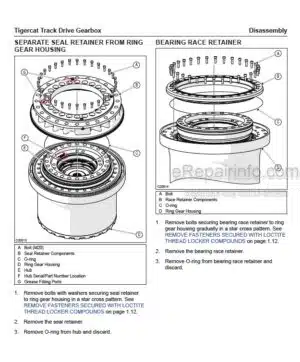

Factory Operator And Service Manual For Tigercat Bar Saw Felling Head. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 190

Number: 38486AENG (may 2017)

Bookmarks

Searchable

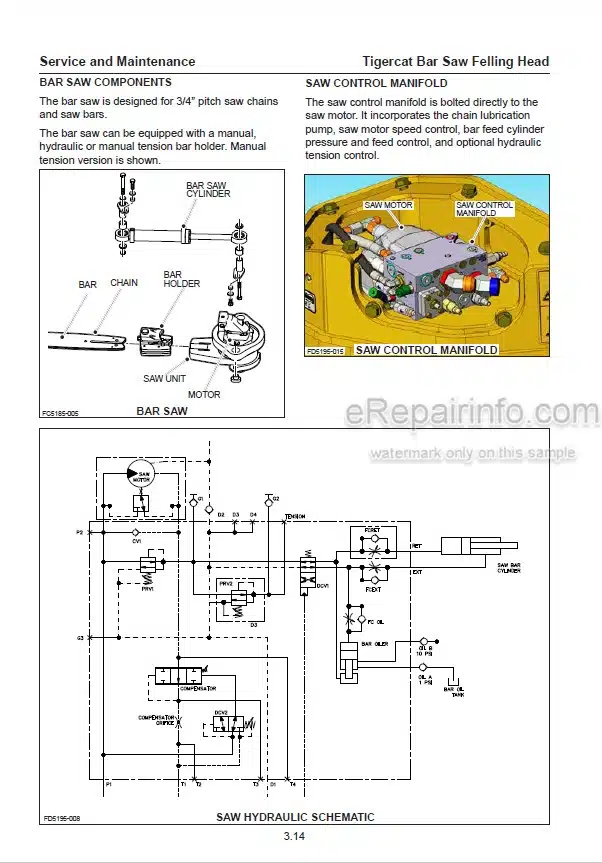

Hydraulic Diagrams

Model

Tigercat Bar Saw Felling Head

Serial Number 51850101 To 51850500

Serial Number 51950101 To 51950500

Contents

INTRODUCTION

NON-APPROVED FIELD PRODUCT CHANGES

-SAFETY

Battery Disconnect Switch

Battery Safety

Before Starting

Cab Exits

Cable Assist

Chain Shot

Cooling System

Diesel Exhaust Fluid (DEF)

Emergency Cab Exits

ER Boom System Precautions

Exhaust Fumes

Felling Headdonts

Felling Trees

Fire Prevention

Fluid Injection Injury

Fluid Leaks

General Safety Precautions

Grease Injection Injury

Hazard Zone

Lightning Safety Awareness

Liquid Starting Aid

Loose Clothing Hazard

Machine Stability And Traction

Parking The Machine

Pressurized Hydraulic Tank

Protective Equipment

Refuelling

Safety Hazards – Operating

Safety Hazards – Viton Seals

Safety Interlock Switch On Front Cab Door

Safety Label Locations

Safety Labels

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Servicing Safety Precautions

Signal Words

Welding

Working With Oil

-CONTROLS AND OPERATION

Bar Saw Components

Bar Saw Controls

Bar Saw Operation

Parking The Head Fd5195

Pictogram Descriptions

Shipping Fd5195

Tilt Frame Fd5195

Tilt Frame Lock Bolts Fd5195

-SERVICE AND MAINTENANCE

Approved Hydraulic Oils

Auxiliary Pressure

Bar Saw Components

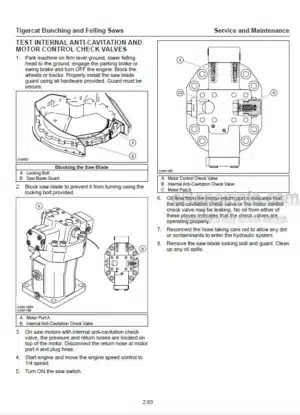

Bar Saw Hydraulic Test Procedure

Chain Lubrication

Chain Tension

Clamp Arms

Cylinder – Assembly Notes And Torques

Fire Prevention

Head Bleed Procedure

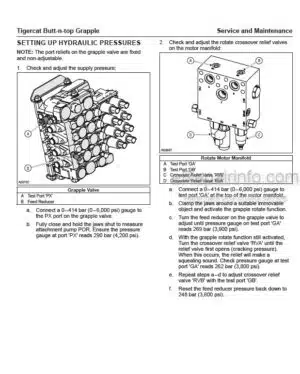

Head Rotate Pressure And Speed Adjustment

Lubrication Schedule

Pressure And Speed Settings

Preventive Maintenance Schedule

Replacing Saw Bar

Replacing Saw Chain

Rotary Manifold Fd5195

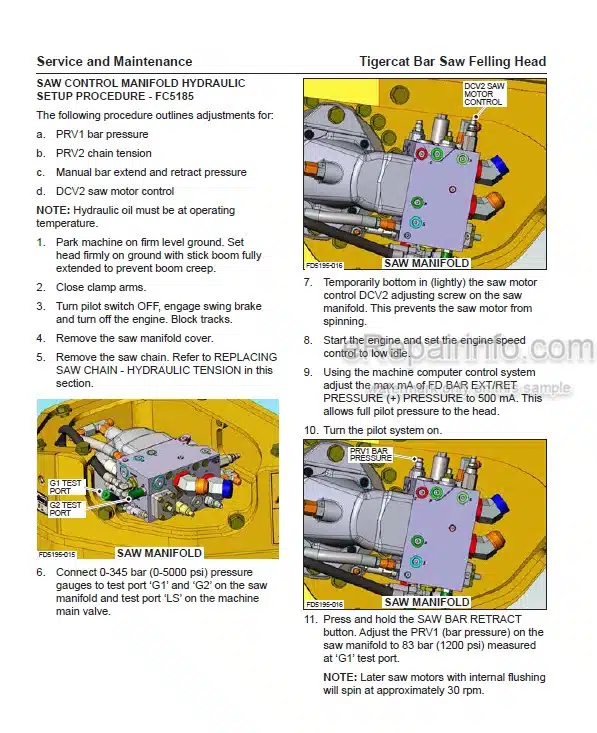

Saw Bar Extend And Retract

Saw Bar Pressure

Saw Control Manifold

Saw Control Manifold Hydraulic Setup Procedure

Saw Main Pressure (Motor Rotate)

Saw Motor Control

Saw Motor Speed Adjustment

Scheduled Maintenance

Tilt Down Speed Adjustment

Tilt Float

Tilt Lock (Optional)

Tilt Up

Tilt Up Pressure And Speed Adjustment

Tools

Tool Size Chart – Bar Saw Assembly

Torque Chart

Torque, Fluid Connections

Torque Specifications – General

Weights Of Commercial Wood

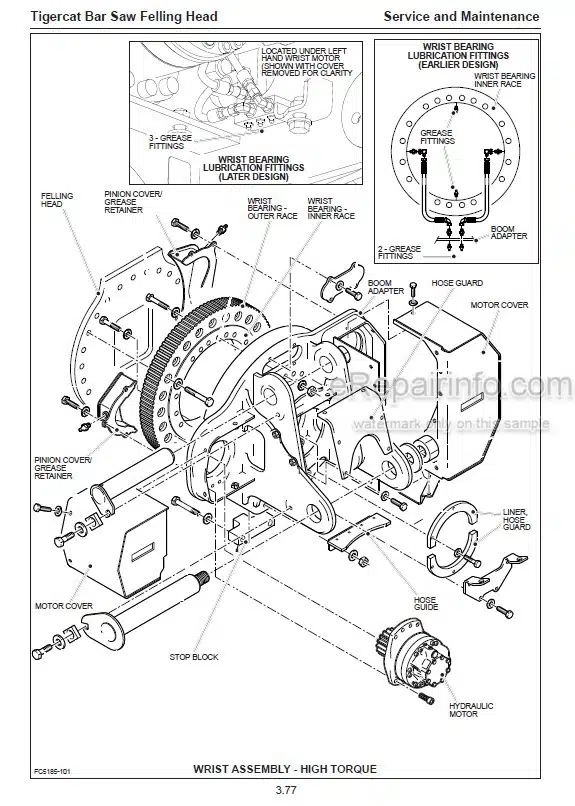

Wrist Assembly – High Torque

Wrist Assembly – Standard Torque

Wrist Bearing Mounting Torque Sequence

Wrist Bearing Seal Replacement

Wrist Bearing Wear Limits

Wrist Control Manifold

Wrist General Setup Procedure

Wrist Hydraulic Circuit Description

Wrist Troubleshooting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.