Factory Workshop Manual For Takeuchi TB125 TB135 TB145 Compact Excavator. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1087

Number: CG4E004

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Models

Takeuchi TB125, TB135, TB145

Contents

1.Workshop Manual for Takeuchi TB125, TB135, TB145

2.Service Manual for Yanmar TNE engine series

1.Workshop Manual for Takeuchi TB125, TB135, TB145

-GENERAL

Safety Precautions

Cautions During Disassembly And Assembly

Cautions During Removal And Installation Of The Hydraulic Units

Cautions During Removal And Installation Of Piping

Handling Of Seals

Tightening Torques

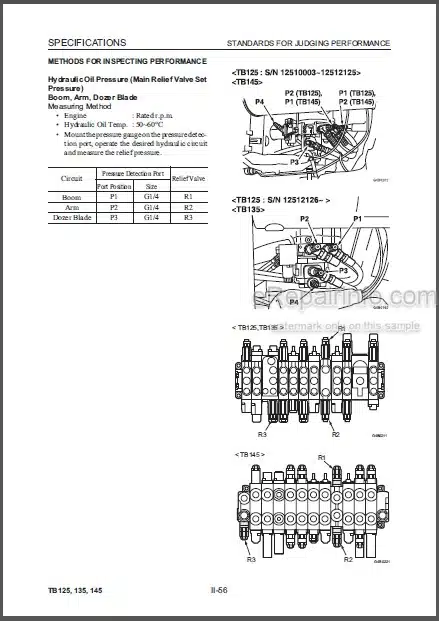

-SPECIFICATIONS

Names Of Components

Dimensions

Specification Tables

Mass Tables

Recommended Lubricants

Types Of Crawler Belts

Types Of Attachments And Tlieir Combinations

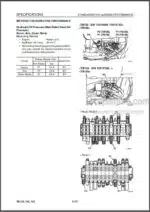

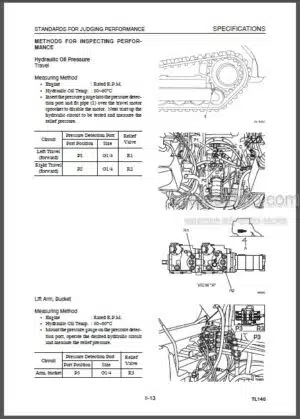

Service Standards

Standards For Judging Performance

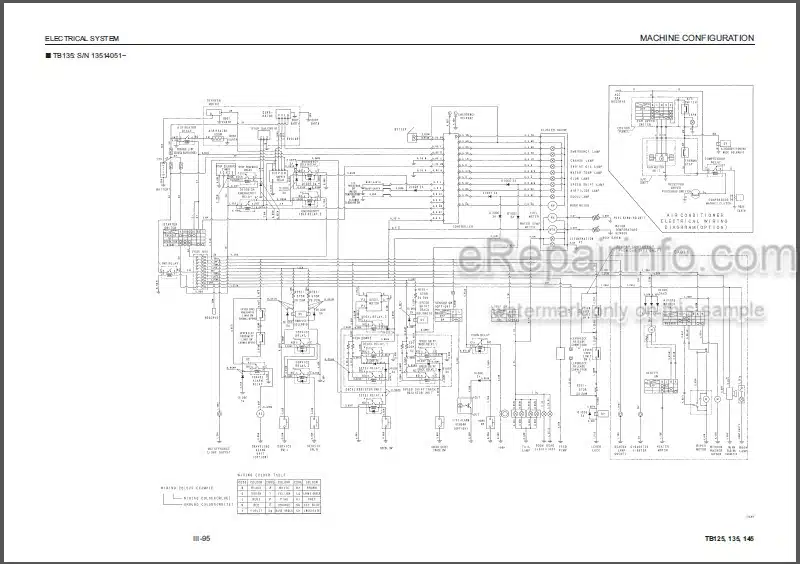

-MACHINE CONFIGURATION

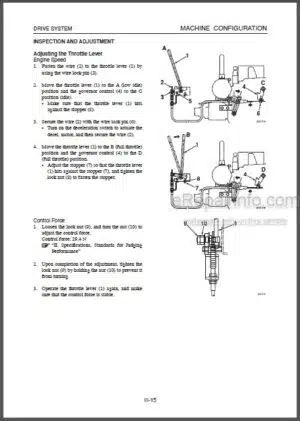

Drive System

Slew System

Travel System

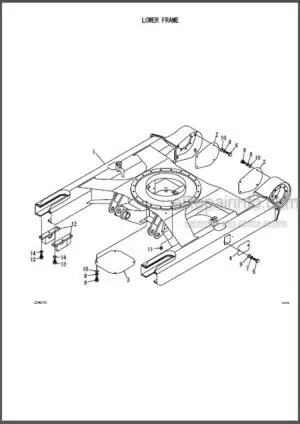

Upper Frame

Control System

Attachments

Hydraulic System

Electrical System

Proportional Control

Air Conditioner System

Security System

-OVERVIEW OF SYSTEM OPERATION

Truck And Heavy Equipment Systems

Air Conditioner-System Operation

Heater System Operation

Environmental Effects On System Operation

Chapter Review

-INSPECTION AND MAINTENANCE WITHOUT GAUGES

Discussion Of Inspection & Maintenance Survey Results

Visual Inspection – System Off

Electrical System Inspection

Performance Inspection – Engine Running

Heater System Inspection

Preventive Maintenance Worksheet

Chapter Review

-TROUBLESHOOTING & SERVICE PROCEDURES

Troubleshooting Overview

Understanding System Function

A Troubleshooting Example

Manifold Gauge Set Installation

Troubleshooting By Manifold Gauge Set Readings

Review Of Frequent Problem Areas

Conclusion

-SECURITY SYSTEM

Notes On Use

Overview Of Functions

Loss Of An Immobilizer Key

Obtaining Multiple Immobilizer Keys

Troubleshooting

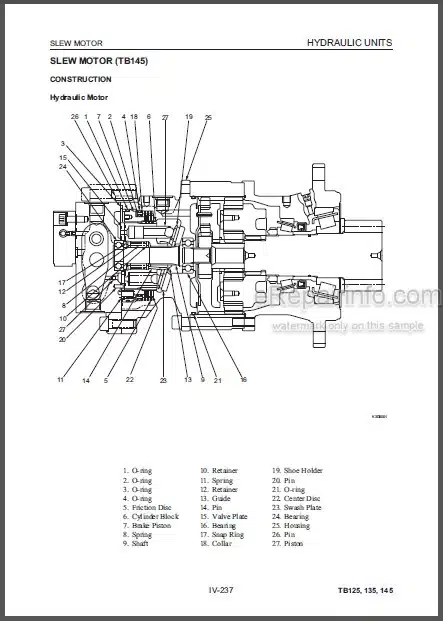

-HYDRAULIC UNITS

Hydraulic Pump

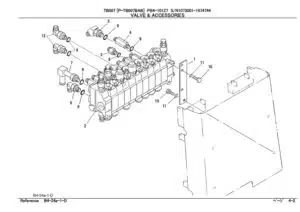

Control Valve

Pilot Valve (Swing)

Shut-Off Valves

Proportional Control Solenoid Valve

Cylinders

Bucket Cylinder For Telescopic Arm )

Tensioning Cylinder

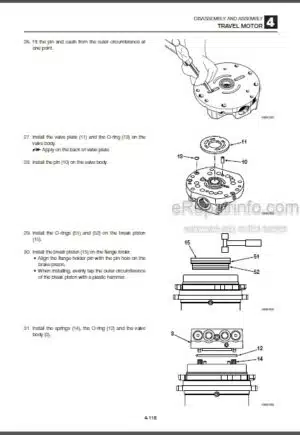

Travel Motor

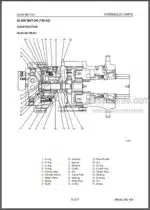

Slew Motor

Slew Motor

Swivel Joint

-TROUBLESHOOTING

Overall Machine

Machine Travel

Slewing

Boom

Arm

Bucket

Boom Swing

Dozer Blade

Auxiliary Hydraulics

2.Service Manual for Yanmar TNE engine series

-SPECIFICATIONS AND PERFORMANCE

2TNE68

3TNE68

3TNE74

3TNE78A

3TNE82A

3TNE82

3TNE84

3TNE88

4TNE82

4TNE84

4TNE88

3TNE84T

4TNE84T

-CROSS SECTIONAL VIEWS

Special Swirl Pгe-combustion Chamber System

Direct Injection System

-COOLING WATER, LUBRICATING OIL AND FUEL OIL

Cooling Waler

Lubricating Oil

Fuel Oil

-TROUBLESHOOTING

Trouble Causes And Remedies

Trouble Diagnosis Through Measurement Of Compression Pressure

-SPECIAL SERVICE TOOLS AND MEASURING INSTRUMENTS

Special Service Tools

Measuring Instruments

-MEASUREMENT, INSPECTION AND ADJUSTMENT

Measuring The Compression Pressure

Adjusting The Valve Head Clearance

Checking The V-Belt Tension

Measuring And Checking The Injection Pressure And Spray Patterns Of The Fuel Injection Valve

Checking And Adjusting The Fuel Injection Timing

Adjusting The No-Load Maximum (Or Minimum) Revolutions

Checking The Cooling Water System And Radiator For Water Leakage

Checking The Battery;

Checking Sensors

Checking The Oil Cooler

Checking The Piston Cooling Nozzle

-MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION

Cylinder Head

Cylinder Block

Valve Rocker Arm

Piston And Piston Ring

Connecting Rod

Camshaft

Crankshaft

Gears

Trochoid Pump

-DISASSEMBLY AND REASSEMBLY

Disassembly

Precautions Before And During Reassembly

-SERVICE DATA

Cylinder Head

Cylinder Block

Valve Rocker Arm

Piston

Piston Ring

Connecting Rod

Camshaft

Crankshaft

Side Gap And Backlash

Others

-TIGHTENING TORQUE

Main Bolt/Nut

Standard Bolt And Nut

-FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM

Exploded Views (Ypfr Type)

Disassembly

Inspection

Reassembly

-FUEL INJECTION PUMP FOR DIRECT INJECTION SYSTEM

Exploded Views (Ypes Type)

Special Service Tools For Disassembly And Reassembly

Disassembly

Inspection

Reassembly

-GOVERNOR

Exploded Views Of Governor For Indirect Injection System

Exploded Views Of Governor For Direct Injection System

Disassembly

Inspection

Reassembly

-TIRBOCHARGER

Specifications

Construction

Waste Gate Valve Adjusting Method

Exploded View Of Turbocharger (W/ Waste Gate)

Tightening Torque

Service Standards

-SERVICE INFORMATION FOR CARB ULG REGULATION

Emission Control Labels

Limiting The No-Load Maximum And Minimum Revolutions

Limiting The Fuel Injection Volume

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.