Factory Service Repair Manual For Same Explorer II Special 70 75 80 85 90 95 HP Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Same Explorer 70HP, 75HP, 80HP, 85HP, 90HP, 95HP

Contents

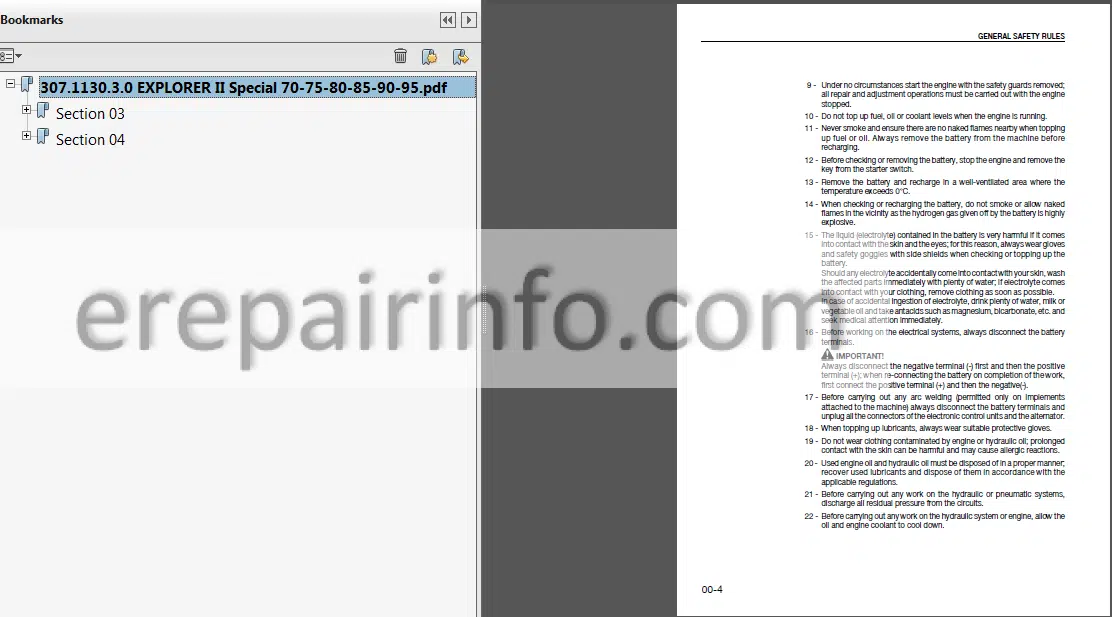

SECTION 00 Contains the general safety rules, information on how to use and update

the manual, the symbols used, the products required, the standard

tightening torques and a conversion table for units of measurement.

SECTION 10 Contains technical descriptions and information regarding the

mechanical and hydraulic operation of machine components, the

designations of the various components, hydraulic diagrams and general

technical data.

SECTION 30 Contains the methods, checks and adjustments regarding the external

components; the operations dealt with in this section do not require

removal of the various assemblies that form the tractor frame and cab.

SECTION 40 Contains information and diagrams regarding the machine’s electrical

and electronic systems

GENERAL SAFETY RULES

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTING OPERATIONS

LIFTING INSTRUCTIONS

HOW THE MANUAL IS STRUCTURED

HOW TO CONSULT THE MANUAL

HOW TO USE AND UPDATE THE MANUAL

TIGHTENING TORQUES

THREADLOCKERS, ADHESIVES, SEALANTS AND LUBRICANTS

CONVERSION FACTORS

-Section 10

TRANSMISSION

Introduction

Description

TRANSMISSION

Connecting Housing

Gearbox And Shuttle Assembly

Bevel Pinion And Range Gearbox Assembly

Four-Wheel Drive Engagement And Parking Brake Assembly

Differential Assembly

Brakes And Rear Axle Assembly (Version 80 – 85 – 90 – 95)

Brakes And Rear Axle Assembly (Version 70 – 75)

REAR PTO

Description 1

Pto Control Clutch Assembly (Versions 80 – 85 – 90 – 95)

Pto Control Clutch Assembly (Versions 70 – 75)

2-Speed Pto And Groundspeed Pto

FRONT AXLE

Final Drive (Versions 80 – 85 – 90 – 95)

Final Drive (Versions 70 – 75)

Pinion, Differential And Differential Lock

HYDRAULIC SYSTEM

DESCRIPTION

Hydraulic Diagram (Versions 80 – 85 – 90 – 95)

Hydraulic Diagram (Versions 70 – 75)

Steering Circuit Gear Pump

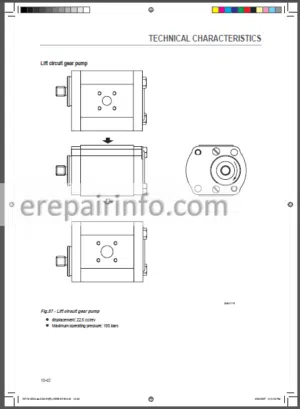

Lift Circuit Gear Pump

Power Steering

Pressure Holding Valve Unit

Auxiliary Services Control Valve

Auxiliary Services Control Valve (Usa Version)

Lift Control Valve (Versions 70 – 75)

Lift Control Valve (Versions 80 – 85 – 90 – 95)

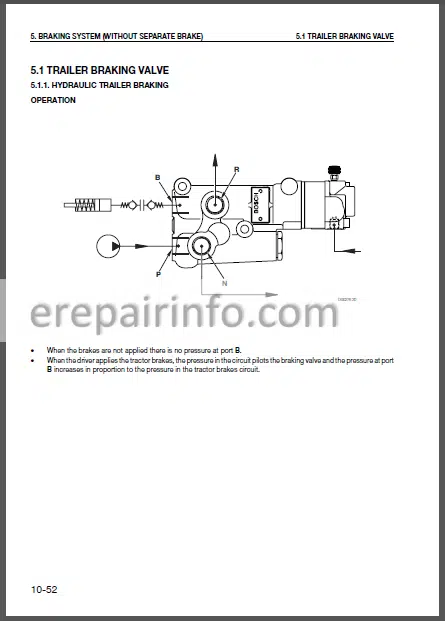

BRAKING SYSTEM (WITHOUT SEPARATE BRAKE)

Description

Trailer Braking Valve

BRAKING SYSTEM (WITH SEPARATE BRAKE VALVE)

Description

Separate-Brakes Valve

Trailer Braking Valve

-Section 30

FRONT HOODS

Removal

Refitting

RADIATOR

Removal

Refitting

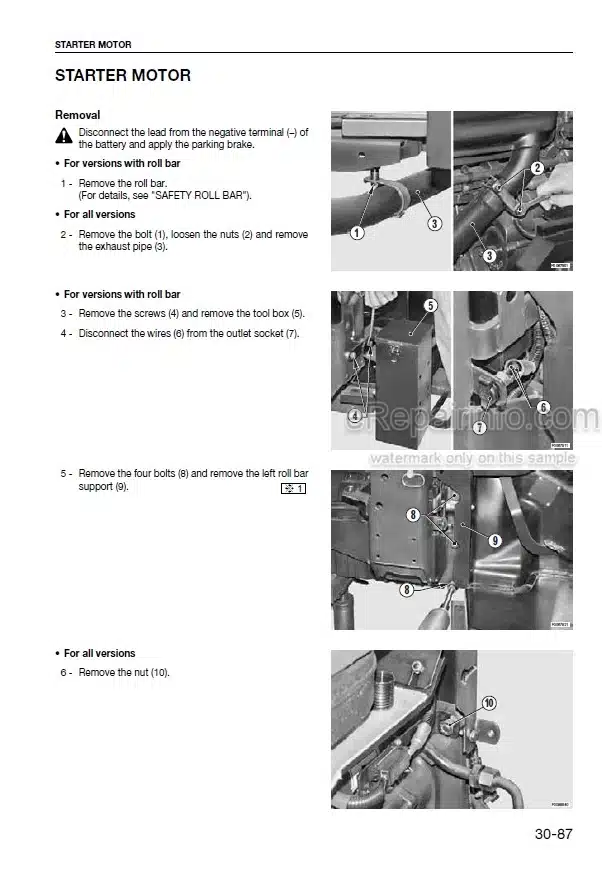

STARTER MOTOR

Removal

Refitting

BATTERY

Removal

Refitting

WHEELS

FRONT WHEELS (4WD Version)

Removal

Refitting

FRONT WHEELS (2WD version)

Removal

Refitting

REAR WHEELS

Removal

Refitting

FRONT AXLE DRIVE SHAFT

Removal

Refitting

FRONT SUPPORT

Removal

Refitting

FRONT AXLE

AXLE ASSEMBLY

Removal

Refitting

Adjusting Front Axle End Float

STEERING CYLINDERS

Removal

Refitting

Disassembly

Assembly

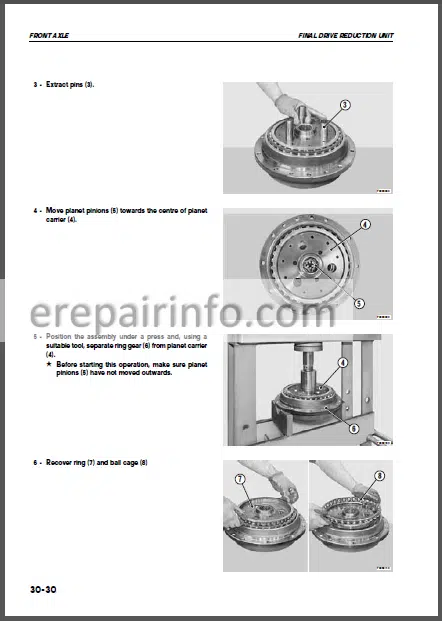

FINAL DRIVE

Removal

Refitting

Disassembly (Version 80 – 85 – 90 – 95)

Assembly

Disassembly (Version 70 – 75)

Assembly

STEERING KNUCKLE HOUSING AND AXLE SHAFT (Version 70 – 75 – 80 – 85 – 90 – 95)

Removal

Refitting

Adjusting Bearings Preload

PINION-DIFFERENTIAL ASSEMBLY

Removal

Refitting

DIFFERENTIAL LOCK

Removal

Refitting

Adjustment

BEVEL GEAR PAIR

Disassembly

Adjustment Of The Differential Preload

Adjustment Of Pinion And Crown Wheel Backlash

Completion Of Assembly

DIFFERENTIAL

Disassembly

Assembly

FRONT AXLE (2WD)

COMPLETE AXLE ASSEMBLY

Removal

Refitting

WHEEL HUB

Disassembly

Assembly

STEERING SUPPORT

Disassembly

Assembly

STEERING CYLINDERS

Removal

Refitting

Disassembly

Assembly

STEERING LEVER

Disassembly

Assembly

INSTRUMENT PANEL

Removal

Refitting

FUEL TANK

Removal

Refitting

POWER STEERING

Removal

Refitting

Relief Valve Setting

Disassembly

Assembly

ROPS FRAME (Version With T58 – T62 Type Fenders)

Removal

Refitting

ROPS FRAME SUPPORT

Removal

Refitting

SAFETY ROLL BAR (Collapsible Version)

SAFETY ROLL BAR1

Removal

Refitting

SAFETY ROLL BAR SUPPORT

Removal

Refitting

ROPS FRAME(Version With T42 And T45 Type Fenders)

Removal

Refitting

ENGINE

Preparation Before Separating The Engine From The Transmission

Preparation For Removal

Refitting

CLUTCH ASSEMBLY

CLUTCH

Checking Clutch Plate Wear (Version 70 – 75)

Checking Clutch Plate Wear (Version 80 – 85 – 90 – 95)

THRUST BEARING

Renewal

CLUTCH MASTER CYLINDER

Removal

Refitting

CLUTCH CONTROL PISTON

Removal

Refitting

CLUTCH CONTROL CIRCUIT

Bleeding The System

BRAKES

REAR AXLE BRAKE DISCS

Renewal

REAR AXLE BRAKE PISTON (Version 80 – 85 – 90 – 95)

Disassembly

Assembly

REAR AXLE BRAKE PISTON (Version 70 – 75)

Disassembly

Assembly

FRONT AXLE BRAKE DISCS

Removal

Refitting

FRONT AXLE BRAKE PISTON

Disassembly

Assembly

PARKING BRAKE

Disassembly

Assembly

BRAKE MASTER CYLINDERS

Removal

Refitting

BRAKING CIRCUIT

Bleeding The System

Brake Bleeding Procedure

FENDERS (For Version With T58 – T62 Type Safety Roll Bar)

Removal

Refitting

FENDERS (FOR VERSION WITH T42 – T45 TYPE SAFETY ROLL BAR)

Removal

Refitting

SEAT SUPPORT (THE SEQUENCE OF PHOTOGRAPHS SHOWS THE VERSION WITH T62 TYPE ROLL BAR)

Refitting

CONNECTING HOUSING

COMPLETE ASSEMBLY

Separating The Engine From The Transmission

Reassembly

GEARBOX AND SHUTTLE ASSEMBLY (4-speed version)

COMPLETE ASSEMBLY

Removal

Refitting

Disassembly

SHUTTLE AND UNDERDRIVE SHAFT

Disassembly

Assembly

PRIMARY SHAFT

Disassembly

SECONDARY SHAFT

Disassembly

Assembly

GEARBOX AND SHUTTLE ASSEMBLY (5-speed version)

COMPLETE ASSEMBLY

Removal

Refitting

GEARBOX SUPPORT AND GEAR SELECTOR RODS

Disassembly

Assembly

REVERSE SHUTTLE SHAFT

Disassembly

Assembly

PRIMARY SHAFT

Disassembly

Assembly

SECONDARY SHAFT

Disassembly

Assembly

AUXILIARY SERVICES DIRECTIONAL

CONTROL VALVE

COMPLETE ASSEMBLY (Version with T58-T62 fenders for 80 – 85 – 90 – 95)

Removal

Refitting

COMPLETE ASSEMBLY (Version with T42-T45 fenders for 70 – 75

Removal

Refitting

DIRECTIONAL CONTROL VALVE (Standard version)

Disassembly

Assembly

COMPLETE ASSEMBLY (USA EXPORT version)

Removal

Refitting

DIRECTIONAL CONTROL VALVE (USA EXPORT version)

Disassembly

Assembly

LIFT (VERSION FOR 80 – 85 – 90 – 95)

COMPLETE ASSEMBLY

Removal

Refitting

Disassembly

Assembly

CONTROL LEVERS (VERSION FOR 80 – 85 – 90 – 95)

Adjustment

LIFT CYLINDER (VERSION FOR 80 – 85 – 90 – 95)

Disassembly

Assembly

BUSHES

Renewal

HYDRAULIC LIFT CONTROL VALVE

Disassembly

Assembly

MECHANICAL DRAFT SENSOR

Removal

Refitting

Disassembly

Assembly

3-POINT LINKAGE (Versions with mechanical lift)

Removal

Refitting

LIFT (VERSION 70-75)

COMPLETE ASSEMBLY

Removal

Refitting

HYDRAULIC LIFT CONTROL VALVE

Removal

Refitting

Assembly

CONTROL LEVERS

Adjustment

3-POINT LINKAGE

Removal

Refitting

REAR AXLE

COMPLETE ASSEMBLY (VERSION 80 – 85 – 90 – 95)

Removal Of The Complete Rear Axle

Refitting

Disassembly

Assembly

PLANET CARRIER ASSEMBLY

Disassembly

Assembly

COMPLETE ASSEMBLY (VERSION 70 – 75 )

Removal Of The Complete Rear Axle 2

Refitting

Disassembly

Assembly

PLANET CARRIER ASSEMBLY

Disassembly2

Assembly

HYDRAULIC PUMPS

PUMP FOR HYDRAULIC LIFT AND AUXILIARY SERVICES2

Removal

Refitting

POWER STEERING PUMP

Removal

Refitting

RANGE GEARBOX AND REAR DIFFERENTIAL ASSEMBLY

COMPLETE ASSEMBLY

Removal

Installation

DIFFERENTIAL

Removal

Refitting

Disassembly

Assembly

PINION (VERSION 80 – 85 – 90 – 95)

Disassembly

Assembly

PINION (Version 70-75)

Disassembly

Assembly

FOUR-WHEEL DRIVE ENGAGEMENT CONTROL

Disassembly

Assembly

4WD OUTPUT SHAFT AND PARKING BRAKE

Disassembly

Assembly

BEVEL GEAR PAIR

Preparation Of Adjustments

Adjustment Of The Differential Bearings Preload

Adjustment Of The Pinion Position

Adjustment Of The Pinion And Crown Wheel

Pump Drive Pto

OUTER GEAR

Disassembly

Assembly

INNER GEAR

Disassembly

Assembly

PTO INPUT SHAFT

Removal

Refitting

PTO CLUTCH

Removal

Refitting

Disassembly (Version 80 – 85 – 90 – 95)

Disassembly (Version 70-75)

Assembly

GROUNDSPEED PTO OUTPUT SHAFT

Disassembly

Assembly

SYNCRO PTO ENGAGEMENT DEVICE

Disassembly

Assembly

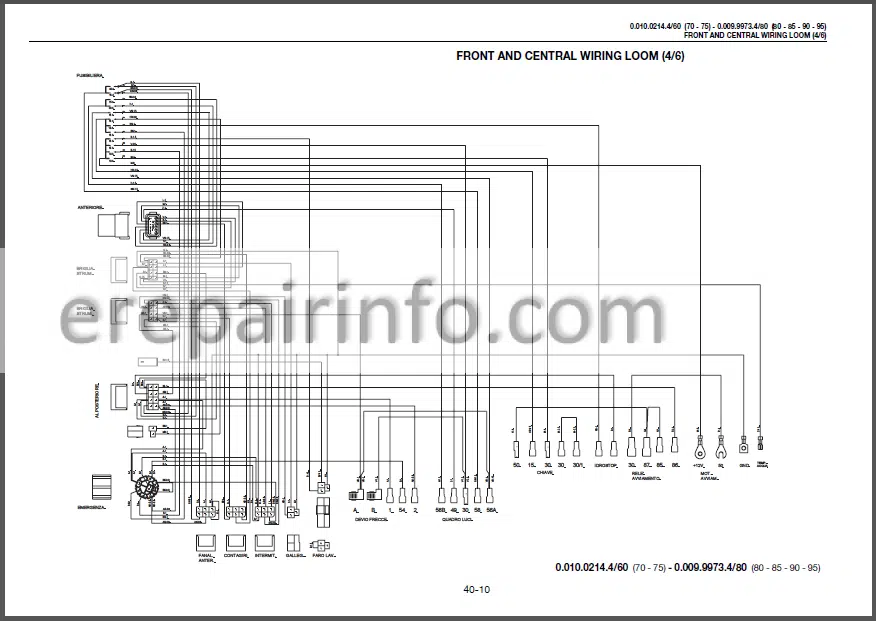

-Section 40

STRUCTURE OF THE UNIT

Introduction 2

List Of Wiring Looms

Definition Of Components And Symbols

General Rules

Modification Of The Tractor’s Electrical/ Electronic Circuits

Main Wiring Faults Vi

A Poor Contact Between Connectors

B Defective Pin Soldering Or Crimping

C Disconnecting Wiring

E Oil Or Dirt On Connectors

Removal, Refitting And Drying Of Connectors And Wiring 5

A Disconnection Of Connectors

B Connecting The Connectors

C Cleaning And Drying Wiring

D Renewal Of Damaged Electrical Components

Diagnostic Instruments

Wire Colour Codes

WIRING LOOMS

Front And Central Wiring Loom (1/6)

Front And Central Wiring Loom (2/6)

Front And Central Wiring Loom (3/6)

Front And Central Wiring Loom (4/6)

Front And Central Wiring Loom (5/6)

Front And Central Wiring Loom (6/6)

Headlamps Wiring Loom On Safety Roll Bar (Standard Version)

Headlamps Wiring Loom On Safety Roll Bar (Iraq Turkey Version)

Rear Wiring Loom (70 – 75 Version) (1/2)

Rear Wiring Loom (70 – 75 Version) (2/2)

Rear Wiring Loom (80 – 85 – 90 – 95 Version) (1/2)

Rear Wiring Loom (80 – 85 – 90 – 95 Version) (2/2)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Very good