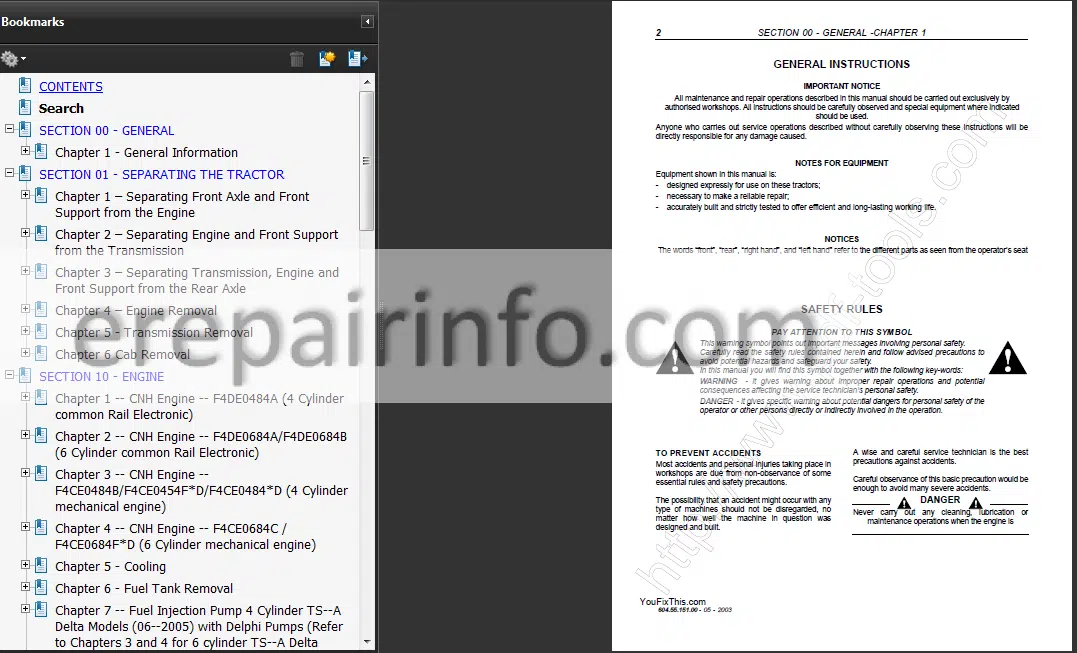

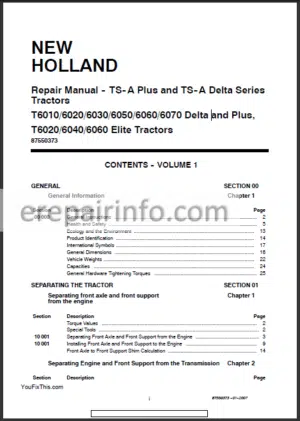

Repair Manual For New Holland TS100A Series Tractors. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 4423

Bookmarks: Yes

Searchable: Yes

Number: 87550373

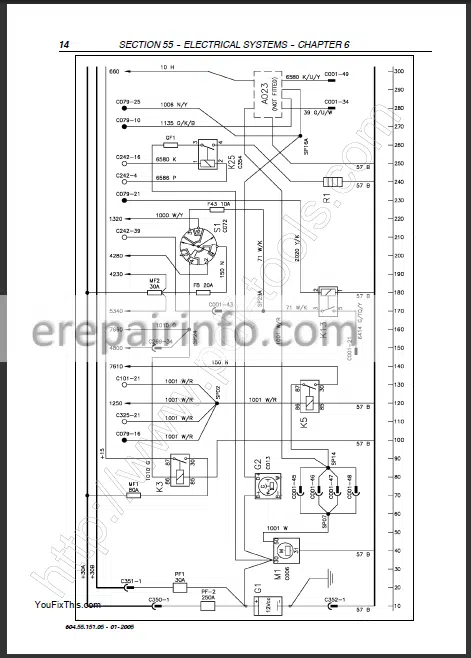

Wiring Diagrams: Yes

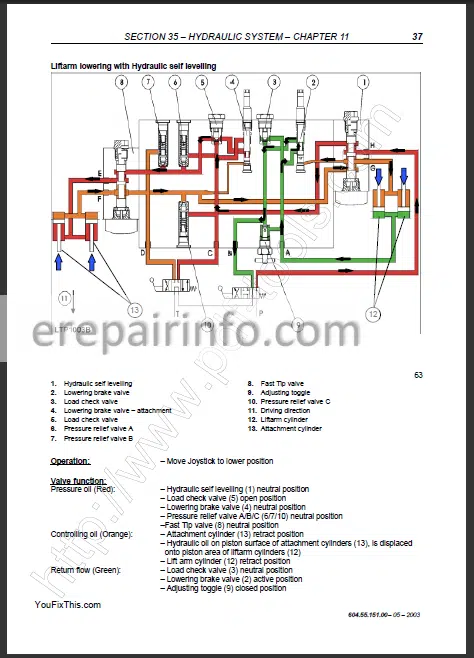

Hydraulic Diagrams: Yes

Model

New Holland

TS100A, TS110A, TS115A, TS125A, TS135A

Contents

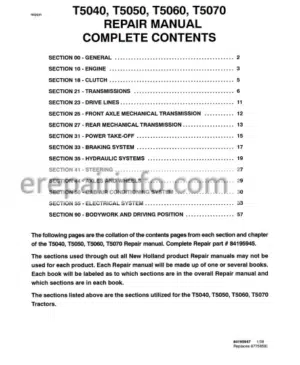

- – Contents

- – General

General Information - – Separating Tractor

Separating Front Axle And Front Support From The Engine

Separating EnginAnd Front Support From ThTransmission

Separating Transmission, Engine And Front Support From The Rear Axle

Engine removal

Transmission Removal

Cab Removal - – Engine

General Specifications

Assembly Clearances – Data

Torque Wrench Settings

Tools

Cooling System

Lubrication System

Lubrication System Components

Engine Overhaul

Bushings

Assembly On The Workbench

Fitting Engine Components

Checks, dimensions and repairs – crankshaft, bearings

Timing system

Bushings

Checks, dimensions and repairs – pistons

Connecting rod – piston assembly

Valves

Valve guides

Valve seats

Valve springs

Fitting the cylinder head

Fuel supply gear pump

CP3 high–pressure pump

Rail (pressure accumulator)

Pressure relief valve

Electro-injector

Pressure limiter for fuel return

CNH Engine

General specifications

Assembly Clearances – Data

Torque wrench settings

Tools

Cooling system

Lubrication system

Camshaft timing operations

Fitting the cylinder head

Cylinder block repairs

Crankshaft

Timing system

Bushings

Checks, dimensions – connecting rod-piston assembly

Valves

Valve guides

Valve seats

Spindle – Rocker arms

Rail (pressure accumulator)

Cooling System Drain

Cooling System Refill

Radiator Removal

Radiator Installation

Thermostat Removal – Engines with Common Rail Fuel Injection

Thermostat Installation – Engines with Common Rail Fuel Injection Thermostat Removal – Engines with Mechanical Fuel Injection Thermostat Installation – Engines with Mechanical Fuel Injection Viscous Fan Assembly Removal

Viscous Fan Assembly Installation

Spring-loaded Automatic Fan Belt Tensioner Removal

Spring-loaded Automatic Fan Belt Tensioner Installation

Coolant Pump Removal

Coolant Pump InstallationCooling System Drain

Cooling System Refill

Radiator Removal

Radiator Installation

Thermostat Removal – Engines with Common Rail Fuel Injection

Thermostat Installation – Engines with Common Rail Fuel Injection Thermostat Removal – Engines with Mechanical Fuel Injection Thermostat Installation – Engines with Mechanical Fuel Injection Viscous Fan Assembly Removal

Viscous Fan Assembly Installation

Spring-loaded Automatic Fan Belt Tensioner Removal

Spring-loaded Automatic Fan Belt Tensioner Installation

Coolant Pump Removal

Coolant Pump Installation

Fuel Tank Removal - – Clutch

- – Transmission Systems

Fault Finding Diagrams

Transmission Disassembly/Assembly Information

Transmission Disassembly

Front Section Removal Middle Section Removal

Rear Section Removal

Front Section Disassembly/Assembly

Middle Section Disassembly/Assembly

Rear Section Disassembly/Assembly

Transmission Top Cover Overhaul

Transmission Control Valve Overhaul

synchronizer Inspection

Transmission Housing Transfer Tubes Removal/Installation

Transmission Assembly

Adjustment of Forward/Reverse and Main (1-4/5-8) synchronizers

High/Low Range Cable adjustment

Adjustment of the High/Low synchronizer - – Drive Lines

Standard Front Axle Four Wheel Driveshaft Removal

Standard Front Axle Four Wheel Driveshaft Installation

SuperSteer Front Axle Four Wheel Driveshaft Removal

SuperSteer Front Axle Four Wheel Driveshaft Installation

Four Wheel Drive Clutch Removal

Four Wheel Drive Multi-Wet Plate Clutch Disassembly

Four Wheel Drive Multi-Wet Plate Clutch Assembly/Adjustments

Four Wheel Drive Dog Clutch Disassembly

Four Wheel Drive Dog Clutch Assembly

Four Wheel Drive Clutch Installation

Four Wheel Driveshaft Oil Supply Manifold Removal

Four Wheel Driveshaft Oil Supply Manifold Installation - – Mechanical Front Axle

Standard Axle Removal

Standard Axle Installation

Hub Cassette Seal Removal / Installation

Front Axle Overhaul — All Options

Multi—Wet Plate Clutch Differential Lock – Disassembly

Multi—Wet Plate Clutch Differential Lock – Assembly

Crown Wheel / Differential – Disassembly – Multi-Wet Plate Clutch Differential Lock

Crown Wheel / Differential – Assembly / Adjustments Multi-Wet Plate Clutch Differential Lock

Dog Clutch Differential Lock – Disassembly / Assembly

Crown Wheel / Differential – Disassembly / Assembly Dog Clutch Differential Lock

Pinion Shaft Removal – Standard Front Axle

Pinion Shaft Installation / Adjustments – Standard Front Axle

Pinion Shaft Removal – SuperSteer and Suspended Front Axle

Pinion Shaft Installation / Adjustments – SuperSteer and Suspended Front Axle

Crown Wheel Adjustments – Multi—Wet Plate Clutch Differential Lock

Differential Bearing Preload – Multi—Wet Plate Clutch Differential Lock

Crown Wheel Adjustments – Dog Clutch Differential Lock

Differential Bearing Preload – Dog Clutch Differential Lock

Limited Slip Self Locking Differential

Axle Assembly – All Options

Swivel Pin & Potentiometer – Removal / Installation

Stub Axle Adjustments

Checking the Alignment of Steering & Drive Wheels - – Mechanical Rear Wheel Drive

Rear Axle Disassembly

Rear Axle Assembly I Adjustments

Hydraulic Differential Lock Control Unit (Multi-Wet plate clutch) Inspection

Hydraulic Differential Lock Control Unit (Multi-Wet plate clutch) Disassembly

Hydraulic Differential Lock Control Unit (Multi-Wet plate clutch) Assembly/Adjustments

Final Drive Case (Left or Right Hand) Removal

Final Drive Case (Left or Right Hand) Installation

Drive Wheel Shaft Removal/Installation

Planetary Gear Set Removal/Installation - – Power Take Off

Sectional View and Torque Values

RPM PT? Sectional Views and Tightening Values

PTO Functionality

Fault Finding

Power Take-Off (PTO) Removal

Power Take-Off (PTO) Installation

Power Take-Off (PTO) 540/750/1000 RPM Disassembly

Power Take-Off (PTO) 540/750/1000 RPM Assembly

2 Speed Shaft Change PTO - – Brakes

Fault Finding

Rear Service Brake Piston (Left or Right Hand) Removal E I Rear Service Brake Piston (Left or Right Hand) Installation EJ Front Service Brake (Left or Right Hand) Disassembly EJ Front Service Brake (Left or Right Hand) Inspection EJ Front Service Brake (Left or Right Hand) Assembly EJ Hydraulic Brake Master Cylinder Removal (All Models) EJ Hydraulic Brake Master Cylinder Installation (All Models) EJ Hydraulic Brake System Air Bleeding

Parking Brake Removal

Parking Brake Disassembly

Parking Brake Assembly

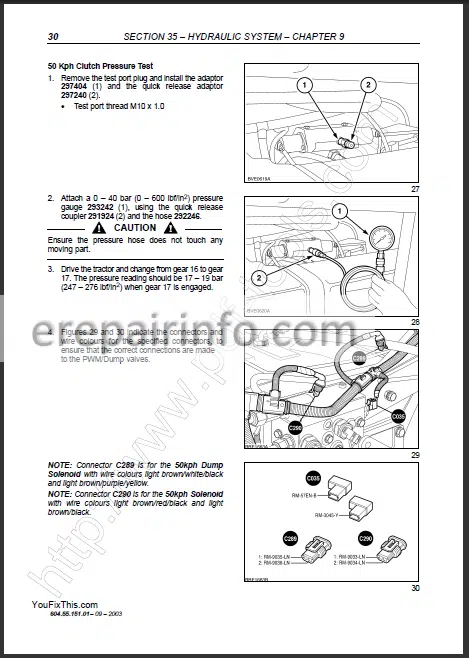

Parking Brake Installation - – Hydraulic System

Hydraulic Circuits

Variable Flow Hydraulic Pump Assembly

Electronic Draft Control

Mechanical Rear Hydraulic Lift

Fixed Displacement Gear Pump

Trailer Brake Auxiliary Valves

Mechanical Remote Control Valves

Closed Centre Electro-Hydraulic Remote Control Valves

Hydraulic Remote Control Valves With configurable Detent

Hydraulic Pressure Testing

External Lift Rams

Front Loader

Mid Mount Remote Valves

Hydraulic Front Lift And Power Take-Off (Pto)

Delta Hydraulic Circuits

Delta – Open Centre System Remote Control Valves

Delta Mid Mount Remote Valves

Integrated Hydraulic Front Lift And Power Take–Off (Pto) (All Models From 06-2005)

Hydraulically Adjustable Right Hand Lift And top Link Cylinders

Electronic Draft Control – Delta Models - – Steering

Steering Motor – Removal and Installation

Steering Motor Overhaul

Steering Column – Removal and installation

Two Wheel Drive Steering Cylinder – Removal and Installation

Two Wheel Drive Steering Cylinder – Overhaul

Four Wheel Drive Steering Cylinder – Removal and Installation

Four Wheel Drive Steering Cylinder – Overhaul

Fast Steer System

Fast Steer Valve Components

Fast Steer Hydraulic Operation

Operating and Monitoring System

Fast Steer Hydraulic Circuit

Fast Steer Valve Removal

Fast Steer Valve Disassembly

Fast Steer Valve Inspection

Fast Steer Valve Re-Assembly

Fast Steer Valve Installation

Steering Column Removal and Installation

Fast Steer Error Codes

Fast Steer H routines

Fast Steer Wiring - – Front Axle And Wheels

Sectional Views

Front Axle

Front Wheel Hub and Spindle Assembly

Spindle Assembly

Front Wheel Settings

Axle Centre Beam and Front Support

Front Wheel Toe-in alignment (Standard Axle) - – Auxiliary Units

Air Conditioning

Leak Testing, Charging, Discharging And System Flushing

Flushing The System

Evacuating The System

Charging The System

Component Overhaul (Excluding Compressor)

Compressor Overhaul

Compressor Removal And Installation - – Electrical System

Electrical Introduction

Analogue/Digital Instrument Cluster

Starting System

Charging System

Battery

Wiring Diagrams

Electrical Harnesses

Calibration Procedures

Fault Codes

Additional Fault Codes

Diagnostic H Routines

Electrical Introduction TS100A Delta Models

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Only problem I have is the price was advertised as $39.95 but cost me 59.95 I believe this was due to currency exchange my issue is that I didn’t know what the country of origin was other than that fantastic

I received my repair manual almost instantly

Thank you