Factory Service Manual For Mitsubishi Forklift. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF (ZIP. File)

Language: English, French

Quantity of Service Manuals: 3

Pages: 224; 216; 407

Number: 99759-7B200; 99759-7B110; SMFEA-AFB33-190

Bookmarks: Yes

Searchable: Yes

Model

Mitsubishi Forklift Chassis And Mast

MC

FBC15N

SN AFB33B-00011-29999

SN A4BC1-10200-up

SN A4BC1-20200-up

SN A4BC1-30200-up

FBC18N

SN AFB33B-30011-49999

SN A4BC1-10200-up

SN A4BC1-20200-up

SN A4BC1-30200-up

FBC18LN

SN AFB33B-50011-99999

SN A4BC1-10200-up

SN A4BC1-20200-up

SN A4BC1-30200-up

FBC20N

FBC25N

SN A4BC2-10200-up

SN A4BC2-20200-up

FBC25EN

FBC25LN

FBC30N

SN A4BC3-20200-up

SN A4BC3-30200-up

SN A4BC3-40200-up

FBC30LN

SN A4BC4-10200-up

Contents

Mitsubishi_FBC15N_To_FBC30LN_Service_Manual_Forklift_Chassis_And_Mast_99759-7B200_FRA.pdf

Mitsubishi_FBC15N_To_FBC30LN_Service_Manual_Forklift_Chassis_And_Mast_99759-7B110.pdf

Mitsubishi_FBC15N_FBC18N_FBC18LN_Service_Manual_Forklift_Chassis_And_Mast_SMFEA-AFB33-190.pdf

Mast_Tilting_Angles.pdf

Main Harness_With_Transistor_Hydraulics_Schematic.pdf

How_To_Use_A_Pick_List.pdf

How_To_Locate_Fluid_Capacities_ES.pdf

How_To_Locate_Fluid_Capacities.pdf

How_To_Determine_Correct_Mast_Rails_Lift_Cylinders_and_Mast_Hosing.pdf

Service Manual Contents of Mitsubishi FBC15N FBC18N FBC18LN Service Manual Forklift Chassis And Mast SMFEA-AFB33-190:

-GENERAL INFORMATION

Model View

Forklift Truck Models Covered

Serial Number Locations

Dimensions

Specifications

-ELECTRICAL SYSTEM

Electrical System – Overview

Wire Colors

Structure

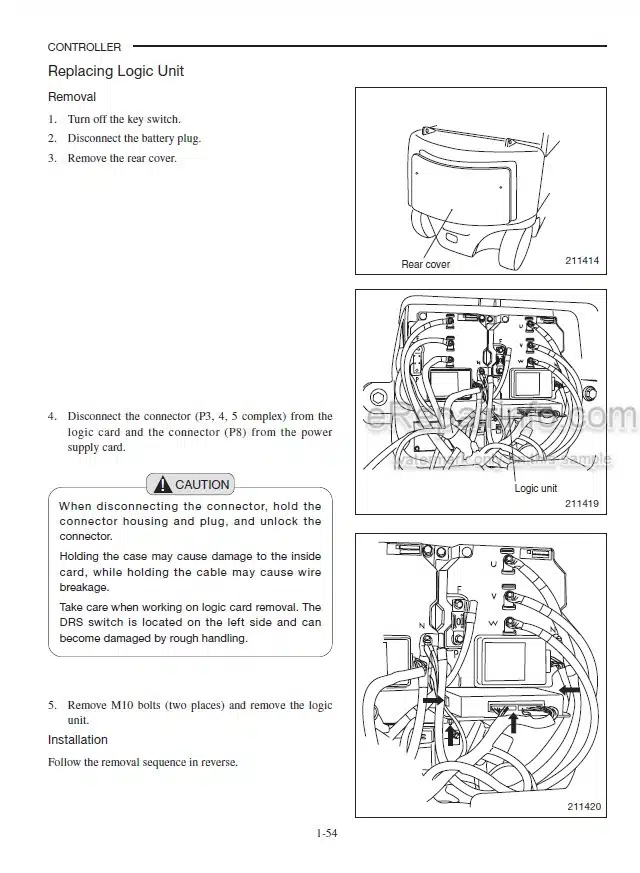

Disassembling and Assembling Electrical Components

Meter Panel

Diagnostic Code List

Switches, Sensors, and Relays

Fuses

Lights

Maintenance on Electrical Connectors

Battery Electrolyte

Troubleshooting

-POWERTRAIN

Powertrain – Overview

Structure

Removing Powertrain

Inspecting Operator Seat

Seat Belt

Installing Powertrain

-MOTOR

Motor – Overview

Traction. Hydraulic, and Steering Pump Motors

Specifications

Structures

Removing Traction Motor

Disassembling Traction Motor

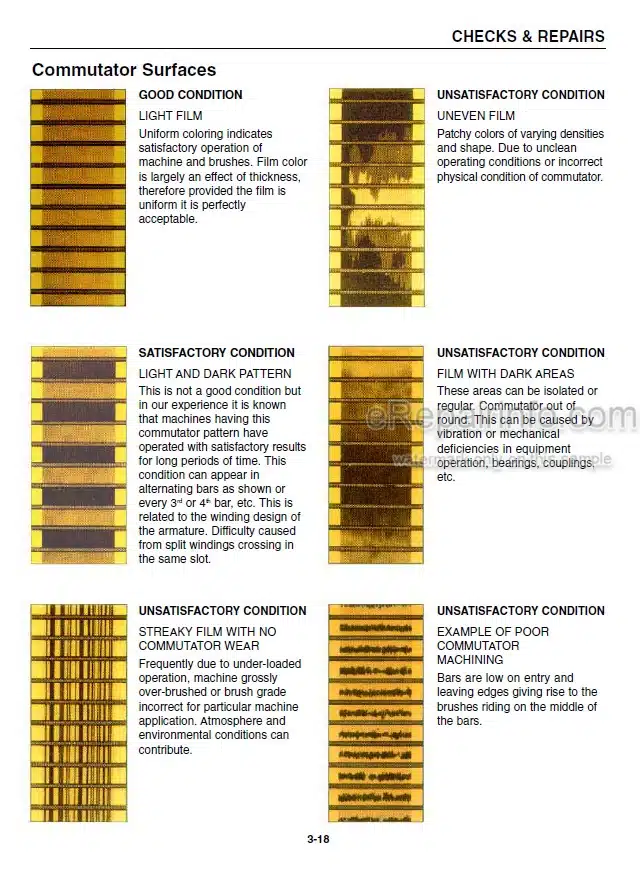

Inspecting Traction Motor

Assembling Traction Motor

Removing Hydraulic Pump Motor

Installing Hydraulic Pump Motor

Disassembling Hydraulic Pump Motor

Inspecting Hydraulic Pump Motor

Assembling Hydraulic Pump Motor

Tightening of High-Power Cable Terminals

Removing Steering Pump Motor

Inspecting Power Steering Motor

-TRANSFER AND DIFFERENTIAL

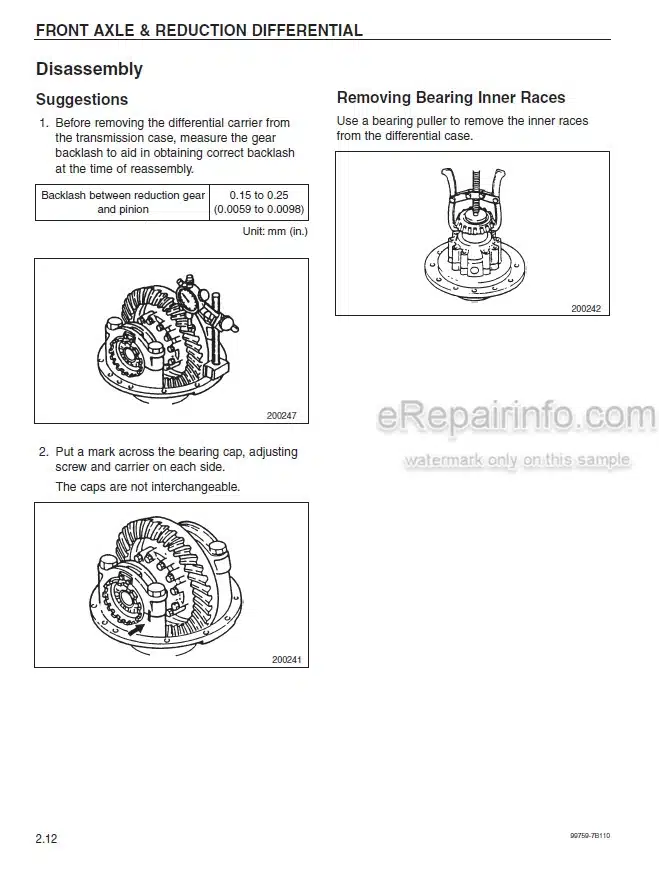

Transfer and Differential – Overview

Transfer Assembly

Disassembling Transfer Units

Transfer Assembly

Reduction Differential

Sendee Data

Troubleshooting

-FRONT AXLE

Front Axle – Overview

Structure

Disassembling Front Axle Assembly

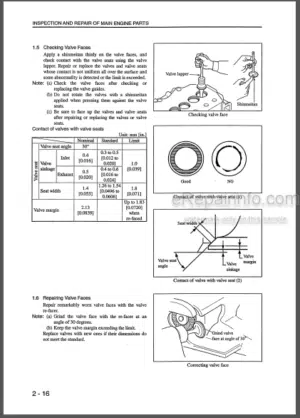

Inspection and Repair After Disassembling Front Axle

Assembling Front Axle Assembly

Service Data

-REAR AXLE

Rear Axle – Overview

Structure and Functions

Rear Axle in General

Disassembly and Reassembly

Rear Axle Adjustment

Troubleshooting

Service Data

-BRAKE SYSTEM

Specifications

Structure

Structure of Wheel Brake Assembly

Disassembling Wheel Brake

Inspection and Repair After Disassembling Wheel Brakes

Assembling Wheel Brakes

Disassembling Master Cylinder

Inspection and Repair After Disassembling Master Cylinder

Assembling Master Cylinder

Disassembling Wheel Cylinder

Inspection and Repair After Disassembling Wheel Cylinder

Assembling Wheel Cylinder

Inspecting and Adjusting Brake System

Inspecting Parking Brake Cable

Troubleshooting

Service Data

-STEERING SYSTEM

Specifications

Structure

Disassembling and Assembling Pipes and Hoses

Disassembling Steering Wheel

Installing Steering Wheel

Installation

Removing Steering Valve

Installing Steering Valve

Disassembling Steering Valve

Inspection After Disassembly

Assembling Steering Valve

Steering Pump

Troubleshooting

Service Data

-HYDRAULIC SYSTEM

Specifications

Structure

Precautions During Removal and Installation

Removing Hydraulic Pump and Steering Pump

Installing Hydraulic Pump

Installing Steering Pump

Removing and Installing Lift Cylinders

Removing Suction Strainer. Return Filter, and Hydraulic Tank

Inspecting Suction Strainer and Return Filter

Installing Suction Strainer, Return Filter, and Hydraulic Tank

Disassembling Hydraulic Pump

Inspecting and Repairing Hydraulic Pump

Assembling Hydraulic Pump

Disassembling Steering Pump

Inspection and Repair After Disassembling Equipment

Assembling Steering Pump

Inspection and Adjustment After Assembling Equipment

Disassembling Lift Cylinders (First Cylinder for Duplex Mast and Triplex Mast)

Assembling Lift Cylinder (First Cylinder for Duplex Mast and Triplex Mast)

Disassembling Lift Cylinders (Second Cylinders for Simplex Mast and Triplex Mast)

Inspection After Disassembling Lift Cylinder (‘Second Cylinder for Simplex Mast and Triplex Mast-)

Assembling Lift Cylinder tSecond Cylinder for Simplex Mast and Triplex Masf)

Disassembling Lift Cylinders (Second Cylinders for Duplex Mast)

Assembling Lift Cylinder (Second Cylinders for Duplex Mast)

Disassembling Tilt Cylinder

Inspection and Repair After Disassembling Tilt Cylinders

Assembling Tilt Cylinder

Disassembling Down Safety Valve

Inspection and Repair After Disassembling Down Safety Valve

Assembling Down Safety Valve

Piping

Hydraulic System Adjustment

Troubleshooting

Service Data

MC Control Valve

Troubleshooting

-MAST AND FORKS

Simplex Mast

Duplex Mast

Triplex Mast

-SERVICE DATA

Inspection Standards

Paris to Be Changed Periodically

Tightening Torques for Standard Bolts and Nuts

Lubrication Instructions

Weight of Main Components

Special Tools

-OPTIONS

Smart Back-up Alarm Option

Foot Directional Control Option (FDP

Strobe Light and Rear Working Light Option

Strobe Light. Rear Working Light and Rear Combination Light Option

PC / PC Converter Option

Steering Wheel Knob Option

EE Option Uncovered Battery and Covered Battery Option

Static Strap Option

Clipboard Holder Option

Rearview Minor Option

Drawbar Pin Option

Battery Side Loading Option

Fire Extinguisher Option

Blue Spot Light Front Option

Blue Spot Light Rear Option

Load Bearing Clamp Lockout (LBCLT Option CMC Model)

Power Hook Up Option

USB Charge Option

Tilt Cylinder Boot Option

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet