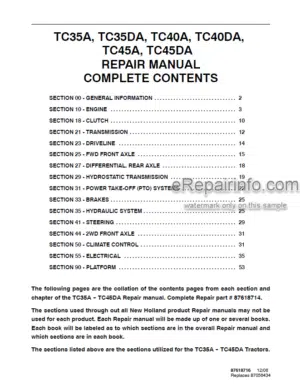

Repair Manual For New Holland TN-DA, TN-SA Series Tractors. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 1474

Bookmarks: Yes

Searchable: Yes

Number: 87393598

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TN60DA, TN60SA, TN70DA, TN70SA, TN75DA, TN75SA, TN85DA, TN95DA

Contents

- General

- Engine

- Clutch

- Transmissions

- Fwd Transfer Box And Auto Fwd

- Front Axle (Fwd)

- Rear Mechanical Drive

- Mechanical Power Take-Off

- Braking System

- Hydraulic System

- Steering

- Axles And Wheels

- Cab Air Conditioning System

- Electrical System

- Platform, Cab, Bodywork

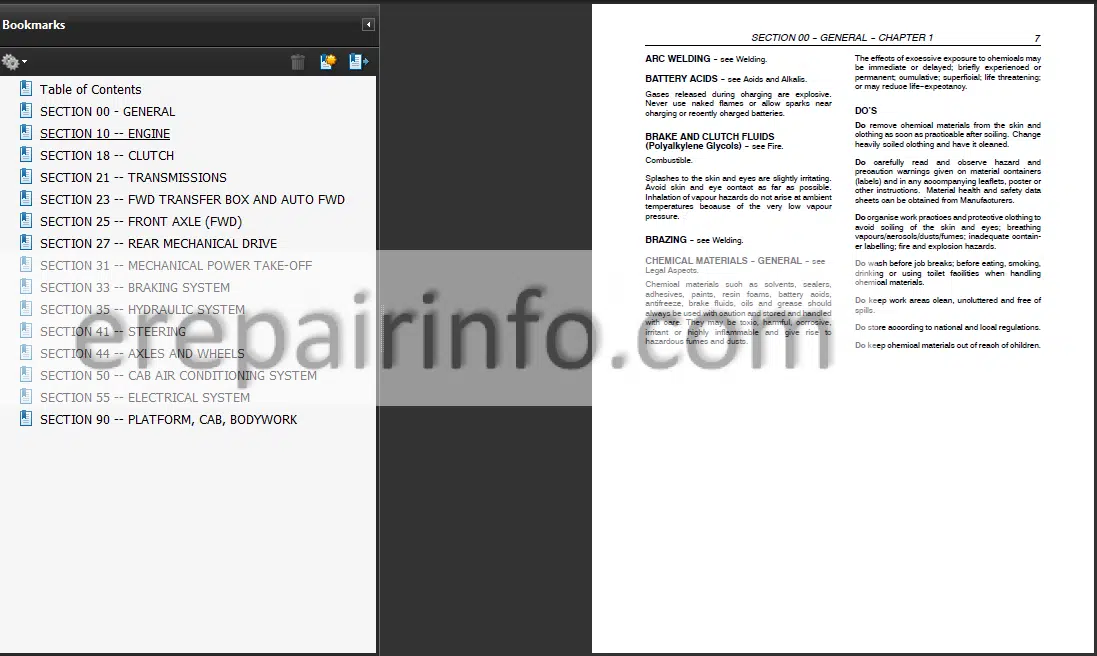

-General

General Instructions

Health And Safety

Precautionary Statements

Safety

Ecology And The Environment

Minimum Hardware Tightening Torques

Federal Emissions Warranty

Lubricants And Fluids

-Engine

–Engine(Three-Cylinder)

Specifications

Special Tools

Tightening Torques

Sectional Views

Engine Troubleshooting

—Overhaul

—-Engine

Removal

Installation

Compression Test

Disassembly

Assembly

—-Checks, Dimensions And Repairs

Cylinder Block

Main Bearings

Flywheel

Connecting Rods

Pistons

Valves

Tappets

Camshaft

Valve Timing

Cylinder Head

Valve Seats

Valve Guides

Injector Sleeves

Crankshaft Front Oil Seal

Valve/Rocker Arm

—Exhaust Pipe

Removal

Installation

— Cooling System (Three-Cylinder)

Specifications

Special Tools

Sectional Views

—Description And Operation

—-Cooling System

Radiator

Thermometer

Thermostat

—Overhaul

—-Coolant Pump

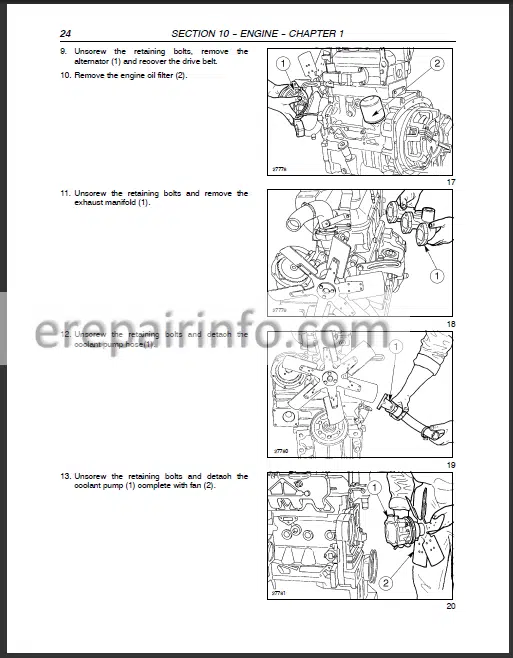

Removal

Installation

Disassembly

Assembly

—-Drive Belt Tension Adjustment

—-Cooling System Thermostat

Removal

Installation

—-Radiator

Removal

Installation

— Lubrication System (Three-Cylinder)

Specifications

Special Tools

Sectional View

—Description And Operation

Oil Filter

Low Oil Indicator

Oil Pump

— Fuel System (Three-Cylinder)

Specifications

Special Tools

—Description And Operation

—-Fuel Injection Pump (Bosch)

Turbocharged Models

All Models

—Overhaul

—-Fuel Tank

Removal

Installation

—-Fuel Injectors

Removal

Installation

—-Injection Pump

Removal

Lock Timing The Injection Pump On A Workbench

Installation

Check Fuel Injection Pump Timing With Pump Installed On Tractor

— Engine (Four-Cylinder)

Specifications

—Tightening Torques

Torque Settings With Angles

—Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

—Overhaul

—-Engine

Removal

Installation

Compression Test

Disassembly

Assembly

—-Checks, Measurements And Repairs

Cylinder Block

Crankshaft

Connecting Rods

Pistons

Camshaft And Valves

Cylinder Head

Crankshaft Front Seal

Crankshaft Rear Seal

Adjusting Valve/Rocker Arm Clearance

— Cooling System (Four-Cylinder)

Specifications

—Description Of Operation

Sectional Views

—Overhaul

—- Coolant Pump

Removal

Installation

—-Thermostart Valve

Removal

Installation

—- Radiator

Removal

Installation

—-Coolant Pump And Alternator Belts

Tension Adjustment

— Lubrication System (Four-Cylinder)

Specifications

—Lubrication System Components

—-Low Oil Pressure Indicator

Functioal Checks

Oil Filter

Replacement

— Fuel System (Four-Cylinder)

Specifications

Special Tools

—Description And Operation

—-Fuel Injection Pump (Bosch)

Turbocharged Models

All Models

—Overhaul

—-Fuel Injectors

Removal

Installation

—-Bosch Fuel Injection Pump

Removal

—-Lock-Timing The Injection Pump

—-Lock Timing The Fuel Injection Pump On A Workbench

Installation

—-Check Fuel Injection Pump Timing With Pump Installed On The Tractor

-Clutch

–Clutch (3-Cylinder Models)

—Specifications

Models With Mechanical Shuttle

Models With Power Shuttle

—Tightening Torques

—Special Tools

—Sectional Views

LukIn/ In Dual Clutch Pack

LukIn Single Clutch

Pto Servo-Assist Control Valve

—Troubleshooting

—Description And Operation

—-Pto Clutch Servo-Assist Control

Engagement

Disengagement

Adjustment

—Overhaul

—-Clutch

Removal

Disassembly

Assembly

Checks And Repair

Flywheel

Installation

—-Clutch Pedal Adjustment

— Clutch (4-Cylinder Models)

—Specifications

Models With Mechanical Shuttle

Models With Power Shuttle

—Tightening Torques

—Special Tools

—Sectional Views

LukIn/ In Dual Clutch Pack

LukIn Single Clutch

Pto Servo-Assist Control Valve

—Troubleshooting

—Description And Operation

—-Pto Clutch Servo-Assist Control

Engagement

Disengagement

Adjustment

—Overhaul

—-Clutch

Removal

Disassembly

Assembly

Checks And Repair

Flywheel

Installation

—-Clutch Pedal Adjustment

-Transmissions

— Mechanical Transmission (16 X 16) Synchro-Command

Main Data

Torque Settings

Tools

Cross-Sectional Views

Description And Operation

Troubleshooting

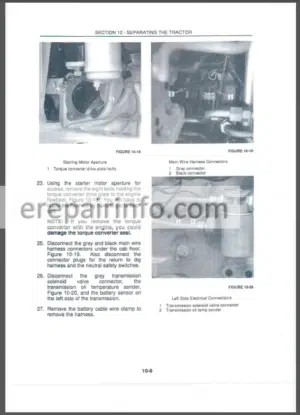

Rear Transmission/Gearbox Casing Removal – Installation

Gearbox Transmission Casing Disassembly – Assembly

Gearbox Control Lever Removal – Installation

Range Gear Control Lever Removal – Installation

— Power Shuttle Transmission (16 X 16) Synchro-Command

Main Data

Torque Values

Special Tools

Cross-Sectional Views

Description And Operation

Transmission-Gearbox Disassembly – Assembly

Power Shuttle Control Valve Disassembly – Assembly

A + B Clutch Valve Solenoids Removal – Installation

Dump Valve Solenoid Removal – Installation

Clutch Casing Disassembly – Assembly

— Power Shuttle Transmission Calibration, Faults And Diagnostics

Fault Codes Indication

—Description Of Systems (Ecm And Cdu)

Automatic Self-Diagnosis (Ecm)

Ecm First Start Up (Self Configuration)

Transmission Disabled Indicator Light

Diagnosis During Operation

Calibration And Diagnostics Unit (Cdu)

Power Shuttle Fault Code Priority

Calibration And Diagnostic Unit Use

Hh Menu Access

H1 – Clutches A And B Calibration

H2 – Clutches A And B Calibration Values Display

H3 – System Configuration

H4 – Power Shuttle Hardware And Software

Revision Levels

H5 – Control Switch Diagnosis

H6 – Clutch A Fill Time Modification And Display

H7 – Clutch B Fill Time

H8 – Erasure Of Data Stored In The Non-Volatile Memory (Nvm)

H9 – Voltmeter Functions

Ha – Clutch Pedal Potentiometer And Status Switch

Clutch Pedal Potentiometer Replacement And Clutch Pedal Switch Adjustment

Hc – Transmission Oil Temperature Sender

Hd – Hi/Lo Synchronizer Operation

He – Gear Change Adjustments

Hf – Stored Error Codes

Troubleshooting Fault Codes

Description Of Systems (Ecm And Est)

Automatic Self-Diagnosis (Ecm)

Ecm First Start Up (Self Configuration)

Transmission Disabled Indicator Light

Diagnosis During Operation

Power Shuttle Fault Code Priority

Electronic Service Tool (Est)

Downloading The Latest Software Into Tnda, Tnsa Series Tractor Power Shuttle Control Module With The Electronic Service Tool

Connecting The Electronic Service Tool (Est) To The Tractor

H1 – Clutches A And B Calibration

H2 – Clutches A And B Calibration Values Display

H3 – System Configuration

H4 – Power Shuttle Hardware And Software

Revision Levels

H5 – Control Switch Diagnosis

H6 – Clutch A Fill Time Modification And Display

H7 – Clutch B Fill Time

H8 – Erasure Of Data Stored In The Non-Volatile

Memory (Nvm)

