Factory Technical Manual For John Deere Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 304

Number: SP2254REN

Hydraulic Diagrams: Yes

Model

John Deere Comeco Loader

2254

Contents

-SAFETY RECOMMENDATIONS

Safety and You

Operation Safety

Service Safety

Safety in Your Service Area

Safety when Cleaning or Storing

Safety Nevers

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Protect Bystanders

Use Handles and Steps

Prevent Machine Runaway

Avoid Exhaust Fumes

Keep Riders off Machine

Handle Fuel Safely—Avoid Fires

No Hands Through Steering Wheel

Safely Service Cooling System

Prepare For Emergencies

Wear Protective Clothing

Use Safety Lights and Devices

Practice Safe Maintenance

Avoid High Pressure Fluids

Use Caution on Hillsides

Stopping and Parking

Service Tires Safely

Avoid Electrical Power Lines

Avoid Contact with Moving Parts

Dispose of Waste Properly

Fire Prevention

-SPECIFICATIONS

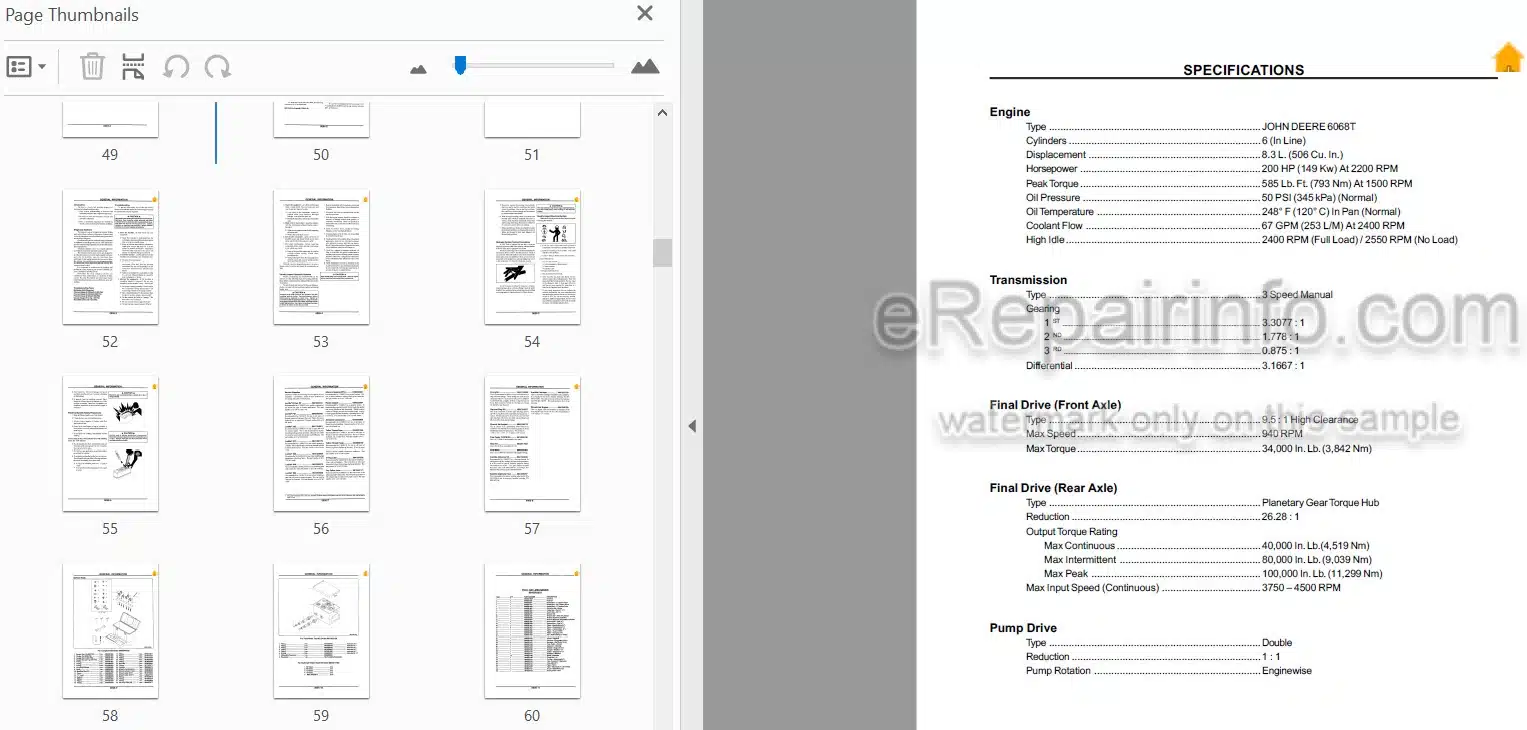

Engine

Transmission

Final Drive (Front Axle)

Final Drive (Rear Axle)

Pump Drive

Double Vane Pump

Single Vane Pump

Variable Displacement Pump (Hydrostatic Transmission)

Variable Displacement Motor (Rear Axle)

Fixed Displacement Motor (Front Axle)

Steering Cylinders

Swing Cylinders

Flex Cylinder

Piler Lift Cylinders

Piler Motor Circuit

Grab Cylinders

Lift Cylinder

Loading System

Control Valve—Boom Lift and Grab

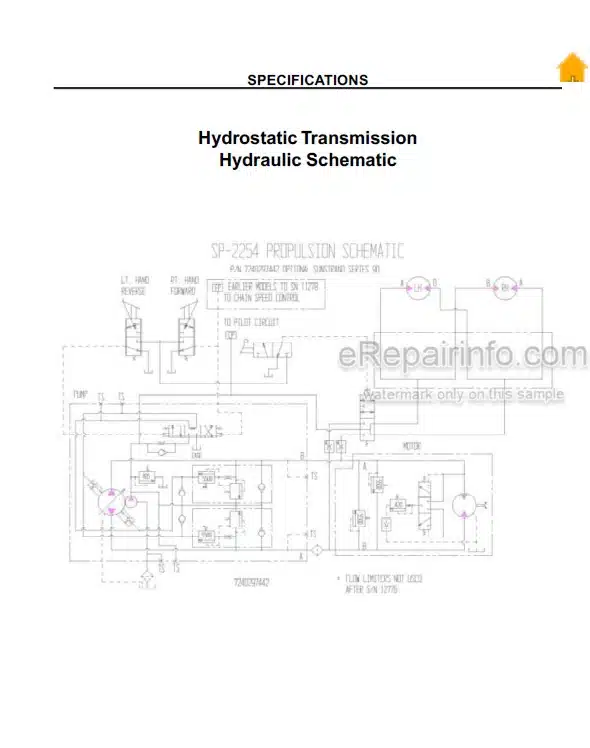

Traction System

Front Axle Motor

Steering System

Piler Chain System

Grab and Lift Schematic

Steer, Swing Flex and Piler Lift Schematic

-CAPACITIES

Engine

Radiator

Transmission

Rear Steering Axle

Front Rigid Axle

Brake Fluid

Hydraulic Tank

Fuel Tank

Torques (Dry)

Tire Inflation Pressure

Pump Drive

-TORQUE SPECIFICATIONS

Torque for SAE Bolts and Nuts in LB-FT

Torque for SAE Bolts and Nuts in NM

Torque for Grade 2 NC Weld Studs

Conversion Factors

Torque for SI (Metric) Bolts and Nuts in NM

Grade or Property Class Head

Marking for SI Bolts

Conversions

Weight Measure

Length Measure

Metric Measurements

Metric to English

English to Metric

Muliplication Factors

Temperature Conversion Chart

Conversion Formulas

-FLUID RECOMMENDATIONS

Engine Coolant Requirements

Antifreeze

Water

Inhibitors (Conditioners)

Filling the System

Ambient Temperature Chart

Sulphur Content

Specifications

Cetane

Cloud Point

Storage And Handling

Hydraulic Oil Chart

Hydraulic Fluid

Gear Oil – Final Drive

Engine Oil

Gear Oil – Pump Drive (if equipped)

Grease

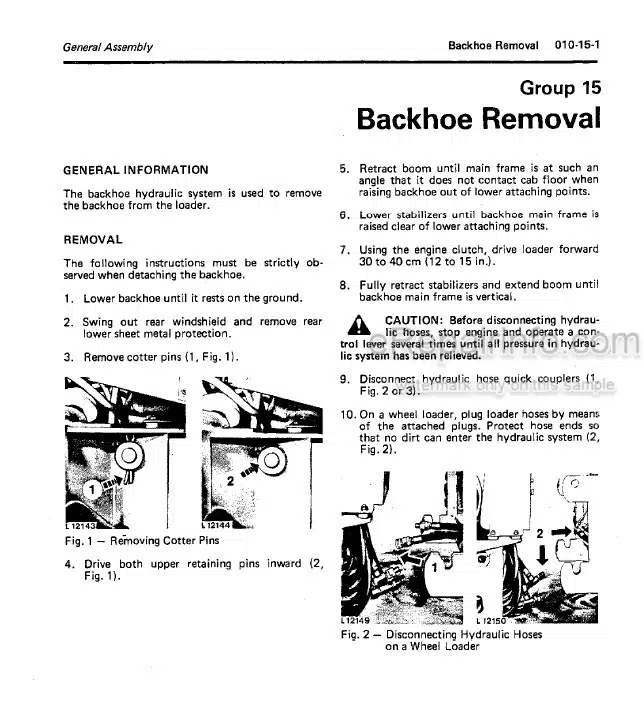

-GENERAL INFORMATION

Introduction

Diagnostic Sections

Troubleshooting Tools

Troubleshooting

Visually Inspect Hydraulic Systems

Hydraulic System Testing Precautions

Visually Inspect Electrical System

Electrical System Safety Precautions

Service Supplies

Service Tools

For Complete Kit Order 0600044329

For Flow Meter Test Kit Order 0601305130

For Optional Tester Hose

Kit Order 0840317083

Tool Set—Mechanics

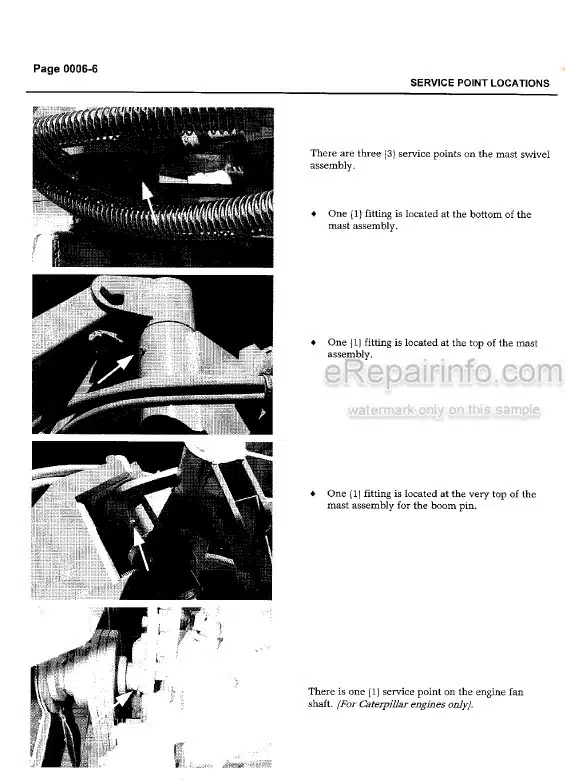

-SERVICE POINTS

Initial Start-Up

First 50 Hours of Operation

Every 10 Hours or Daily Operation

Start Engine

Every 70 Hours of Operation

Every 140 Hours – 2 Weeks of Operation

Every 250 Hours – Monthly Operation

Every 500 Hours – 2 Months of Operation

Every 1000 Hours —4 months of Operation

As Necessary

-HYDROSTATIC SYSTEM

The System Circuit

The Basic Closed Circuit

Case Drain and Heat Exchanger

General Description and Cross Sectional Views

Variable Displacement Pumps

Fixed Displacement Motor

Charge Pump

Charge Relief Valve

System Check Valves

PV with Charge Pump

Charge Pump Components

Pump Charge System

Multi-Function Valves

Pressure Limiter and High Pressure Relief Valves

Bypass Valves

PV Showing Location of Multi-Function Valves

Cross Section of Multi-Function Valve

Circuit Diagram Showing Pressure Control Mechanisms

Auxiliary Mounting Pads

Pump Control Options

Hydraulic Displacement Control (HOC)

PV with Auxiliary Mounting Pad

PV with Hydraulic Displacement Control

Initial Start-Up Procedure

Fluid and Filter Maintenance

System Operation Hot

Neutral Difficult or Impossible to Find

Trans Only Operates in One Direction

System Will Not Operate in Either Direction

Low Motor Output Torque

Improper Motor Output Speed

Excessive Noise and Vibration

System Response is Sluggish

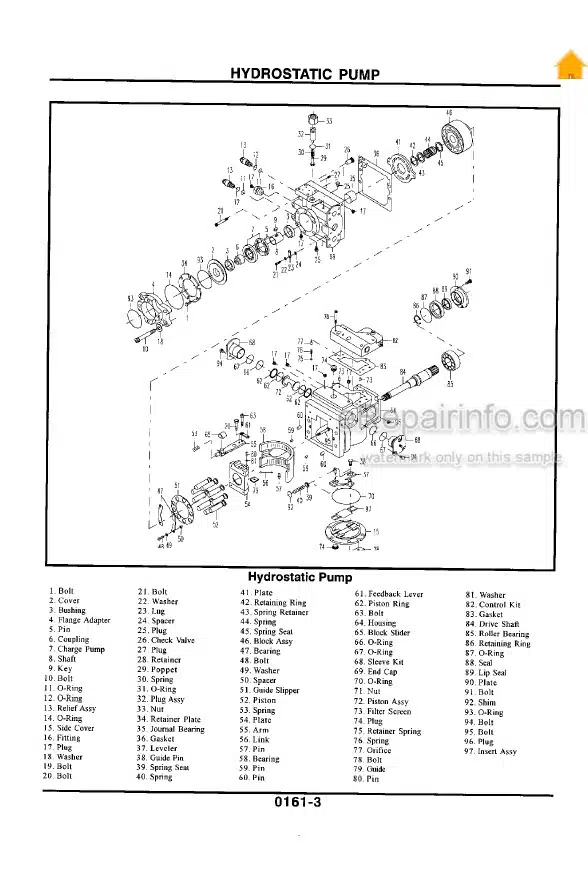

-HYDROSTATIC PUMP

Hydrostatic Pump

Pump Adjustments

Charge Relief Valve Adjustment

Multi-Function Valve Pressure Adjustment

Engaging the Bypass Function

Hydraulic Displacement Control (HOC)

Shaft Seal and Shaft Replacement

Pump Minor Repairs

Multi-Function Valve Cartridges

Charge Relief Valve

Charge Pump

Installing the Charge Pump

Auxiliary Pad Installation

Auxiliary Pad Conversion

Hydraulic Displacement Controls

Displacement Control Components

Displacement Control Filter Screens

Displacement Control Orifice Check Valve

Displacement Control Orifices

Disassembly Procedures for

Variable Displacement Pump

Reconditioning and Replacement of Paris

Assembly Procedures for

Variable Displacement Pump„

0TWO WHEEL/4 WHEEL DRIVE CONTROL VALVES

Control Valve

Theory of Operation

Hydraulic Symbol

Selector Valve

Theory of Operation

Hydraulic Symbol

-FORWARD/REVERSE FOOT PEDAL CONTROL

Forward/Reverse Control Valve

Disassemble and Assemble Foot Controller

Theory of Operation

Solenoid De-energized

Solenoid Energized

-FRONT AXLE MOTOR

Front Axle Ground Drive

Minor Repair—Front Axle Motor

Special Tools

Special Tools

-REAR MOTOR REPAIR

Rear Wheel Motor

Theory of Operation

Repair Instructions

-MINOR REPAIRS

Cover Plate Seals Replacement

Shaft Seal Replacement

Rotary Group Removal

Rotary Group Inspection

Rotary Group Assembly

-MAIN HYDRAULIC SYSTEM

Introduction

The Effect Of Contamination

The Purpose Of Hydraulic Fluid

Component Mechanical Clearances

Definition of Contamination

Component Failure States

Component Contamination Failures

Contaminants In Hydraulic Systems

Hydraulic Oil Storage

Oil Filtration

Hydraulic Components

Aeration and Cavitation

Troubleshooting Tips

All Hydraulic Functions Slow

Hydraulic Function Slow

No Hydraulic Functions

Pump Not Delivering Oil

Insufficient Pressure Buildup In Pump

Pump Making Noise

Slow Steering—Both Directions

High Steering Effort

Directional Control Valve Can’t Get Pressure

Directional Control Valve Delivers Erratic Pressure

No Response When Steering Wheel Is Slowly Turned

Wrong Response To Steering Wheel

Continuous Steering Wheel Rotation

No Response To Steering Wheel

Drive Elements (Coupling, Gears, & Shafts)

Hydraulic Cylinder or Motor

Directional Valves

Flow Control Valves

Accumulators

Pressure Relief Valves

Return Lines

Filters

Coolers

Pressure Gauge

Pressure Line

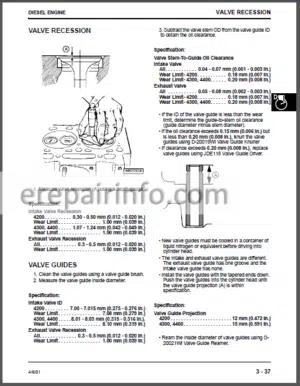

Diesel Engine

Oil Line Leakage

Suction Line – Characteristics

Oil Tank – Hydraulic Fluid

-PUMP REPAIR

Double Vane Pump

Theory of Operation

Maintenance

Service Tools

General Repair

Pump Disassembly

Disassemble Cartridge Kit

Cartridge Kit

Clean and Inspect

Before Assembly

Cartridge Kit Assembly

Pump Assembly

Troubleshooting

Single Vane Pump

Theory of Operation

Maintenance

Service Tools

General Repair „

Pump Disassembly

Clean and Inspect

Before Assembly

Assembly

-DIRECTIONAL CONTROL VALVE

2 Bank Pilot Operated Directional Control Valve

Suggested Too Is

Relief Settings

Overhaul

Valve Bank Disassembly

Tie Bolts

Section Seals

Transition Check

Pilot Operated Section Disassembly

Control Spool & Seals

Spool Disassembly

Preparation of Parts

Cleaning, Inspection and Repair

Assembly

Spool Assembly—Spring Centered

Section Assembly

Transition Check Assembly

Valve Bank Assembly

Solenoid Operated Section Disassembly

Troubleshooting

Oil Leaks At End Of Spool

Spool Does Not Return To Neutral

No Motion, Slow or Jerky Action of Hydraulic System

No Relief Valve Action (High Pressure)

Load Will Not Hold

Load Drops When Spool Is Moved From Neutral To A Power Position

Joystick

Disassembly

Assembly

-CYLINDER REPAIR

Tools and Supplies

Disassemble

Clean And Inspect

Assemble

Cylinder Leak Test

Test Cylinder

Optional Cushion Theory Of Operation

Adjustment

-RELIEF VALVE

Theory of Operation

Repair

Removal

Disassembly

Clean and inspect

Assembly

Erratic Pressure

Low or No Pressure

Excessive Noise or Chatter

-STEERING SYSTEM

Priority Valve

Theory of Operation

Main Spool Repair

Relief Valve Adjustment

Relief Valve Repair

Repair Instructions

Necessary Tools

Disassembly

Clean And Inspect

Reassembly

Troubleshooting

Slow Steering, Hard Steering or Loss of Power Assist

Wander: Loader Will Not Stay In A Straight Line

Drift: Loader Veers Slowly In One Direction

Slip: A Slow Movement Of Steering Wheel Fails to Cause Any Movement of the Steered Wheels

Hang-Up: Temporarily Hard Steering

Soft Steering

Erratic Steering

Free Wheeling: Steering Wheel Turns Freely With No Feeling of Pressure and No Action on Steered Wheels

Free Wheeling: Steering Wheel Turns with Slight Resistance but Results In Little or No Steered Wheel Action

Excessive Free Play At Steering Wheel

Excessive Free Play At Steered Wheels

Binding Or Poor Centering Of Steering Wheel

Steering Valve Locks-up

Steering Wheel Oscillates Or Turns By Itself

Steered Wheels Turn In Wrong Direction When Operator Activates Steering Wheel

-BRAKE SYSTEM

Theory of Operation

Diagnosing Malfunctions

Removal

Repair

Brake Slave Cylinder

Removal

Clean and Inspect

Assembly and Installation

Brake Master Cylinder

Removal

Disassembly and Repair

Assembly and Installation

Adjusting Master Cylinder

Bleeding the Brake System

Bleeding the Master Cylinder

Bleeding the Slave Cylinders

-OPERATOR’S STATION

Theory Of Operation

Glass And Moldings

Air Intake (Pressurizer) System

Air Conditioning System

Air Conditioning Circuit

Receiver/Dryer Operation

Thermostat Switch Operation

Expansion Valve Operation

Compressor Relief Valve Operation

Heating System

Air Conditioning Specifications

AC Circuit Operational Information

Refrigerant Cautions

R134A Component Oil Charge

R134A Refrigerant Recover, Recycling And Charging System Installation Procedure

Recover R134A System

Evacuate R134A System

Air Conditioning System Test

Charge R134A System

Air Conditioning Operational Checks

Visual Inspection of Components

System Operating Checks

System Performance Checks

Blower/Air Conditioning Circuit

Service Equipment and Tools:

Insufficient Heating

Inadequate Removal of Ice or Fog

Heater Valve Not Shutting Off Coolant Flow

Air Conditioning System Does Not Operate

Air Conditioner Does Not Cool Cab Interior

Air Conditioner Runs Constantly, Too Cold

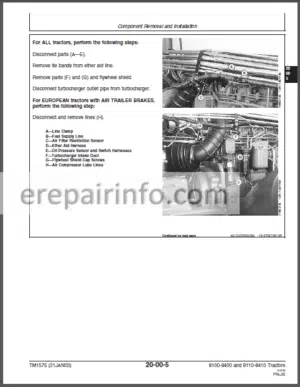

-TRANSMISSION

Transmission

Differential

Final Drive

Brakes

Transmission Does Not Drive with Engine Running

Transmission Drives in One Direction Only

Transmission Drives Exratically

Noisy Transmission Operation

Lack of Power or Sluggish

Excessive Transmission or Final Drive Noise

Oil Seeping From Outer Axle Seal

Excessive Driveline Vibration

Weak or No Brakes

Brakes Will Not Release

Hissing Noise at Brake Valve

Brakes Apply For A Period of Time and Then Release On Their Own

Brake Will Not Engage Adequately

Brake Is Noisy

Brake Has Excessive Wear

Brake Disc Overheats

Specifications

Necessary Supplies

Drain Oil, Remove Suction Screen

Transmission Removal

Remove and Repair Shifter Forks and Cam

Shifter Fork Installation

Front Cover With Shifter Cam Installation

Remove and Install Lube Pump

Countershaft Removal

Differential Removal

Differential Disassembly

Differential Assembly

Transmission Assembly

Differential Bearing End Play Adjustment

Countershaft Bearing End Play Adjustment

Transmission Installation

-FOUR WHEEL TORQUE HUB REPAIR

Cross Sectional View

Oil Information

Oil Temperature

Oil Change

Oil Fill Level and Volume

Tightening and Torquing Bolts

The Roll Test

The Leak Test

Main Disassembly – Part One

Cover Disassembly

Main Disassembly – Part Two

Hub-Spindle Disassembly – Part One

Hub-Spindle Disassembly- Part Two

First Stage Carrier Disassembly

Second Stage Carrier Disassembly

First Stage Carrier Sub-Assembly

Second Stage Carrier Sub-Assembly

Cover Sub-Assembly

Hub-Spindle Sub-Assembly-Part One

Hub-Spindle Sub Assembly-Part Two

Main Assembly

-ELECTRICAL SYSTEM

Visually Inspect Electrical System

Safety Precautions

Specifications

Theory of Operation

Cleaning Battery Posts

Jumping the Battery

Charging the Batteries

Precautions for Alternators

Inspection

Shorted Circuit

High Resistance or Open Circuits

Grounded Circuits

Ignition Switch Test

Alternator Output Check

Starter Solenoid Check

Starter Motor Check

Start Switch Check {Push Button)

Horn Switch Check

Horn Check

Nothing Works

Some Electrical Components Work

Starter Will Not Crank Engine

Engine Cranks Slowly

Starter Turns, But Engine Will Not Crank

Starter Still Runs After Engine Starts

Low Battery Output

Starter Solenoid Chatters

Noisy Alternator

Gauge Does Not Work (Applies To All Gauges)

Horn Does Not Work

Oil Pressure Sending Unit

Oil Pressure Switch

Engine Coolant Temperature Gauge Sender Engine Coolant Temperature Switch

Hydraulic Oil Temperature Sender

Fuel Sending Unit

Hydraulic Filter Pressure Switch

Air Filter Restriction Switch

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.