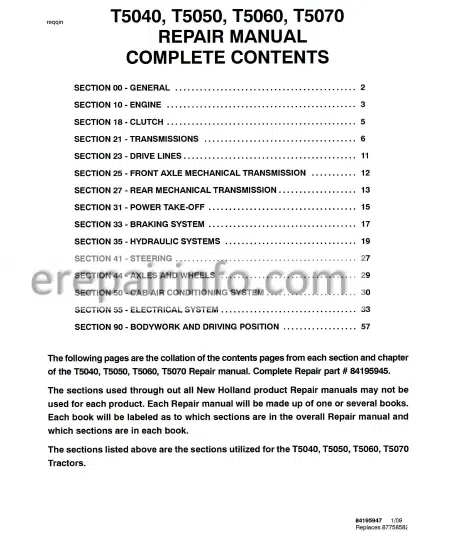

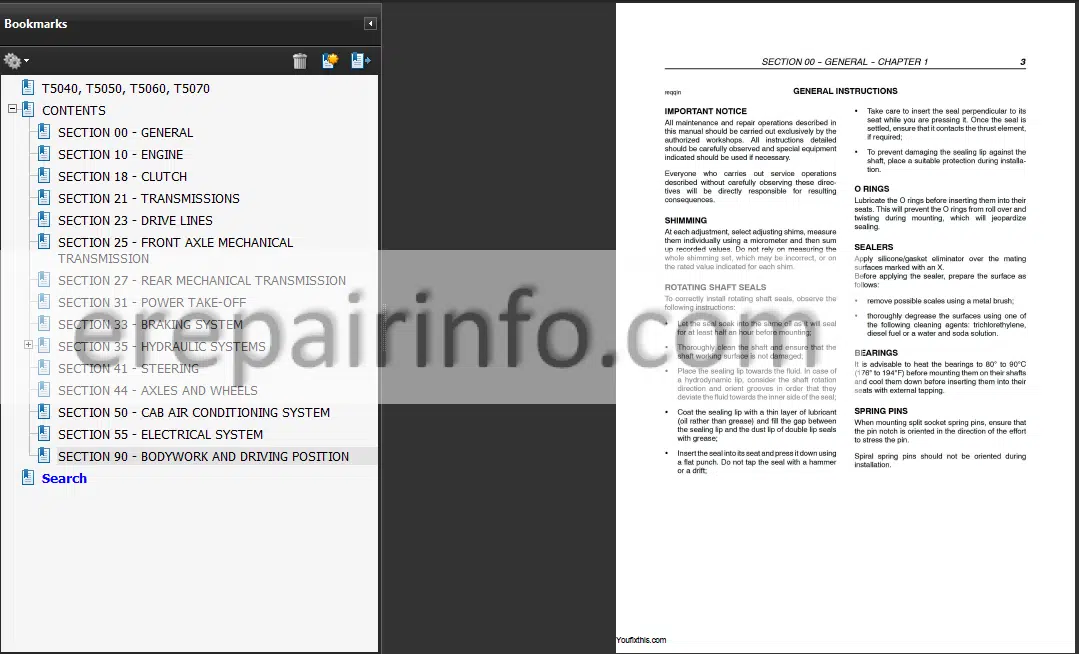

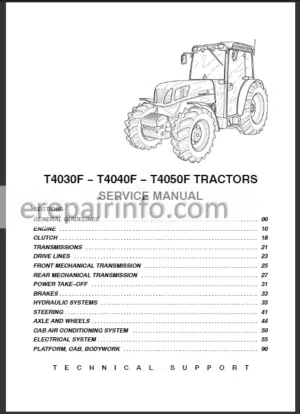

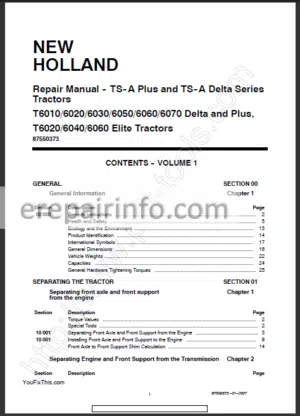

Repair Manual For New Holland T5000 series. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 1752

Bookmarks: Yes

Searchable: Yes

Number: 84195947; 84195945

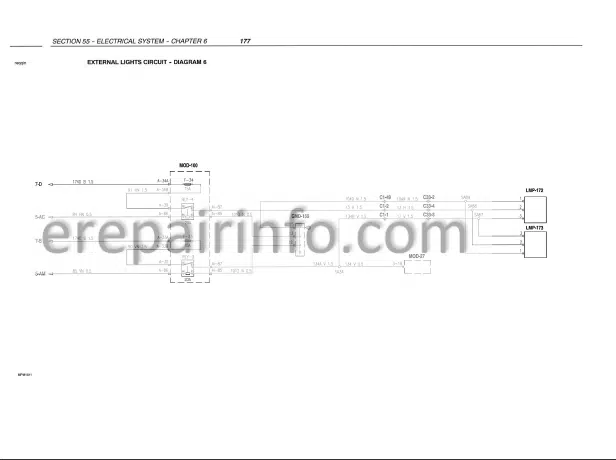

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

New Holland T5040, T5050, T5060, T5060

Contents

- – General

General Instructions

Health And Safety

Precautionary Statements

Safety

Ecology And The Environment

Minimum Hardware Tightening Torques

Federal Emissions Warranty

California Emission Control Warranty Statement

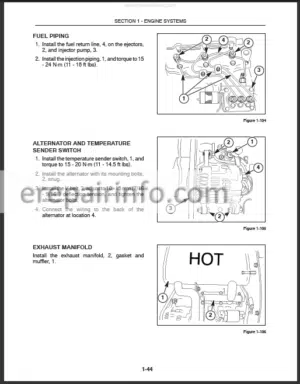

Consumables - – Engine

Crankshaft Front Seal

Crankshaft Rear Seal

Valve Tappet And Rocker Arm Clearance

Engine Injector

Bosch Injection Pump

Injector Pump

Bosch Injection Pump

Fuel Circuit Air Bleeding

Coolant Pump

Thermostat Valve

Radiator

Coolant Pump And Generator Drive Belts

Adjusting Tension - – Clutch

Longitudinal Section OfLuk Clutch

Electrohydraulic Power Take Off

Longitudinal Section OfLuk Clutch

Mechanical Power Take Off

Longitudinal Section Through Flexible Coupling

Power Shuttle Unit

Troubleshooting

Checks, Measurements And Repairs

Dual Clutch

Main Transmission Clutch Release

Adjustment

Test Bench Overhaul And Adjustment

Coplanarity Adjustment Of Dual Clutch Release Levers

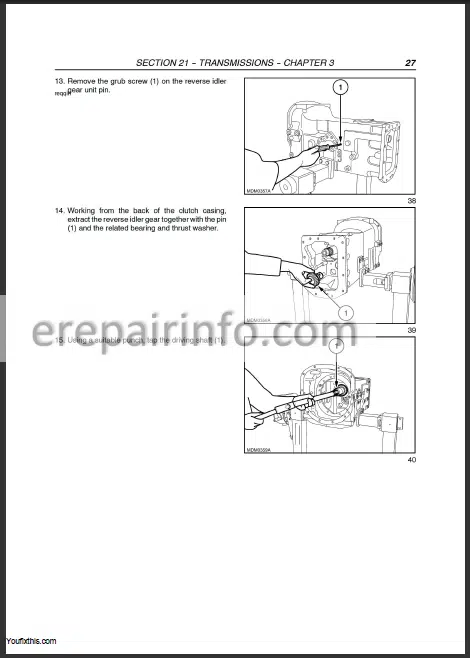

Single Disk Clutch - – Transmissions

Transmission Diagrams

Torques

Clutch Reverser Casing - – Drive Lines

Electro-Hydraulically Engaged Drive Gear

Services Control Valve

Services Control Valve (For Tractors Without Power Shuttle)

Drive Gear Assembly

Drive Gear Housing Removed - – Front Axle Mechanical Transmission

LimSlip SelfLocking Differential Operation

Front Differential Lock

Rules For Correctly Installing The Axle Support To The Engine

Front Axle

Front Axle Differential

Front Axle Differential With Lim Slip Unit

Front Axle Differential Lock Clutch Assembly

Front Epicyclic Final Drive Without Brake

Front Epicyclic Final Drive With Brake

Wheel Hub Seal With Brake

Stub Axle Adjustments

Pinion And Crown Wheel Adjustments

Adjusting The Bevel Pinion Shaft Bearing Preload With Shims

Adjusting The Bevel Crown Wheel Bearings And Checking The Clearance Between The Sides Of The Bevel Drive Teeth - – Rear Mechanical Transmission

Hydraulically Controlled Rear Differential Lock

Rear Gearbox Transmission Casing

Gearbox Transmission Casing

Gearbox Driving Shaft End Float Adjustment

Adjusting The Position Of Differential Lock Engagement Sleeve

Pinion And Crown Wheel Adjustments

Determining The Bevel Pinion Positioning Adjustment Ring

Adjusting The Bevel Gear Pair

Tapered Roller Bearings Adjustment For Pinion Shaft

Adjusting The Bevel Crown Wheel Bearings And Checking The Clearance Between The Bevel Drive Teeth

Bevel Drive Adjustments

Adjusting The Preloading On The Bevel Drive Bearings

Adjustment Of The Clearance Between The Sun And Planet Pinion Teeth

Differential Lock Control Pedal Stroke

Adjustment

Final Drive Casing

Epicyclic Final Drive

Drive Wheel Shaft - – Power TakeOff

Mechanical Pto

Pto Controlled Directly From The Engine Clutch

Pto Synchronized With Gears

Selecting The Speed With The Lever

Cooling System

Power TakeOff Housing

Mechanical Power TakeOff Shafts - – Braking System

Service Brakes

Service Brake On Front Axle

Parking Brake

Pilot Valve Operation

Brakes At Rest

Braking Applied On Just One Pedal

Braking Applied On Both Brake Pedals

Hand Brake Control

Travel Adjustment

Parking Brake Casing

Brakes Hydraulic System

Air Bleed

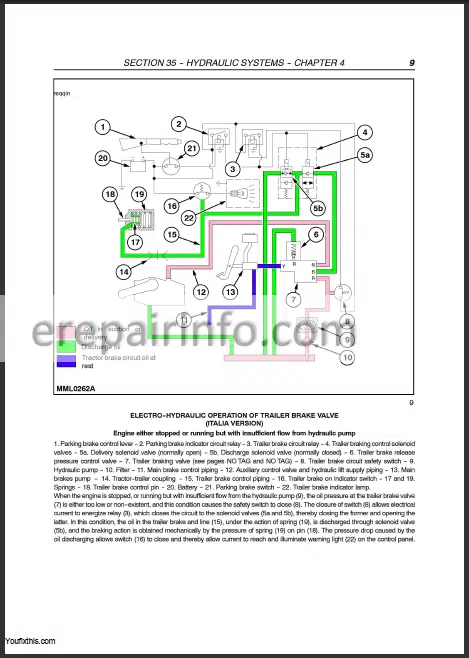

Tractor Equipped With Hydraulic Trailer Braking Valve

Tractor Equipped With Braking On The Front Axle

Tractor Equipped With Pneumatic Trailer Braking Valve

Service Brake Pump

Adjusting The Height Of The Service Brakes Pedals

Right Or Left Brake - – Hydraulic Systems

Hydraulic Lift Circuit

Arm Lift Phase

Neutral Phase

Arm Lower Phase

Lift Oil Pump

Fast Raise/Lower Control

Linkage Adjustments

Position Control Rod Adjustments

Draft Control Rod Adjustments

Fast Raise/Lower Device Adjustments

Adjustment Of The Upper Stroke Limit Of The Fast Raise/Lower Device

Rear Lift External Controls

Rear Lift

Rear Hydraulic Lift

Lift Adjustments

Adjusting Position Control

Lift Arms Maximum Raise Position Adjustment

Adjusting Draft Control

Lift Control Valve

Lift Pressure Relief Valve - – Steering

Balancing Valve Components

Neutral Position

Steering To Right

Steering To The Left

Manual Turning To The Right

Manual Turning To The Left

Hydrostatic Steering Control Valve

Hydrostatic Steering Control Valve With Control Valve Removed

Hydrostatic Steering Control Valve

Bench Test

Checking Rotating Valve Wear

Checking Return To Neutral Position

Seal Check

Pressure Relief Valve Calibration

Checking The Hydrostatic Steering Pressure Relief Valve With

Control Valve Installed On Tractor

Power Steering Oil Pump

Front Axle Steering Cylinder - – Axles And Wheels

Front Wheel Track Diagram

Torques

Sectional Views

Front Axle Hub

Front Axle

Stub Axle

Checking Wd Front Wheel Camber And ToeIn

Checking Wd Front Wheel Alignment - – Cab Air Conditioning System

Main Components Of The Air Conditioning System

Compressor

Condenser

Receiver/Dryer

Thermostatic Expansion Valve

Thermostatic Switch Defrost

Evaporator

Cab Heating And Ventilation Controls

Ventilation

Electric Fan

Air Filter

Heating

Temperature Control Knob ()

Ignition Switch

Cab Air Conditioning Controls

Air Conditioning And Temperature Control Knobs

Heater Control Knob

Electric Fan Control Knob

Instructions For Use

Start-Up

Adjustment

Switching Off

Air Conditioning System Recovery Recycling Evacuation Charging Station

Meaning

Checking For Refrigerant Leaks Using An Electronic Leak Detector

Refrigerant Gas Leak Test

Maintenance

Maintenance Of The Air Conditioning System

Troubleshooting

Visual Inspection Of Components

Checks And Adjustments

Functional Tests

Checking The Temperature Of The Air Coming Out Of The Vents Inside The Cab

Variations In Working Temperatures Of The Cab Air Conditioning System

Checking For And Eliminating Any Gas Leaks

Compressor Drive Belt

Fitting The Compressor Drive Belt

Tension Adjustment

Periodic Checking Of Drive Belt

Air Conditioning Compressor

Compressor Oil

Type And Quantity

Heating Pipes

Air Conditioning Pipes

Air Conditioner Condenser

Cab Heating Unit

Air Conditioner Evaporator

Electric Fan - – Electrical System

Standard Dashboard

Analog/Digital Instrumentation Panel

Instruments

Rev Counter

Engine Coolant Temperature Indicator

Fuel Level Indicator

Liquid Crystal Displays

Clock

Central Display

Ground Speed Display

Information Monitor

Setting And Resetting The Hours Worked

Resetting Hours Worked

Setting Hours Worked On A New Dashboard

Brightness Control

Access To The “Setup Menu” Via Keypad

Manual Calibration

Automatic Forward Speed Calibration

Hour System Clock Setting

Speed Unit Of Measurement Setting

Beep Setting

Implement Width Setting

Slip Percentage Setting

Heavy/Light Maintenance Setting

Access To The “Warnings Not Displayed” Menu

Warnings Of A Critical Nature

Warnings Of A NonCritical Nature

Calling Up Functions From Keypad

Area Worked

Area Per Hour

Odometer

Maintenance Periods

Hours Worked, Air Brake Pressure Brake And Battery Charge

Wheel Slip And Power TakeOff Speed

Rear Implement Position

Access To The “Setup Menu” With The Cal Button

Calling Up Functions With The Cal Button - – Bodywork And Driving Position

Hood

Platform

Driver’s Seat

Cab

Cab RightHand Or LeftHand Door

Glued Cab Windshield

Fitting The Window

Cab Rear Windshield

Seal On Lh Upright

Strip On Rh Upright

Fixed Padding On Rh Wall

Fixed Padding On Lh Wall

Hydraulic Control Lever Guard

Cab Ceiling Fitting

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.