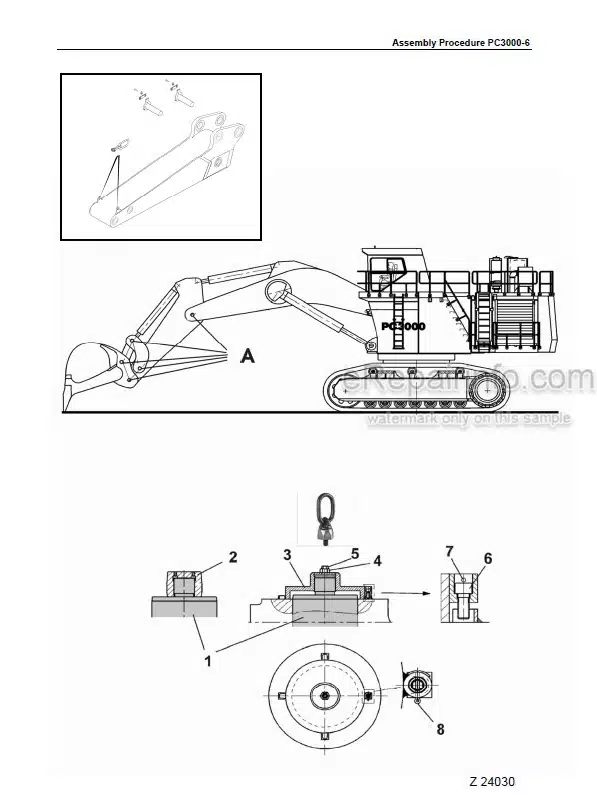

Factory Field Assembly Procedure For Komatsu Hydraulic Excavator.

Format: PDF

Language: English

Pages: 334

Number: GEN00060-10

Bookmarks: Yes

Searchable: Yes

Model

Komatsu Hydraulic Excavator

PC2000-8

Contents

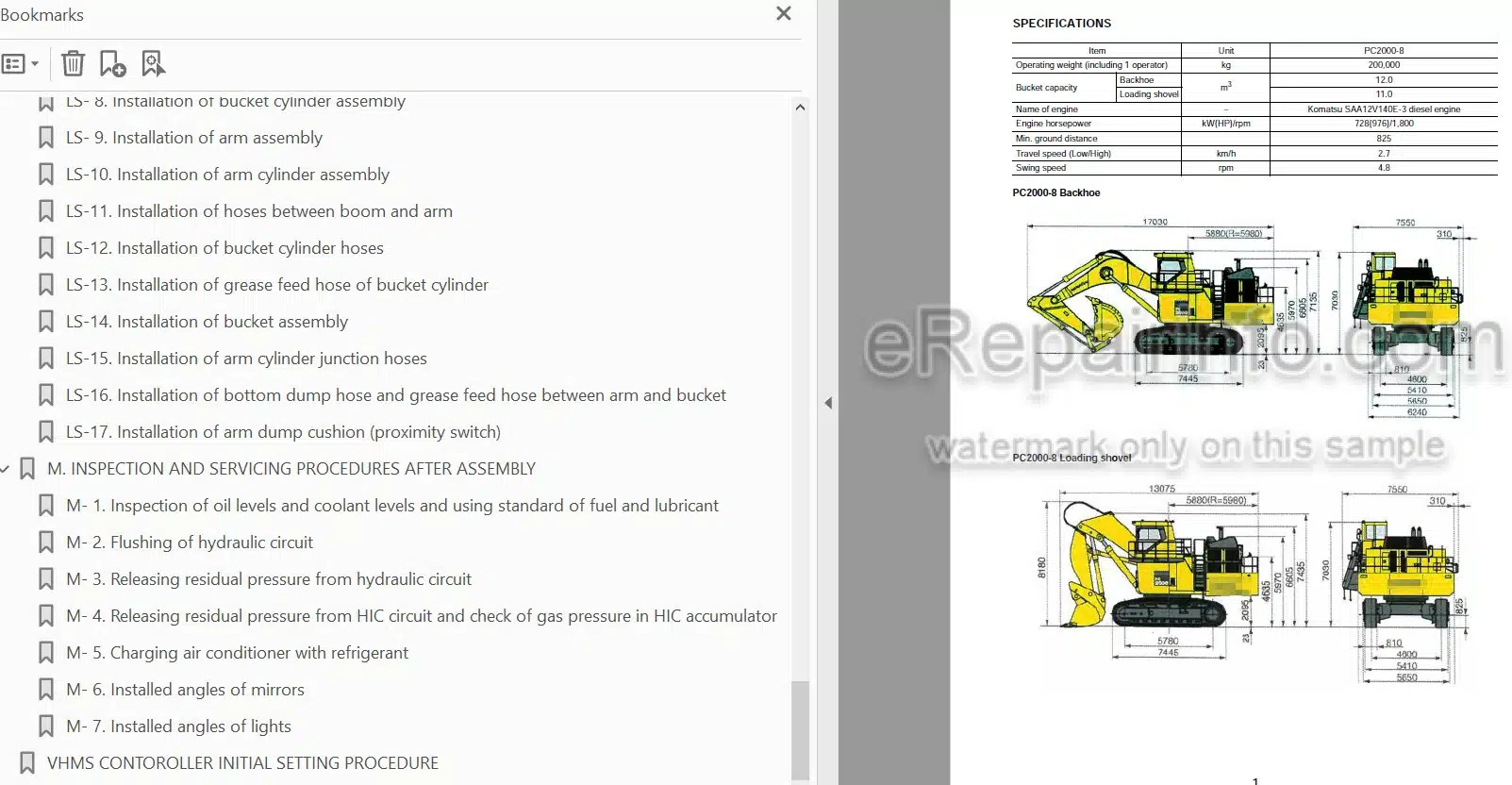

SPECIFICATIONS

PRECAUTIONS FOR FIELD ASSEMBLY

DISPOSAL OF REMOVED PARTS

ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE

FLOWCHART OF MAIN ASSEMBLY PROCEDURE

KIT LAYOUT DIAGRAM

TRANSPORTATION POSTURES

LIST OF PARTS SENT INDIVIDUALLY (Assembly of undercarriage)

TOOLS AND EQUIPMENT TO BE USED FOR LOCAL ASSEMBLY

TIGHTENING TORQUE

COATING MATERIALS LIST

-ASSEMBLY OF CHASSIS

Assembly Of Track Frame Assembly And Center Frame Assembly

Installation Of Idler Cushion Cylinder Piping

Installation Of Travel Motor Piping

Installation Of Travel Motor Cover

Filling Swing Circle With Grease

Assembly Of Revolving Frame Assembly And Undercarriage

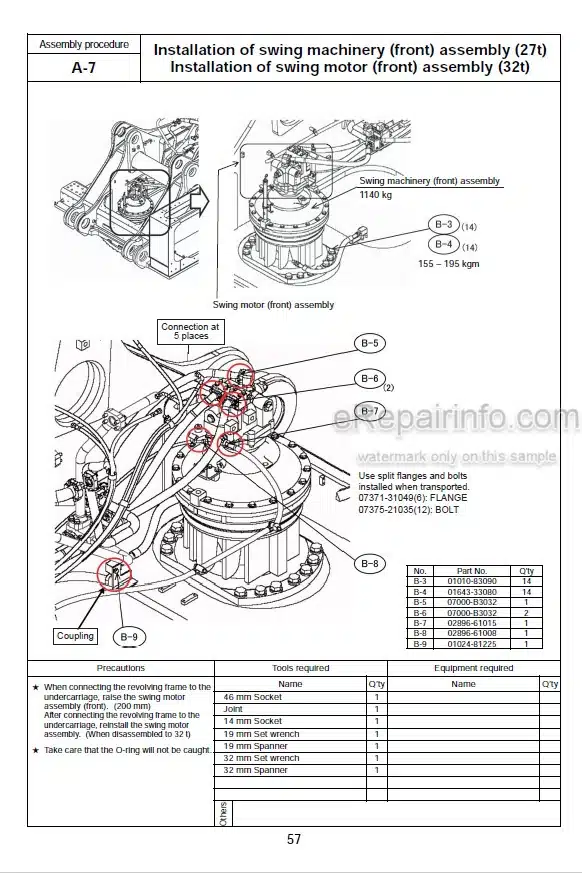

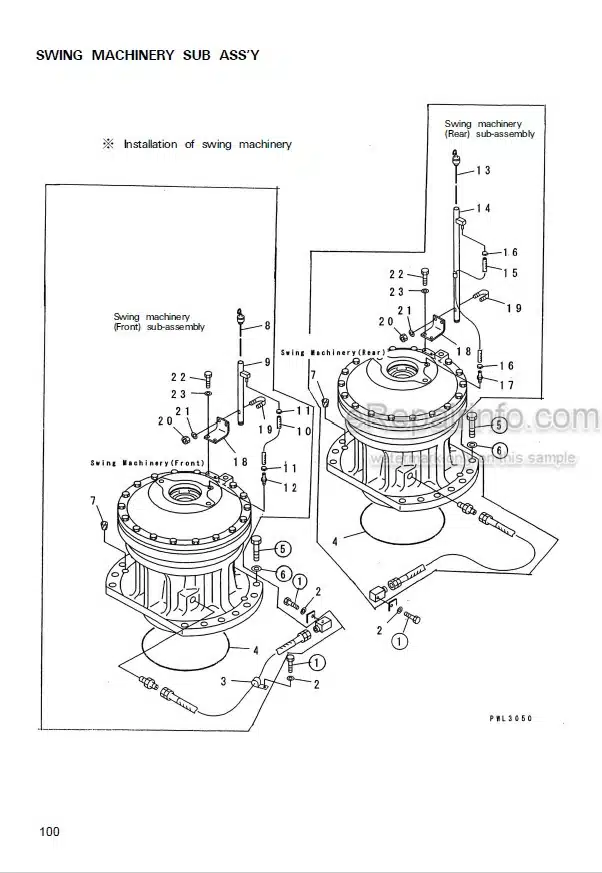

Installation Of Swing Machinery (Front) Assembly (27T) Installation Of Swing Motor (Front) Assembly (32T)

Connection Of Swivel Joint Piping

Connection Of Swing Circle Grease Piping

Installation Of Hydraulic Tank Assembly

Installation Of Fuel Tank Assembly

Connection Of Fuel Tank Assembly Piping And Wiring

Installation Of Cab Base Assembly

Installation Of Emergency Escape Ladder

Installation Of Left Floor Assembly

Connection Of Cab Base Assembly Piping

Connection Of Cab Base Assembly Wiring

Connection Of Left Floor Assembly Heater Piping

Connection Of Left Floor Assembly Wiring

Installation Of Tail Pipe

Installation Of Power Container Assembly

Connection Of Suction Piping

Connection Of Oil Cooler Piping And Pump Drain Piping

Connection Of Fan Motor Drain Piping

Installation Of Suction Unit Undercover

Connection Of Delivery Piping

Connection Of Pilot Piping And Fan Motor Piping

Connection Of Power Container Assembly Fuel Piping

Connection Of Power Container Assembly Air Conditioner Piping

Connection Of Power Container Assembly Heater Piping

Connection Of Power Container Assembly Wiring

Installation Of Operator’s Cab Assembly

Installation Of Rotary Lamp (If Equipped)

Installation Of Orbcomm Antenna (If Equipped)

Connection Of Operator’s Cab Assembly Wiring

Connection Of Operator’s Cab Assembly Hydraulic Piping

Connection Of Operator’s Cab Assembly Window Washer Hose

Connection Of Operator’s Cab Assembly Air Conditioner Piping

Connection Of Operator’s Cab Assembly Heater Piping

Installation Of Operator’s Cab Rear Floor Assembly

Installation Of Handrail Around Operator’s Cab

Installation Of Track Frame Ladder

Installation Of Power Container Side Catwalk Assemblies Fright And Left)

Installation Of Right Floor Assembly, Grease Can Cover Assembly And Center Floor

Installation Of Fuel Tank Right Catwalk Assembly

Installation Of Fuel Tank Front Catwalk Assembly

Adjustment Of Exterior Parts Clearance

Connection Of Grease Reel Piping

Installation Of Access Ladder Assembly

Installation Of Counterweight Assembly

Installation Of Deformation Preventing Stoppers For Catwalk Assemblies(Left And Right) On The Side Of Power Container

Installation Of Handrail On Counterweight

Installation Of Handrail Clamps

Connection Of Fuel Cut Wire

Connection Of Drain Piping Under Power Container

Connection Of Battery Wiring

Setting Of Hydraulic Tank Strainer

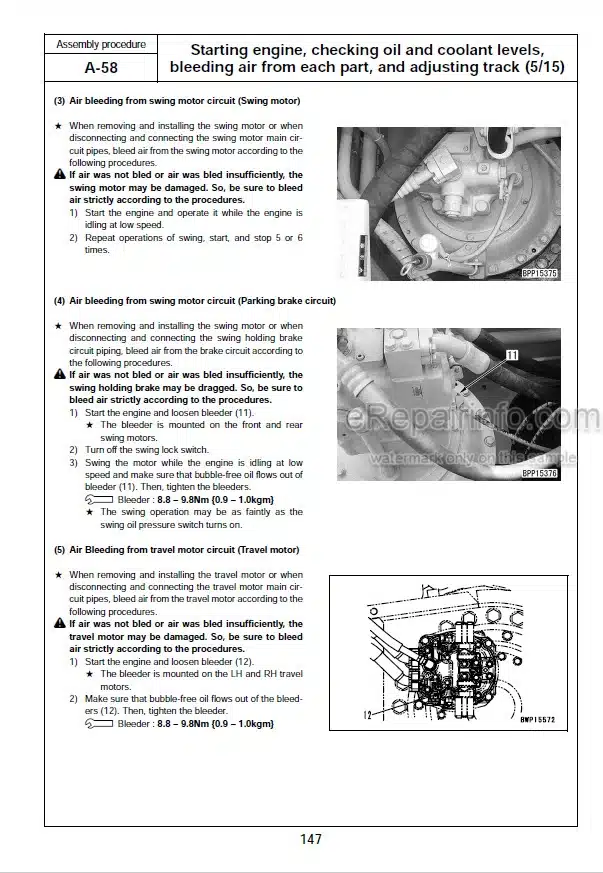

Starting Engine, Checking Oil And Coolant Levels, Bleeding Air From Each Part, And Adjusting Track

Permanent Tightening Of Swing Circle Bolt

Parts To Be Touched Up After Field Assembly (Chassis Side)

Connection Of Engine Heater Connection Port

Installation Of Optional Harness

Installation Of Rear Lamps

Installation Of Rear Camera

Connection Of Emergency Stop Switch (If Equipped) (At The Right Below Container)

Connection Of Emergency Stop Switch (If Equipped) (At The Left Side Of Ladder)

Installation Of Engine Oil And PTO Oil Pipings

Installation Of Coolant Piping

Installation Of Guard Bracket (If Equipped)

-ASSEMBLY OF BACKHOE

Installation Of Boom Cylinder

Installation Of Boom Cylinder Hoses (Serial No. 20095 And Up)

Assembly Of Boom Sub Assembly

Installation Of Boom Assembly

Installation Of Boom Cylinder Head Side

Installation Of Hoses Between Boom And Chassis

Installation Of Arm Assembly

Installation Of Arm Cylinder

Connection Of Hoses Between Boom And Arm

Connection Of Auto Grease Piping

Connection Of Wiring Between Boom And Chassis

Installation Of Bucket Assembly

Installation Of Bucket Link

Bleeding Air From Cylinders

Parts To Be Touched Up After Field Assembly (Work Equipment Side)

Bleeding Air From Auto Grease Circuit

-ASSEMBLY OF LOADING SHOVEL WORK EQUIPMENT

Installation Of Arm Cylinder Bottom Parts

Installation Of Boom Cylinder To Machine Body

Installation Of Boom Cylinder Hoses

Installation Of Boom Cylinder Piping

Installation Of Boom Assembly

Installation Of Boom Cylinder Head Pins

Installation Of Hose Between Machine Body And Boom

Installation Of Bucket Cylinder Assembly

Installation Of Arm Assembly

Installation Of Arm Cylinder Assembly

Installation Of Hoses Between Boom And Arm

Installation Of Bucket Cylinder Hoses

Installation Of Grease Feed Hose Of Bucket Cylinder

Installation Of Bucket Assembly

Installation Of Arm Cylinder Junction Hoses

Installation Of Bottom Dump Hose And Grease Feed Hose Between Arm And Bucket

Installation Of Arm Dump Cushion (Proximity Switch)

-INSPECTION AND SERVICING PROCEDURES AFTER ASSEMBLY

Inspection Of Oil Levels And Coolant Levels And Using Standard Of Fuel And Lubricant

Flushing Of Hydraulic Circuit

Releasing Residual Pressure From Hydraulic Circuit

Releasing Residual Pressure From HIC Circuit And Check Of Gas Pressure In HIC Accumulator

Charging Air Conditioner With Refrigerant

Installed Angles Of Mirrors

Installed Angles Of Lights

VHMS CONTOROLLER INITIAL SETTING PROCEDURE

PC2000-8 Main pump air bleeding check sheet

FIELD ASSEMBLY INSPECTION REPORT

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.