Factory Technical Manual For John Deere Harvester. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 250

Model

John Deere Cameco Harvester

CH3500

Contents

-GENERAL SPECIFICATIONS

Specifications

John Deere 6081 Engine

Description

Preliminary Service Intervals

Common Wear Parts

-GENERAL CAPACITIES

Harvester Capacities

Tire Inflation Pressure

-TORQUE SPECIFICATIONS

Suggested Torque Values For Grades 5.6,8.8,10.9, 12.9 Zinc Plated Cap Screws

Suggested Torque Values For Grades 5.6,8.8,10.9, 12.9 Zinc Plated Cap Screws

Torque for Grade 2 NC Weld Studs

Suggested Torque Values And Clamp Loads For Grades 2, 5 & 8 Cap Screws

Grade or Property Class Head Marking for SI Bolts

Conversion Factors

-FLUID RECOMMENDATIONS

John Deere Engine Coolant Requirements

John Deere Prediluted Antifreeze/

Summer Coolant

John Deere Cool-Gard

John Deere Antifreeze/Summer Coolant Concentrate

John Deere Antifreeze/Summer Coolant

Hydraulic Fluid

Diesel Fuel

Engine Break-in Oil (John Deere)

Diesel Engine Oil

Gear Oil—Pump Drive, Chopper Box and Basecutter

Gear Oil—Final Drive

Grease

-GENERAL INFORMATION

Straight O-Ring Boss Fittings

Angled O-Ring Boss Fittings

37° Flare Cone Fittings

Hex Flats Recommended Rotation

Four Bolt Flange Fittings

Flange Metric Bolt Torque Chart

Flange SAE Bolt Torque Chart

Conversions

Weight Measure

Length Measure

Metric (Sit) Measurements

Metric to English

English to Metric

Multiplication Factors

Temperature Conversion Chart

Conversion Formulas

Recommended Supplies

Hydraulic Gauge Kit

CH3500 Specialty Tools and Part Numbers

-SERVICE POINTS

Harvester Component Locations

Harvester Service Point Locations

Harvester Grease Point Locations

Grease Point Locations

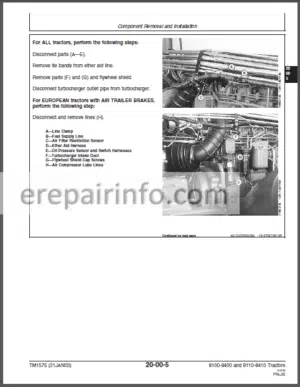

-ENGINE

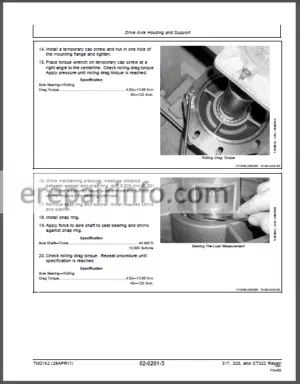

Pump Drive

Pump Drive Removal

Disassembly

Clean and Inspect

Assembly

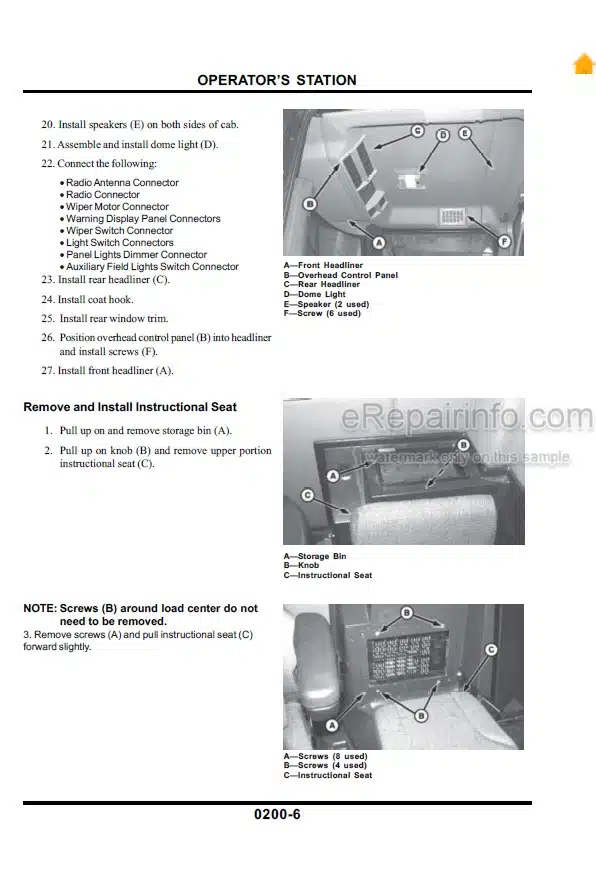

-OPERATOR’S STATION

Other Material

Remove and Install Cab Windshield

Remove and Install Cab Roof

Remove and Install Instructional Seat

Cab Door Latch Striker

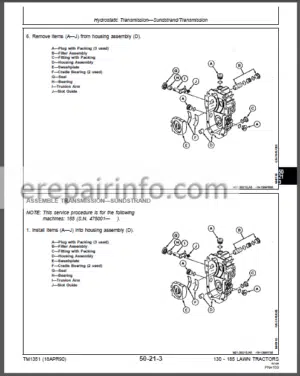

-HYDROSTATIC TRANSMISSION

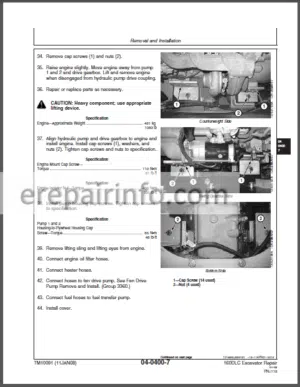

Hydrostatic Pump

Hydrostatic Pump

Manual and Electrical Displacement Control

Suggested Tools And Supplies

General Repair Instructions

Manual and Electrical Displacement

Control Replacement!

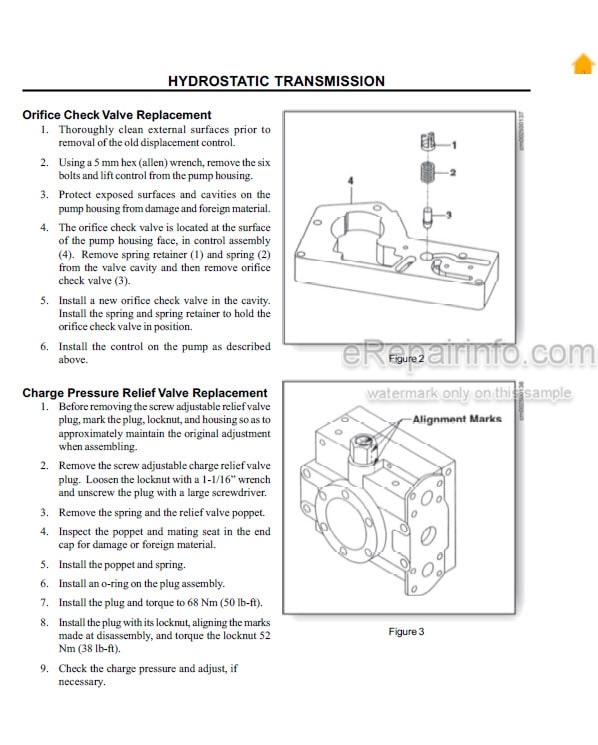

Orifice Check Valve Replacement

Charge Pressure Relief Valve Replacement

Shaft Seal Replacement

Multifunction Valve Cartridge Replacement (2 Per Pump)

Charge Pump Disassembly

Charge Pump Reassembly

Variable Displacement Motor (Wheel)

Shaft Seal Disassembly

Inspect

Assembly

About Servicing The Motor

Cartridge Disassembly

Housing Disassembly

Reconditioning and Replacement of Shaft Assembly

Piston Ring Reconditioning and Replacement

Reconditioning and Replacement of Bearing Plate, Valve Segment, and Cylinder Block

4-Way Valve and Feedback Springs

Housing Assembly

Housing Assembly

Fixed Displacement Motor (Track)

Cartridge Assembly

Reconditioning and Replacement of Piston Rings

Cylinder Block Assembly

Cylinder Block Assembly

End Cap to Main Housing Assembly Track Fixed Displacement Motor

Disassembly

-FINAL DRIVE

Safety Information

Installation of the Gearbox to the harvester

Gearbox Lubrication

Oil Filling

Oil Draining and Replacement

Disassembly

Reassembly

Brake Check

-WHEEL AND TRACK

Right Side View

Track Assembly

Track Assembly

Track Alignment

Roller Lubrication

Idler Lubrication

Track Shoe Tightening

Track Shoe Inspection Torque

Sprocket Tightening

Rear Axle Maintenance

Track Adjustment

Front Idlers

Lubrication

Identifying Master Link For Chain Removal

Recoil Spring Repair

Recoil Spring Adjustment

Specifications

Link Rail Wear

Link Rail Measurement

Rebuildability

Link Percentage Worn Chart

Sealed Track Bushings & Pins

Bushing and Pin Wear

Wear Measurement

Wear Limits—Service and Destruction

Track Bushing Allowable Wear Chart

Internal Pitch Wear

Measurement Technique

Detrimental Effects of Excessive Pitch

Allowable Wear

Internal Pitch Percentage Worn Chart

Track Rollers

Track Roller Lubrication

Seal Assembly

Specifications

Carrier Roller

Carrier Roller Lubrication

Carrier Roller Assembly

Specifications

Sprocket Wear Patterns

Sprocket Replacement

Tip Gouged

Rolling Undercarriage

Roller Wear Diagnosis

How To Measure Roller Wear

Specifications

Carrier Roller Percentage Worn

Track Roller Percentage Worn

Rolling Undercarriage

Flange To Boss Measurement

Idler Tread Wear Measurement

Swapping Idlers

Check Idler Flange Wear

Flange Top Wear

Flange Side Wear

Idlers Percentage Worn Chart

Track Shoe Problems

Grouser Wear Measurement

Wear Limits—Service and Destruction

Grouser Wear

Plate Wear and Leading/Trailing Edge Wear

Bolt Hole Wallowing Out

Self-Locking Track Nut

Sprocket Chain Roller Alignment

Wheel Assembly

Wheel Assembly

Remove And Replace Front Wheel Bearings

Suggested Tools

Remove Rear Wheel Assembly

To Remove And Mount Tire Onto Wheel Assembly

Install Wheel Assembly

Tire Pressure Specifications

-MAIN HYDRAULIC SYSTEM

Multiple Gear Pump

World Multiple Gear Pump

World Multiple Gear Pump (Piggyback)

Multiple Gear Pump Repair

Suggested Tools

Repair Precautions

Bushing Removal Tool

Seal Removal Tool

Bushing Installation Tool

Special Steel Sleeve

Seal Installation Tool

Disassembly

Clean and Inspect

Assembly

Start Up Procedure

Recommended Test Procedure

External Relief Settings

Overhaul

Valve Bank Disassembly

Front and Rear Feed Roller Valves

Assembly Procedure

Track Fixed Displacement Motor

Seal Replacement

Disassembly

Clean and Inspect

Assembly

-STEERING SYSTEM

Relief Valve Adjustment

Relief Valve Repair

Priority Valve

Disassembly/Reassembly

Troubleshooting

Steering Linkage

Remove and Install Steering Cylinder

Repair Steering Cylinder

Check Front Axle Toe-In

Adjust Front Axle Toe-In

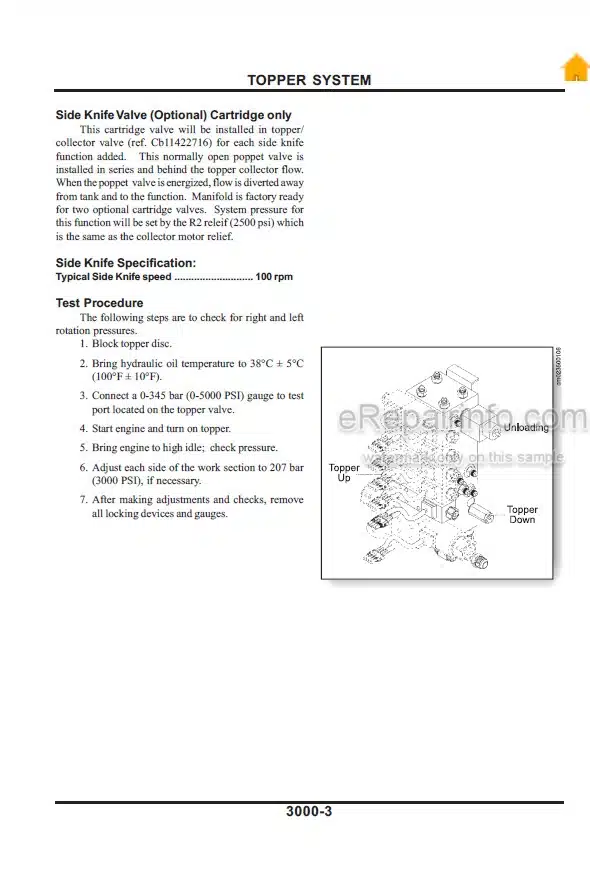

-TOPPER SYSTEM

Collector, Crop Divider, Feed Roller, and

Elevator Motor

Suggested Tools

Collector Motor

Disassembly

Clean and Inspect

Assembly

Topper

Topper Repair

Collector Drum and Motor Removal

Topper Assembly Removal

Clean and Inspect

Drum and Topper Assembly

Shredder Topper

Topper Repair

Collector Drum and Motor Removal

Topper Assembly Removal

Clean and Inspect

Drum and Topper Assembly

Scroll Cylinder

Suggested Tools

Disassembly

Clean And Inspect

Assembly

Topper Lift

Disassemble and Assemble Topper

Lift Cylinder

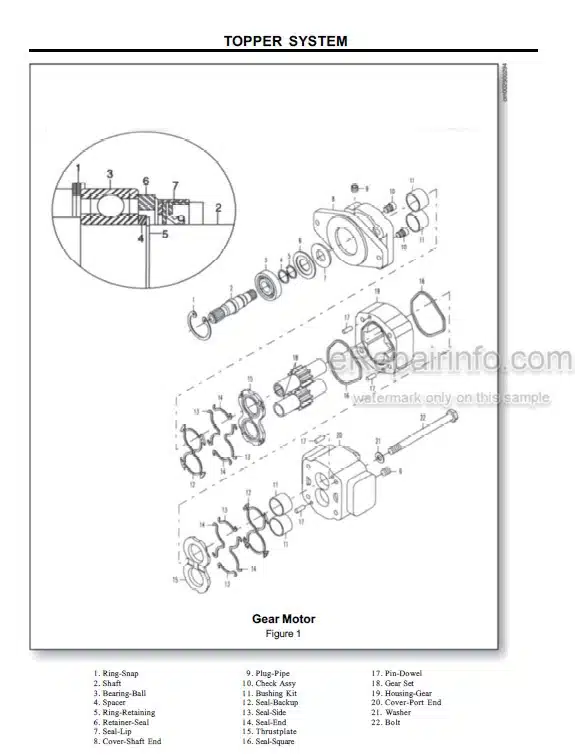

Gear Motor

Gear Motor Repair

Suggested Tools

Repair Precautions

Bushing Removal Tool

Seal Removal Tool

Bushing Installation Tool

Disassembly

Clean And Inspect

Assembly

Start Up Procedure

Recommended Test Procedure

-CROP DIVIDER SYSTEM

Crop Divider

Crop Divider Removal

Disassembly

Clean and Inspect

Assembly

Crop Divider Shoe Assembly

Crop Divider Shoe Removal

-FEEDROLLER SYSTEM

Knockdown Roller

Buttlifter Roller (B1)

Bottom Feed Roller (B2, B3, B4, B5)

Top Floating Feed Roller (T1,T2,T3,T4,T5)

-BASECUTTER SYSTEM

Basecutter Gearbox

Leg Shaft Removal

Basecutter High Drive Assembly

Basecutter Lift Cylinder (Wheel)

Wheel Basecutter Lift Cylinder Disassembly

Basecutter Lift Cylinder (Track)

Suggested Tools

Track Basecutter Lift Cylinder Disassembly

-CHOPPER SYSTEM

Remove

Chopper Gearbox Pre-Assembly and Installation

Top and Bottom Drum Installation

Final Assembly of Chopper Box

Differential Chopper Blade and Kicker Installation

Differential Chopper Timing and Adjustments

Chopper System

Differential Chopper Timing

Slip Clutch

Disassembly

Assembly (Flywheel, Slip Clutch Assembly and Adjustment)

Field Setting of Slip Clutch

Clean and Close Box

Assembly Chopper Motors

Assembly Chopper Deflector Shields and Adjustments

Install and Adjust Sill Plate

Chopper Motor Repair and Overhaul

Shaft Seal and Cover

Drive End Cover and Seal

Distributor End Cover and Seal

Distributor Housing and Seal Dismantling

Assembly

Distributor Piston Rings

Crankshaft and Cylinder Block Assembly

Inspection and Repair

Assembly

Procedure for Preloading Taper Roller Bearing on Motor

Bearings

Pistons and Piston Seals

Piston Pads

Testing

Hydraulic Test

-CLEANING SYSTEM

Fan Assy

Installing The Hub To Motor Shaft

Installing Fan Blades, Doubler Plates, and Backing Plate

Safety Startup

Variable Primary Extractor Pump

Manual Displacement Control

Suggested Tools

Multi-Function Valve Adjustment

Stroke Limiter Adjustment!

Charge Relief Adjustment

Minor Repair

General Repair

Manual Displacement Control Replacement

Orifice Check Valve Replacement

Charge Pressure Relief Valve Replacement

Shaft Seal Replacement

Multi-Function Valve Cartridge Replacement (2 per pump)

Charge Pump Disassembly

Reassembly

Primary Extractor Motor

Tools Required

Disassembly Shaft Seal

Disassembly End Cover with Integral Shuttle and Low Pressure Relief Valve

Disassembly of End Cover

Disassembly of Rotating Group

Reassembly

Reassembly of Shaft Seal

Reassembly of End Cover

Shaft Bearing Cone Driver (End Cover end)

Low Clearance Bearing Puller

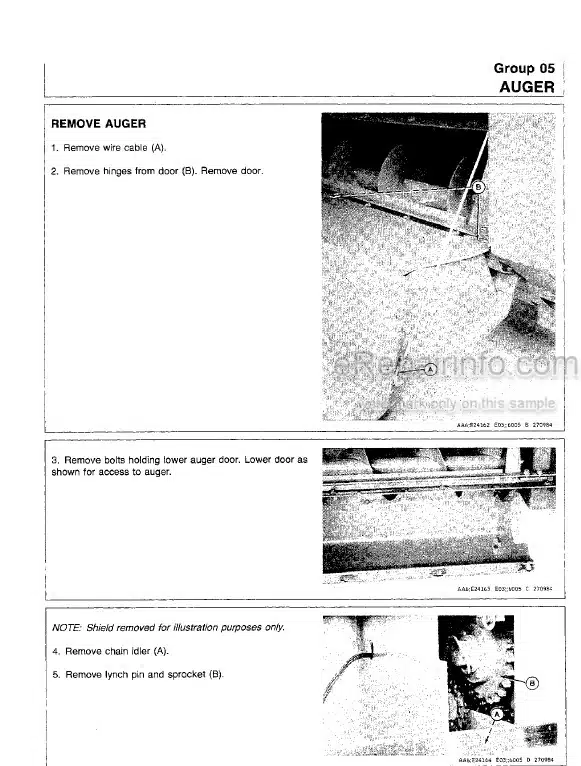

-ELEVATOR SYSTEM

Standard Capacity Elevator System

Elevator Group

Chain Adjustment

Changing Chain and Sprockets

Headshaft Repair

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.