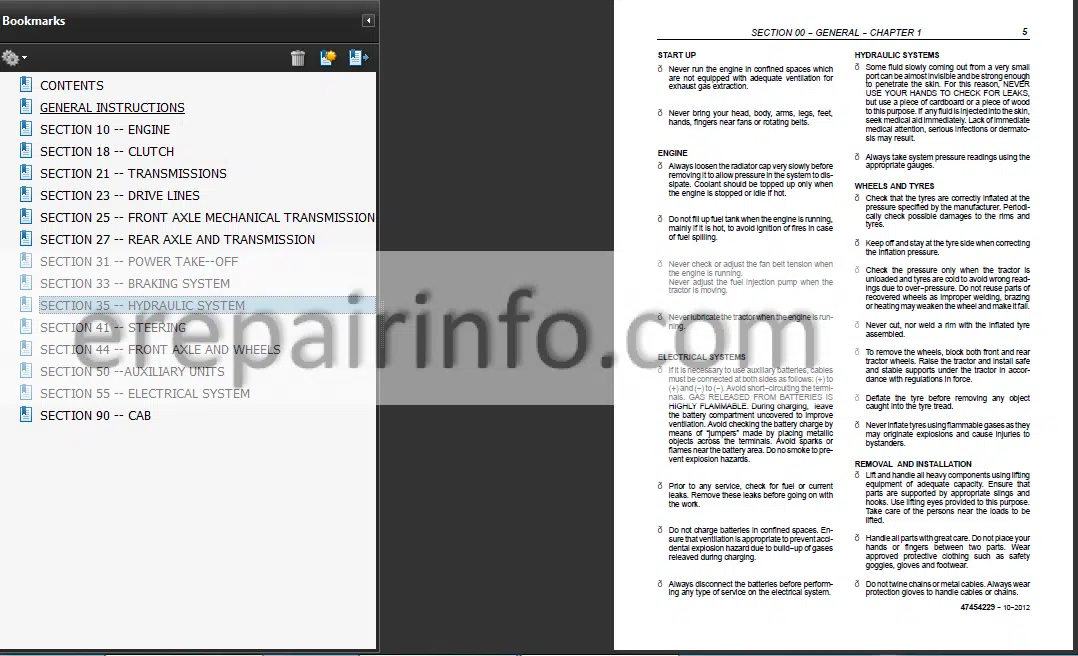

Contents

- -General

–General Instructions And Health And Safety Chapter

General Instructions

Notes For Spare Parts

Notes For Equipment

Safety Rules

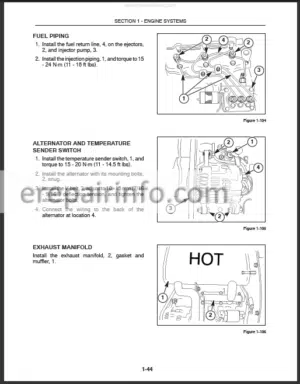

Consumables - -Engine

–Engine System

General Specification

Injection Pump Calibration Data

General Specifications

Tightening Torques

Tools

Cross-Al Views

Lubrication And Cooling System Diagrams

Fault Diagnosis

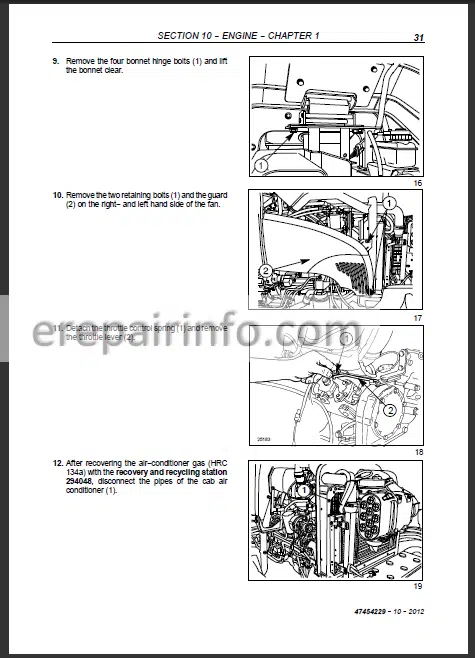

Engine Removal-Installation

Engine Bench Overhaul

Checks, Measurements And Repairs

Radiator Removal-Installation

Crankshaft Front Oil Seal Removal Installation

Coolant Pump Removal Installation

Cooling System Thermostat

Bosch Injection Pump Removal Installation

Bosch Injection Pump Timing

Bosch Injection Pump Air Bleeding

Injectors Removal Installation - -Clutches

General Specifications

Tightening Torques

Tools5

Cross-Sectional Views

Clutch Troubleshooting

Removal – Installation

Overhaul

Minimum Permissible Dimensions After Refacing 2

Adjustments

Adjustment Of The Main And Pto Clutch Control Linkage

Pto Clutch Servo Control - -Gearbox

–Mechanical Transmission

Main Data1

Tightening Torques

Tools3

Section Views

Description And Operation8

Fault Diagnosis

Removal – Refitting See Sect

–Reverser (12X12)

Main Data

Tightening Torques

Tools

Section Views

Description And Operation

Fault Diagnosis

Removal-Refitting

–Reverser And Creeper (20X12)

Main Data

Tightening Torques

Tools

Section Views

Description And Operation

Fault Diagnosis

Removal-Refitting

Main Data

Tools

Cross-Sectional Views

Clutch Control Pressure Test

Cross-Sectional View Of Power Shuttle Control Valve Block

Power Shuttle Hydraulic Circuit

Description And Operation

Installation – Removal

Main & Power Shuttle Control Clutch Adjustments - -Drive Lines

–Drive Lines

Section Description Page

Main Specification

Torque Settings And Tools

Cross–Sectional Views

Transmission Shafts And Guard (Disassembly – Assembly)

Drive Gear Housing (Removal – Installation)

Drive Gear Housing Removed (Disassembly – Assembly)

–Drive Lines (Electrohydraulic 4Wd)

Main Specification

Torque Settings And Tools

Cross–Sectional Views

Transmission Shafts And Guard (Disassembly – Assembly)

Drive Gear Housing (Removal – Installation)

Drive Gear Housing Removed (Disassembly — Assembly) - -Front Axle Mechanical Transmission

–Front Axle Mechanical Transmission

Main Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Complete Front Axle Removal – Installation

Front Axle Removal – Installation

Steering Knuckle Bearing Pins Replacement

Stub Axle Adjustment

Wheel Hub Bearing Adjustment

Bevel Drive Adjustment

Front Axle Differential Overhaul

Front Axle Differential With Lim-Slip Overhaul

Leading Drive Wheels Toe-In Check - -Rear Axle And Transmission

–Rear Axle And Transmission

Main Data

Tightening Torques

Special Tools

Cross-Sectional Views

Description And Operation And Troubleshooting

Transmission-Gearbox Casing Removal-Installation

Transmission-Gearbox Casing Disassembly-Overhaul

Gearbox Driven Shaft End Float Adjustment

Differential Lock Engagement Sleeve Adjustment

Determining The Bevel Pinion Positioning Adjustment Ring

Adjusting The Taper Roller Bearings For The Bevel Pinion Shaft

Adjusting The Bearings And Checking The Backlash

Differential Pinion And Side Gear Backlash Adjustment - -Power Take-Off

–Mechanical Power Take – Off

Main Specification

Tools

Torque Settings

Sectional Drawings

Description And Operation

Troubleshooting

Removal – Refitting

Bench Overhaul - -Braking System

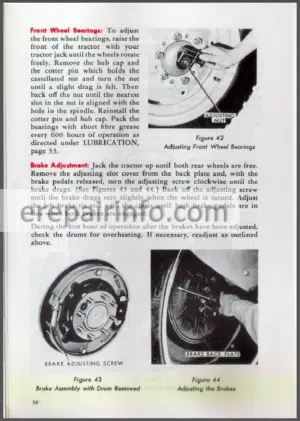

–Braking System

Main Data

Tightening Torques

Cross-Sectional Views

Description & Operation

Tools – Troubleshooting

Front Brake Assembly Mod Td565 And Td575 Removal And Refitting -Overhauling On The Bench

Service Brake Removal And Refitting

Removal-Refitting Of Front Brake Pumps

Bleeding Air From The Front Braking System

Adjusting Service Brake Pedals Travel

Parking Brake Travel Adjustment - -Hydraulic System

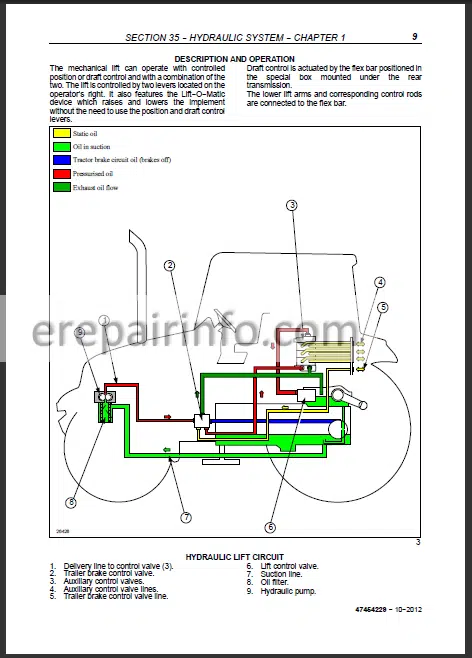

–Rear Mechanical Hydraulic Lift

Main Specification

Tightening Torques

Tools

Cross-Sectional Views

Description & Operation

Hydraulic Circuit

Description And Operation Of Lift Phases

Fault Diagnosis

Hydraulic Lift – Disassembly Reassembly

Hydraulic Lift – Bench Overhaul

Adjusting The Lift

Linkage Adjustment

Pressure Relief Valve – Disassembly Reassembly

Pressure Relief Valve – Setting

Lift Control Valve – Disassembly Assembly And Overhaul On Bench

Lift Pump

–Open Centre System Auxiliary Control Valves

Section Description Page

Main Data – Tools

Auxiliary Control Valves – Sectional Views

Description And Operation

Fault DiagnosisSee Chapter

Auxiliary Control Valves – Assembly-Disassembly

Spool Binding Test

Spool Leakage Test

Adjustment Of The Automatic Detent Release Pressure

–Trailer Brake Auxiliary Control Valve

Description And Operation

Hydraulic Diagram

Description And Operation Of Valve Phases

Trailer Brake Auxiliary Control Valve Linkage Adjustment - -Steering

–Steering

Principal Data

Tightening Torques

Section Views

Hydraulic Diagram

Operation

Fault Diagnosis

Tools

Hydrostatic Steering Control Valve – Removal-Installation

Hydrostatic Steering Control Valve – Disassembly-Assembly

Hydrostatic Steering Control Valve – Bench Testing

Hydrostatic Steering Oil Pump – Disassembly-Assembly

Steering Cylinder (Two-Wheel Drive Axle) – Removal-Refitting

Steering Cylinder (Four Wheel Drive Axle) – Removal-Refitting - -Front Axle And Wheels

–Front Axle And Wheels

Principal Data

Sectional Views

Torque Settings

Equipment – Fault Diagnosis

Removal-Refitting-Overhaul

Wheel Hub Disassembly–Assembly

Stub Axle Overhaul

Checking Wheel Alignment - -Auxiliary Units

–Auxiliary Units Chapter

Safety Instructions

General Characteristics

Equipment

Operating Principles

Fault Diagnosis

Cab Controls

Use

Main Components Of The Cab Air Conditioning System

Refrigerant Recovery-Recycling And Evacuation-Charging Stations

Drying Recharging And Checking Cooling

Functional Testing Of Air Conditioning System

Summary Of The Cab Air-Conditioning System Charging Operations

Checking For Refrigerant Leaks Using An Electronic Leak Detector

Summary Of Fault Diagnosis And Maintenance

Air Conditioning And Heating Pipes – Replacement

Receiver-Drier – Replacement

Condenser – Replacement

Compressor – Removal-Refitting

Compressor Drive Belt Tension Adjustment - -Electrical System

–Instruments Chapter

Analogue Instruments And Introduction

Transmitter And Switches

Components Chapter

Section Description

Introduction

Component Description

–Starting System

Technical Information

Tightening Torques

Description And Operation

Starting Circuit

System Tests

Removal And Re-Installation Of Starter Motor

Servicing

Bench Tests

–Charging System

Technical Information

Tightening Torques

Description And Operation

System Testing And Trouble-Shooting

Removal, Re-Installation And Servicing

–Battery

Technical Information

Description And Operation

Removal And Re-Installation

Battery Checking And Maintenance

Charging The Battery

Battery Problems – Frequent Causes

–Electrical Circuits

Contents

Fuses (All Versions)

Symbols Used In Electrical Circuits

Electrical Wire Colour Coding

Ground Locations

—Electrical Diagrams

General Diagrams (W/Out Cab)

General Diagrams (W/Cab)

Analogue Instrument Circuit And Connector Overview

Start–Up Circuit And Connector Overview

Direction Indicator & Hazard Warning Light Circuit And Connector Overview

Windscreen And Rear Window Wiper/Washer Circuit And Connector Overview

Brake Light Circuit And Connector Overview

Heating And Air-Conditioning System Circuit And Connector Overview

Work Lamps Circuit And Connector Overview

Main And Dipped Headlights, Horn Circuit And Connector Overview

Park Lights, Circuit And Connector Overview

Valve Clearance Adjustment

Coolant Pump Overhaul

Compression Test - -Bodywork And Driver Position

–Bodywork And Driver Position

Disassembly-Assembly

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.