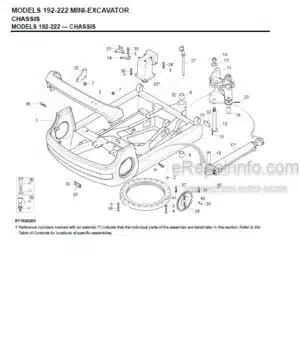

Factory Service Manual For Gehl And Mustang Skid Steer Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 366

Issued: march 2020

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Gehl Skid Steer Loader

R135 GEN: 2

R150 GEN: 2

R165

Mustang Skid Steer Loader

1350R NXT2

1500R NXT2

1650R

Contents

-INTRODUCTION

Safety Symbol and Signal Words

Contents and Use of this Manual

Machine Orientation

Proper Machine Use

Service and Registration

Fields of Application

Using Attachments

Vibration Information

Fire Extinguisher Location

Manufacturer Information

Indicator and Operation Symbols

-SAFETY

Safety Symbol and Signal Words

Mandatory Safety Shutdown Procedure

Safety Reminders

Crystalline Silica Exposure

Safety Decals

-SAFETY EQUIPMENT

Guards and Shields

Operator’s Position

Safety Interlock System (Hydraloc)

Parking Brake

ROPS/FOPS

Rear Window Emergency Exit

Lift Arm Support

Battery Disconnect Switch (Option)

-INDICATORS AND CONTROLS

Control Keypad

Accessory Keypad Indicators/Buttons

Optional Lights/Lockout Keypad Indicators/Buttons

Information Center Electronic Display

Controls

Two-Speed Drive (Option)

Lift Arm Float

Hydraglide™ Ride Control System

Beacon/Position/Work Lights

HVAC (Optional)

Windshield Wiper/Washer

Dome Light

Accessory Plug

Battery Disconnect Switch (Option)

Attachment Mounting

Auxiliary Hydraulic System

-OPERATION

Before Starting the Engine

Starting the Engine

Run-In Period

Stopping the Machine

Engine Stalling

Parking the Machine

Brake Release Operation (Option)

Jump-starting

Travel Drive Operation

Transport on Public Roads

Lift Arm Operation

Changing Attachments

Self-Leveling (Option)

Using Buckets

Using Pallet Forks

Loading and Transporting the Machine on a Transport Vehicle

Towing

Lifting the Machine Using a Crane or Hoist

Diesel Particulate Filter (DPF) Regeneration Procedures (DPF Models)

-MAINTENANCE

Maintenance Schedules

Maintenance Log

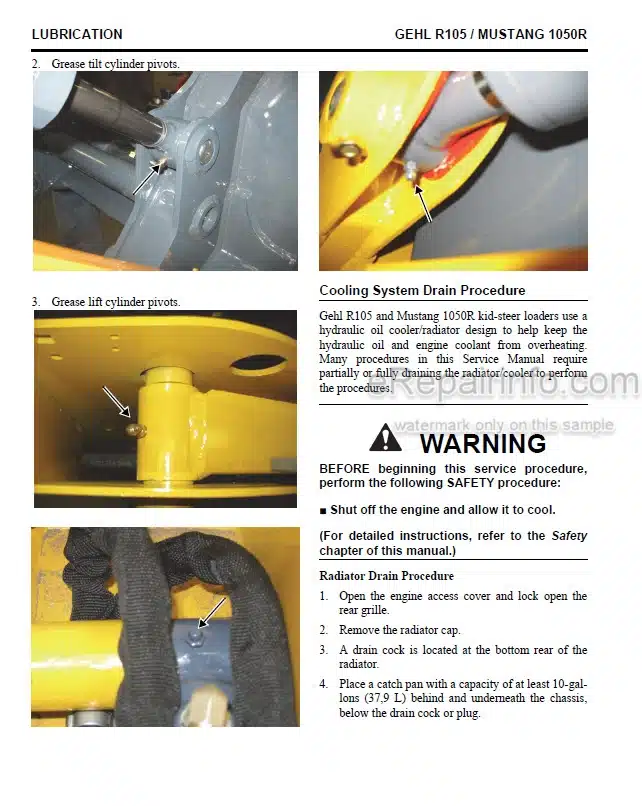

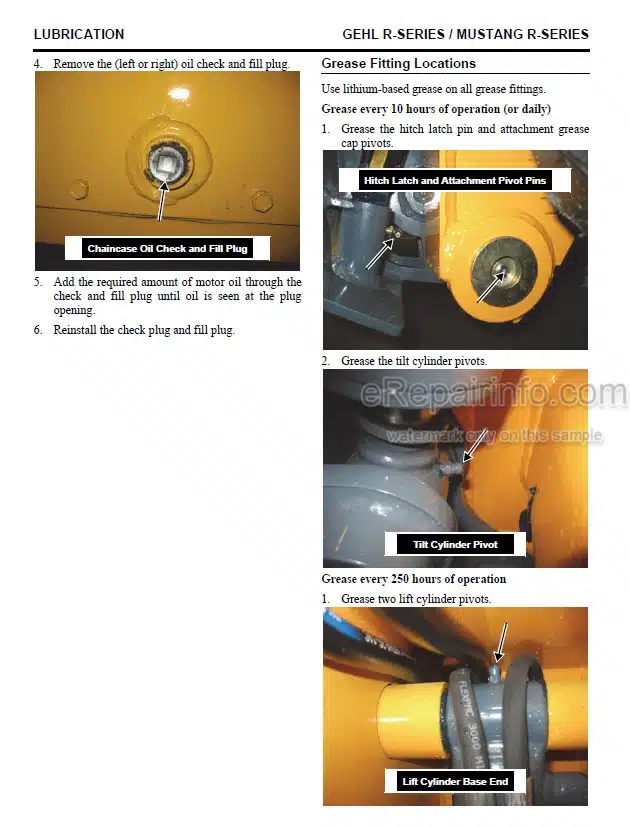

General Lubrication

Removing Foreign Material

Tilting the ROPS/FOPS

Lifting the Machine

Engine Maintenance

Fuel System Maintenance

Engine Air Cleaner

DPF Service (DPF Models)

