Factory Service Repair Manual For New Holland TN60VA TN75VA TN95VA Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1330

Bookmarks: Yes

Searchable: Yes

Number: 87352286

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TN60VA, TN75VA, TN95VA

Contents

- GENERAL

- ENGINE

- CLUTCH

- TRANSMISSIONS

- FWD TRANSFER BOX AND AUTO FWD

- FRONT AXLE MECHANICAL TRANSMISSION

- REAR AXLE MECHANICAL TRANSMISSION

- MECHANICAL POWER TAKE-OFF

- BRAKES

- HYDRAULIC SYSTEMS

- STEERING

- AXLES AND WHEELS

- CAB CLIMATE CONTROL

- ELECTRICAL SYSTEM

- PLATFORM, CAB, BODYWORK

-General

–General

General Instructions

Health And Safety

Precautionary Statements

Safety

Ecology And The Environment

Minimum Hardware Tightening Torques

Federal Emissions Warranty

Consumables

-Engine

–Engine

—Specifications

Engine Type

Timing System

Valve Timing Gears

Crankcase And Cylinder Block

Crankshaft And Bearings

Connecting Rod

Piston

Tappet

Rocker Arm And Valve

Rotating Counterweight Dynamic Balancer

Cylinder Head

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

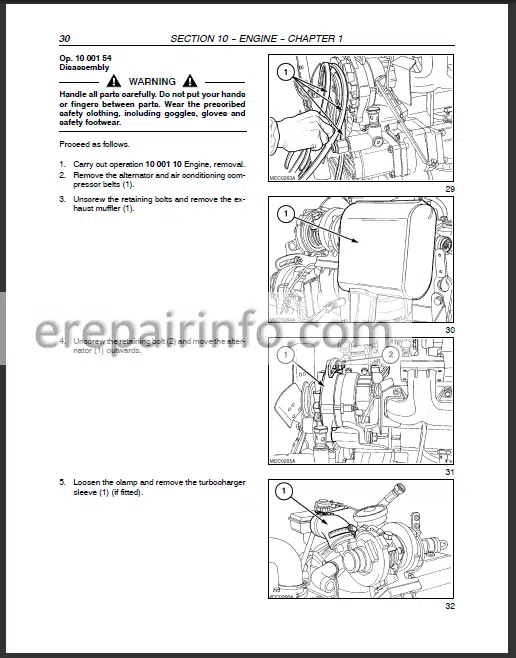

—Overhaul

—-Engine

Removal

Installation

Compression Test

Disassembly

—–Assembly

Crank, Main Bearings And Thrust Rings

Rear Cover With Seal And Engine Flywheel

Synchronizing The Timing Gears

Bosch Injection Pump

Cylinder Head

Valve And Rocker Arm

Fuel Injectors

Cooling System Belt

—-Cylinder Block

Inspection

—-Crankshaft And Main Bearings

Crankshaft Inspection

Main Bearing Inspection

Main Bearing Cap Bolt Inspection

—-Crankshaft Front Oil Seal

Removal

Installation

—-Engine Flywheel

Refacing

—-Flywheel Bolts

Inspection

—-Connecting Rods

Inspection

—-Pistons With Rings, Pins, Connecting Rods, Big End Caps And Bearings

Inspection

Assembly

Installation

—-Valves, Tappets And Camshaft

Valves, Grinding

Dimensions (Mm) Of Valves And Valve Guides

Valve Timing Check

Tappets Inspection

Camshaft Inspection

—-Cylinder Head

Inspection

Valve Seats, Grinding

Valve Guides, Replacement

—-Rotating Counterweight Dynamic Balancer

Assembly

Installation

—-Exhaust Pipe

Removal

Installation

–Cooling System

Specifications

Special Tools

—Description And Operation

Sectional Views

—Overhaul

Thermostat

Flushing The System (Models Without Cabs)

Flushing The System (Models With Cabs)

Coolant Thermometer

—-Coolant Pump Drive Belt

Adjustment

—-Coolant Pump

Removal

Installation

Disassembly

Assembly

—-Thermostat Valve

Removal

Installation

—-Radiator

Removal

Installation

–Lubrication System

Specifications

Description and Operation

—Overhaul

—-Oil Pump

Removal

Installation

–Fuel System

Specifications

Special Tools

—Description And Operation

—-Fuel (Bosch) Pump

Turbocharged Models

Cold Start Compensation (All Models)

Thermostatic Switch

Mechanical Cold-Start Accelerator (Ksb)

—Overhaul

—-Fuel Tank

Removal

Installation

—-Injector Sleeves

Inspection

Removal

Installation

—-Injectors

Removal

Installation

—-Bosch Fuel Injection Pump

Removal

Installation

Checking the Fuel Injection Pump Timing with the Pump Installed on the Tractor

Lock-time the Fuel Injection Pump with Pump Removed from the Tractor

—-Fuel Circuit Air Bleeding

-Clutch

–Clutch

—Specifications

Luk 11/11 Clutch

Luk 11 Clutch

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

Troubleshooting

Overhaul

—Clutch

Removal

Installation

—-Dual Disk Clutch 11/11

Disassembly

Assembly

—-Single Disk Clutch 11 (Fitted With Power Shuttle)

Disassembly

Assembly

—Checks, Measurements And Repairs

Dual Disk Clutch

Adjustment Of 11/11 Dual Clutch Release

Adjustment Of 11 Single Plate Clutch Release Levers

Transmission Clutch Pedal Adjustment

Mechanical Pto Clutch Control Adjustments

— Servo Assist Pto Control

—Description Of Operation

Sectional Views

—Checks, Measurement And Repairs

Adjusting The Pto Clutch Servo Control

Hydraulic Pto Servo Assist Cable Adjustment

Adjusting The Pto Switch

– Transmissions

— Mechanical Transmission

—Specifications

Reverser

Creeper Unit

Transmission And Range Gear

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

Gearbox, Creeper Unit And Reverser

Creeper Unit

—Overhaul

—- Rear Transmission-Gearbox Casing

Removal

Installation

—-Gearbox Transmission Casing

Disassembly

Assembly

—-Gearbox Control Lever

Removal

Installation

—-Range Gear Control Lever

Removal

Installation

—-Shuttle Control Lever

Removal (Models Fitted With Mechanical Transmission)

Installation

—Adjustments

Transmission-Gearbox Casing

— Mechanical Transmission With Splitter

—Specifications

Reverser

Creeper Unit

Transmission And Range Gear

Splitter

—

Tightening Torques

Tools

—Description And Operation

Sectional Views

—-Troubleshooting

Gearbox, Creeper Unit And Reverser

Creeper Unit

Splitter Device

—Overhaul

—-Splitter Device And Creeper Unit Gearbox, Shafts And Bearings

Removal

Installation

— Power Shuttle Transmission With Dual Command (2 Speed Power Shift) Function

—Specifications

Reverser

Creeper Unit

Transmission And Range Gear

Power Shuttle

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

Gearbox, Creeper Unit And Reverser

—Overhaul

—-Gearbox Transmission Casing

Disassembly

Assembly

—-Power Shuttle Control Valve

Disassembly

Assembly

—-Accumulator

Disassembly

Assembly

—-Gearbox Control Valve Solenoid Valve

Removal

Installation

—-Gearbox Control Valve Solenoid Valve

Removal

Installation

—-Clutch Casing

Disassembly

Assembly

—Calibrations

Hh Menu Access

H1 – Clutches A (Lo) And B (Hi) Calibration

H2 – Clutches A (Lo) And B (Hi) Calibration Values Display

H3 – System Configuration

H4 – Software Revision Level

H5 – Control Switches Diagnosis

H6 – Clutch A (Lo) Fill Time Modification And Display

H7 – Clutch B (Hi) Fill Time Modification And Display

H8 – Deleting Data From The Non–Volatile

Memory (Nvm) (Eeprom)

H9 – Voltmeter Functions

Ha – Clutch Pedal Position And Neutral Switch Display

Hb – Transmission Oil Temperature Display

Hd – Shuttle Synchroniser Position

He – Gear Change Adjustments

Hf – Faults Stored In The Non-Volatile Storage Of The Ecu

First Start-Up

—

Diagnostics

Ecu Location

—Fault Codes

Fault Code Indication

Fault Code Decoding

—Wiring Diagram1

Power Shuttle Electronic Control Unit Input/Output

Wiring Diagram (32 + 16 And 44 + 16)

—Control Unit Description And Operation

Ignition

Shift From (High) Forward To Reverse Gear

Shift From Reverse To (High) Forward Gears

Shift From (Low) Forward Gear To Reverse Gear

Shift From Reverse To (Low) Forward Gear

– Fwd Transfer Box And Auto Fwd

— Fwd Transfer Box

—Specifications

Fwd Electrohydraulic Engagement

Drive Shaft Data

—

Tightening Torques

Special Tools

—Description Of Operation

Sectional Views

Troubleshooting

—Overhaul

—-Drive Shafts And Guard

Disassembly (Mod Tn70Na Or Tn75Na)

Assembly

—-Drive Shafts And Guard (Mod Tn60Va, Tn75Va, Tn95Va)

Disassembly

Assembly

—-Drive Gear Housing Assembly

23 202 50 Removal

Installation

—-Drive Gear Housing Removed

Disassembly

Assembly

—-Drive Gear Housing Removed

Removal

Installation

—Calibrations

Hh Menu Access

H3 – System Configuration

H4 – Software Revision Level

H5 – Control Switch Diagnostics

H8 – Deleting Data From The Non-Volatile Memory (Nvm) (Eeprom)

H9 – Voltmeter Functions

Hd – Fwd Engagement Position

Hf – Faults Stored In The Non-Volatile Storage Of The Ecu

First Start-Up

—Diagnostics

Ecu Location

—Fault Codes

Automatic Fwd Fault Codes Indication

Fault Code Decoding

—Wiring Diagram

Pto And Fwd Electronic Control Unit Input/Output

-Front Axle Mechanical Transmission

— Front Axle Mechanical Transmission (Supersteert Axle)

Specifications

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

Hydraulically Controlled Differential Lock – Front Axle

—Overhaul

—-Front Axle Assembly

Removal

Installation

—-Pinion And Front Axle Differential Housing

Removal

Installation

—-Front Axle Differential Drive

Disassembly

Assembly

—-Front Axle Differential

Overhaul

—-Front Differential Lock Clutch Assembly

Disassembly

Assembly

—-Front Epicyclic Final Drive With Brake

Disassembly

Assembly

—-Wheel Hub Seal With Front Brakes

Disassembly

Assembly

—-Front Epicyclic Final Drive

Disassembly

Assembly

—-Wheel Hub Seal Replacement Less Front Brakes

Disassembly

Assembly

—-Wheel Hubs And Steering Knuckle

Disassembly

Assembly

—-Steering Knuckle Pins And Bearings

Disassembly

Assembly

—-Steering Sensor Replacement

Disassembly

Assembly

—Adjustments

Steering Sensor

Pinion

Differential

Pinion Backlash

— Front Axle Mechanical Transmission

Specifications

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

—Overhaul

—-Front Axle, Assembly

Removal

Installation

—-Front Axle Pivot Bushings

Replacement

—-Front Axle Steering Cylinder

Disassembly

Assembly

—-Wheel Hubs And Steering Knuckle

Removal

Installation

—-Front Epicyclic Final Drive

Disassembly

Assembly

—-Front Axle Differential Housing (For Models Without Brakes)

Removal

Installation

—-Hydraulically Controlled Differential Lock With Pinion (For Models Without Brakes)

Disassembly

Assembly

—-Front Axle Mechanical Differential Lock (Models Without Brakes)

Disassembly (Pinion Removed)

Assembly

—Front Axle Steering Sensor

Replacement

—-Pinion With Differential Front Axle (Models With Brakes)

Removal

Installation

—-Pinion With Mechanically Controlled Differential Lock(Models With Brakes)

Overhaul

Assembly

—-Front Axle Pinion

Disassembly

Assembly

—-Mechanical Differential Lock (Electro-Hydraulically Controlled)

Disassembly (Pinion Removed)

Assembly

—Adjustments

Pinion (For Models Without Brakes)

Leading Drive Wheels Toe-In Check

Front Axle Steering Sensor

Pinion (Models With Brakes)

– Rear Axle Mechanical Transmission

— Rear Axle Mechanical Transmission

—Specifications

Pinion And Differential

Final Drive

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

Pinion And Differential

Final Drive

Hydraulically Controlled Differential Lock

—Overhaul

—-Rear Transmission Gearbox

Disassembly

Assembly

—-Rh Or Lh Lateral Final Drive Housing Assembly

Removal

Installation

—-Drive Wheel Shaft

Disassembly

Assembly

—-Epicyclic Final Drive

Removal

Installation

—Adjustments

Adjusting The Position Of Differential Lock Engagement Sleeve

—-Adjusting The Pinion

Adjustment Of The Clearance Between The Side And Planetary Pinion Teeth

– Mechanical Power Take-Off

— Mechanical Power Take-Off

Specifications

Special Tools

Tightening Torques

—Description And Operation

Sectional Views

—Troubleshooting

—Overhaul

—-Mechanical Pto

Disassembly

Assembly

-Brakes

–Brakes

Specifications

Tightening Torques

—Description and Operation

Sectional Views

—

Special Tools

Troubleshooting

—Overhaul

—-Right or Left Hand Brake

Removal

Installation

—-Brake Hydraulic Pump

Removal

Installation

Service Brakes Control Pedals Stroke Adjustment (Tractors with Cabs)

—-Brake Hydraulic System Air Bleeding

—-Parking Brake

Removal

Installation

—Adjustments

Handbrake Control Stroke Adjustment

– Hydraulic Systems

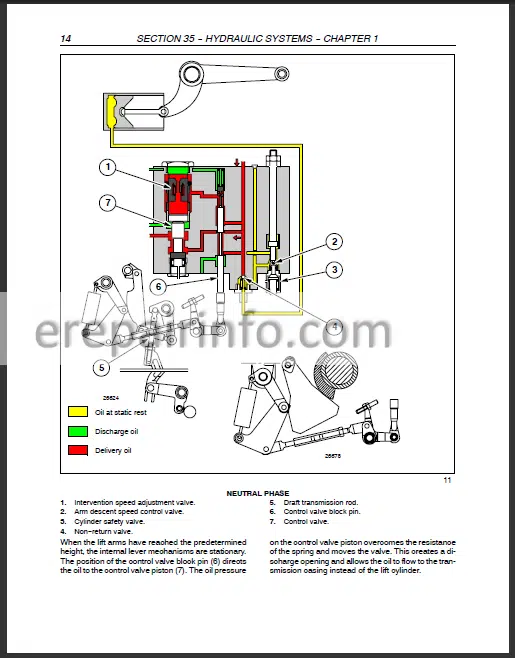

— Rear Mechanical Hydraulic Lift

—Specifications

Rear Hydraulic Lift

Implement Hitching Device

—

Tightening Torques

Special Tools

—Description And Operation

Sectional Views

—Troubleshooting

—Overhaul

—-Lift Internal Controls (With The Lift Removed)

Disassembly

Assembly

Adjustments

—-

Rod Mechanism Adjustments

Lift Arm Descent Speed Adjustments

Upper Stroke Limit Adjustment Check

Operations To Be Performed To Adjust The Upper Stroke Limit

Of The Lift-O-Matic Device

—-Arm Shaft And Lift Cylinder (With The Lift Removed)

Disassembly

Assembly

—-Lift Control Valve DA (With Control Valve Removed)

Disassembly

Assembly

—-Lift Pressure Relief Valve

Removal

Installation

Settings

— Open Center System Auxiliary Control Valves

Specifications

Special Tools

Tightening Torques

—Specifications

Sectional Views

—Overhaul

—-Auxiliary Control Valves (With The Unit Removed)

Disassembly

Assembly

Testing

— Electronically Controlled Hydraulic Lift

—Specifications

Electronically Controlled Hydraulic Lift

Implement Hitching Device

—

Tightening Torques

Special Tools

—Description and Operation

Sectional Views

—Overhaul

—-Electronically Controlled Hydraulic Lift

Removal

Assembly

—-Draft Sensor Support (With Lift Removed)

Removal

Assembly

—-Lift Electronic Control Center

Removal

Installation

—-Lift Arm Potentiometer

Removal

Installation

—-Draft Sensor

Removal

Installation

—-Electronically Controlled Hydraulic Lift

Disassembly

Assembly

—-Hydraulic Control Valve

Removal

Installation

Disassembly

Assembly

—-Control Valve Block Pin

Disassembly

—-Non-return Valve

Disassembly

Assembly

—Calibrations

Cylinder Safety Valve

Lift

Connection Between the Calibration and Diagnostic Instrument 380000282 to the Diagnostic Connector

—Fault Codes

—Diagnostics

Front/Rear Electronic Lift Electronic Control Unit Input/Output Wiring Diagram

— Non-Stop Flow Gear Pump

—Specifications

Hydraulic Pump C 42

Bosch 25 Hydraulic Pump

—Description and Operation

Sectional View

—Overhaul

—-Lift Oil Pump (With the Pump Removed)

Disassembly

Assembly

-Steering

–Steering

Specifications

Tightening Torques

Tools

—Description and Operation

Sectional Views

—Troubleshooting

—Overhaul

—-Hydrostatic Steering Wheel

Removal

Installation

—-Hydrostatic Steering Control Valve

Removal

Installation

Disassembly (with the control valve removed)

Assembly

Bench Testing

— Non-Stop Flow Gear Pump

—Specifications

Hydraulic Pump A 25

Hydraulic Pump A 31 Xrp2

—Tightening Torques

—Description And Operation

Sectional Views

—Overhaul

—-Hydrostatic Steering Oil Pump (With The Pump Removed)

Disassembly

Assembly

– Axles And Wheels

— Axles And Wheels

—Specifications

Sectional View

—

Tightening Torques

Tools

Troubleshooting

—Overhaul

—-Front Axle Hub

Disassembly

Assembly

—-Front Axle

Removal

Installation

—-Stub Axle

Removal

Installation

—Adjustments

Checking the Alignment of the Leading Wheels

– Cab Climate Control

— Heating, Ventilation, And Air Conditioning

Safety Precautions

Specifications

Special Tools

—Description And Operation

—-Main Components

Sanden Sd 5H11 Model Compressor

Condenser

Filter/Dryer

Thermostatic Expansion Valve

Electronic Thermostatic Switch (Antifrost)

Evaporator

—-Warnings For Air Conditioning System Repair Operations

—-Cab Heating And Ventilation Controls

Ventilation

Electric Fan

Air Filter

Temperature Control Knob

Ignition Switch

—-Cab Air Conditioning Controls

Temperature Control Knob

Electric Fan Control Knob

—-Recovery-Recycling And Evacuation-Charging Stations (380000315)

—-Filter/Drying, Recharging And Refrigeration Check

Recycling Of Recovered Refrigerant

Discharge Of Recovered Oil

Transfer Of Decontaminated Refrigerant From Cylinder (19) To An External Cylinder

Evacuation And Charging The Cab Air Conditioning System Using The Evacuation/Charging Station 380000315

Charging The Graduated Cylinder (31) Of The Evacuation/Charging Station

Evacuation Of The Cab Air Conditioning System

With New Oil

Charging The Cab Air Conditioning System With Refrigerant (After Evacuation)

—-Summary Of The Air Conditioning System Charging Operations

—-Checking For And Eliminating Any Gas Leaks

Testing For Leaks With Leak Detector 380000314

—-Checking For Refrigerant Leaks Using An Electronic Leak Detector

Leak Detector (380000314)

Refrigerant Gas Leak Test

—Adjustments

—Troubleshooting

Visual Inspection Of Components

—-Functional Tests

Checking Air Temperature

Checking For Gas Leaks (With Detector 38000314)

—Overhaul

—-Cab Heating/Air Conditioning System

Removal

Installation

—-Cab Heating Unit

Disassembly

Assembly

—-Cab Air Conditioning System Evaporator Unit

Disassembly

Assembly

—-Cab Fan Unit

Disassembly

Assembly

– Electrical System

— Instruments

—Specifications

Analog Instruments

Indicator Light Panel

Transmitters, Sensors And Switches

Electronic Module Instruments

—Maintenance

Replacing The Multi-Purpose Warning Lights On The Instrument Panel

–Components

—Description Of Components

Central Console Panel

Analog Control Panel

Digital Instrument Control Panel

Dashboard Controls

Central Console Controls

Controls On Right–Hand Mudguard

(Version With Electronically Controlled Lift)

External Controls

Cab Controls On Cab Ceiling

Cab Air Conditioning Controls

Controls On Right–Hand Cab Upright

—Maintenance

—-Electronic Lift Control Lights

Replacement

—-Front Headlight Bulbs

Replacement

—-Front Sidelight And Direction Indicator Lamp Bulbs

Replacement

—-Front And Rear Work Light Bulbs

Replacement

—-Work Light Bulbs On Tractors With Roll Bar

Replacement

—-Rear Sidelights, Brake And Direction Indicator Light Bulbs

Replacement

—-Courtesy And Adjustable Reading Light Bulbs

Replacement

—-Number Plate Light

Replacement

— Starting System

Specifications

Tightening Torques

Description And Operation

—Troubleshooting

Fault Diagnosis

—System Testing

Starting System Test On Tractor

Current Absorbed On The Starter Motor Circuit

Starting System Circuit Resistance

Battery Positive Cable

Starter Motor Ground Connection

Battery Ground Cable

—Overhaul

—-Starter Motor

Removal

Installation

—-Starter Motor

Disassembly

Assembly

Armature Axial End-Float

—Testing

Starter Motor Test (Without Load)

Bench Tests

— Charging System

Specifications

Tightening Torques

—Description And Operation

Alternator Operation

—System Testing And Troubleshooting

Battery Check

Driving Belt Check

Warning Light Check

Alternator Wire Connection Tests

Charging Current And Regulated Voltage Tests

Charging Circuit Voltage Drop Tests

Maximum Alternator Output Test

—Overhaul

—-Alternator

Removal

Disassembly

Assembly

Overhaul

Installation

–Battery

Specifications

Description And Operation

—Overhaul

—-Battery

Removal

Installation

—

Battery Checking And Maintenance

Troubleshooting

— Electrical Circuits

—Specifications

Electrical Circuit Components

—Description And Operation

Location Of Fuses And Relays (Version With Cab)

A1 Version (With Cab) – Fig 1

A2 Version (With Cab) – Fig 2

A3 Version (With Cab) – Fig 4

A4 Version (With Cab) – Fig 6

A5 Version (With Cab) – Fig 8

A6 Version (With Cab) – Fig 10

Fuse And Relay Layout On Cab Right-Hand Upright

Location Of Fuses And Relays (Version Without Cab)

A1 Version (Without Cab) – Fig 14

A2 Version (Without Cab) – Fig 15

A3 Version (Without Cab) – Fig 17

A4 Version (Without Cab) – Fig 19

Operator Safety Circuit – Fig 21

Power Sockets – Fig 22

Symbols Used In Electrical Circuits

Wire Color Coding

Wiring Diagrams And Connections Identification Code

Ground Location Points

Electrical Circuits

Wiring Diagrams A – B – C – D

Starter And Recharging Circuit (Diagram A)

Operator Safety Circuit (Diagram B)

Tail/Side Lights, Full Beam, Dipped Beam, Number Plate And Instrument Lighting (Diagram C)

Direction Indicator And Hazard Lights Circuit (Diagram D)

Wiring Diagrams E – F – G

Cooling And Heating System, Windscreen Wiper, Rear Window Wiper, Radio And Internal Lighting (Diagram E)

Cooling And Air-Conditioning System, Windscreen Wiper, Rear Window Wiper And Internal Lighting (Diagram F)

Work Lights, Rotating Beacon Circuit (Diagram G)

Wiring Diagrams – I/1 – I/2 – I/3 – L

Power Shuttle Circuit (Transmission Side) (Diagram I/1)

Power Shuttle Circuit (Dashboard Side) (Diagram I/2)

Power Shuttle Circuit (Dashboard Side) (Diagram I/3)

Rear Electronic Lift Circuit (Diagram L)

Wiring Diagrams M – N – O – P

Differential Lock And Brake Lights Circuit (Mechanical Fwd Version) (Diagram M)

Differential Lock And Brake Lights Circuit (Electrohydraulic Fwd Version) (Diagram N)

Differential Lock And Brake Lights Circuit (Permanent Fwd Version) (Diagram O)

Fwd Control Unit Circuit (Diagram P)

Wiring Diagrams Q/1 – Q/2 – R/1 – R/2

Transmission Circuit (Version With Permanent Fwd And Mechanical Lift) (Diagram Q/1)

Transmission Circuit (Version With Permanent Fwd And Mechanical Lift) (Diagram Q/2)

Transmission Circuit (Version With Electrohydraulic Fwd And Electronic Lift) (Diagram R/1)

Transmission Circuit (Version With Electrohydraulic Fwd And Electronic Lift) (Diagram R/2)

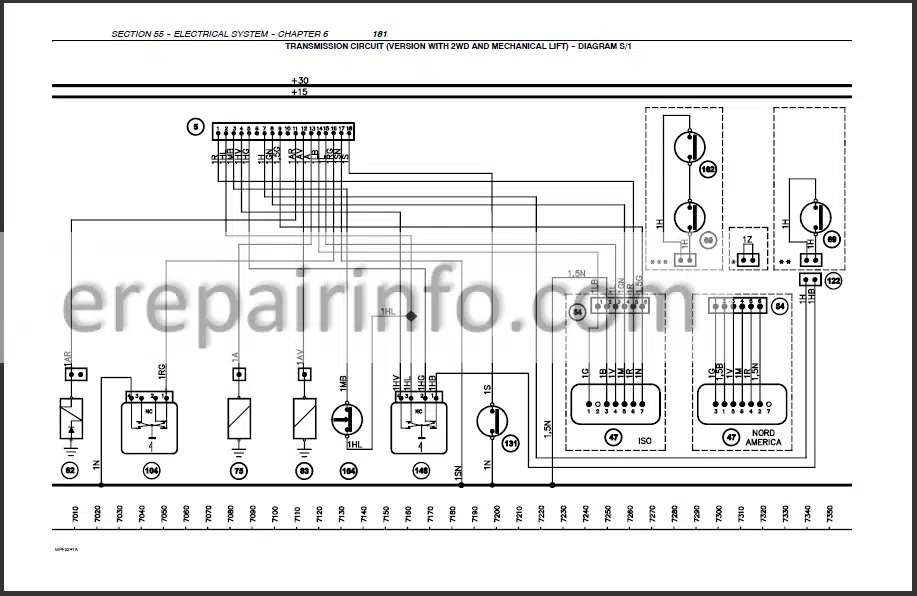

Wiring Diagrams S/1 – S/2 – T/1 – T/2

Transmission Circuit (Version With 2Wd And Mechanical Lift) (Diagram S/1)

Transmission Circuit (Version With 2Wd And Mechanical Lift) (Diagram S/2)

Transmission Circuit (Version With Permanent Fwd And Electronic Lift) (Diagram T/1)

Transmission Circuit (Version With Permanent Fwd And Electronic Lift) (Diagram T/2)

Wiring Diagrams U/1 – U/2 – V – Z – W

Transmission Circuit (Version With Permanent Fwd And Electronic Lift) -Dashboard Side (Diagram U/1)

Transmission Circuit (Version With Permanent Fwd And Electronic Lift) – Dashboard Side (Diagram U/2)

Horn, Power Sockets (Iso — North America) Circuit (Diagram V)

Digital Instrument Circuit (Diagram Z)

Sensors And Transmitters Circuit (Diagram W)

Power Shuttle Electronic Control Unit Input/Output Wiring Diagram (Diagram X)

Rear Electronic Lift Control Unit Input/Output Wiring Diagram (Diagram Y)

Front Pto And Fwd Electronic Control Unit Input/Output Wiring Diagram (Diagram K)

— Cab Electrical Components

—Overhaul

—-Direction Indicator Switch

Replacement

Installation

—-Multi-Indicator Panel

Removal

Installation

—

Zero–Setting Hours Worked

Setting Hours Worked

—-Services Electronic Control Unit

Removal

Installation

—-Power Shuttle Electronic Control Unit

Removal

Installation

—-Fusebox

Removal

Installation

—-Fuses – Relays

Removal

Installation

—-Loudspeakers

Removal

Installation

—-Internal Lighting Support Fitting

Removal

Installation

—-Windscreen Wiper Motor

Removal

Installation

—-Rear Windscreen Wiper Motor

Removal

Installation

– Platform, Cab, Bodywork

— Platform, Cab, Bodywork

—Overhaul

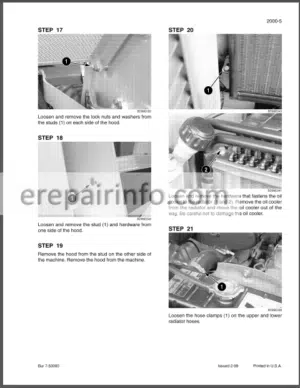

—-Hood

Removal

Installation

—-Hood Rh/Lh Side Panel

Removal

Installation

—-Instrument Panel Lower Guard

Removal

Installation

—-Platform Assembly

Removal

Installation

—-Instrument Panel Support Fitting

Removal

Installation

—-Front Roll Bar

Removal

Installation

—-Cab Assembly With Platform

Removal

Installation

—-Cab Windows Seals

Removal

Installing The Window

—-Seal On Right- Or Left-Hand Upright

Removal

Installation

—-Cab Ceiling Fitting

Removal

Installation

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.