Factory Operators Manual For New Holland Tractor. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 253

Number: 87639930 2/07

Bookmarks: Yes

Searchable: Yes

Model

New Holland Tractor TV145

Contents

Air-Conditioning Condenser Cores, Check

Air Filter Restriction Light ON

Articulation Lock

Articulation Stop Adjustment

As Required Maintenance

Audible/Visual Alarms

Auxiliary Hydraulic Drive Suction Filter, Change

Auxiliary Hydraulic High Pressure Return Filter Change

Ballast Limitations

Ballasting Weight Calculation Chart

Battery Connections, Clean

Battery Cover and Location

Battery Electrolyte Level, Check

Blue Valve (Detent)

Brake Fluid, Change

Brake Fluid Reservoir Level, Check

Brakes Troubleshooting

Braking System

Bulb Replacement

Cab

Cab Air Filters, Change

Cab Air Filters, Clean

Cab Controls, Additional

Cab-End Axle Oil Level

Cab-End Control Lever Functions

Cab-End Implement to Cab ClearanceJ

Cab-End Lighting

Cab-End (Rear) Drawbar

Cab-End Three-Point Hitch, Lubricate

Cab Floor, Cleaning

Cab Mounted Accessories

Cab Mounted Accessories Installation

Cab Seat and Upholstery, Cleaning

Cab Troubleshooting

Calibrating the Electronic Instrument Control System

California Emission Control Statement

California Proposition 65 Warning

Changing the PTO Stub Shaft

Changing Tractor Direction

Chemical Safety

Cold Start Aid Ether Injection

Cold Weather Starting

Connecting the Drawbar

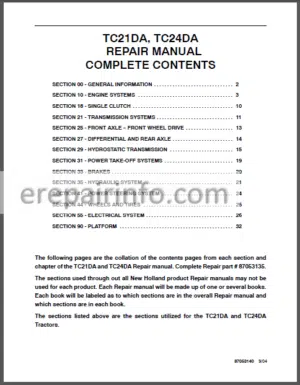

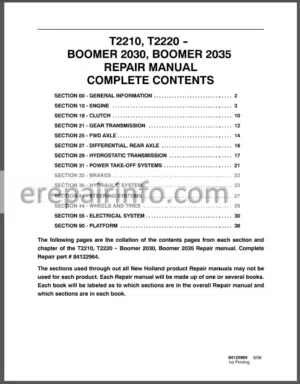

Contents

Control Pad

Control Pad Functions

Controls and Instruments Overview

Crankcase Breather Element, Change

Critical Alarms

Daily Cleaning, Additional

Deliver Report

Diesel Fuel Selection Chart

Differential Lock

Dimensions

Drawbar Preparation

Dynamic Braking

Ecology and the Environment

Electrical System Troubleshooting

Electronic Display Monitor

Electronic Instrument Control System (EIC)

Electronic Instrument Control System (EIC)

