Factory Operators Manual For Zetor Tractor. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 226

Number: 222.213.403 (january 2019)

Bookmarks

Searchable

Model

Zetor Tractor

Proxima GP 80

Proxima GP 90

Proxima GP 100

Proxima GP 110

Contents

LOCATION OF SERIAL NUMBERS

-SAFETY INSTRUCTIONS FOR USERS

Used Pictograms

General Safety Regulations

Proper Clothing

Starting The Engine

Driving Operation

Risk Of The Tractor Overturning

Transportation Of Persons, Operation

Fire Prevention Principles

Preventive Daily Maintenance

Driver’s Seat

Front Passenger’s Seat Notification

Protection Of Cab Against Aerosols

Level Of External And Internal Noise

The Level Of Vibrations On Driver’s Seat

Aggregation Tractor – Machine/Trailer

Tractors Equipped With Front End Loader

Principles For Operating Tractors Equipped With Front End Loader

Zetor Tractors Used For Work In The Woods

Safety Labels

-PREVENTIVE DAILY SERVICE

Preventive Daily Maintenance

Fuel System Leaks

Engine Oil Level

Cooling System

Windshield Washer Tank

Washer Nozzle

The Liquid Reservoir For Control Of The Clutch

Trailer Brakes

Hydrostatic Steering

Air Cleaner

Cab Filtration

Hitches

Inspection Of Fouling Of Coolers

After Work With Front Implements And In Case Of Cooler Clogging

Tyres And Wheels

Short Functional Test

-ACQUAINTANCE WITH TRACTOR

Safety Cab

Opening Doors From The Outside

Opening The Door From The Inside

Rear Window

Side Window

Emergency Exits

Sun Visor And Hinged Lid Cover

Shelf

Tools Box

Right Rear Panel

Internal Lighting

Rear View Mirrors

Aggregation Opening

Passenger’s Seat

Drivers Seat Sears

Tilt Steering Wheel

Tilting And Protrusion Of Steering Wheel

Heating Control Panel, * Air-Condition

Heating Valve Control (A)

Switch Air-Condition (C)

Air Circulation In Cabin Control (D)

Proper Function Of The Heating And Air-Condition System

Fast Heating Of The Cabin Area

Fast Cooling Of The Space Of The Cabin

Immediately After Cooling The Cabin

Operation Of Heating Or Air-Condition With Tractor’s Work

Heating And Air Conditioning Vents

Heating And Air Conditioning Vents Control

‘Air Filter With Active Carbon

Control Panel On Right Cab Pillar

Wiper And Washer Of The Front Window

Front Wiper Speed Switch

Rear Window Wiper

Panel Of The Instrument Panel

Lights Switch

Switch Of Warning Lights

Lights Switch Between The Grill And The Cabin

Direction Lights, Lower Beam Head Lights, Head Lights And Horn Switches

Switch Box

Switch Box Key In The Position (0)

Switch Box Key In The Position (I)

Switch Box Key In The Position (II)

