Factory Service Repair Manual For Same Silver 80 90 100.4 100.6 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 470

Bookmarks: Yes

Searchable: Yes

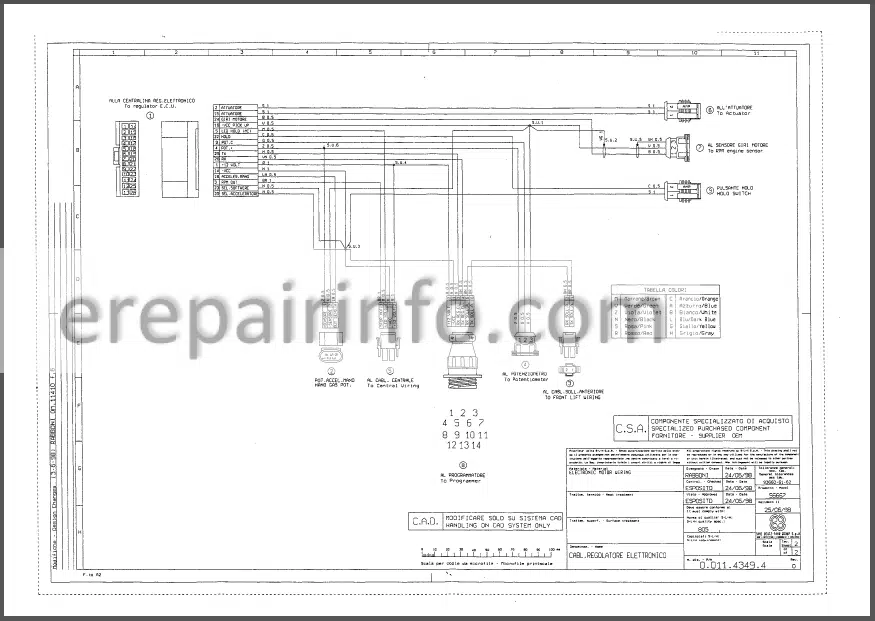

Wiring Diagrams: Yes (bad quality)

Hydraulic Diagrams: Yes (bad quality)

Model

Same Silver 80, 90, 100.4, 100.6

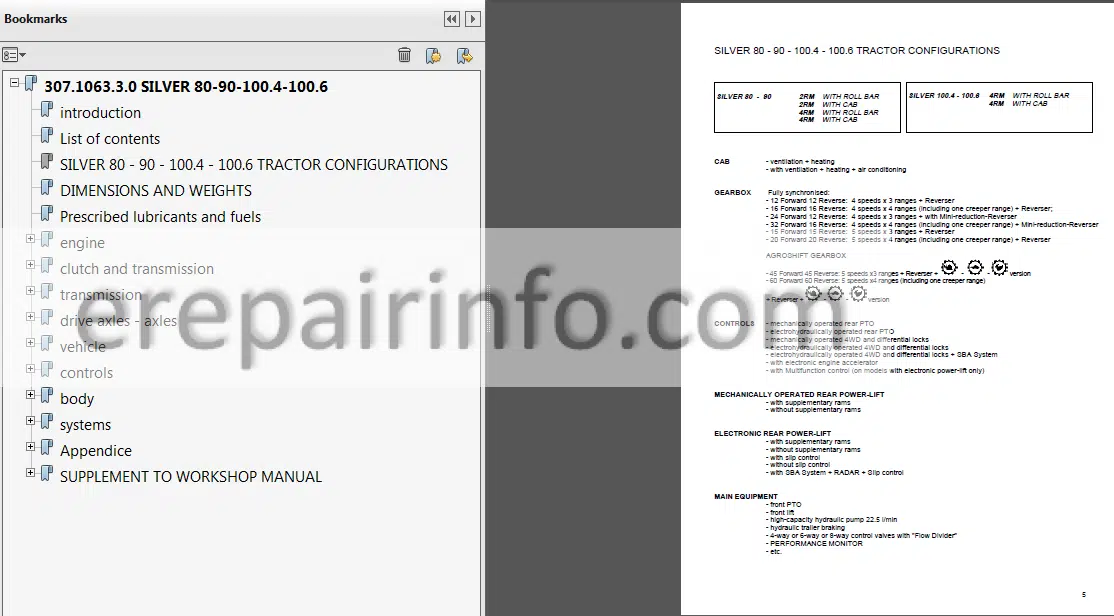

Contents

- SILVER 80-90-1004-1006 Tractor Configurations

Dimensions And Weights

Capacities - – ENGINE

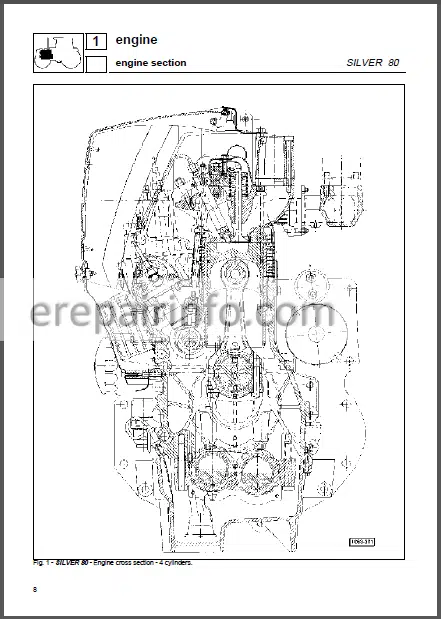

Engine Section Views

General Characteristics

Lubrication System(Specifications)

Fuel Supply System (Specifications)

Turbocharger For Silver 90-1006 (Specifications)

Cooling System (Specifications)

Cylinder Block

Timing Cover

Cylinders

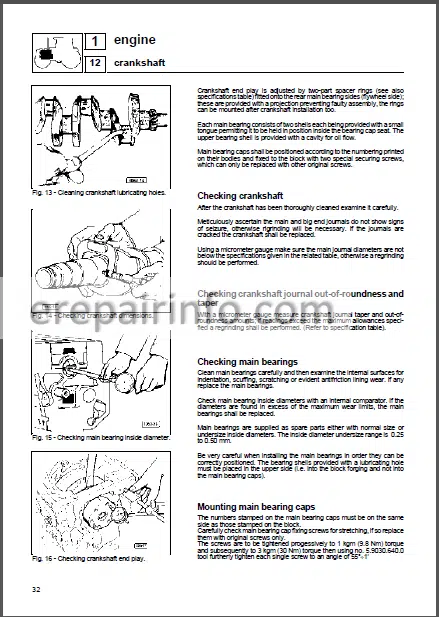

Crankshaft

Connecting Rods

Pistons

Counterbalance Weights

Flywheel

Camshaft

Cylinder Heads

Lubrication System

Fuel System

Injectors

Engine Governor (Mechanical)

Adjustment Of Mechanical Governor External Controls

Adjustment Of Anti-Hunting Device

Electronic Rpm Control

Putting The Electronic Rpm Control Into Service

Injection Pump

Engine Timing

Injection Pump Timing

Injection Pump Calibration

Fuel Prefilter

Fuel Filter

Checking The Fuel Supply Pump

Cooling System

Fan Unit

Pulley Alignment

Belt Tension Adjustment

Intake And Exhaust

Turbocharging System

Engine Air Filter

Tightening Torques

Engine Assembly

Refitting The Engine

Fault Diagnosis - – CLUTCH

Engine-Gearbox Clutch

Clutch Pedal Adjustment

Bleeding Air From The Hydraulic System

Fault Diagnosis

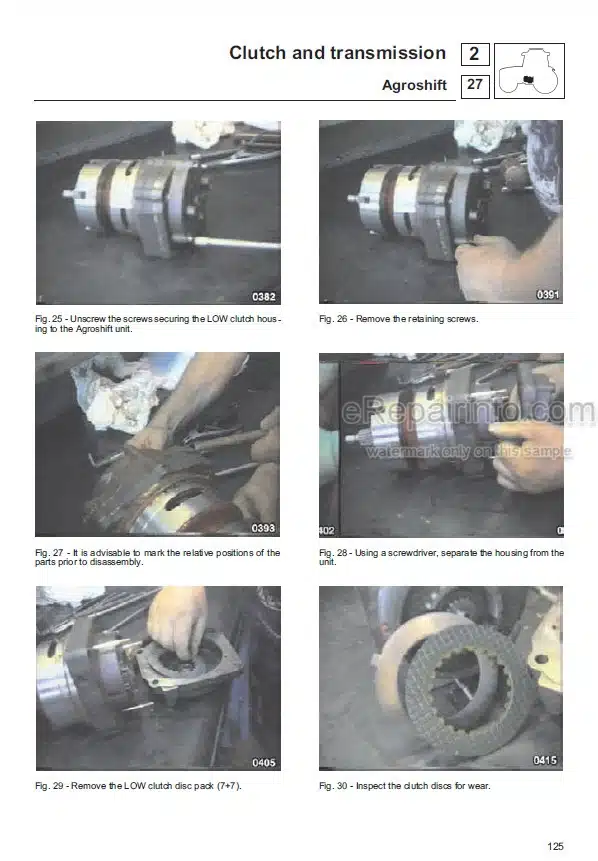

Agroshift

Specifications

Operating Diagrams

Assembling The Clutch

Adjustment Of End-Float

Fitting The Clutch Assembly To The Gearbox (Main Operations)