Additional Features

Electronic Instrument Control System (EIC) Calibrating

Electronic Instrument Control System (EIC) Normal Operation

Electronic Instrument Control System (EIC) Troubleshooting

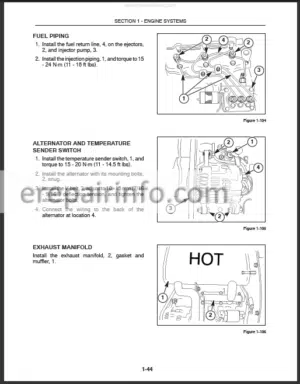

Engine Accessory Drive Belt, Inspect

Engine Air Cleaner Elements, Change

Engine Air Intake Connections, Check

Engine Block Heater

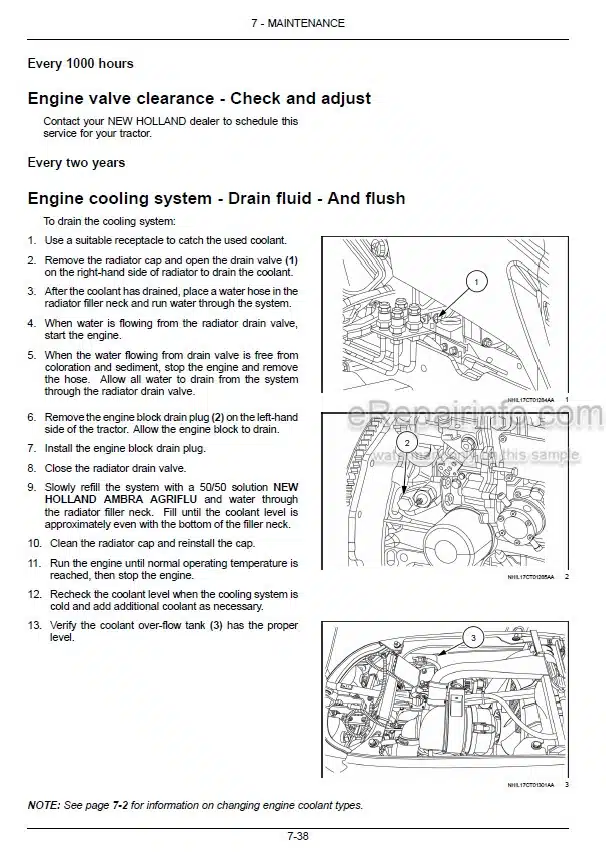

Engine Coolant and Filter/Conditioner, Change Engine Coolant Level, Check

Engine-End Axle Oil, Change

Engine-End Axle Oil Level, Check

Engine-End Axle Oscillation Pivots, Lubricate

Engine-End (Front) Drawbar

Engine-End Implement to Hood Clearance

Engine-End Three-Point Hitch, Lubricate

Engine-End Lighting

Engine-End Valves

Engine Hood

Engine Identification

Engine Idle Speed

Engine Oil and Filter, Change

Engine Oil Level, Check

Engine Oil Selection

Engine Outer Air Filter Element, Clean

Engine Running – Normal Operation

Engine to Splitter Box Drive Shaft Steady Bearing, Lubricate

Engine Troubleshooting

Entering the Cab

Environment

Ether Canister, Install

Every 10 Hours of Operation or Daily

Every 50 Hours of Operation

Every 300 Hours of Operation