V-Belt Maintenance

Cooling System

Hydraulic System

Cab Heater Filter Replacement

Hydraulic Hose Maintenance

Chaincases

Seat and Restraint Bar Switches

Bucket Cutting Edge

Wheel Nuts

Tires

Electrical System

Windshield Washer Reservoir

Long-Term Storage

Final Shutdown / Decommissioning

-HYDROSTATIC SYSTEM

Introduction

Charge Pressure Test and Adjustment

Hydrostatic Pump Relief Valves

Hydrostatic Pump Removal and Installation

Hydrostatic Pump Drive Coupling Removal and Installation

-DRIVE SYSTEM

Introduction

Drive Chain Adjustment

Axle Housing Assembly Removal and Installation

Axle and Wheel Bearing Disassembly/Assembly

Drive Chain Removal and Installation

-CONTROLS

Drive System Mechanical Control Linkage

Neutral Centering

Control Handle Position Adjustment

Control Linkage Tracking Adjustment

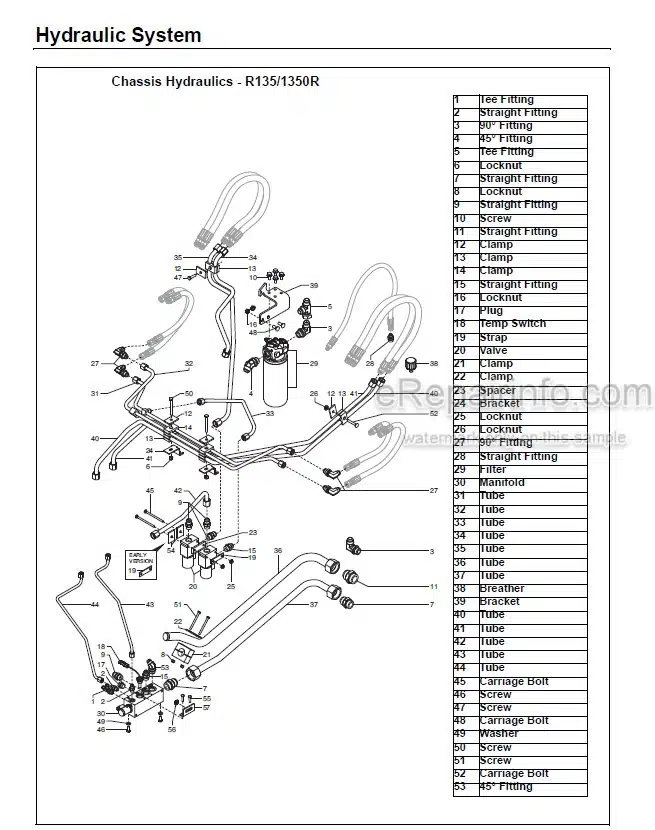

-HYDRAULIC SYSTEM

Introduction

General Hydraulic Service Notes

Pressure Test and Adjustment

Tilt Cylinder Test

Self-Leveling Valve Test

Self-Leveling Valve Adjustment

Lift Cylinder Test

Solenoid Valve Test

Solenoid Valve Disassembly/ Reassembly

Hydraglide Ride Control Solenoid Test

Hydraulic Cylinder Disassembly/ Assembly

Main Control Valve

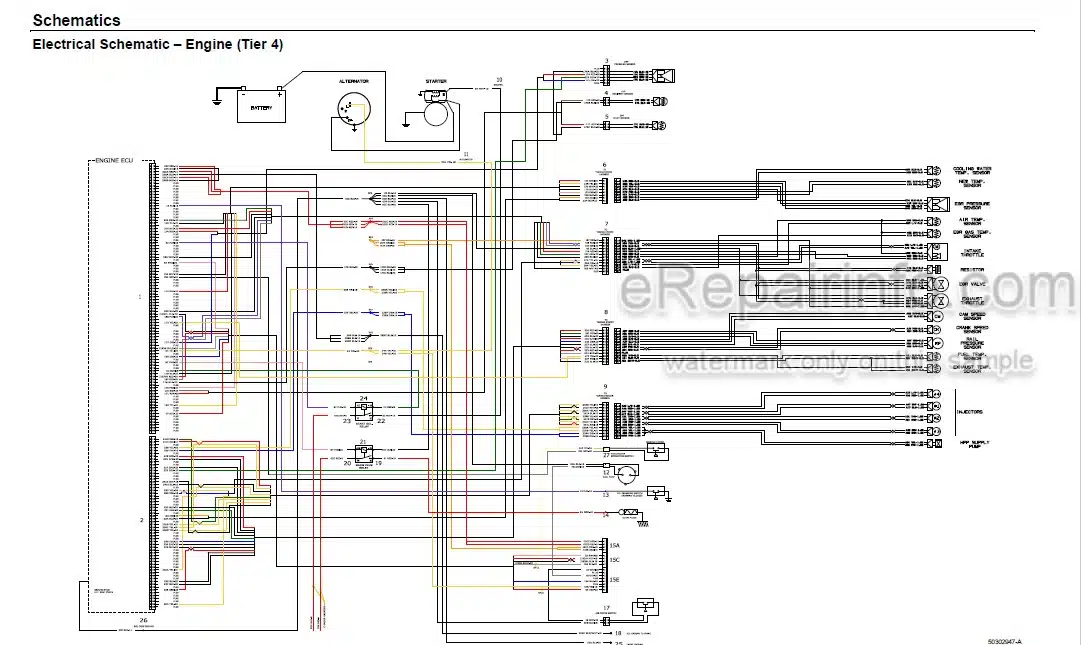

-ELECTRICAL SYSTEM

Power Distribution

Start/Glow Solenoid Test

Control Modules

J1939 Data Connector

Electrically-Controlled Standard Auxiliary Hydraulics Troubleshooting

Electronic Throttle Test

Main Control Unit LEDs/Pins Description

Controller Area Network (CAN) Functional Detail

Work Light Bulb Replacement

Dome Light Bulb Replacement

Battery Removal/Installation

-LIFT ARMS AND ROPS/FOPS

Lift Arm Bushing Replacement

Lift Arm Stop Installation and Adjustment

R150/1500R, R165/1650R Lift Cylinder Removal/Installation

R135/1350R Lift Cylinder Removal/Installation

R150/1500R. R165/1650R ROPS/ FOPS Removal/Installation

R135/1350R ROPS/FOPS Removal/Installation

ROPS/FOPS Rear Window Removal and Installation

-MODELS R165/1650R TIER 4 ENGINE REMOVAL/INSTALLATION

Model R165/1650R Engine Removal

Model R165/1650R Engine Installation

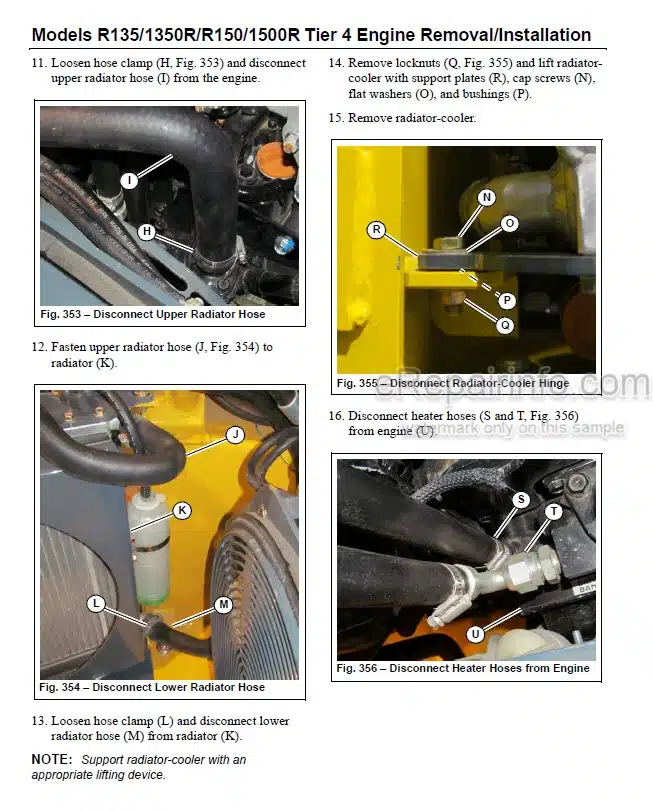

-MODELS R135/1350R/R150/1500R TIER 4 ENGINE REMOVAL/INSTALLATION

Models R135/1350R/R150/1500R Engine Removal

Models R135/1350R/R150/1500R Engine Installation

-TROUBLESHOOTING

Engine Troubleshooting

Indicator Lamp Troubleshooting

Seal and Hose Troubleshooting

Hydraulic System Troubleshooting

Hydrostatic Drive System Troubleshooting

Electrical Troubleshooting

Error Codes

Hydraulic Schematic

Electrical Schematic

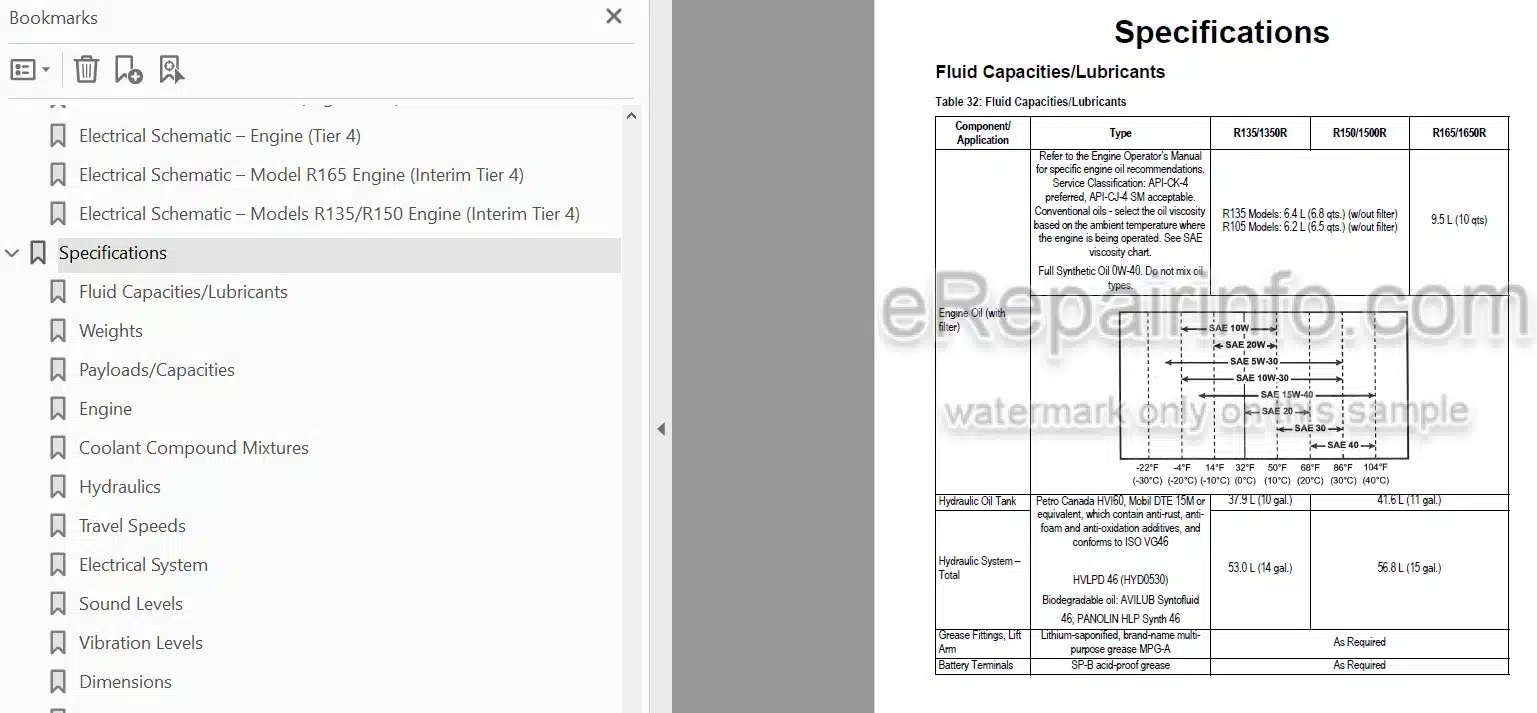

-SPECIFICATIONS

Fluid Capacities/Lubricants

Weights

Payloads/Capacities

Engine

Coolant Compound Mixtures

Hydraulics

Travel Speeds

Electrical System

Sound Levels

Vibration Levels

Dimensions

Features

Common Materials and Densities

INDEX

TORQUE SPECIFICATIONS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.