Factory Service Manual For Tigercat Harvester. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 592

Number: 51802ENG (may 2020)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Harvester

1185

Serial Numbers 11850101 To 11850500

Contents

-INTRODUCTION

Machine Identification And Serial Numbers

Non-Approved Field Product Changes

Regulatory Information

Warranty – EPA

EC Declaration Of Conformity

-SAFETY

Attachment Safety

Battery

Cab Exits

Calibration

Chain Shot

Clean And Inspect

Competent Person

Compliance With Instructions And Required Record Keeping

Diesel Exhaust Fluid (DEF)

Diesel Fuel

Dry Chemical Cleanup

Electrical

Electrical Hazards

ER Boom System

Fastener Torque And Reuse

Fighting Fires

Fire Prevention

Fluid Hazards

Grease Injection Injury When Using Pneumatic Grease Guns

Harvesting Attachment

Hazardous Materials

Hazards

High Pressure Injection Injuries

Hydraulic Hazards

Interlock Door Switch

Lifting And Carrying

Lifting Components Safely

Lightening Safety Awareness

Lock Out/Tag Out

Logging Safety

Loose Clothing Hazard

Machine Fire

Machine Hazards

Machine Stability And Traction

Maintenance

Material Lifting And Handling

Notice Labels

Operating Hazards

Operational Recommendations

Pneumatic Grease Guns

Read This Manual First

Refuelling The Machine

Retained Hydraulic Pressure

Safety Labels

Safety Precautions, General

Safety Symbols

Service Safety Precautions

Shipping Components

Signal Words

Thread Locking /Adhesive Compounds And Sealants

Transporting The Machine

Tree Felling Operations

Welding, Prior To

What To Do After A Machine Fire Has Occurred

What To Do If You Are Outside And See Lightening Or Hear Thunder

Work Conditions And Tools

Working With Oil

-CONTROLS AND OPERATION

Activity Log Screen

Adjusting The Start/Stop Values

Adjustments

Adjust Menu Screen

Adjust Rights Screen

Aftertreatment System – Engine Idle Too Long Alarm

Aftertreatment System Technical Failure Severe Alarm

Air Conditioning Control

Air Recirculation Filters

Alarm Messages – Types

Alarms

All Wheel Drive Switch

Attachment Rotate CW/CCW

Attachment Rotate Screen

Audio System

Auto Leveling

Auxiliary Power Outlets

Backlight

Back Up Camera

Band Width Limiting Adjustments – About

Battery Disconnect Switch

Bogie Balance Adjustment

Braking

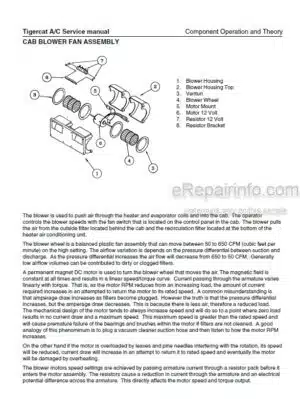

Cab Air Conditioning, Heating And Ventilation

Cab Air Filters And Vents

Cable Assist

Camera And Display

Computer

Computer Display

Computer Display Messages

Control Panel

Coolant

Coolant Level Sensor Error Alarm

Cooling Fan Adjustments

Cooling Fan Clean Switch

Cooling Fan Full On/Automatic

Crane

Current Output Error

Date/Time Adjustments Screen

DEF Level

DEF Quality Low Alarm

DEF Tank Empty Alarm

Differential Lock Engaged Alarm

Differential Locks Engaged Alarm

Digital Output Error

Display Adjustments Screen

Door Safety Interlock

Drive

Drive Charge Filter Bypassed Alarm

Drive Charge System Alarm

Drive Motor Speed Sensor Alarm

Drives Adjustments Screen

Drive Speed Sensor Off Alarm

Electronic Device Holder

Emergency

Engine

Entering And Exiting The Cab

ER Boom System, Instructions

Fan Full On Alarm

Fine Control

Fine Control-About

Fire

Fire Suppression

Fire Suppression Discharged Alarm

Fire Suppression Fault Alarm

Fire Suppression System – Amerex

Fire Suppression System – Fogmaker

Fire Suppression System – Fogmaker

Fresh Air Filter

Front Differential Lock Switch

Fuel Low Level Alarm

Gear Selection Switch

General Crane Adjustments

General Machine Adjustments

Harvesting Head

Heater

Holding Brakes

Home Screen

Horn/Safety Alert Switch

HVAC

Hydraulic Motor Speed High Alarm

Hydraulic Oil

Idling The Machine

Ignition Key Switch

Inducement Locked Engine Limited To Low Idle Alarm

Information

Interior Cab Light Switch

Interlock Reset Switch

Interlock System

IQAN Module Fault Alarm

Joystick

Key Switch

Ladder And Platform Raise/Lower Switch

Language Adjustment

Left Joystick

Leveling

Leveling Adjustment Screen

Load Sensing, Operating Tips

Logging Out Of The Computer

Machine

Machine Orientation Screen

Machine Start-Up

Machine Voltage High Alarm

Machine Voltage Low Alarm

Main Boom Adjustments Screen

Main Boom Up/Down

Main Fuel Filter Clogged Alarm

Main Menu – About

Main Menu Screen

Manual Leveling

Maximum

Measure Menu Screen

Methods Used To Make Adjustments

Min/Max Current Values

Min Max, Slopes

Min/Max Values

Module No Contact Error Alarm

Modules Screen

Module VREF Error Alarm

Oil Grade Adjustments Screen

Oil Grade Selection

Operating The Machine

Operator Adjustments Screen

Operator’s Manual Case

Operator’s Seat

Oscillation Balance Screen

Oscillation Balance Switch

Overhead Control Panels

Parking Brake Switch

Passwords

Pedal Controls

Pictograms

Portable Fire Extinguishers

Positioning The Crane And Harvesting Head For Maintenance

Preferences Screen

Pre-Start Checks

Programmable Foot Pedal

Programmed Selector Switches

Pump Drive Gearbox Oil Temperature High Alarm

Raw Vs Scaled Values

Rear Camera

Rear Differential Lock Switch

Restarting An Engine

Return Filter Bypassed Alarm

Right Joystick

Right Joystick Pod

Rotate (Attachment)

Scaled Vs Raw Values

Seat

Service Brake Pressure Low Alarm

Starting The Engine

Start/Stop Slopes

Start/Stop Values

Steer Angle Sensor

Steering

Stick Boom Adjustments Screen

Stopping The Engine

Storage Compartments

Switch

System Menu Screen

Telescope Adjustments

Telescope Adjustments Screen

Telescoping Boom Extend/Retract,

Temperature Control

Travel Direction Swap Pedal

Travel Direction Switch

Travel/Engine Speed Adjust Switch

Turn Signal

Unlock Adjust Screen

USB Ports

Vents

Voltage Input Error Alarm

Warmup Mode

Water In Fuel Alarm

Webasto Fault Alarm

Windshield

Worklights

-LUBRICATION AND MAINTENANCE

Accumulator

Adding Oil

Adding Oil To The Hydraulic Oil Tank

Aftertreatment System

Air Conditioning System

Air Intake System

Approved Anti-Seize Pastes For Exhaust/Aftertreatment Line (Tigercat By FPT Tier 4F Engines)

Approved Hydraulic Oils

Articulation Bearing

Articulation Lock Installation

Axle

Axle Input Shaft Lubrication

Battery

Bogie Axles

Boom Guides

Boosting The Battery

Brakes

Cab

Care Of The Machine

Case Return Strainer

Centre Joint

Changing The Engine Fuel Filter

Changing The Fuel Filter/Water Separator Element

Charging The Batteries

Checking Telescopic Stick Boom Play

Checking The Hydraulic Oil Level

Cleaning

Common And Custom Torque Specifications

Compartment, Storage

Compressor Belt Tension

Condenser, A/C, Cleaning

Coolant Heater See Engine Coolant Heater

Coolant Heater Unit Preventive Maintenance

Coolant Shut-Off Valve

Cooler Package

Crane Lubrication

Crankcase Ventilation Filter

Cylinder Locks

DEF

Diesel Exhaust Fluid (DEF)

Disabling The Oscillation Lock Cylinders

Disconnecting The Transmission

Draining

Draining The Oil

Emergency Exit

Engine

Filter Restriction Indicator

Filters

Fire

Fluid Analysis Program

Flywheel Housing

Fuel System

Fuses

Fuses And Relays

General Safety Information

General Torque Specifications

Hydraulic Oil

Hydraulic Oil System

Hydraulic Oil Tank

Input Shaft Lubrication

Installing And Uninstalling The Ladder

Jumping The Batteries

Ladder

Leveling Cylinders

Lock

Low Voltage Disconnect Adjustment

Lubrication

Machine Weight

Manual Hand Pump – Engine Enclosure And Fuel Tank

New Machine Maintenance

Oil

Oscillation

Oscillation Joint

Portable Ladder

Pressure And Speed Settings

Pressure Washing The Machine

Preventive Maintenance

Pump Drive Gearbox

Radiator

Refuelling

Releasing

Remote Fuel Tank Filling

Return Strainer

Rotary Manifold Reservoir

Rotary Manifold Seal Lubrication

Scheduled Maintenance

Serpentine Belt

Service And Lubrication Schedule

Service Lights

Slew Bearing Lubrication

Steer Cylinder Lubrication

Storage Compartment

Swing Drive Gearbox

Taper Lock Pins Re-Torquing

Telescopic Stick Boom

Tilt

Tilting

Tire Pressures

Torque, Fluid Connections

Torque Values

Towing The Machine

Transmission

Transporting The Machine

Unloader Valve

Vacuum Pump

Weight

Weights Of Commercial Wood

Windshield Washer Fluid Reservoir

Work Light Fuses

-HYDRAULIC SYSTEM

General Machine Setup

Hydraulic Oil Heat-Up

Working Pump And Valve Set-Up

-ELECTRICAL AND COMPUTERS

Backup Camera Setup

Calibrating The Joysticks

DASA Computer Software (Optional)

Harvester Sensor Calibration

IQAN Software

UDST Test – Engine Fault Codes T4F

-DRIVE

Bogie Balance Set – Up

Charge Pressure And Brake Check

Drive Set-Up

-BRAKES AND DIFFERENTIAL LOCKS

Modular Manifold Set-Up

Service Brake Pressure Set-Up

-COOLING SYSTEM AND FAN

Cooling Fan Circuit Setup

-STEERING, CENTRE JOINT AND OSCILLATION LOCK

Harvester Oscillation Cylinder Purge

-LEVELER

Leveler Assembly

-HARVESTING ATTACHMENT

Attachment Pump Set-Up

Attachment Rotation Speed Set-Up

-MISCELLANEOUS

Automatic Fire Suppression System – Amerex

Fogmaker Fire Suppression System

Tire Pressure Monitoring System

ELECTRICAL SCHEMATICS

HYDRAULIC SCHEMATIC

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.