Every 600 Hours of Operation

Every 1200 Hours or Annually

Every 1200 Hours or Two Years

Every 1800 Hours

Exterior Light Configuration

External Lighting

External Mirrors

Federal Emissions Warranty

First 50-Hour Service

Flexible Link Ends

Floor and Foot Controls

Flow Control Adjustment

FNR Lever Operation

Foot Brake

Front Axle Drive Shaft Steady Bearing, Lubricate

Front Axle Drive Shaft Slip Yoke, Lubricate

Front Console Controls

Front Steenng Cylinder Pins, Lubricate

Fuel Filter Element, Change

Fuel Filter Primary (Rear) Element, Change Fuel Injection System, Bleeding

Fuel Injectors, Clean and Reset

Fuel Requirements

Fuel System Water Separator, Drain

Fuel Tank Hoses and Connections, Inspect

Fuel Tanks, Drain

Fuel Tanks, Filling

Fuse and Relay Panel

Fuses and Relays, Change

General Information

Green Valve

Hauling the Tractor on a Transporter

Headlamp Adjustment

Heating System Hoses, Check

Hitch Position Set-Up

Hood

Hydraulic Coupler Connection

Hydraulic Coupler Kit (3/4’9

Hydraulic Motor Operation Setup

Hydraulic Oil, Change

Hydraulic Oil Filter, Change

Hydraulic Oil Heater

Hydraulic Quick Couplers

Hydraulic System, Inpecting

Hydraulic System Troubleshooting

Hydrostatic System Operation

Hydrostatic System Troubleshooting

Identification Numbers

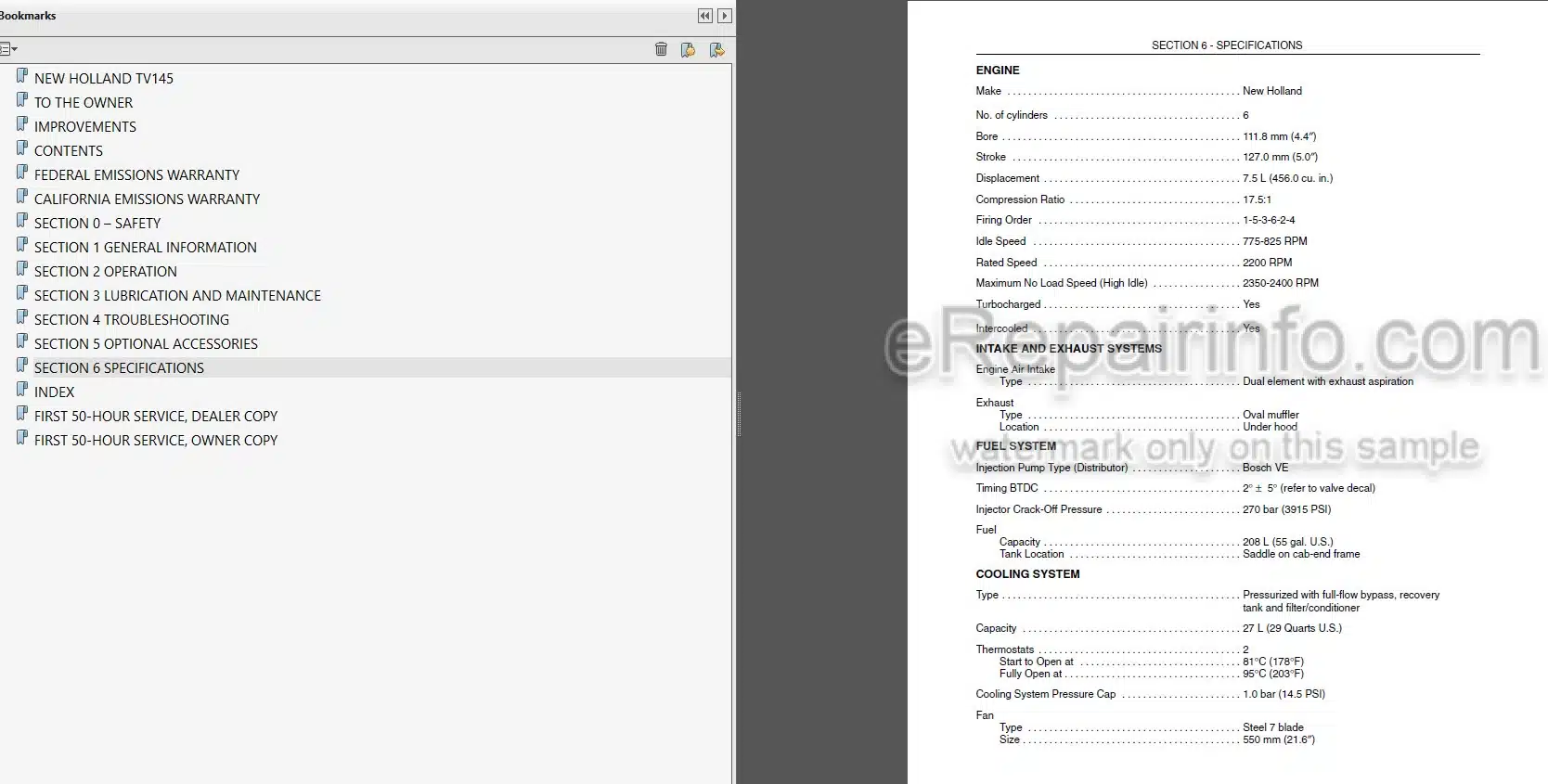

Indicator Light Display

Implement Warning Lamps & SMV Symbol

Improvements

In-Line Fuel Filter, Change

International Symbols

Introduction to this Manual

Jacking the Tractor

Key Switch

Left Side Post Controls

Light Chart

Liquid Ballast

Liquid Ballast Calculations

Loader Accessories

Loader Safety Information

Lockout Levers

Lower Articulation Pin, Lubricate

Lubricants and Capacities

Lubrication and Maintenance

Lubrication and Maintenance Chart

Master Circuit Breaker, Resetting

Master PTO Shields

Minimum Hardware Tightening Torques

Mirror

Multi-Function Switch

Non-Critical Alarms

Oil Change Interval

Oil Cooler Condenser Cores, Check

Operating Continuous Flow Hydraulic Equipment

Operation

Operation Troubleshooting

Operator Seat Controls

Operator’s Manual Holder

Operator’s Seat

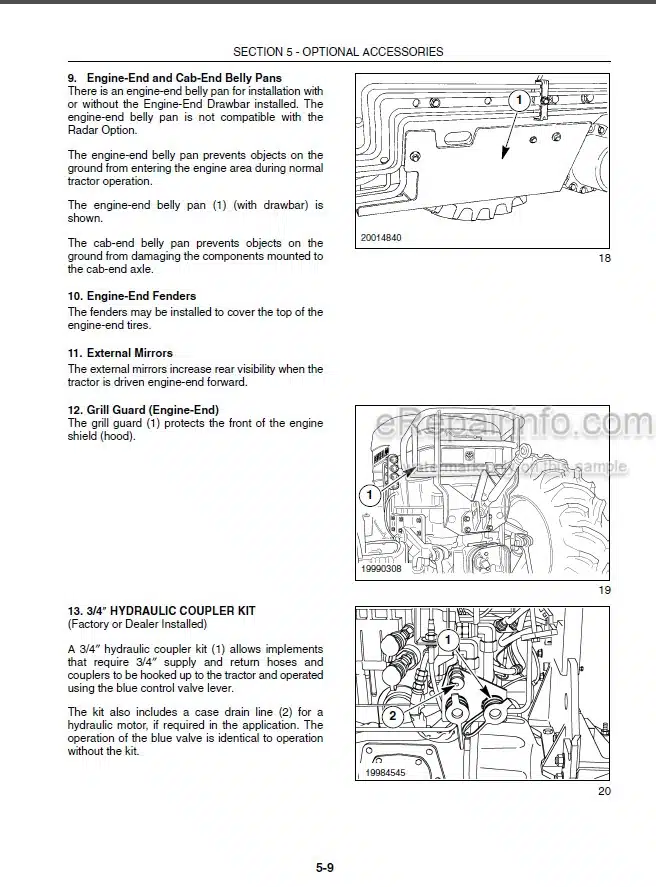

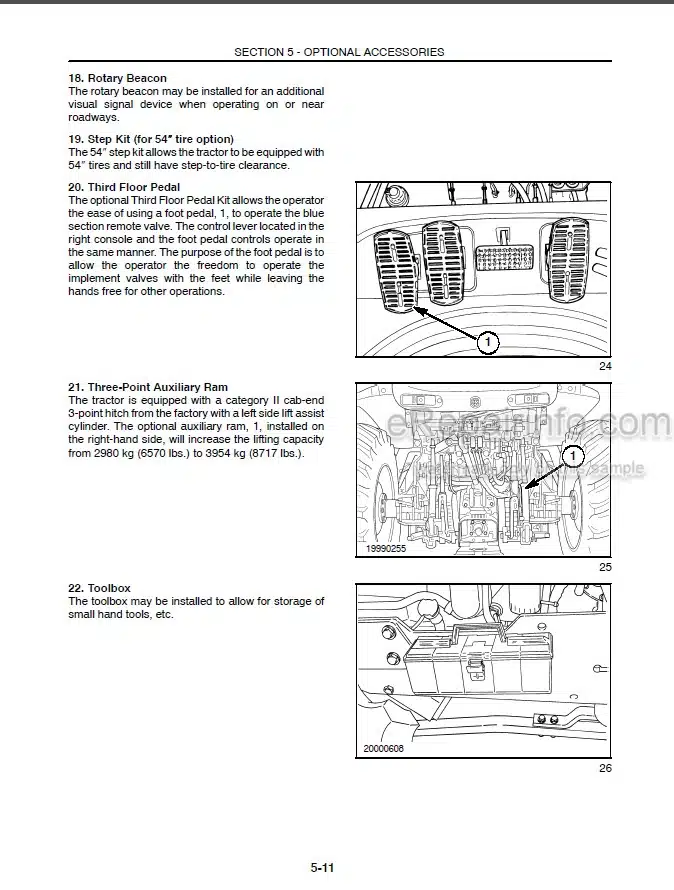

Optional Accessories

Overhead Climate Controls

Overhead Controls

Override Switch

Park Brake

Park Brake Linkage Adjustment, Check

Plastic and Resin Parts

Power Take Off (PTO)

Precautionary Statements

Pre-Operation Checks

Pressure Release Detent Adjustment

Protective Shielding

PTO

PTO Connection

PTO Operation

Radiator Condenser Cores, Check

Radiator System Hoses, Check

Radio

Rear Steering Cylinder Pins, Lubricate

Rear Window

Remote Control Operation

Removing Equipment

Removing Guards to Gain Access to Components for Inspection / Maintenance

Right Side Post Controls

Roof Warning Light Bulbs, Change

Safety

Safety Cab

Safety Chain

Safety Decals

Seat Adjustments

Seat Belt

Seat Console Controls

Seat/Console Rotation

Semi-Mounted Implements

Seven Pin Auxiliary Connector

(Six) 6-Position Rim

(Six) 6-Position Wheel Spacing Adjustment

Slow Moving Vehicle

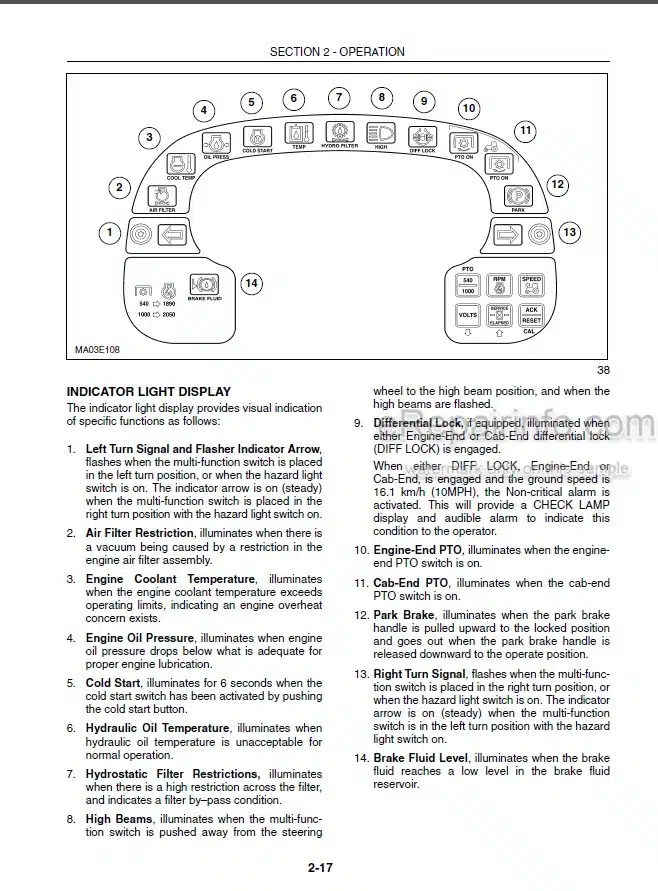

Specifications

Speed Range Operation

Splitter Box Drive Shaft Slip Yoke, Lubricate

Starter Battery Cable Connections, Clean

Starter Solenoid Shield

Steering Wheel and Column

Stop/Tail/Tum Bulb Replacement

Storing the Tractor

Tan Valve (Detent Float)

Three-Point Hitch

Three-Point Hitch Controls

Three-Point Hitch Linkage Adjustments

Three-Point Hitch Operation

Three-Point Hitch System Error Codes

Three-Point Hitch Troubleshooting

Throttle and Hydrostatic System Operation

Tire and Rim Repair

Tire and Rim Service

Tire and Wheel Options

Tire and Wheel Spacing

Tire Condition and Air Pressure, Check

Tire Pressure and Load Capacity Chart

To The Owner

Towing a Disabled Tractor

Tractor Accessories

Tractor Ballast

Tractor Booster Starting

Tractor Identification Data

Tractor Lighting

Tractor Orientation

Tractor Start-up and Engine Operation

Tractor Warning Lamps and SMV Symbol

Troubleshooting

Upper Articulation Pin, Lubricate

Vehicle Identification Plate

Weights

Welding and Battery Charging

Wheel Hardware Torque, Check

Wheel Spacers

Wheel Track Width

Wheel Tread Spacing and Articulation Stops

Wheel Weights

Windshield Washer Fluid Reservoir, Check

Windshield Wiper and Washer Switches

Windshield Wiper Blade, Change

Work Lights Bulb Replacement

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.