Factory Operators Manual For Tigercat Feller Buncher. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 184

Number: 31379AENG (march 2011)

Bookmarks

Searchable

Model

Tigercat Feller Buncher

845C

L845C

Serial Number 84511501 To 84511860

Serial Number 84521501 To 84521860

Contents

INTRODUCTION

STANDARDS TOPS, FOPS, OPS

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Battery Disconnect Switch

Battery Safety

Cab Exits

Cooling System

Emergency Cab Exits

Engine Doors

ER Boom System Precautions

Exhaust Fumes

Felling Trees

Fire Prevention

Fluid Injection Injury

Fluid Leaks

Grease Injection Injury

Hazard Zone

Hydraulic Pressure Hazard

Lightning Safety Awareness

Loose Clothing Hazard

Machine Stability And Traction

Noise Level Inside Cab

Parking Hazards

Protective Clothing

Safety Interlock Switches On Cab Doors

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Signal Words

Vibration Levels Inside Cab

Welding, Prior To

Working With Oil

-CONTROLS & OPERATION

Accumulating Arms Control, Joystick

Accumulation Mode Feature

Air Conditioner/Heater Controls

Amerex Fire Suppression System (Optional)

AM/FM Stereo CD

Anti-Stall – Switch With Light

Attachment Electronic Adjustment Procedure

Auto Idle – Light

Auxiliary Power Outlet

Battery Booster Jumper Plug

Battery Disconnect Switch

Boom Controls

Care Of The Machine

Case Drain Strainers

Cigarette Lighter

Clamp Arms Control, Joystick

Cleaning

Cleaning A/C Condenser, Oil Cooler, Radiator

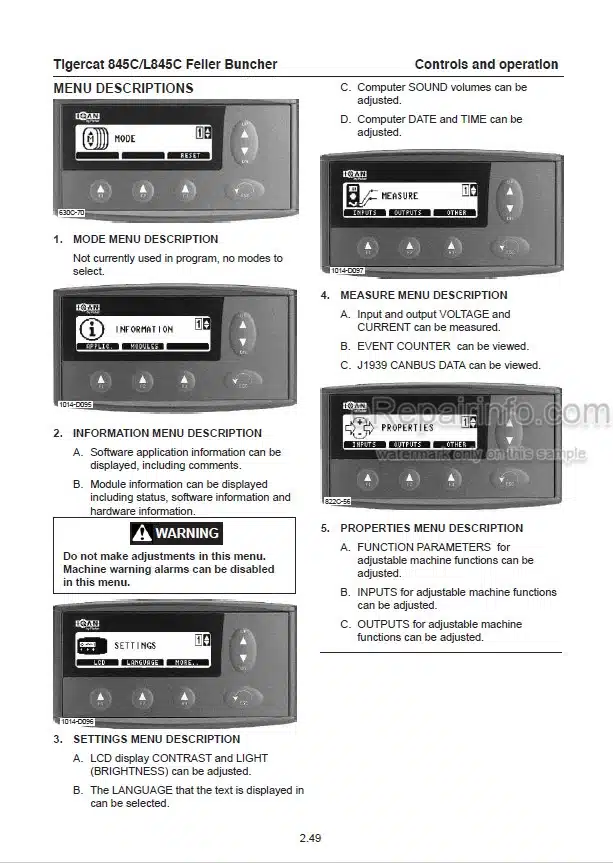

Computer Control System (IQAN MDM Display)

Control Panel

Cooling Assembly

Cooling Fan – Switch

Display Module

Doors, Service Access

Emergency Exits

Engine Air Cleaner

Engine Anti-Stall – Switch With Light

Engine Door, Power – Switch

Engine Hot Water Shut Off Valves

Engine, Restarting After Engine Run Out Of Fuel

Engine, Stopping

ER Boom System, Special Operating Instructions

Felling Head Operating Instructions

Filter Fresh Air – A/C Unit

Filter Re-Circulating Air – A/C Unit

Filters:

Fire Suppression System (Optional)

Foot Pedals, Track Drive

Fuel Heater Switch

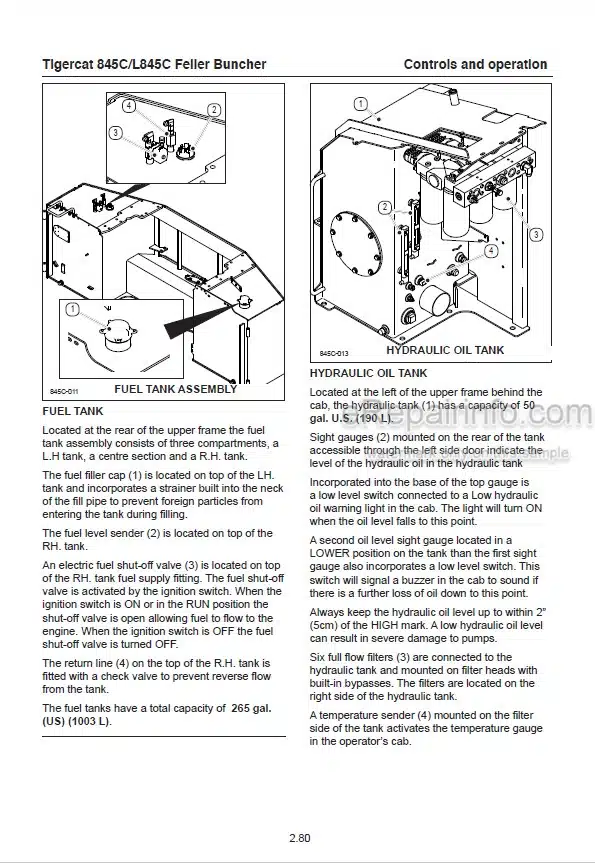

Fuel Tanks

Fuel Tank Shut-Off Valves

Fuses And Relays

Graffiti Removal

Hand Fill Pump, Hydraulic Oil

Horn, Safety Alert – Switch

Hot Water Shut Off Valves (Engine)

Hydraulic Oil Tank

Ignition Key Switch

Instrument Panel

Interior Lights

Joysticks, Left And Right Hand

Key Switch

Levelling Controls, Joysticks

Levelling Electronic Adjustment Procedure

Lights, Interior

Lights, Service

Load Sensing, Operating Tips

Machine Preparation

Master Alarm

Moving Instructions

Operating Machine

Operating Tips With Load Sensing

Operator’S Seat

Pictogram Descriptions

Pilot System Interlock Switch (Front Door)

Pilot System “Off *- Push Button Switch

Pilot System Reset – Push Button Switch

Power Engine Door – Switch

Removal Of Anti-Corrosion Spray (If Applicable)

Saw – Switch

Service Access Doors

Service Lights

Stereo AM/FM Radio/CD

Swing Brake – Switch With Light

Swing Control, Joystick

System Fuses And Relays

Throttle Switch

Track Components

Track Drive, Foot Pedals

Track, Low/Drive – Switch With Light

Travelling (Boom Raised)

Travel Speed Control Lever

Warm Up Mode

Warning Lights;

Work Lights Switch

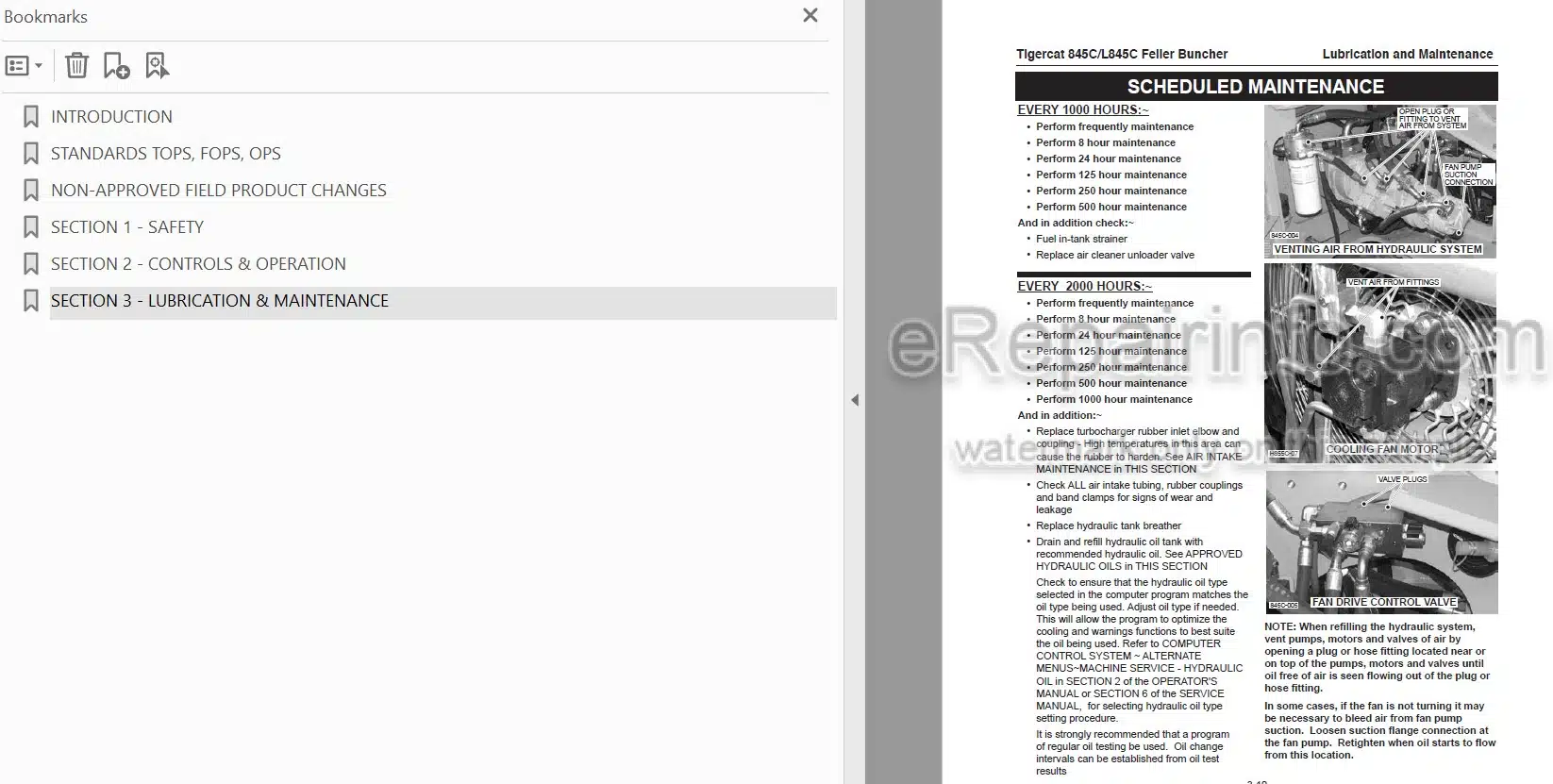

-LUBRICATION & MAINTENANCE

Air Conditioning System, Checking The System

Air Intake Maintenance

Approved Hydraulic Oils

Case Drain Strainers

Emergency Exits, Check Monthly

Engine Air Cleaner

Engine Air Cleaner Maintenance

Er Boom System

Filters

Fire Prevention

Fuel Tank

Hydraulic Oils, Approved

Hydraulic Tank Pressurization Instructions

Lubrication Points Diagram Leveller

New Machine Maintenance

Oil Sample Collection Procedures

Oil Sampling Program

Pressure And Speed Settings

Pressure Setting Procedures

Preventive Maintenance Schedule

Scheduled Maintenance

Swing Drive Lubrication

Torque Chart

Torque Chart, General

Torque, Fluid Connections

Track Operation And Wear Prevention

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.