Factory Operating Maintenance Instructions For Bomag Single Drum Roller. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 210

Number: 00807641 (august 2015)

Bookmarks: Yes

Searchable: Yes

Model

Bomag Single Drum Roller

BW226DH-4IBVC

S/N 101 585 01 1001 >

S/N 101 585 44 1001 >

Contents

-INTRODUCTION

Foreword

Machine Type Plate And Engine Type Plate

-TECHNICAL DATA

Noise And Vibration Data

-SAFETY REGULATIONS

Information And Safety Stickers/Decals On The Machine

-DISPLAY AND CONTROL ELEMENTS

General Notes

Description Of Indicators And Control Elements

Display And Control Elements Variocontrol

Description Of Indicating And Control Elements Variocontrol

Line Graph Automatic (EVIB)

Description Of Line Diagram Automatic (EVIB)

Line Graph Manual (EVIB)

Description Of Line Diagram Manual (EVIB)

Bar Diagram (EVIB)

-OPERATION

General

Tests Before Taking Into Operation

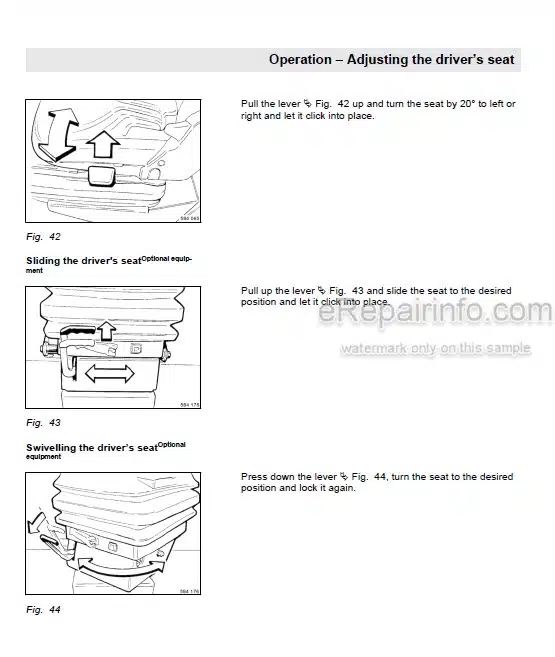

Adjusting The Driver’s Seat

Electronic Immobilizer Optional Equipment

Starting The Engine

Driving The Machine

Stopping The Machine, Operating The Parking Brake

Using The Machine For Rock Crushing

Shutting Down The Engine

DPF-Regeneration

Switching The Vibration On And Off

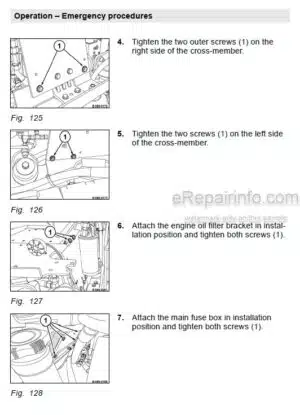

What To Do In Events Of Emergency

Operating The Heating/Air Conditioning System Optional Equipment

Operating The Hood

LC-Display – Changing Display Fields

LC-Display – Changing Settings

BVC/BTM05 Settings Before Start-Up

Variocontrol, Selecting The Operating Mode

Measuring Pass With Variocontrol

Finishing Compaction Of A Track

Printing Measuring Data After Completing Compaction

Teaching Distance Pulses

Amplitude Limitation (BVC Only)

Changing The Paper Roll In The Measuring Value Printer Only BTM Prof

Changing The Printer Ribbon In The Measuring Value Printer Only BTM Prof

Towing In Case Of An Engine Failure

Loading/Transport

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

Every 10 Operating Hours

Every 250 Operating Hours

Every 500 Operating Hours

Every 1000 Operating Hours

Every 2000 Operating Hours

Every 4000 Operating Hours

Every 6000 Operating Hours

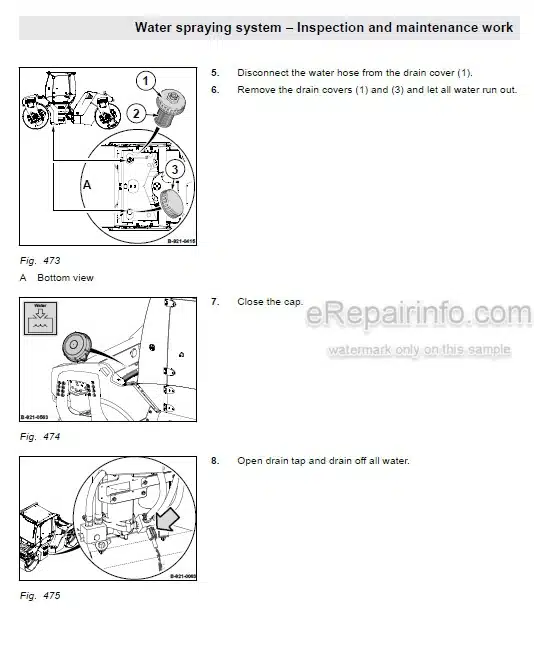

As Required

-TROUBLE SHOOTING

Preliminary Remarks

Starting The Engine With Jump Leads

Fault Code Display

Reading Out Faults BVC/BTM05

Fuse Assignment

Engine Faults

-CABIN ASSEMBLY BEFORE INITIAL COMMISSIONING

Preparations

Cabin Assembly

Final Function Tests And Checks

-DISPOSAL

Final Shut-Down Of Machine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet