Factory Operators Manual For Tigercat Feller Buncher. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 285

Number: 43586AENG (january 2020)

Bookmarks

Searchable

Model

Tigercat Feller Buncher

720G

724G

726G

Serial Number 7205601–7206600

Serial Number 7243101–7244000

Serial Number 7265001–7266000

Contents

INTRODUCTION

MACHINE IDENTIFICATION AND SERIAL NUMBERS

STANDARDS FOR MACHINE OPERATOR PROTECTIVE STRUCTURES

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Articulation Lock Bar

Avoid Injury From Backover Accidents

Battery Disconnect Switch

Battery Safety

Boom Cylinder Lock

Cab Exits

Cooling System

Diesel Exhaust Fluid (DEF)

Exhaust Fumes

Felling Trees

Fire Prevention

Fluid Injection Injury

General Safety Precautions

Grease Injection Injury

Hazard Zone

Interlock Door Switches

Lightning Safety Awareness

Machine Stability And Traction

Notice Labels

Operating Safety Precautions

Parking The Machine

Pilot System Pressure Release

Preparing The Machine For Maintenance

Protective Clothing

Release Pilot System Pressure

Safety Hazards

Safety Precautions

Safety Signal Words

Servicing Safety Precautions

Transporting The Machine

Welding, Prior To

Working With Oil

-USING HIGH-SPEED DISC SAWS SAFELY

Comments And Instructions

Dangers

Foreword

Housing Types

Saw Head Do Nots

Type Of Housing Makes A Difference

-CONTROLS AND OPERATION

Accumulating Arms

Air Conditioner-Heater Controls

Air Vents, Cab

Alarm Light

Audio System

Auxiliary Power Supply-12 Volt

Battery Boosting

Battery Disconnect Switch

Bluetooth Functions

Boom Lift

Brakes

Clamp Arms

Cold Weather Starting

Computer

Computer And Display

Coolant Heater, Engine (Optional)

Cutter Switch-(Saw)

Diagnostics Connection, Engine

Drive Control

Eco Mode

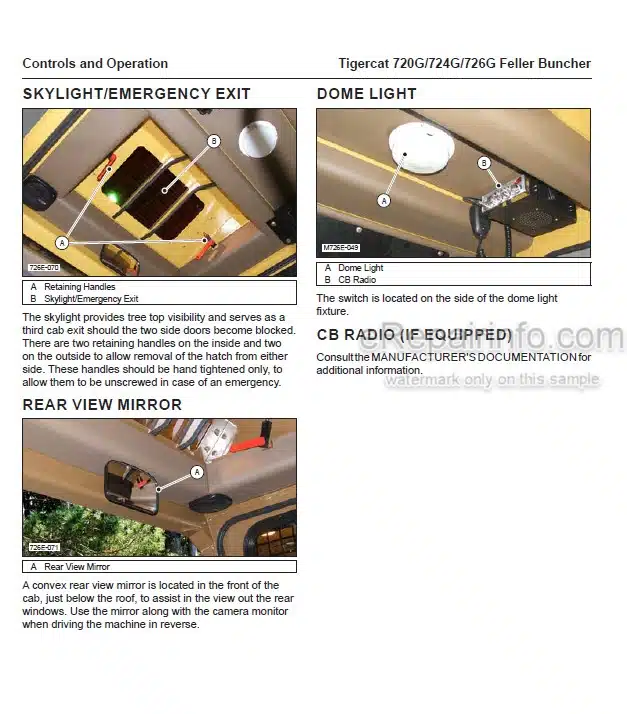

Emergency Exit/Skylight

Engine

Engine Coolant Shut-Off Valve

Fan Switch (Engine Cooling)

Filters

Fire Detection System

Fire Extinguisher

Foot Pedal Controls

Gear Shift Lever

Head Tilt

Heater, Engine Coolant (Optional)

Horn

Ignition Key Switch

Instrument Panel

Interlock Reset Switch

Joystick Controls

Light-Dome

Lighter-24 Volt

Machine Preparation

Mirror, Rearview:

Operating Machine:

Parking Brake Switch:

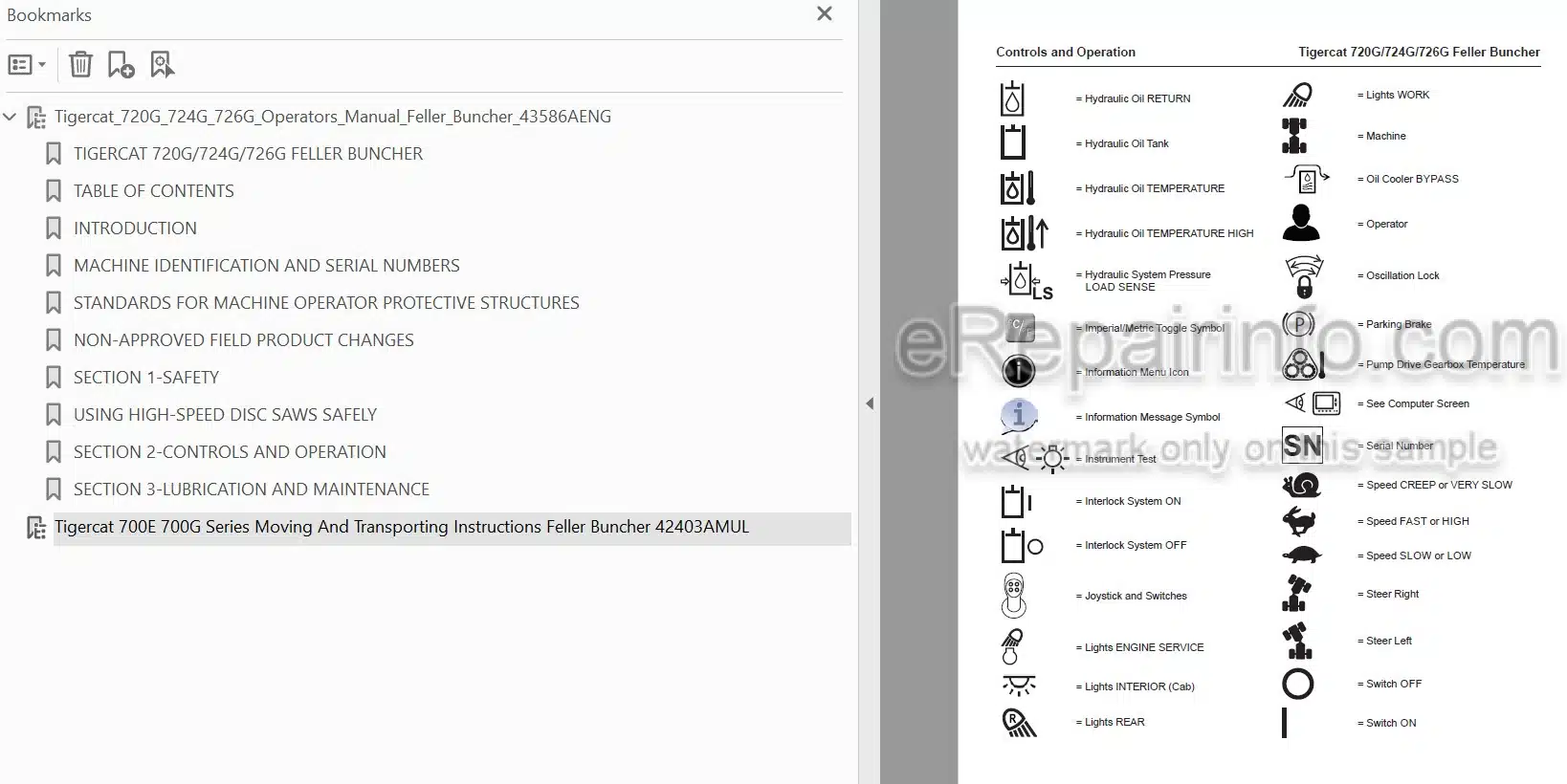

Pictograms

Pressurized Water System:

Prestart Checks:

Rear View Mirror:

Refuelling

Restarting Engine That Has Run Out Of Fuel Or When A Fuel Filter Has Been Replace

Seat–Air Ride

Seat–Standard

Skylight/Emergency Exit

Starting Engine

Steering Wheel (Optional)

Switches

Telematics System (Optional)

Travel Speed Control Lever

USB Port

Water System, Pressurized

-LUBRICATION AND MAINTENANCE

Access Doors And Covers

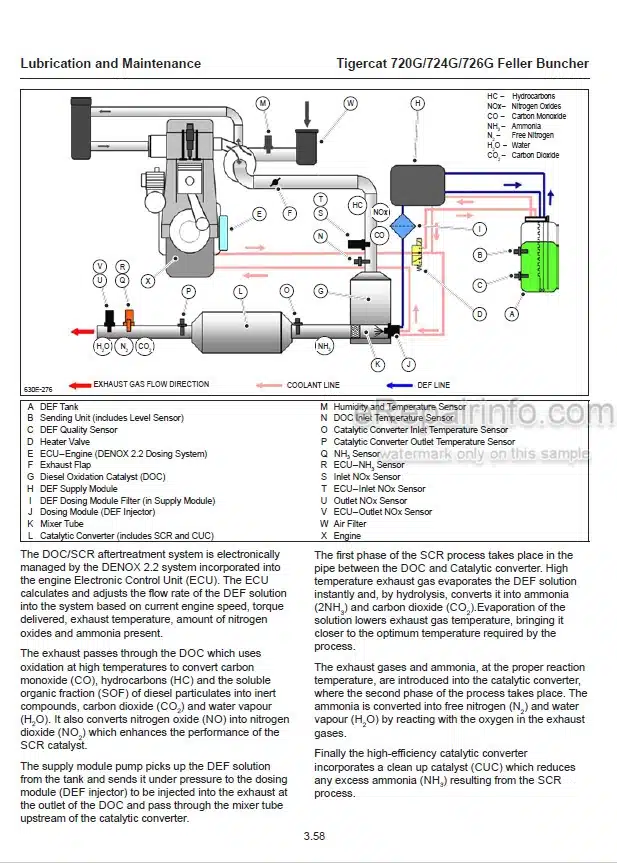

Aftertreatment System (Tier 4F Machines Only)

Air Conditioning System

Air Intake System

Anti-Corrosion Spray, Removal

Articulation Lock Bar

Axles

Battery Care

Belts, Engine

Brake, Parking

Care Of Polycarbonate Windows

Care Of The Machine

Case Drain Strainer

Center Joint

Center Joint Lock Pin

Commercial Wood, Weights

Cooler Package, Cleaning

Diagnostics Connection

Diesel Exhaust Fluid (DEF) (Tier 4F Machines Only)

Diesel Exhaust Fluid Tank

Driveshafts

Emergency Exits

Engine Access Panels

Engine Air Precleaner

Engine Diagnostics Connection

Filters

Fire Prevention

Fluid Analysis Program

Fuel Heater

Fuel, Refuelling

Fuel Tank

Fuses And Relays

Graffiti Removal

Heater, Fuel

Hydraulic Oil Hand Fill Pump

Hydraulic Oil Operating Range Chart

Hydraulic Oil Tank

Hydraulic System

Lubrication And Service Points

New Machine Maintenance

Oil Lost From Leakage

Parking Brake

Pressure And Speed Settings

Pressure Washing

Pressurized Water System Maintenance

Preventive Maintenance Schedule

Pump Drive Gearbox

Refilling The Hydraulic System

Refrigerant Specification

Refuelling Procedure

Scheduled Maintenance

Service And Lubrication Points

Startup Procedure After Major Machine Maintenance

Strainers

Tire Pressures

Torque Chart, General

Torque Chart, Specific

Torque, Fluid Connections

Towing Instructions

Transmission

Travel Speed Control Lever Adjustment

Windows

-TIGERCAT 700E 700G SERIES MOVING AND TRANSPORTING INSTRUCTIONS FELLER BUNCHER 42403AMUL

Transporting Instructions

Vehicle Moving Instructions

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.