H9 – Voltmeter Functions

Ha – Clutch Pedal Potentiometer And Status Switch

Clutch Pedal Potentiometer Replacement And Clutch

Pedal Switch Adjustment

Hc – Transmission Oil Temperature Sender

Hd – Hi/Lo Synchronizer Operation

He – Gear Change Adjustments

Hf – Stored Error Codes

Troubleshooting Fault Codes

—Fault Codes

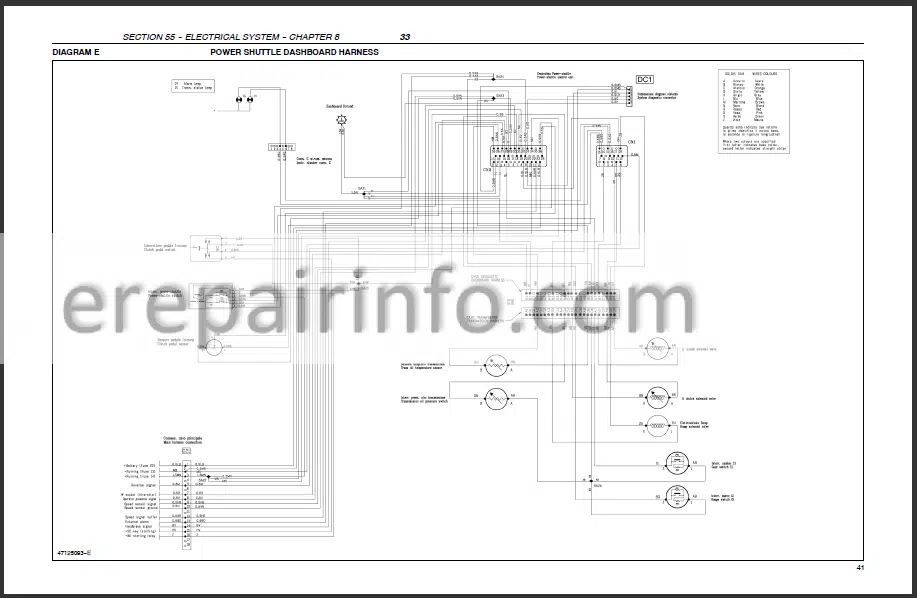

Power Shuttle (16 X 16) Electronic Control Module

Input/Output Wiring Diagram

-Fwd Transfer Box And Auto Fwd

— Fwd Transfer Box

Main Data

Torque Settings

Tools

Cross-Sectional Views

Description And Operation

Troubleshooting

Transmission Shafts And Guard Removal-Installation (Tnsa Models)

Transmission Shafts And Guard Removal-Installation (Tnda Models)

Drive Gear Housing Removal-Installation

Drive Gear Housing (Mechanical) Disassembly-Assembly

Drive Gear Housing (Electro-Hydraulic) Disassembly-Assembly

— Auto Fwd, Calibration And Diagnostics

Automatic Fwd Fault Codes

—Calibration And Diagnostic Unit (Cdu)

Hh Menu Access

H3 – System Configuration

H4 – Software Revision Level

H5 – Control Switches Diagnostics

H8 – Deleting Data From The Non-Volatile Memory

H9 – Voltmeter Functions

Hd – Fwd Engagement Position

Hf – Errors Stored In The Non-Volatile Memory Of The Ecm

—First Start-Up

—Electronic Service Tool (Est)

Downloading The Latest Software

Connecting The Electronic Service Tool

Hh Menu Access

H3 – System Configuration

H4 – Software Revision Level

H5 – Control Switches Diagnostics

H8 – Deleting Data From The Non-Volatile Memory

H9 – Voltmeter Functions

Hd – Fwd Engagement Position

Hf – Errors Stored In The Non-Volatile Memory Of The Ecm

First Start-Up

Troubleshooting

Ecm Location

– Front Axle (Fwd)

— Front Axle (Super Steer Axle)

Main Data

Torque Settings

Tools

Cross-Sectional Views

Description And Operation

Troubleshooting

Front Axle Assembly Removal-Installation

Bevel Drive And Front Axle Differential Housing Removal-Installation

Front Axle Bevel Drive Overhaul

Front Axle Differential Overhaul

Front Axle Differential Lock Clutch Assembly Overhaul

Front Epicyclic Final Drive Removal-Installation

Wheel Hub And Steering Knuckles Removal-Installation

Steering Knuckle Pins And Bearings Replacement

Front Wheels Adjustment (Toe-In)

— Front Axle (Fwd)

Main Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Front Axle – Removal/Installation

Front Axle – Disassembly

Front Axle Differential With Lim-Slip Overhaul

Front Axle – Assembly

Steering Knuckle Pins And Bearings – Replacement

Stub Axle Adjustment

Bevel Drive Adjustment

Front Epicyclic Final Drive Removal – Installation

Front Wheels Adjustment (Toe-In)

– Rear Mechanical Drive

— Rear Mechanical Transmission

Main Data

Tightening Torques

Tools

Cross-Sectional Views

Description And Operation

Troubleshooting

Rear Transmission Gearbox Removal-Installation

Differential Lock Engagement Sleeve-Adjustment

Lh Or Rh Final Drive Box Assembly Removal-Installation

Drive Shaft Removal-Installation

Epicyclic Final Drive Removal-Installation

– Mechanical Power Take-Off

— Servo-Assist Pto

Main Data

Tools

Tightening Torques

Pto Servo-Assist Valve – Description And Operation

Cross-Sectional Views

Description And Operation Of Pto

Pto Clutch Engagement/Oil Flow

Pto Clutch Disengagement/Oil Flow

Pto Clutch Servo Control Adjustment

Hydraulic Pto Servo Assist Cable Adjustment

Pto Engaged Switch Adjustment

Mechanical Pto Assembly Removal–Installation

Pto Brake

– Braking System

— Braking System

Main Data

Torque Settings

Cross-Sectional Views

Tools

Description And Operation

Troubleshooting

Right Or Left-Hand Brake Removal-Installation

Braking System Hydraulic Pump Removal-Installation

Brake Hydraulic System Air Bleeding

Parking Brake Brake Disks Removal-Installation

Handbrake Control Travel Adjustment

— High Pressure System Description And Operation

Precautionary Statements

Description And Operation

High-Pressure System Hydraulic Pump

Hydraulic System Configuration Table

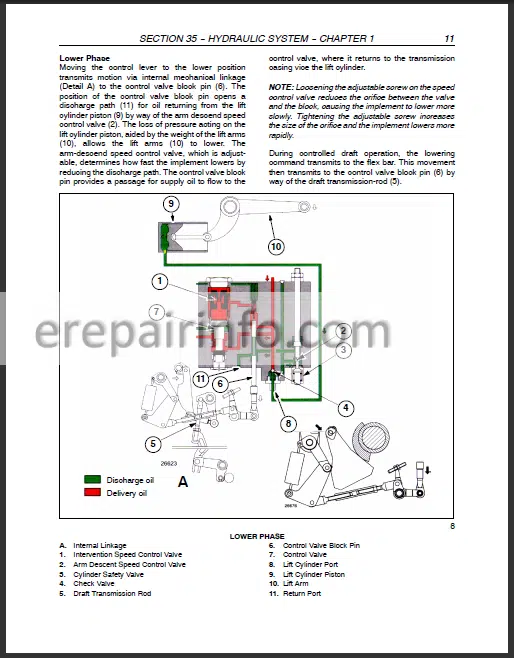

Mechanically Controlled Hydraulic Lift

Lift-O-Matic

Hydraulic Power Lift (Hpl) Control Valve Oil Flow

Remote Control Valves

Rear Remote Valve Arrangement

Rear Remote Valve Stacking

Rear Remote Valve Control Levers

Deluxe Quick-Fit Couplers

Zero-Pressure Return Port

Mid-Mount Control Valves (Optional)

Switching Between Single And Double Acting Cylinders

Double-Acting Valve With Automatic Detent Release And Float

Double-Acting Valve Less Automatic Detent Release And Float

Single-Acting Valve Less Automatic Release And Float

Tn60Da, Tn60Sa, Tn70Da, Tn70Sa, Tn75Da And Tn75Sa Hydraulic System Diagram

— High Pressure System Overhaul And Adjustment

Specifications

Torque Settings

Hydraulic Lift Tools

Cross-Sectional Views

Hydraulic Lift Troubleshooting

Mechanically Controlled Lift Internal Controls Disassembly-Assembly

Mechanically Controlled Lift Adjustments

Mechanically Controlled Lift Rod Mechanism Adjustments

Lift Arm Descent Speed Adjustments

Upper Stroke Limit Adjustment

Adjusting The Upper Stroke Limit Of The Lift-O-Matic Device

Arm Shaft And Lift Cylinder Disassembly-Assembly

Mechanically Controlled Lift Control Valve Disassembly-Assembly

Lift Pressure Relief Valve Removal-Installation

Lift Pressure Relief Valve (Calibration)

High Pressure (Lift) Pump Disassembly-Assembly

— Low-Pressure System Description And Operation

Low-Pressure, Steering And Lubrication System – General Description

Low-Pressure Oil Flow

Transmission Lubrication System

Steering System Oil Flow

Electro-Hydraulic Rear Differential Lock

Electro-Hydraulic Front Differential Lock

Electro-Hydraulic Four-Wheel Drive (Fwd)

Pto Servo-Assist Valve And Piston

— Low-Pressure System Test Fitting Locations

System Test Fitting Locations

-Steering

–Steering

Torque Settings Main Data – Tools

Description And Operation

Troubleshooting

Hydrostatic Steering Wheel Removal-Installation

Hydrostatic Steering Control Valve Removal-Installation

Hydrostatic Steering Control Valve (Removed) Disassembly-Assembly

Hydrostatic Steering Control Valve Bench Testing

Steering Control Cylinder Removal-Installation

Steering Control Cylinder Disassembly-Assembly

— Open Center Flow Gear Pump

Main Data

Torque Settings

Cross Sectional Views

Description And Operation

Hydrostatic Steering Oil Pump – Disassembly-Assembly (With Unit Removed)

-Axles And Wheels

–Axles And Wheels

Main Data

Cross-Sectional Views

Torque Settings

Tools

Troubleshooting

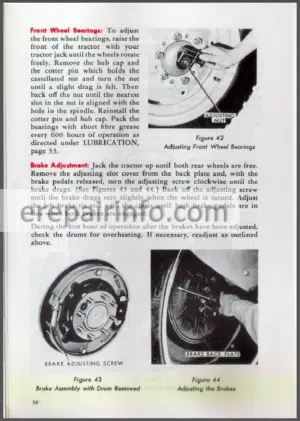

Front Axle Hub Disassembly-Assembly

Front Axle Removal-Installation

Stub Axle Overhaul

Checking The Alignment Of The Front Wheels (Toe In)

– Cab Air Conditioning System

— Cab Air Conditioning System

Cab Air Conditioning System Safety

Use Of The Air Conditioning System

Tools And General Characteristics

Operating Principles

Main Components Of The Cab Air Conditioning System

Cab Heating And Ventilation Controls

Cab Air Conditioning And Temperature Controls

Function And Cooling Tests

Troubleshooting

Refrigerant Recovery – Recycling And Evacuation – Charging Stations

Filter/Drying, Recharging And Refrigeration Check

Checks And Elimination Of Gas Leaks

Compressor Drive Belt Tension Adjustment

Cab Air Infeed Vents Removal And Installation

Cab Heating/Air Conditioning System Removal And Installation

Cab Heating Unit Disassembly And Assembly

Cab Air Conditioning System Evaporator Unit Disassembly And Assembly

Cab Electric Fan Unit Disassembly And Assembly

-Electrical System

–Instruments’

—Instrument Panels

Analog Instrument Panel (3-Cylinder Version)

—-Digital Instrument Panel (All Models)

Indicator Light Panel

—-Digital Instrument Display

—Controls On The Dashboard And Control Panel

Hazard Warning Lights Switch

Headlight Switch

Power Shuttle Control Lever

Transmitters, Sensors And Switches (Models With 3-Cylinder Engines)

Transmitters, Sensors And Switches (Models With 4-Cylinder Engines)

–Components

—Description Of Controls

Hazard Warning Lights Switch

Headlight Switch

Power Shuttle Control Lever

Light Control Lever

Power Socket For Rotating Beacon

Auxiliary Power Outlets

Controls On Right Hand Cab Upright

Cab Internal Lighting

—-Cab Air Conditioning/Heating Controls

Air Conditioning System Operation

—Light Bulb Maintenance

—-Replacing Component Light Bulbs

Front Head Lamp

Corner Light Bulbs

Side Direction Indicator Lamp

Rear Direction And Stop Indicator Lamp

Cab Front And Rear Work Lights

Courtesy Light And Adjustable Reading Light

Adjustable Reading Light

Instrument Panel Bulbs

Replacing The Front Side Lights, Brake And Direction Indicator Lamp Bulbs

Rear Sidelights, Brake And Direction Indicator Light Bulbs (3-Cylinder)

Work Light Bulb Replacement (3-Cylinder)

Replacing The Turn Indicator, Flasher, And Brake Light Bulbs (Rops)

Work Lights (Rops)

–Starting System

Specifications

Tightening Torques

Troubleshooting

—Description And Operation

Marelli Starter Motor

Iskra Starter Motor

—Starting System Testing

Current Absorption

Starter Motor (No Load)

—-Circuit Resistance (Voltage Drop)

Battery Cable – Positive

Starter Motor Ground Connections

Battery Cable – Negative (Ground)

—Overhaul

—-Starter Motor

Removal

Disassembly

Testing

Installation

–Charging System

Specifications

Tightening Torques

—Description And Operation

Alternator (3-Cylinder Version)

Alternator (4-Cylinder Version)

General Operation (All Models)

—Testing And Troubleshooting

Precautions And Preliminary Checks

—-Tests Performed On The Tractor

Alternator Wire Connection Test

Charging Current And Regulated Voltage Test

Charging Circuit Voltage Drop Test

Maximum Alternator Output Test

—Overhaul

—-Alternator

Removal

Tests Performed On A Workbench

Disassembly

Assembly

Installation

–Battery

Specifications

Description And Operation

—Overhaul

—-Battery

Removal

Installation

Servicing

–Connectors

Electrical Circuit Connectors/Component Connectors

Wire Color Coding

Ground Location Points (Models With 3-Cylinder Engine)

Ground Location Points (Models With 4-Cylinder Engine)

Connector Location Points (Models With 3-Cylinder Engine)

Connector Location Points (Models With 4-Cylinder Engine)

Connector Illustrations / Pin-Out

— Cab Electrical Components

—Overhaul

—-Light Control Switch And Lever

Removal

Installation

—-Analog/Digital Instrument Control Panel

Removal

Installation

—-Fusebox, Fuses And Relays

Removal

Installation

Fuses/Relay Replacement

—-Speakers

Removal

Installation

—-Cab Internal Light Fixture

Removal

Installation

—-Windscreen Wiper Motor (Front)

Removal

Installation

—-Windscreen Wiper Motor (Rear)

Removal

Installation

— Wiring Diagrams

How To Use Wiring Diagrams

Auto Fwd / Mechanical Lift / Less Cab / 3-Cylinder

2Wd (Mechanical Fwd) / Mechanical Lift / With Cab / 3-Cylinder

Electro-Hydraulic Fwd / Mechanical Lift / With Cab / 3-Cylinder

Auto Fwd / Mechanical Lift / With Cab / 3-Cylinder

2Wd (Mechanical Fwd) / Mechanical Lift / With Cab / 4-Cylinder

Electro-Hydraulic Fwd / Mechanical Lift / With Cab / 4-Cylinder

Symbols Used In Electrical Diagrams

– Platform, Cab, Bodywork

–Cab

Tools

Hood Opening Removal And Installation

Protective Grill Removal And Installation

Hood Guard Removal And Installation

Instrument Panel Lower Guard Removal And Installation

Platform Assembly Removal And Installation

Safety Frame Roof Removal And Installation

Cab With Platform Assembly Removal And Installation

Cab Windows (Replacing Glued Cab Windows)

Rh Or Lh Upright Seals Removal And Installation

Cab Ceiling Fitting Removal And Installation

Sun Shade Removal – Installation

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.