Factory Service Manual For Sperry New Holland TR75-85 Combine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 423

Number: 40007520

Bookmarks: Yes

Wiring Diagrams: Yes

Model

Sperry New Holland Combine

TR75 TR85

Contents

-BRAKE SYSTEM

Brake Drum And Shoes – Style I Transmission

Hydraulic System

Introduction

Labor Guide

Slave Cylinders – Style I Transmission

-CLEANING SYSTEM

Cleaning Fan Removal

Cleaning Fan Shaft Installation

Cleaning Shaft Removal Only

Introduction

Labor Guide

Shoe

Shoe Bushing Tightening Sequence

-CLUTCH HYDRAULIC ACTUATION SYSTEM

Bleeding

Clutch Adjustment

Introduction

Labor Guide

Master Cylinder

Pedal Adjustment

Slave Cylinder

-CONCAVES

Concave And H-Frame Adjustment

Concave Installation

H-Frame

H-Frame Parts

Installation

Introduction

Labor Guide

-DIFFERENTIAL – STYLE I TRANSMISSION

Assembly

Disassembly

Installation

Labor Guide

Parts List

Removal

Specifications

Torque Values

-DISCHARGE BEATER AND GRATE

Discharge Beater

Discharge Beater Grate

Introduction

Labor Guide

Removal Of The Discharge Beater – Style I

Removal Of The Discharge Beater – Style Ii

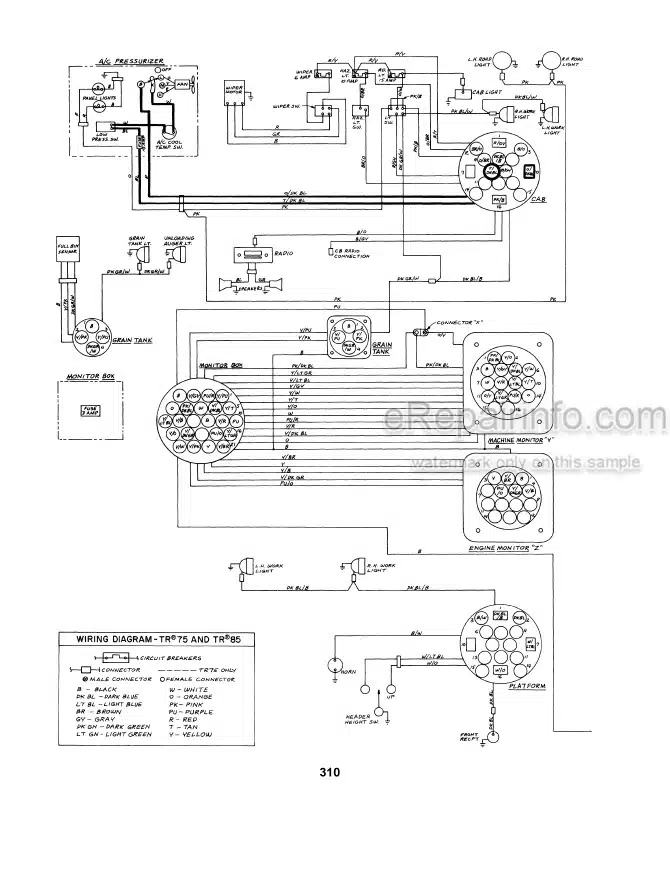

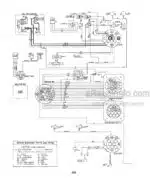

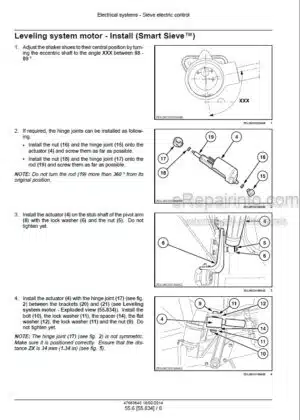

-ELECTRICAL SYSTEM

Assembly

Component Location

Electrical Charging System

Engine Starting System (Tr85)

General Location Of Components

Introduction

Normal Operation Of Electrical System

Using The Wiring Diagram

-FINAL DRIVE

Final Drive Installation

Final Drive – 32″ Wheels

Final Drive – 26″ Wheels

Introduction

Labor Guide

Safety

-GENERAL INFORMATION

-GROUND DRIVE TRANSMISSION-STYLE I

Disassembly (Installed On Machine)

Disassembly (Removed From Machine)

Introduction

Labor Guide

Lubrication

Removal Of Style I

Service Of Transmission Components

Specifications

Torque Values

-GROUND DRIVE TRANSMISSION – STYLE II

Assembly

Brake And Differential Parts

Differential Parts

Disassembly

Introduction

Labor Guide

Removal

Tools Needed

Transmission Parts

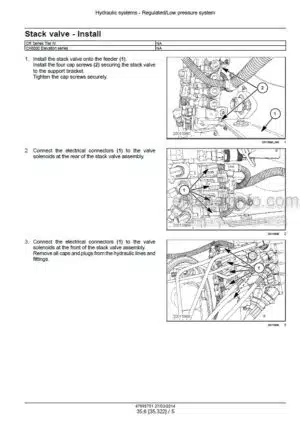

-HYDRAULIC SYSTEM

AHHC Valve Operation

AHHC Valve Parts

Assembly

Automatic Head Height Control Operation

Automatic Head Height Control Valve Service

Auxiliary Functions

Bladder Accumulator Operation

Directional Control Valve Operation

Directional Control Valve Parts

Directional Control Valve Repair

Directional Control Valve Trouble Shooting

Double-Acting Lockout Plunger

Head Height Control Trouble Shooting

Head Lift Cylinder Repair

Hydraulic Pump Parts List

Hydraulic System Function

Hydraulic System Pressure Testing

Inspect Parts For Wear

Introduction

Labor Guide

Meter (Gerotor) End

Placing Pump Back Into Service

Precharging And Recharging

Pump Repair

Pump Trouble Shooting

Secondary System Relief Valve Parts

Secondary System Relief Valve Repair

Single-Acting Lockout Plunger

Steering And Traction Vari-Drive Cylinder Repair

Steering Control Operation

Steering Control Unit

Steering Control Unit Parts

Steering System Trouble Shooting

Unloading Auger Cylinder Repair

-HYDROSTATIC TRACTION DRIVE

Charge Pump Repair Procedures

Disassembly

Explanation Of Terms Used In Failure Analysis

Hydrostatic System Specifications

Hydrosatic Transmission Components

Hydrostatic Transmission Repair Procedures

Hydrostatic Transmission Service Tools Needed

Instructions For Parts Evaluation

Introduction

Labor Guide

Other Information

Rotating Group Component Inspection

Rotating Group Parts

System Components Function And Adjustment

System Function

Troubleshooting

Trouble Shooting Chart

-LOADING AND UNLOADING SYSTEMS

Belt Installation

Belt Removal

Driven Sheave Removal

Grain Tank Cross Auger Service

Labor Guide

Left Side Drive Belt

Loading System

Unloading Auger Removal

Unloading Auger Slip Clutch Service

Unloading Auger U-Joint Service

Unloading System

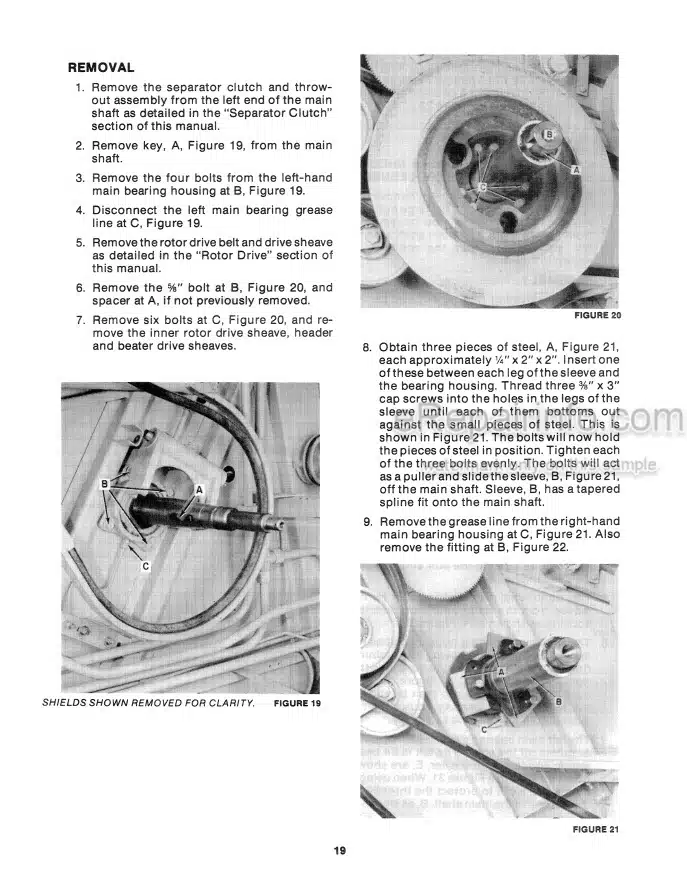

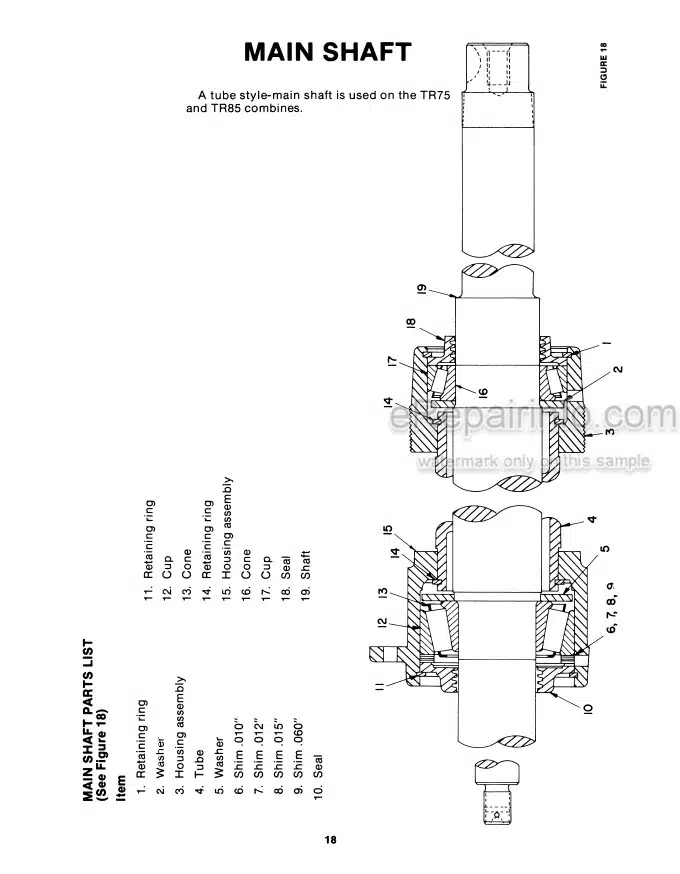

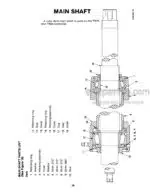

-MAIN SHAFT

Assembly

Disassembly

Installation

Labor Guide

Parts List

Removal

-POWERED REAR AXLE

Flow Limiters

Flow Limiter Operation

Labor Guide

Motor Assembly

Motor Disassembly

Motor Parts

Motor Parts Inspection

Motor Repair Procedures

Other Information

Powered Rear Axle Control Valve Operation

Powered Rear Axle Motor Operation

Safety

System Function

Troubleshooting

-ROTOR DRIVE

Assembly

Introduction

Labor Guide

Removal Of Lower Variator Sheaves

Rotor Drive – Torque Sensing Drive

Rotor Drive Vari-Speed Motor And Speed Screw

Rotor Drive Vari-Speed Motor And Speed Screw Parts

Servicing

Specifications

Spring Compression Tool

-ROTOR GEARBOXES

Converting Chart

Inspection

Labor Guide

Left-Hand Gearbox Parts List – Style I

Left-Hand Input Shaft Assembly

Left-Hand Input Shaft Disassembly

Left-Hand Rotor Gearbox

Parts Layout

Removing Gearboxes

Right And Left-Hand Output Shaft Assembly Style I

