Repair Manual For New Holland TV140 Tractor. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 2494

Bookmarks: Yes

Searchable: Yes

Number:

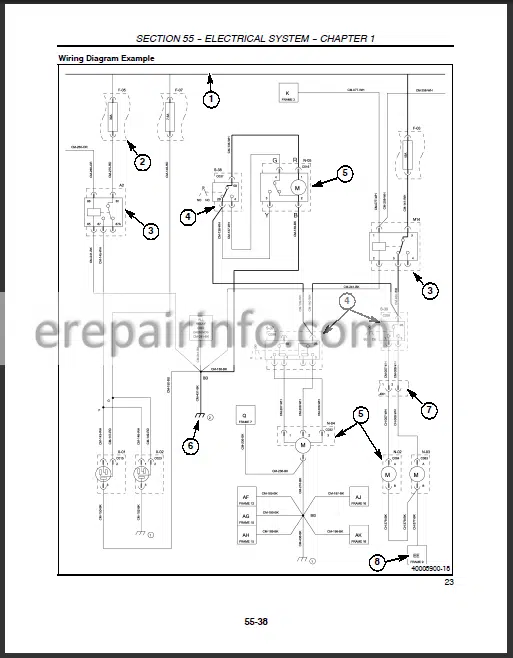

Wiring Diagrams: Yes

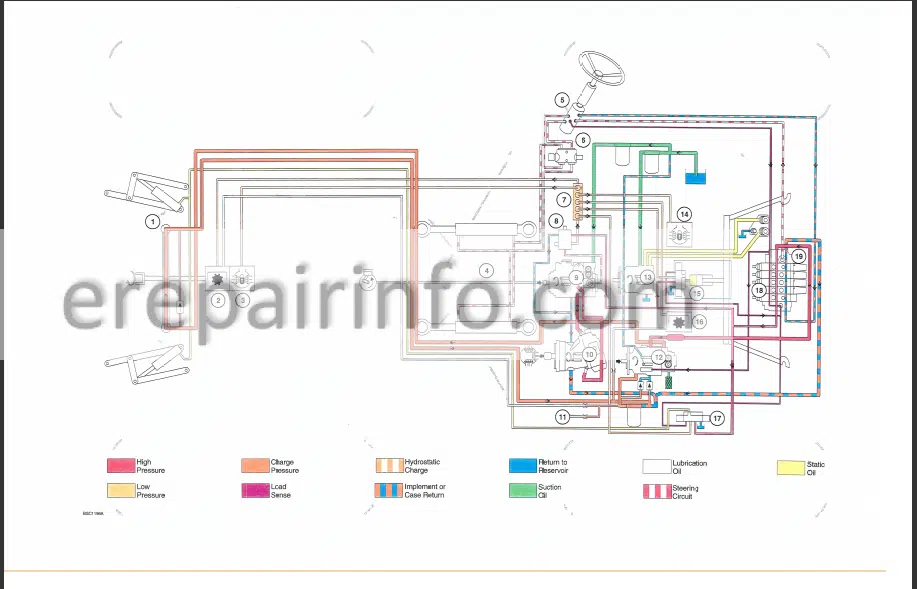

Hydraulic Diagrams: Yes

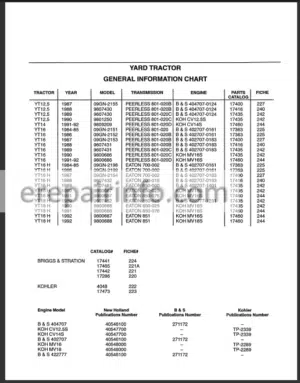

Model

New Holland TV140

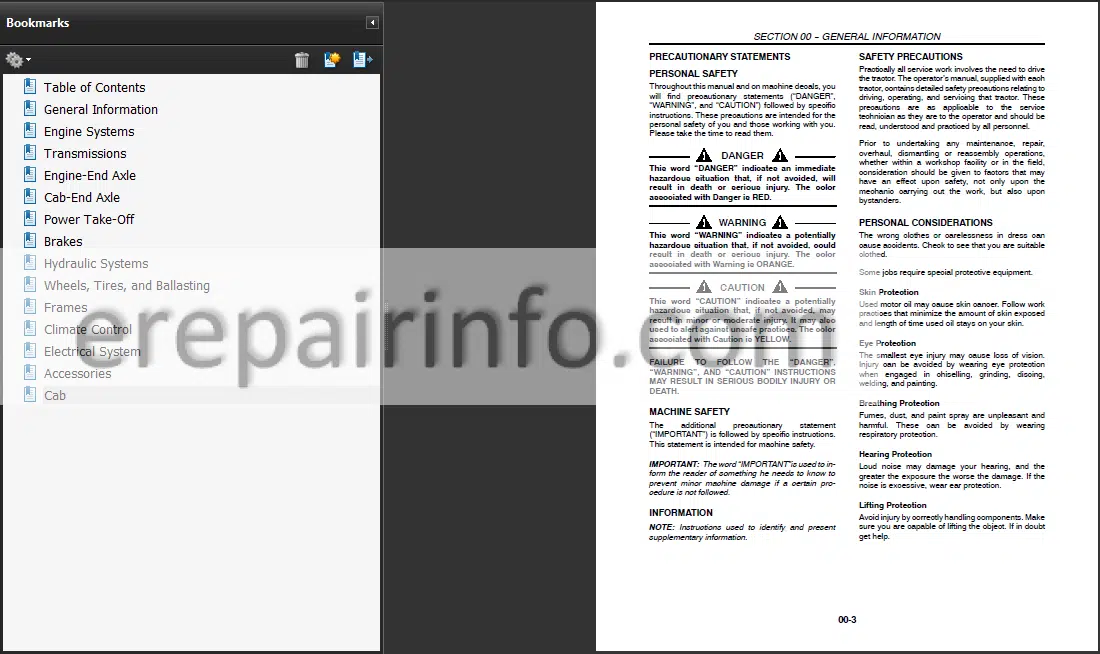

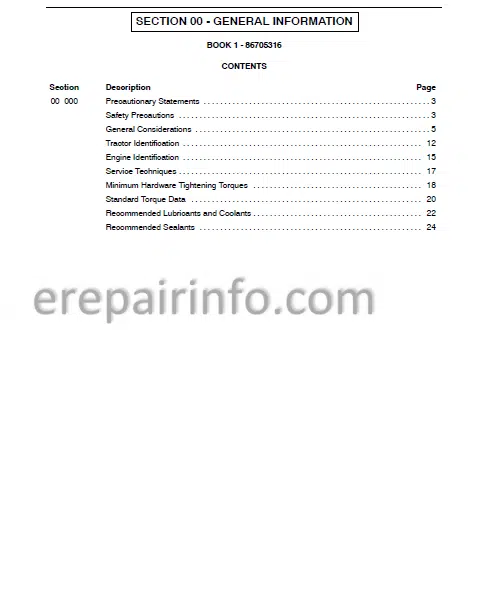

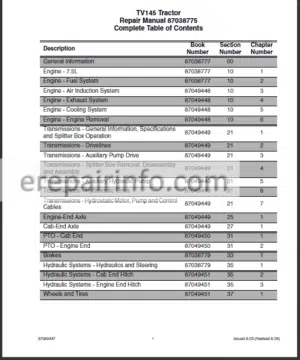

Contents

- – General Information

Precautionary Statements

Safety Precautions

General Considerations

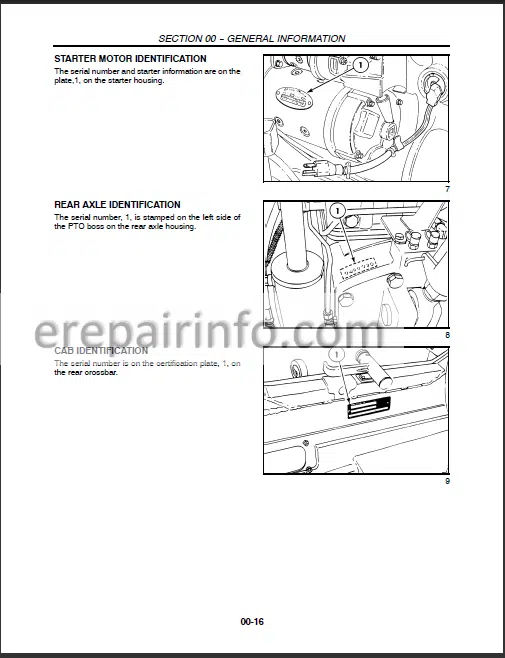

Tractor Identification

Engine Identification

Service Techniques

Minimum Hardware Tightening Torques

Standard Torque Data

Recommended Lubricants And Coolants

Recommended Sealants - – Engine Systems

Air Induction System

Bolt Torque Specifications

Air Induction System Description And Operation

Component Operation

Turbocharger Boost Testing

Air Induction SystemRemoval And Repair Of Components

Turbocharger Intake Tube

Turbocharger Outlet Tube

Air Filter Housing, Precleaner, And Air Induction Scoop

Turbocharger

Repair Time Schedule

Exhaust System

Bolt Torque Specifications

Exhaust System Description Of Operation

Exhaust System Component Removal And Repair

Exhaust Muffler And Stack

Repair Time Schedule

Engine Specifications

Cylinder Head Assembly

Camshaft Assembly

Connecting Rods

Pistons

Manifolds

Cylinder Block Assembly

Timing Gears

Lubrication System

Troubleshooting

Dynamometer Engine Testing

Dynamometer Engine Break In

Compression Test

Engine Overhaul

Engine Removal

Engine Disassembly

Engine Component Disassembly, Inspection, And Assembly

Front Timing Gears, Oil Pan, Camshaft, And Valve Tappets (Lifters)

Pistons And Connecting Rods

Crankshaft And Main Bearings

Oil Pump And Sump Tube

Oil Cooler/Filter Support Assembly

Flywheel

Engine Assembly

Engine Installation

Repair Time ScheduleEngine Overhaul

Cooling System

Bolt Torque Specifications

Cooling System Description And Operation

Individual Component Operation

Cooling System Troubleshooting

Cooling System Testing

Cooling System Tests

Cooling SystemRemoval And Repair Of Components

Radiator

Thermostat

Cooling Fan (North American Models)

Cooling Fan And Viscous Clutch (International Models)

Fan Belt Tensioner

Water Pump

Repair Time ScheduleCooling System

Type

Air Filter Configuration

Primary

Secondary

Manufacturer

Model

Bearing Type

Maximum Boost Pressure - – Transmissions

Introduction

Orientation

Splitter Box

Hydrostatic Drive Description

Safety

Power Flow

Description Of Operation

Splitter Box Description

Splitter Box Gear Sets

Hydrostatic And Hydraulic System Components

Hydrostatic Drive Description

Moving A Disabled Tractor

Troubleshooting And Testing

Pressure Testing

Range Select Control Switch And Valve

Splitter Box

Auxiliary Pump

Auxiliary Drive Housing

Auxiliary Couplers

Articulation Joint Drive Shafts

Upper Drive Shaft

Engine Power Input Shaft

Lower Drive Shaft

Splitter Box Power Input (Top) Shaft

Splitter Box Power Output (Bottom) Shaft

EngineEnd Axle Drive Shaft

Splitter Box

Tapered Bearing End Play Check And Adjustment

Hydrostatic Motor

Hydrostatic Pump

Fnr Lever Cables

Repair Time Schedule - – Engine End Axle

Axle Shaft Preload

Axle Shaft Spacer Selection Table

Differential Bearing Preload

Differential Bearing Shim Table

Drive Pinion Preload

Drive Pinion Spacer Table

Tightening Torques

Drive Path

Drive Pinion

Axle Shaft And Trumpet Housing

Differential Lock

Troubleshooting

Trumpet/Axle Disassembly

Planetary Disassembly

Planetary Inspection

Planetary Reassembly

Planetary Ring Gear Removal

Planetary Ring Gear Installation

Trumpet/Axle Inspection

Trumpet/Axle Reassembly

Pinion Gear Removal

Pinion Gear Disassembly

Pinion Gear Inspection

Center Housing Inspection

Pinion Gear Reassembly

Pinion Bearing Preload

Drive Pinion Spacer Table

Pinion Gear Installation

Differential Disassembly

Differential Inspection

Differential Reassembly

Differential Bearing Preload

Differential Bearing Shim Table

Differential Lock Internal Operating Components Overhaul

Differential Lock Valve And Tube Removal

Differential Lock Valve And Tube Inspection

Differential Lock Valve And Tube Installation

Oscillating Components

Rear Trunnion Inspection

Rear Trunnion Installation

Front Trunnion Removal

Front Trunnion Inspection

Front Trunnion Installation

Diff Lock Switch Removal

Diff Lock Switch Inspection

Diff Lock Switch Installation

Apply Solenoid And Valve Removal

Apply Solenoid And Valve Inspection

Apply Solenoid And Valve Installation

Breather Removal

Breather Inspection

Breather Installation

Repair Time Schedule - – Cab End Axle

Repair Time Schedule - – Power TakeOff

Cab End Pto Clutch Control Valve Operation

Cab End Output Drive

Electrical Operation

Cab End Pto Electrical Circuit

Troubleshooting

Disassembly And Repair

Preliminary Procedures

Cab End Pto Clutch

Cab End Pto Shafts And Gears

Pto Switch - – Brakes

Brake Disc Components

Foot Pedal Linkage

Master Cylinder

Reservoir

Hose Reservoir To Master Cylinder

Tubes Pressure Supply

Park Brake Lever

Park Brake Cables And Links

Brake Pedal Switch

Park Brake Switch - – Hydraulic Systems

Auxiliary Hydraulics

Component Identification

Hydraulic Circuits

Description Of Operation

Steering Control Valve

Troubleshooting And Testing

Disassembly And Repair

Implement Pump

Implement Valve

Priority (Inlet) Valve Section

Tan (Float) Valve Section

Blue (Detent) Valve Section

Green (Standard) Valve Section

Implement Valve

Implement Valve Control Linkage

Control Lever Cable

Control Pedal Assembly

Control Pedal Cable

Steering Control Valve

In Cab Flow Control Cables

Hydraulic System Hoses

Hydraulic Oil Heater

Engine End Remote Valves

Hydraulic Oil Cooler

Hydraulic Oil Cooler ByPass - – Wheels, Tires, And Ballasting

Proper Jacking

Tire Inflation

Tire And Wheel Options - – Frames

Engine Hood

Hood Support Assembly

Side Panels, Right Hand And Left Hand

Front Grille

Cab End Fenders

Left Hand And Right Hand

Engine End Fenders

Left Hand And Right Hand

Heatshield

Engine End Drawbar

Cab End Drawbar

Front Axle Support

Frame Side Rails

Steering Pins

Pivot Pins

Front Frame

Rear Frame - – Climate Control

Description And Operation

Refrigerant Information

The Basics Of Refrigeration

Individual Component Operation

Compressor And Clutch

Condenser

ReceiverDrier

Thermal Expansion Valve

Evaporator/Heater Assembly

Blower Motor Assembly

Thermostatic Switch

High And Low Pressure Switches

Heater Control Valve

Switched Power: Fuses And Hvac Relay

Air Filtration

Troubleshooting And Testing

General Safety And Service Precautions

Recovering RA Refrigerant With Oem

System Evacuation And Recharging With Oem

Oil Level Check Or Adjustment

Leak Detection

Performance Testing

Pressure/Temperature Relationship Chart

Conditions For Performance Testing

Gauge Readings And Interpretations

Performance Test And Diagnosis Summary

General Troubleshooting Summary

Heating System

Air Conditioning System

Air Conditioning Component

Thermal Expansion Valve

Evaporator/Heater Assembly

Condenser

High And Low Pressure Switches

Compressor

Compressor Clutch

Receiver Drier

Air Conditioning Hoses

Heater Control Valve

Recirculation Door Control

Blower Speed Control

Heater Hoses

Repair Time Schedule - – Electrical System

Electrical System

Using Schematics

Circuit Troubleshooting

Temporary Wiring Harness Repair

Description Of Operation

Batteries

Starting And Charging Systems

Starter

Batteries Troubleshooting

Starter Troubleshooting

Eics Error Codes

Eics Connector Chart

Alarms

ThreePoint Hitch Controller - – Accessories

Electrical Kits And Accessories

Frame And Platform

Hydraulic And Pto Kits

Loader Kits And Accessories - – Cab

Cab Mounts

Cab

Cab Roof

Taillight Panel

Cab Fenders

Wiper Motor Cover

Windshield Wipers

Doors

Cab Door Lock And Latch

Lock Cylinder

Window Latch

Door Glass

Side Windows

Floor Mats

Seat Console

Fender Well Covers

Seat

Console Assembly

Steering Logic Valve Trip Linkage

Rotating Grommet Assembly

Headliner

Louvers

Radio And Speakers

Calibration (Adjustments)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.