Testing The Clutch Control Unit Supply Pressure

Fault Diagnosis - – GEARBOX

Gearbox, General Characteristics And Configurations

Views Of The Gearbox

Removal Of Gearbox From Tractor

Dismantling The Gearbox

Examining The Gearbox Components

Adjusting The Bevel Drive

External Mechanical Controls

Tightening Torques

Attaching The Gearbox To The Rear Axle, Lift And Engine

Power Take-Off

Views Of Pto Controls

Operating Diagrams

Specifications

Assembly Of The Rear Output Shaft

Pto Clutch

Pto Clutch Specifications

Views Of The Pto Clutch

Checking The Clutch

Testing The Clutch Operating Pressures

Checking End-Float Of The Pto Clutch Front Shaft

Refitting The Pto Assembly (Main Operations)

Fault Diagnosis - – AXLES

Views Of The Rear Axle

Fitting The Rear Axle Half-Shafts

Removal And Dismantling Of The Rear Axle Epicyclic Reductions

2Wd Front Axle, General Description And Specifications

Removal And Refitting Of Axle On The Front Support

Wheel Hub

Inspection And Checks

4Wd Front Axle, Specifications

Adjusting Wheel Alignment And Steering Angle

Section Views Of 4Wd Axle

Checks And Adjustments

Section View Of 4Wd Hub

Epicyclic Reduction

Special Refitting Operations And Adjusting The Preloading Of The Hub Carrier Bearings

Half-Shafts

4Wd Axle Tightening Torques

4Wd Bevel Drive Adjustment

Internal Adjustment Of Differential Lock

4Wd Axle Fault Diagnosis

Sba System

Fitting The Steering Angle Sensor

Removal Of Differential Unit From Front Axle

Removal Of Front Wheel Drive And Differential Lock Clutch

Adjustment Of Front Bevel Drive With Sba System

Fitting The Differential Unit On The Front Axle

Front Wheel Drive Clutch On Models With Sba System, Specifications

Front And Rear Differential Lock Clutches On Models With Sba System

Fault Diagnosis - – VEHICLE

Brakes, General Description And Specifications

Brake Pumps, Disassembly And Examination

Examining And Adjusting The Brake Assembly

Checking The Parking Brake Linings

Bleeding Air From The Hydraulic Braking System

“Separate Brakes” Valve

Operating Diagram For “Separate Brakes” Valve

Fault Diagnosis

Electronic Power-Lift Controls

Electronic Power-Lift Specifications

Operation Of The Electronic Power-Lift

“All Round Tester”

Electronic Power-Lift Self-Diagnosis

Putting The Electronic Lift Into Service

Auto-Man Procedure For Entering The Constant Wheel Value For An Undefined Tyre Size

Calibrating The Draft Sensor

Calibrating The Steering Sensor

Functional Testing Of System Components

Electronic Power-Lift Hydraulic Control Valve

Testing The Hydraulic Lift Operating Pressure

Electronic Power-Lift Operating Diagrams

Views Of The Lift

Section Views Of The Draft Sensor

Installing The Draft Sensor

On-Board Radar

Precautions Regarding Electronic Apparatus

Checking The Mechanical Components Of The Electronic Power-Lift

Mechanically Controlled Power-Lift, Specifications

Section Views Of The Mechanically Controlled Power-Lift

Fitting The Control Lever Lock Screw And Lever Shaft Cam

Fitting The Ring Seal On The Lift Piston

Hydraulic Control Valve For Mechanically Controlled Power-Lift, Views And Hydraulic Circuit Diagrams