Right And Left-Hand Output Shaft Disassembly Style I

Right Hand Gearbox Parts List Style I

Right Input Shaft Assembly Style I

Right Hand Input Shaft Disassembly Style I

Right Hand Rotor Gearbox

Rotor Gearbox Coupler Alignment

Rotor Gearbox Coupler Parts

Rotor Gearbox Installation

Servicing Rotor Gearboxes Style Ii

Servicing The Left Hand Gearbox Style I

Servicing The Right Hand Gearbox Style

Shim Chart

Shim Use Chart

-ROTORS

Assembly

Balancing

Disassembly

Inspection

Installation

Introduction

Labor Guide

Rasp Bar Shimming

Removal Of Rotors

Rotor Component Alignment

Rotor Timing

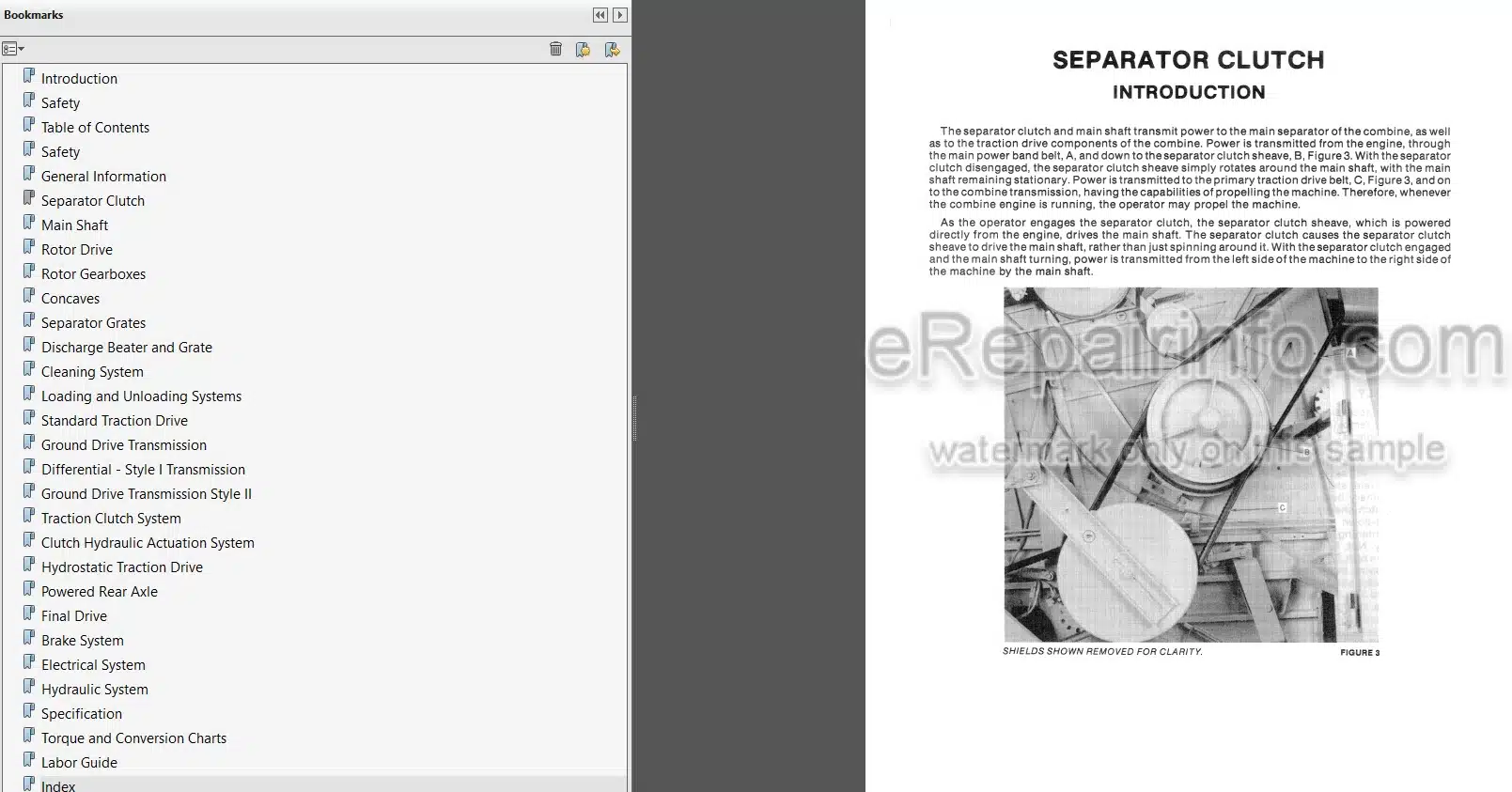

-SEPARATOR CLUTCH

Adjustment

Assembly

Disassembly

Inspection

Introduction

Labor Guide

Parts List

-Separator Grates

Installation

Introduction

Labor Guide

Removal

-SPECIFICATIONS

Base Unit

Caterpillar Diesel Engine

Feeder

Ford Diesel Engine

Hydrostatic Drive

Standard Traction Drive

Table Of Speeds

-STANDARD TRACTION DRIVE

Labor Guide

Vari Intermediate Sheave Disassembly

Torque And Conversion Charts ,

Conversion Table (Inches To Millimeters)

Conversion Table (Millimeters To Inches)

-TRACTION CLUTCH SYSTEM

Assembly – Style I

Assembly – Style II

Clutch Parts – Style I

Clutch Parts – Style II

Clutch Specifications Styles I And II

Disassembly – Style I

Disassembly – Style II

Installation

Installation – Style I

Inspection

Inspection Style I And II Clutch

Introduction

Labor Guide

Removal – Style I Clutch

Removal – Style II Clutch

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.