Manual Throttle

Pedals And Levers

Reversing Lever

Gear Shifting Lever

Road And Reduced Speeds Shifting Lever

PTO Selection Control Lever

Lever Of Shifting Of Speed 540 (Or 540E) And 1,000 Rpm Of The Rear Output Shaft

Lever Of Hand Brake And Hitch For Single-Axle Trailer

Battery Disconnector

Fuel Tank

-INSTRUMENT PANEL

Instrument Panel – Signal Lamps

Instrument Panel – Instruments

Instrument Panel – Buttons

Display Description

Display – Change Of Display

Display – Display Of Air Pressure In The Air-Pressure System Of The Tractor

Display – Warning Of Low Air Pressure In The Air-Pressure System Of The Tractor

Display – Resetting Data

Display – Manual Brake

Display – Service Menu

Service Menu

Display – Indicator Of Service Inspection Intervals

Exceeding The Service Interval

Zeroing (Reset) Of The Indicator Of Service Inspection Intervals

Error Signalling

Display – Error Messages

Description Of The Display Of Error Messages

Current Error Messages Display

Symbols Of Tractor Nodes

Display – History Of Defects

Display – Setting Language Mutation

Display – Backlight Of Display

Display – Setting Of Day And Night Backlight Of The Display

Display – Setting The Automatic Mode Of The Display Backlight

Display – Setting And Calibration

Travel Speed Calibration

Display – Machined Area

Machined Area Menu

Processed Area – User Selection

The Processed Area – Setting Of The Width Of Aggregation

Machined Area Record

Work Area Counter

Instrument Panel – Warning

Replenish Fuel

High Temperature Of The Cooling Liquid

Signalling Of Driver’s Seat

-OPERATION

Starting The Engine

Non-Permitted Starting

If You Do Not Succeed In Starting The Engine

Ignition System Failure Signalization

Coolant Heater

Starting The Engine While Using Coolant Heater

Immediately After Start

Engine Heating

Error Signalling

Drive Away

Diesel Particle Filter

Diesel Particle Filter – System Failures Signalization

Diesel Particle Filter Failure Codes

Diesel Particle Filter Regeneration

Gear Shifting

Reversing Lever

Shifting Road And Reduced Speeds

Torque Multiplier

Indication Of The Multiplier Function

Gear Shifting From Lower To Higher Gears

Gear Shifting From Higher To Lower Gears

Travelling Up The Slope

Travelling Down The Slope

Differential Lock

Control Of Front Driving Axle

Driving With Engaged Front Driving Axle

Manual Brake – Signalization

Foot Brakes

Emergency Braking

Brakes Of Trailers And Semi-Trailers

Connection Of The ABS System Of The Trailer Or Semi-Trailer

The Button For Temporary Deactivation Of Brakes Of The Trailer Or Semi-Trailer

Warning Indication Of Air Pressure Drop

Air Brakes Of Trailers And Semi-Trailers

One-Hose And Two-Hose Brakes

One-Hose Brakes

Two-Hose Brakes

Hydraulic Brakes Of Trailers

Connecting And Disconnecting Quick Couplings Of Trailer Hydraulic Brakes

The Socket For Connection Of The Electrical Installation Of The Trailer Or Semi-Trailer

Stopping The Engine

Leaving The Tractor

Warning Signalization Of Hydrostatic Steering Failure

Important Warnings

-RUNNING-IN THE TRACTOR

General Principles Of New Tractor Run-In In First 100 Hours Of Operation

In First 10 Hours Of Operation

From 100 Hours Of Operation

-TRANSPORT USE

Front Hook

Multistage Adjustable Suspension

Height Adjustment And Disassembly Of The Cbm Stage Hitch

Automatic Mouth Of The Cbm Stage Hitch

Modular System Of Hitches For Trailers And Semi-Trailers

Swinging Draw-Bar Console Module

Swinging Draw-Bar Console With A Fixed Pin Module

Console With A 0 80 Ball Module

Towing Bar

Hitch For A Single-Axle Cbm Semi-Trailer

-RUNNING-IN THE TRACTOR

General Principles Of New Tractor Run-In In First 100 Hours Of Operation

In First 10 Hours Of Operation

From 100 Hours Of Operation

-TRANSPORT USE

Front Hook

Multistage Adjustable Suspension

Height Adjustment And Disassembly Of The CBM Stage Hitch

Automatic Mouth Of The CBM Stage Hitch

Modular System Of Hitches For Trailers And Semi-Trailers

Swinging Draw-Bar Console Module

Swinging Draw-Bar Console With A Fixed Pin Module

Console With A 0 80 Ball Module

Towing Bar

Hitch For A Single-Axle CBM Semi-Trailer

Coupling Of A Single-Axle Trailer

Uncoupling Of A Single-Axle Trailer

Hook Of The Mounting For A Single-Axle Trailer

Coupling With A Trailer Or Semi-Trailer

Maximum Permissible Vertical Static Load Of Hitches For Trailers And Semi-Trailers

-PTO DRIVE OF AGRICULTURAL MACHINES

Work With PTO Shaft

Setting Of The Display Of The Rear PTO Shaft Speed

Display Of Revolutions Of PTO Shafts

Replaceable End Points Of Rear PTO Shaft

Control Elements Of PTO Shafts

The Rear PTO Shaft – The Gear Shift Lever Of Dependent And Independent Revolutions

The Rear PTO Shaft – The Gear Shift Lever Of Revolutions Of The PTO Shaft

The Buttons For Activation Of PTO Shafts

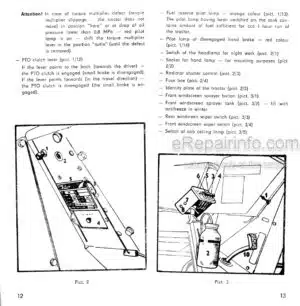

Automatic Disengagement Of PTO Clutch

Setting Automatic Disengagement Of PTO Shaft Clutch – Display Description

Setting The Limits Of The Automatics Of The Three-Point Hitch

Automatic Disengagement Of PTO Shaft Clutch – Return To Basic Setting

Work With Automatic Disengagement Of PTO Shaft Clutch

Facilitating Connection Of Joint Shaft Of An Aggregated Machine To The Tractor

Working Modes Of PTO Shafts

Activation Of The Rear PTO Shaft – Independent Revolutions – Common Working Mode

Activation Of The Rear PTO Shaft – Independent Revolutions – Stationary Working Mode

Deactivation Of The Rear PTO Shaft – Independent Revolutions

Switching On The Rear PTO Shaft – Dependent Revolutions

Front PTO Shaft

Activation Of The Front PTO Shaft – Common Working Mode

Activation Of The Front PTO Shaft – Stationary Working Mode

Deactivation Of The Front PTO Shaft

Maximum Transferred Output

Drive Of Machines With Greater Inertia Masses

-HYDRAULIC SYSTEM

Hydraulic System

Hydraulics Control Panel

Amount Of Oil Taken From Outer Hydraulic Drives

Connecting And Disconnecting Quick-Couplers

Quick-Couplings With Drip Collection

Connecting Machines And Tools To External Hydraulic Circuit

Front Outlets Of The External Hydraulic Circuit

Control Of The External Hydraulic Circuit Front Outlets

-MECHANICAL HYDRAULICS

Ways To Regulate Inner Hydraulic Circuit

Controlling The Inner Hydraulic Circuit

Free (Floating) Position

Adjustable Stop

Three-Point Hitch Lowering Speed Control

Hydraulic System Sensitivity Control

Position Regulation Of The Lifting Of The Rear Three-Point Hitch

Power Regulation Of The Lifting Of The Rear Three-Point Hitch

Mixed Regulation Of Lifting The Rear Three-Point Hitch

Exterior Rear Hydraulic Arms Controls

Outer Hydraulic Circuit

Outer Hydraulic Circuit Controls

Locking Control Levers

Different Functions Of Outer Hydraulic Circuit Control Levers

-ELECTRO-HYDRAULIC SYSTEM

Control Element Functions

Equipment ‘off’

Blocking Cancellation

Quick Sinking

Transport Of Implements

Stop Position

Vibration Compensator (Damper)

Limitation Of The Upper Position Of The Three-Point Hitch

Lowering Speed

Free Position

Setting The Control Of Three-Point Hitch

Manual Setting Of Control Of Three-Point Hitch

Automatic Control Of Three-Point Hitch

Using The Rear Control

External Control Buttons Of The Electro-Hydraulic System

Indication Of Ehr-B Errors

Description Of Minor Errors Of The Ehr-B Electro-Hydraulic System

Outer Hydraulic Circuit

Outer Hydraulic Circuit Controls

Locking Control Levers

Different Functions Of Outer Hydraulic Circuit Control Levers

-HITCHES

Rear Three-Point Hitch

Safety Principles Of Working With The Three-Point Hitch

Height Adjustment Of The Lifting Draw-Bars

Fixed And Free Position Of The Lower Hydraulic Draw-Bars

Limiting Draw-Bars

Upper Pull Rod

Selection Of Holes In The Bracket

Lower Draw Bar With Slipping Out End Pieces

Lower Draw Bar With CBM Hooks

Securing Lower Draw Bars With CBM Hooks

Front Three-Point Hitch

Controlling Front Three-Point Hitch

Adjusting The Lowering Rate Of The Front Three-Point Hitch

Hydraulic Lock Of The Front Three-Point Hitch

Working And Transport Position Of The Front Three-Point Hitch

Driving With Agricultural Machines Attached To The Front Three-Point Hitch

-WHEEL TREAD CHANGE

Change Of Front Wheels Track With Front Drive Axle

Gauges Of The Front Wheels Of The Front Drive Axle Of The Tractors Equipped With Screwed Footer Discs

Possible Adjustable Tracks Of The Front Wheels Of The Front Driving Axle Of The Tractors

Front Wheels Track Of Front Drive Axle In Tractors Equipped With Non-Removable Discs

Front Wheels Toe-In

Adjustment Of Toe-In Of The Wheels Of The Front Driving Axle

Setting Wheel Stops With Front Drive Axle

Front Drive Axle Fenders

Rear Wheels Wheel Track

Gauges Of The Tractor Rear Wheels Equipped With Screwed Footer Discs

Rear Wheel Track Change

The Gauges Of The Tractor Rear Wheels Equipped With Solid Discs

-ADDITIONAL WEIGHTS

Weights In Front Of The Bonnet Mask

Weights Of The Front Three-Point Hitch

Weights Of Rear Wheels

Valve For Filling Tyre Tubes With Liquid

Chocking Of Front Wheels

Procedure Of Filling The Tyres With Liquid

Procedure Of Draining Liquid From The Tyres

Antifreeze Solution For Tyre Filling

-ELECTRIC INSTALLATION

Basic Service Information

Accumulator Battery

Battery Disconnector

Accumulator Battery Maintenance

Alternator

Alternator Maintenance

Electric Installation Overload

Fuse Panels

Checking The Adjustment Of The Front Grill Headlights

Adjusting The Front Grill Headlights

List Of Lamps

-TRACTOR MAINTENANCE

Service Inspections

Steps Performed Daily Before The Start Of Work

Steps Performed Every 50 Hours Of Work

Steps Performed Every 100 Hours Of Work

Steps Performed Every 500 Hours Of Work

Steps Performed Outside The Interval Of 500 Hours Of Work

Monthly Performed Actions

Filling And Filter Replacement

Fuels, Coolants And Lubricants Used – Amounts

Zetor Service Fillings

Motor Oils

Oil In The Gearbox And Final Drivehousing

Oil In The Rear Axle Gantries

Oil For The Front Driving Axle

Oil For The Hydrostatic Steering Of The Tractors

Specification Of Oils For Zetor Engines Equipped By Diesel Particle Filter

Specification Of The Oil For The Gearbox Housing And The Final Drive Housing

Specification Of The Oil For The Portals

Specification Of Oil For The Front Driving Axle

Specification Of Oil For The Tractor Hydrostatic Control System

Other Recommended Service Fillings Tested On Zetor Tractors

Oils For Zetor Engines Which Are Equipped With Diesel Particle Filter

Oil In The Gearbox And Final Drivehousing

Oil In The Rear Axle Gantries

Oil For The Front Driving Axle

Oil For The Hydrostatic Steering Of The Tractors

Front Pto Oil

Plastic Lubricant For The Tractor

A/C Coolant

Liquid For The Cooling System Of The Tractors

Liquid For Control Of The Travel Clutch

Fuel For Zetor Engines Which Are Equipped With Diesel Paricle Filter

Tractor Greasing Plan

Safety Instructions For Lubrication Of The Tractor

Solid Front Drive Axle

Hitch For A Single-Axle Semi-Trailer

Front Three-Point Hitch

Three-Point Hitch

Hitch Mouth For A Trailer

Upper Linkage Bracket

Pin Of Coupling Switching Off

Reversion Lever Pin

Technical Maintenance Of The Tractors After A General Overhaul Of The Main Groups

-MAINTENANCE INSTRUCTIONS

Front Bonnet Opening

Checking Oil Levels In Engine

Draining Oil From Engine

Replacing Full-Continuous Motor Oil Filter

Pouring Oil To Engine

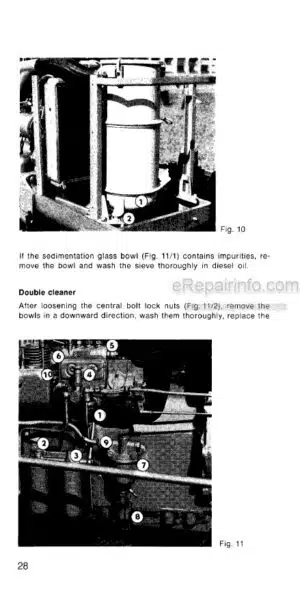

Fuel Filter Element Replacement

Fuel System Venting

Maintenance Instruction Of Dry Air Filter

Air Cleaner Disassembly

Main Air Filter Element Regeneration

Replacing Dry Filter Locking Element

Back Assembly Of Air Filter Elements

Checking Amount Of Oil In Hydrostatic Steering Tank

Replacing Oil And Hydrostatic Steering Filter Element

Venting Hydraulic Circuit Of Hydrostatic Steering

Replacing The Hoses Of Hydrostatic Steering

Replacing Coolant

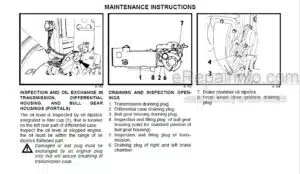

Check And Replacement Of Oil In Gearbox, Axle Drive And Rear Axle Portals

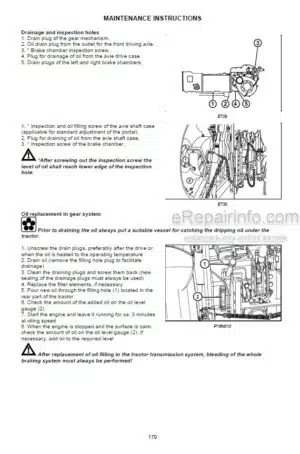

Drainage And Inspection Holes

Oil Replacement In Gear System

Changing Suction Filter

Replacement Of The Transmission Oil Cleaner Element With Hydraulic Pump Suction Filter

Replacement Of Oil Filter Element Of Pushing Filter Of The Brake System

Gearbox Distributor – Replacement Of Oil Cleaner Cartridge

Front PTO

Filling, Controlling And Draining Hole Of Oil Of Front Drive Axle

Filling, Controlling And Draining Hole Of Oil Of Front Wheels Reducers

Addition Of The Liquid For Control Of The Clutch

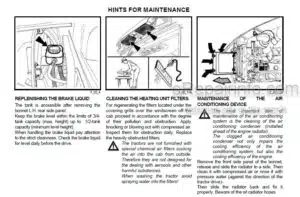

Cleaning The Heating Filters

Air Filter With Active Carbon

Carbon Filter Installation Instructions

Air-Conditioning Maintenance

Draining Condensate From The Air Reservoir

Checking The Air Systems For Leaks

Working Pressure Of Air Brakes

Maintenance And Treatment Of Tyres

Tractor Shutdown And Recommended Points For Tractor Lifting

Diesel Particle Filter Maintenance

-ADJUSTMENT

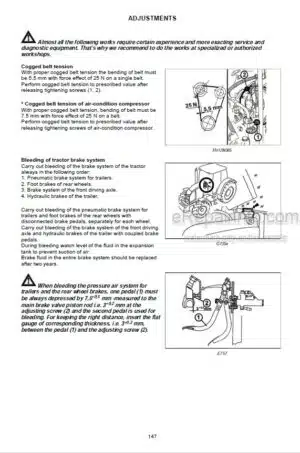

Cogged Belt Tension

Bleeding Of Tractor Brake System

Check And Adjustment Of Service And Parking Brakes

Service Brake Adjustment

Parking Brake Adjustment

Bleeding Of Hydraulic Clutch Circuit

Adjustment Of Hitch For Single-Axle Trailers

Adjustment Of Bowden Cable

-MAIN TECHNICAL PARAMETERS

Main Tractor’s Parameters (Mm)

Technical Data Of Engines

Permitted Maximum Load Of Front Axle (Kg)

Permitted Maximum Load Of Rear Axle (Kg)

Permitted Maximum Weight Of Set ‘tractor + Mounted Machine’ (Kg)

Manoeuvrability Condition

Front Tires Steerability

Change Of The Load-Bearing Capacity Of The Front Tyres (%)

Bearing Capacity Of Rear Tires

Change Of The Load Capacity Of The Rear Tyres (%)

Permitted Combinations Of Wheels For Tractors

Performance On Rear PTO Shaft

Lifting Force Of The Three-Point Hitch

Tensile Force

Forward Travelling Speed Of The Tractor – 40 Km/H

Backward Travelling Speed Of The Tractor – 40 Km/H

Rear Independent PTO Shaft Rotation

Speed Of The Zuidberg Front PTO

Clearance-Circle And Turning Circle Diameter

Calculation Of Tractor Load Limit

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet