Repair Manual For New Holland TR89, TR99 Combines. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 1298

Bookmarks: Yes

Searchable: Yes

Number:

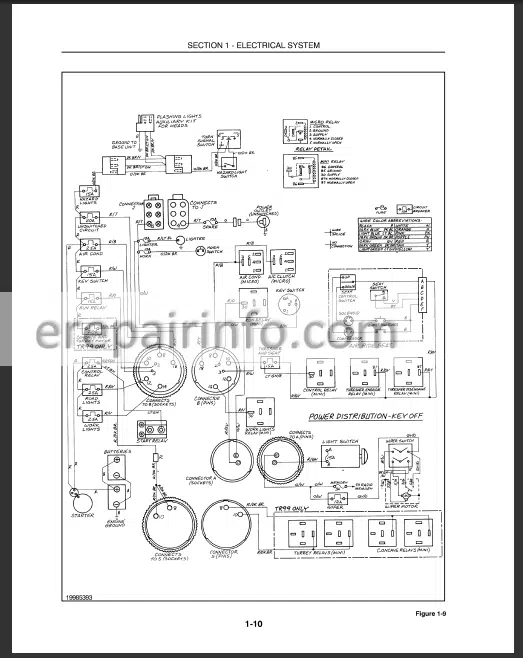

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland TR89, TR99

Contents

Activating the automatic head height control circuit

Activating the head run circuit

Air conditioner compressor clutch

control circuit

Air conditioning circuit

Air conditioning electrical system

Air ride seat

Alternator installation

Alternator removal

Alternator testing

Automatic head height control circuit

Automatic head height lower circuit

Automatic head height raise circuit

Automatic head tilt (lateral float) circuit

Battery charge level, park brake, and

drives engaged alarm systems

Bosch alternator

Bosch alternator repair

Circuit breakers

Cleaning fan and feeder variable speed control circuits

Cleaning fan speed decrease circuit

Cleaning fan speed increase circuit

Coil spark suppression diode test

Cold start circuit

Cold start system

Concave control circuit (TR only)

Definition of terms

Diode chart

Diode test procedure

Diodes

Disengaging the automatic head height circuit

Drives engaged alarm system

Electrical connector chart

Electrical system components

Electrohydraulic circuits troubleshooting

Electrohydraulic electrical system

Electrohydraulic function

Electrohydraulic stack valve main

power circuit

Electronic stone trap detection circuit

Electronic stone trap electrical system

Engine and hydraulic system alarm lights

Engine electrical system

Engine run circuit

Engine start circuit

Engine start (cranking) circuit

Fan (pressurizer) circuit

Fan speed control circuit

Feeder reverser circuit

Feeder reverser reverse direction circuit

Feeder speed decrease circuit

Feeder speed increase circuit

Fuel solenoid run circuit

Fuses

Gauge checks

Gauge circuits

General electrical

Grain loss monitor circuit

Ground speed calibration

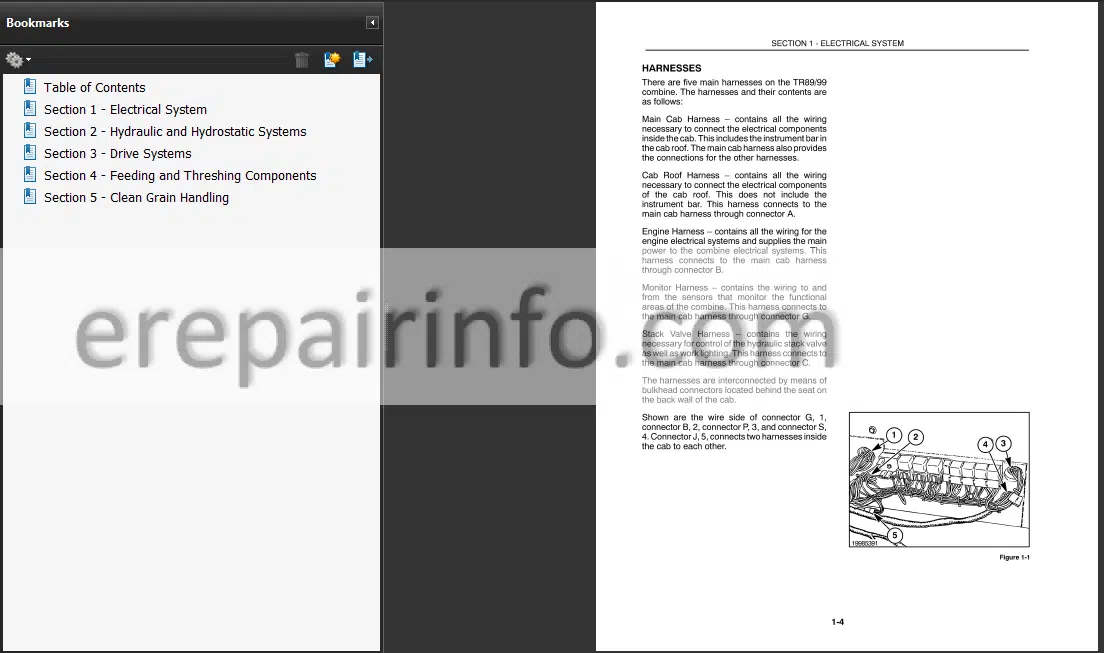

Harnesses

Hazard and turn signal lights

Hazard light circuit

Head drive control circuit

Head drive lockout

Head engage circuit

Head lower circuit

Head raise circuit

Head raise/lower control circuit

Head tilt circuit (manual control)

Head tilt clockwise circuit

Head tilt clockwise lower microswitch circuit

Head tilt clockwise raise microswitch circuit

Head tilt counterclockwise circuit

Head tilt counterclockwise lower microswitch circuit

Head tilt counterclockwise raise microswitch circuit

Hour meter

Hydraulic reel speed control circuit

Instrument bar circuit

Instrument bar power

Key switch positions

Lateral tilt indicator

Left turn signal circuit

Light electrical systems

Main ground locations

Main power circuits for feeder reverser, unloading auger swing, and reel foreaft

Main power circuit for reel lift, head lift, and head tilt circuit

Main power circuit for the rotor variator

Master solenoid relay activated circuit

Momentary switches

Monitor circuit

Monitor electrical systems

Monitor power for shaft speed sensors

Monitor power for tachometers, unloading

auger position and full bin channels, and grain loss console

Monitor stone door open warning circuit activated (light and buzzer activated)

Monitor stone door open warning circuit not activated (light and buzzer off)

Potentiometers

Power circuit to the head height microswitches

Powered rear axle

Powered turret circuit (TR only)

Powerup sequence

Preparing the head for testing

Reel aft circuit

Reel circuit

Reel fore/aft circuit

Reel forward circuit

Reel lower circuit

Reel raise circuit

Regulator replacement

Relay chart

Relay test procedure

Relays

Right turn signal circuit

Road lights

Road lights activated circuit

Rotor speed variator circuit speed decrease

Rotor speed variator circuit speed increase

Rotor variator circuit

Seat adjustment rails disassembly

Seat adjustment rails reassembly

Seat back and bottom cushion disassembly

Seat back and bottom cushion reassembly

Seat components disassembly

Seat components reassembly

Seat disassembly

Seat installation

Seat removal

Seat suspension assembly

Seat suspension disassembly

Solenoid activation chart

Solenoid coils

Solenoid coil test procedure

Solenoid operation

Thresher clutch alarm/neutral start thresher disengaging

Thresher clutch alarm/neutral start thresher engaged

Thresher disengage circuit

Thresher drive control

Thresher engage circuit

Troubleshooting electrohydraulic circuits

Unloading auger drive control circuit

Unloading auger drive run circuit

Unloading auger swing circuit

Unloading auger swingin circuit

Unloading auger swingout circuit

Variable speed control electrical system

Wiring diagrams

Work lights

Work lights activated circuit

Adjusting charge pressure relief valve motor

Adjusting the speed control linkage

Assembling the head drive cylinder

Assembling the head lift cylinder

Assembling the hydraulic pump

Assembling the power steering cylinder

Assembling the rotor variable speed cylinder

Assembling the stack valves

Assembling the steering control unit

Assembling the Terrain Tracert (lateral float) cylinders

Assembling the unloading auger drive cylinder

Assembling the unloading auger swing cylinder

Case pressure

Charge pressure

Charge pump circuit

Circuit components

Control valve

Controls, hydrostatic system

Cylinders

Disassembling the head drive cylinder

Disassembling the head lift cylinder

Disassembling the hydraulic pump

Disassembling the power steering cylinder

Disassembling the rotor variable speed cylinder

Disassembling the stack valves

Disassembling the steering control unit

Disassembling the Terrain Tracert (lateral float) cylinders

Disassembling the unloading auger drive cylinder

Disassembling the unloading auger swing cylinder

Electrohydraulic stack valve labor guide

Electrohydraulic stack valve operation

Electrohydraulic stack valve service

Electrohydraulic stack valve solenoid activation

Explanation of terms used in failure analysis, hydrostatic system

Feeder reverser control valve section

Feeder reverser forward direction circuit

Feeder reverser reverse direction circuit

Feeder reverser valve

Feeder reverser valve in neutral position

Feeder reverser valve troubleshooting

Gauge information

Head drive cylinders

Head drive cylinders cross section

Head lift control valve section

Head lift cylinders

Head lift cylinders cross section

Head lift valve troubleshooting

Head lower circuit

Head raise circuit

Head valve

Head valve in neutral position

High pressure

Hydraulic pump

Hydraulic pump labor guide

Hydraulic pump operation

Hydraulic pump parts layout

Hydraulic system

Hydraulic system oil flow

Hydraulic system pressure testing

Hydraulic system troubleshooting

Hydrostatic system

Hydrostatic system controls

Hydrostatic system major repairs

Hydrostatic system minor repairs

Hydrostatic system operation

Hydrostatic system troubleshooting

Inspecting the control valve

Installing the charge pressure relief valve

Installing the charge pump

Installing the control valve

Installing the head drive cylinder

Installing the head lift cylinder

Installing the hydraulic pump

Installing the hydrostatic motor

Installing the hydrostatic pump

Installing the loop flushing valve

Installing the multifunction valve

Installing the power steering cylinder

Installing the rotor variable speed cylinder

Installing the shaft (pump and motor)

Installing the shaft seal

Installing the steering control unit

Installing the Terrain Tracert (lateral float) cylinders

Installing the unloading auger drive cylinder

Installing the unloading auger swing cylinder

Introduction, cylinders

Introduction, hydraulic system

Introduction, hydrostatic system

Labor guide, cylinders

Labor guide, Electrohydraulic stack valve

Labor guide, hydraulic pump

Labor guide, hydrostatic system major repairs

Labor guide, steering control unit

Main hydraulic system oil flow

Main pump and motor circuit

Major repairs motor, hydrostatic system

Major repairs pump, hydrostatic system

Master solenoid energized

Master solenoid not energized

Master valve

Master valve section

Master valve troubleshooting

Metric conversions

Minor repairs, hydrostatic system

Motor repairs, hydrostatic system

Multifunction valve

Multifunction valve adjustment

Neutral switch

Operation, hydraulic pump

Operation, hydrostatic system

Parts layout unloading auger swing cylinder

Power steering cylinders

Power steering cylinders cross section

Pressure checks, hydrostatic system

Pressure specifications, hydrostatic system

Priority system (steering), pressure testing

Pump repairs, hydrostatic system

Rebuilding the stack valves

Reel drive hydraulic system

Reel foreaft aft circuit

Reel foreaft control valve section

Reel foreaft forward circuit

Reel foreaft valve

Reel foreaft valve in neutral position

Reel foreaft valve troubleshooting

Reel lift control valve section

Reel lower circuit

Reel raise circuit

Reel valve

Reel valve in neutral position

Reel valve troubleshooting

Relief valve

Removing the charge pressure relief valve

Removing the charge pump

Removing the control valve

Removing the head drive cylinder

Removing the head lift cylinder

Removing the hydraulic pump

Removing the hydrostatic motor

Removing the hydrostatic pump

Removing the loop flushing valve

Removing the multifunction valve cartridge

Removing the power steering cylinder

Removing the rotor variable speed cylinder

Removing the shaft (pump and motor)

Removing the shaft seal

Removing the stack valves

Removing the steering control valve

Removing the Terrain Tracert (lateral float) cylinders

Removing the unloading auger drive cylinder

Removing the unloading auger swing cylinder

Rotor speed control valve in neutral position

Rotor speed control valve section

Rotor speed decrease circuit

Rotor speed increase circuit

Rotor speed lockout valve

Rotor speed variator valve

Rotor speed variator valve troubleshooting

Rotor variable speed cylinder

Rotor variable speed cylinder cross section

Sauer/Sundstrand service centers

Schematics, hydraulic system oil flow ,

Secondary system (all hydraulic functions except steering), pressure testing

Serial number identification

Serial number plate

Servicing the unloading auger drive and head drive valve

Solenoid activation chart

Solenoids

Specifications, hydrostatic system

Startup procedures

Startup procedures, hydraulic system

Startup procedures, hydrostatic system

Steering control unit

Steering control unit labor guide

Steering control unit operation

Steering control unit parts layout

Steering rod adjustment

Terms used in failure analysis

Terrain Tracert (head tilt) clockwise circuit

Terrain Tracert (head tilt) control valve section

Terrain Tracert (head tilt) counterclockwise circuit

Terrain Tracert (head tilt) valve

Terrain Tracert (head tilt) valve in neutral position

Terrain Tracert (head tilt) valve troubleshooting

Terrain Tracert (lateral float) cylinder

Terrain Tracert (lateral float) cylinder cross section

Toein adjustment

Torque values, hydrostatic system

Troubleshooting, hydraulic system

Troubleshooting, hydrostatic system

Troubleshooting, unloading auger drive

and head drive control valve

Unloading auger drive and head drive control valve

Unloading auger drive and head drive control valve troubleshooting

Unloading auger drive cylinder

Unloading auger swing control valve section

Unloading auger swing cylinder

Unloading auger swing cylinder cross section

Unloading auger swing in circuit

Unloading auger swing out circuit

Unloading auger swing valve

Unloading auger swing valve in neutral position

Unloading auger swing valve troubleshooting

Air conditioning filter

Air conditioning process

Air conditioning system

Air conditioning system performance test and diagnosis chart

Adjusting the brake system

Adjusting the disk brake

Adjusting the gearshift linkage

Adjusting the master cylinder

Adjusting the parking brake

Adjusting the separator clutch

Adjustments and maintenance

Assembling the bell housing

Assembling the brakes

Assembling the carrier

Assembling the counter shaft

Assembling the cover

Assembling the differential

Assembling the differential half shafts

Assembling the disc brake

Assembling the final drive input shaft

Assembling the final drive output shaft

Assembling the hub/spindle

Assembling the input shaft

Assembling the main hub

Assembling the main shaft bearings

Assembling the master cylinder

Assembling the pinion shaft

Assembling the separator clutch

Assembling the shifter forks

Assembling the slave cylinder

Assembling the transmission

Assembly, cylinder block and pistons

Assembly, distributor and distributor seals

Assembly, shaft, seals and bearings

Assembly of the main hub

Ball joint replacement

Bell housing

Bell housing parts

Bleeding the hydraulic brake system ,

Blower fan

Blower fan switch

Blower motor and fan assembly overhaul

Brake and differential parts

Brake system

Checking refrigerant for excess air

Cleanliness A/C system

Component identification high torque RWD {TR)

Compressor clutch

Compressor protection: highpressure and lowpressure cutout switches

Compressor pump

Condenser

Condenser, overhaul

Containers for storing recycled refrigerant

Containment, air conditioning refrigerants

Contaminants

Control valve assembly

Control valve disassembly

Control valve installation

Control valve operation

Control valve removal

Cylinder block and pistons

Description high torque RWD {TR)

Description & operation, system components A/C system

Diagnosis charts A/C system

Differential parts

Disassembling the bell housing

Disassembling the brake assembly

Disassembling the carrier

Disassembling the counter shaft

Disassembling the cover

Disassembling the differential

Disassembling the disc brake

Disassembling the final drive

Disassembling the final drive input shaft

Disassembling the final drive output shaft

Disassembling the input shaft

Disassembling the main hub

Disassembling the main shaft bearings

Disassembling the master cylinder

Disassembling the pinion shaft

Disassembling the separator clutch

Disassembling the slave cylinder

Disassembling the transmission

Disassembly, cylinder block and pistons

Disassembly, distributor and distributor seals

Disassembly, shaft, seals and bearings

Disc brake

Disc brake parts

Disposal, empty or near empty disposable containers

Distributor and distributor seals

Drive motor

Electrical diagram, air conditioner

Electrohydraulic control valve

Engine PTO shaft

EQUATRAC II valve operation

Evaporator

Evaporator core, overhaul

Extraction and recycling equipment, refrigerant

Expansion valve

Expansion valve, overhaul

Filling the master cylinder

Filter, air conditioning

Final drive

Final drive input shaft parts

Final drive output shaft parts

Final drive parts

Flow limiter operation

Flow limiter removal and installation

Flow limiters

Flushing, A/C system

Function of internal components high torque RWD {TR)

General description and operation air Oil requirements powered rear axle (TR)

conditioning system

Oil supply high torque RWD (TR)

Highpressure and lowpressure switches,

Onoff switch

overhaul

Operating principle high torque

Highpressure cutout switch

RWD (TR)

High torque rear wheel drive system (TR)

Operational checks NC system

Hydrostatic circuit operation

Overhaul, components NC system

Inspecting the bell housing

Inspecting the master cylinder

Parts inspection

Inspecting the slave cylinder

Inspection final drive

Performance tests NC system

Installation, drive motor

Performance test and diagnosis

Installation, kingpin and bushings

Installation, steering cylinder

Powered rear axle (TR)

Installing the bell housing

Powered rear axle motor operation

Installing the differential

Powered rear axle motor repair

Installing the final drive

Powered rear axle motor shaft seal replacement

Installing the main shaft

Installing the main shaft left side

Powered rear axle motors

Installing the main shaft right side

Powered rear axle torque hubs

Installing the main shaft left bearing

Precautions, general safety and

Installing the main shaft right bearing

service NC system

Installing the main sheave

Installing the master cylinder

Installing the motor and torque hub

Installing the separator clutch

Installing the slave cylinder

Installing the transmission

Introduction NC system

Introduction brakes

Introduction engine PTO shaft

Introduction final drive

Introduction main shaft

Introduction powered rear axle (TR)

Introduction separator clutch

Introduction transmission

Labor guide NC system

Labor guide brakes

Labor guide engine PTO shaft

Labor guide final drive

Labor guide main shaft

Labor guide powered rear axle (TR)

Labor guide separator clutch

Labor guide transmission

Leak testing NC system

Adjusting the concaves

Adjusting the concaves in a wedge

Adjusting the concaves using swing gauges

Adjusting the concaves using the rotors

Adjusting the feeder slip clutch

Adjusting the rotor speed

Assembling and installing the reverser gearbox

Assembling the header drive jackshaft

Assembling the left rotor gearbox

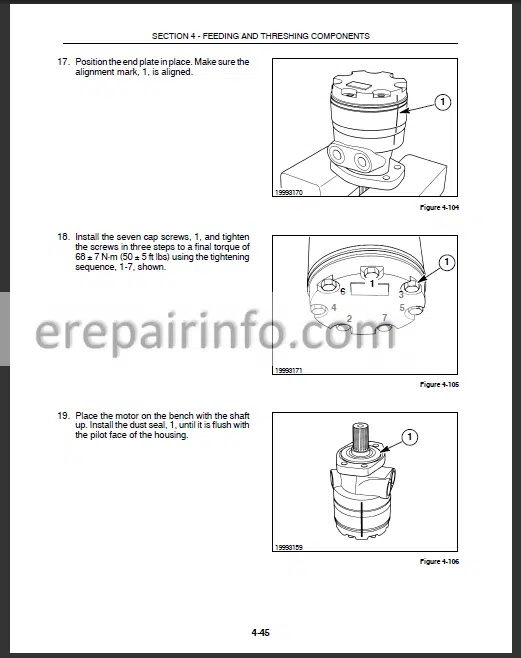

Assembling the reverser motor

Assembling the right rotor gearbox

Assembling the rotor

Assembling the torque sensing drive

Balancing the rotor

Belt tension adjustment header drive clutch

Concave module wire removal

Concaves

Concaves module types

Concaves types

Cradle and feeder face plate

Disassembling the front drum

Disassembling the header drive jackshaft

Disassembling the left rotor gearbox

Disassembling the reverser motor

Disassembling the right rotor gearbox

Disassembling the rotor

Disassembling the torque sensing drive

Discharge beater

Discharge beater and grate

Discharge beater grate

Discharge beater parts layout

Electronic stone trap

Feeder

Feeder face plate and cradle

Feeder floor

Feeder maintenance

Feeder slip clutch

Front drum

Header drive belt

Header drive clutch

Header drive clutch belt tension adjustment

Header drive clutch linkage adjustment

Header drive jackshaft

Inspecting the left rotor gearbox

Inspecting the right rotor gearbox

Installing the concaves

Installing the discharge beater

Installing the discharge beater grate

Installing the front drum

Installing the feeder slip clutch

Installing the ?H? frame

Installing the header drive belt

Installing the intermediate idler sheave

Installing the lower variator sheave

Installing the rotor drive belt

Installing the rotor gearboxes

Installing the rotors

Installing the separator grates

Installing the stone roll

Installing the torque sensing drive

Installing the upper pivot shaft

Introduction concaves

Introduction discharge beater and grate

Introduction feeder

Introduction rotor drive

Introduction rotor gearboxes

Introduction rotors

Introduction separator grates

Labor guide concaves

Labor guide discharge beater and grate

Labor guide feeder

Labor guide rotor drive

Labor guide rotor gearboxes

Labor guide rotors

Labor guide separator grates

Left rotor gearbox

Left rotor gearbox parts

Linkage adjustment header drive clutch

Main concave removal

Main concave wire removal

Parts inspection rotors

Preparing to remove the separator grates

Removing and disassembling the reverser gearbox

Removing and installing the cradle

Removing and installing the feeder face plate

Removing and installing the feeder floor

Removing the feeder slip clutch

Removing and installing the cam and solenoid

Removing and installing the header jackshaft drive belt variable speed

Removing and installing the hydraulic reel drive pump belt

Removing the main drive belt

Removing and installing the main drive belt

Removing and installing the variable speed motor

Removing and installing the variable speed screw

Removing the concave extensions

Removing the concave module

Removing the discharge beater and shaft

Removing the discharge beater grate

Removing the feeder from the combine

Removing the front drum

Removing the ?H? frame

Removing the header drive belt

Removing the header drive jackshaft

Removing the intermediate idler sheave variable speed

Removing the lower variator sheave

Removing the reverser motor

Removing the rotor drive belt

Removing the rotor gearboxes

Removing the rotors

Removing the separator grates

Removing the stone roll

Removing the torque sensing drive

Removing the upper pivot shaft idler

Replacing theagitator mount

Replacing the rasp bar mount

Reverser gearbox

Reverser motor

Right rotor gearbox

Right rotor gearbox parts

Right side drives fixed speed

Rotor balance stand

Rotor configurations

Rotor drive

Rotor gearboxes

Rotors

Rotors used to adjust the concaves

Separator grates

Shimming the rotors for endplay

Singlespeed right rotor gearbox

Special tools rotor gearboxes

Stone roll

Swing gauges used to adjust the concaves

Torque sensing drive removal and spring compression tool

Transducer replacement

Twospeed right rotor gearbox

Upper pivot shaft

Variable speed motor

Variable speed screw

Wedge used to adjust the concaves

Adjusting the cleaning fan RPM

Bubbleup auger

Bubbleup auger gearbox removal

Cleaning fan

Clean grain and filling system

Clean grain and filling system labor guide

Cleaning fan assembly

Cleaning fan disassembly

Cleaning fan drive assembly

Cleaning fan drive disassembly

Cleaning fan housing installation

Cleaning fan housing removal

Cleaning fan labor guide

Cleaning shoe

Cleaning shoe labor guide

Cross auger installation

Cross auger removal

Cross auger housing installation

Cross auger housing removal

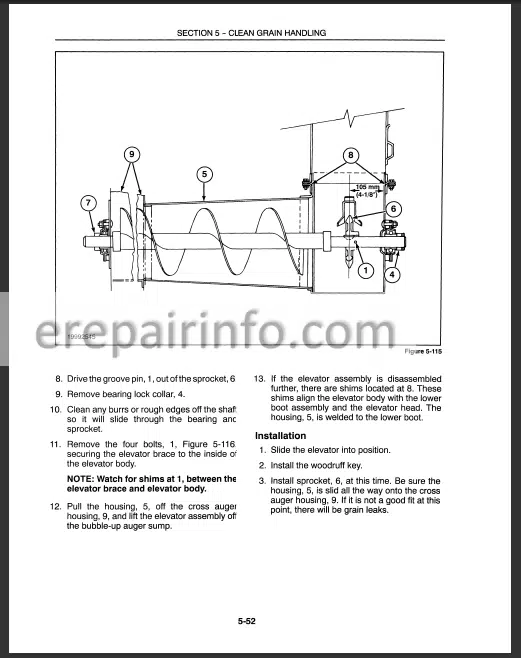

Elevator installation

Elevator removal

Elevator chain

Elevator head installation

Elevator head removal

Elevator installation

Elevator removal

Elevator head assembly

Elevator head disassembly

Grain pan installation

Grain pan removal

Lower cross auger installation

Lower cross auger removal

Lower shoe installation

Lower shoe removal

Shoe bushing tightening

Shoe eccentric shaft installing

Shoe eccentric shaft removal

Slip clutch installation

Slip clutch removal

Slip clutch and elevator head assembly

Slip clutch and elevator head disassembly

Tailings return system

Tailings return system labor guide

Telescoping unloading auger installation

Telescoping unloading auger removal

Unloading auger and tube installation

Unloading auger and tube removal

Unloading system

Unloading system cross auger installation

Unloading system cross auger removal

Unloading system drive belt installation

Unloading system drive belt removal

Unloading system jackshaft installation

Unloading system jackshaft removal

Unloading system labor guide

Upper cross auger installation

Upper cross auger removal

Upper shoe installation

Upper shoe removal

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.