Adjusting The Controls Of The Mechanically Controlled Power-Lift

Checking The Lift Mechanism

Testing The Operating Pressure

Removal Of The Lift Control Valve

Disassembly Of The Lift Control Valve

Sensing Arm

Auxiliary Lifting Cylinders

Specifications For Control Valve Springs

Fault Diagnosis

Front Hydraulic Power-Lift, General Description And Specifications

Checks

Hydraulic Accumulator And Anti-Shock Valve For Front Power-Lift

Front Power Take-Off, General Description And Specifications

Hydraulic Operating Diagrams For Front Pto

Front Pto Views

Installing The “Ring-Feeders”

Checking The Front Pto Clutch

Checking Clutch Plate Clearances

Checking The Front Pto Operating Pressure

Front Pto Fault Diagnosis

Specifications For Front Pto Springs - – CONTROLS

Hydrostatic Power Steering, General Description And Specifications

Examining And Testing The Hydrostatic Power Steering System

Assembly Instructions For The Hydrostatic Power Steering Control Valve

Hydrostatic Power Steering Operating Diagram

Mechanical Controls

Electrohydraulic Controls

System Configuration

Electrohydraulic Valves

Hydraulic Operating Diagrams

Rear Differential Lock Control Cylinder For Models With Sba System

Front Wheel Drive Disengagement Cylinder For Models Without Sba System

Adjusting Front And Rear Differential Lock Controls For Models Without Sba System

Adjusting Front Wheel-Drive Controls For Models Without Sba System

Multifunction Control

Performance Monitor

Putting The Performance Monitor Into Service

Performance Monitor Retrofit Procedure - – BODYWORK

Platform

Cab

Instructions For Fitting The Front Windscreen And Lower Side Glass

Fitting The Seal

Cab Air Filter

Removal And Refitting Of The Cab And Platform

“Normal” Electric Heating System

“High-Power” Electric Heating System

Cab Air Conditioning System - – SYSTEMS

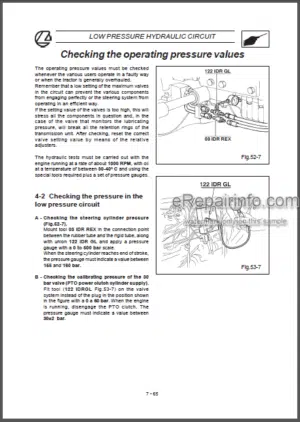

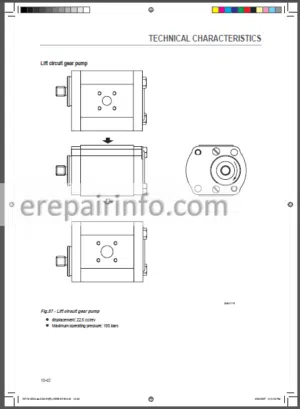

Hydraulic System

Auxiliary Hydraulic Systems

Hydraulic Trailer Braking

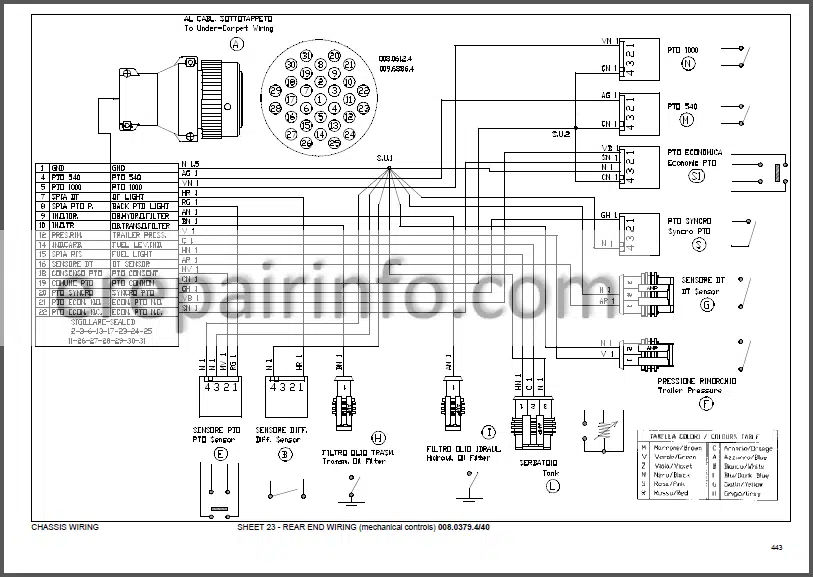

Electrical System

Specifications And Components

Wiring Diagrams - – APPENDIX

Conversion Tables

Parts

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Super manual only pictures could be better.