Factory Service Manual For Tigercat Shovel Logger. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 852

Number: 51129AENG (march 2020)

Bookmarks

Searchable

Wiring Diagrams

Hydraulic Diagrams

Model

Tigercat Shovel Logger

S855E

LS855E

Serial Number 85553001 To 85554000

Serial Number 85503001 To 85504000

Contents

-INTRODUCTION

Machine Identification And Serial Numbers

SAE Standards For Machine Operator Protective Structures

Non-Approved Field Product Changes

Regulatory Information

Warranty-EPA

-SAFETY

Backover Accidents – Avoiding

Battery Safety

Boom Systems

Cab Exits

Cable Assist

Chain Shot

Chain Shot-Logging Safety

Emergency Cab Exits

ER Boom Function, Switchable

ER Boom System Precautions

Felling Trees

Fire Prevention

Fluid Injection Injury

Fluid Leaks

General Safety Precautions

Grease Injection Injury

Hydraulic Pressure Hazard

Interlock Switch, Safety

Lightening Safety Awareness

Liquid Starting Aid

Loose Clothing Hazard

Machine Stability And Traction

Machine Stability And Traction

Moving Trees

Operating Safety Precautions

Parking The Machine

Pneumatic Grease Guns, Using

Protective Clothing

Safety Hazards – Operating

Safety Hazards-Viton Seals

Safety Interlock Switch On Front Cab Door

Safety Labels

Safety Precautions, General

Safety Precautions, General

Safety Precautions, Operating

Safety Precautions, Servicing

Safety Symbols

Seat Belt

Servicing And Repair

Servicing Safety Precautions

Signal Words

Soft Ground Applications

Transporting The Machine

Viton Seals

Wet Chemical Cleanup Procedure

Working With Oil

-CONTROLS AND OPERATION

A/C/Defrost Switch

A/C Heater Fan Speed

Air Source Switch

Alarm And Alarm Light

Attachment, Instructions And Precautions

Auxiliary Input

Auxiliary Power Outlet, 12 V

Battery Boosting

Battery Disconnect Switch

Belt Routing, Serpentine

Bottom Refuelling

Cab Dome Light Switch

Cab Temperature Control

Camera

Cold Weather Starting

Computer

Computer And Display

Computer Display (Home Screen)

Computer Display Messages

Control Panel

Coolant Shut-Off Valves

Current Output Channels

Display Video

Electronic Device Holder

Emergency Exits

Engine Coolant Heater Control (Optional)

Engine Speed Switch

Engine, Stopping

ER Boom System, Instructions

Escape Hatch Removal For Maintenance Or Repair

Escape Hatch Replacement

Fan Service Mode

Fan Switch, A/C / Defrost

Fan Switch, Cooling System

Fire Extinguisher, Cab

Fire Extinguisher, Portable

Fire Suppression System

Fire Suppression System Type A

Fire Suppression System Type B

Fuel, Refuelling Procedure

Fuel Tank

Horn/Safety Alert Switch

Hydraulic Oil Tank Vacuum Switch

Ignition Key Switch

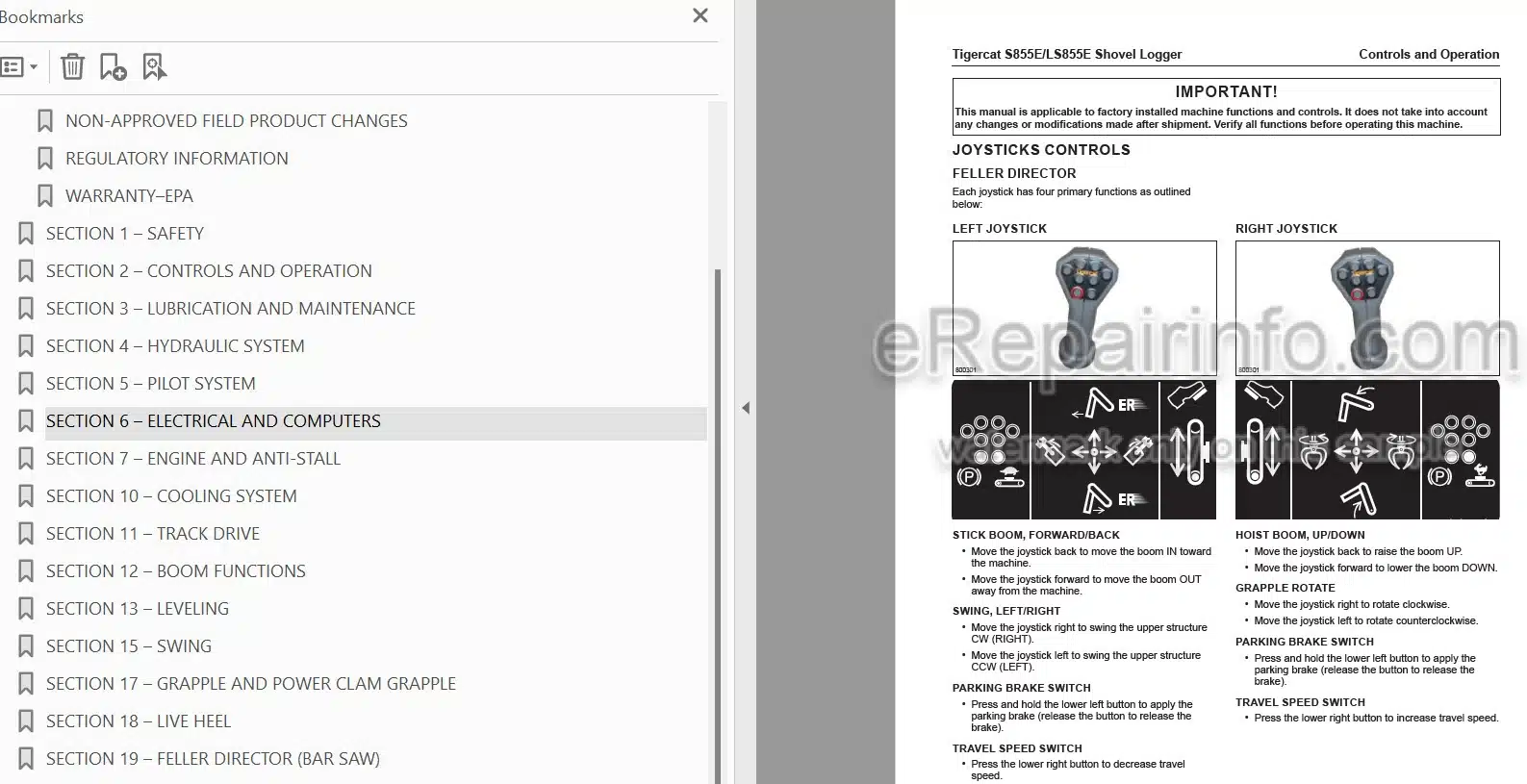

Joystick Controls

Key Switch

Load Sensing, Operating Tips

Operating The Machine

Operating Tips With Load Sensing

Operation Modes

Operator’s Manual

Operator’s Seat

Pictograms

Pilot System Off Switch

Pilot System Reset Switch

Pilot System Safety Interlock Switch (Front Door)

Power Roof Switch

Radio

Rearview Camera

Refuelling Procedure

Safety Interlock Switch (Front Door)

Saw Switch

Seat, Operator’s

Serpentine Belt Routing

Service Light Switch And Indicator

Skyview Camera

Slope Indicators

Starting Engine

Storage Area

Swing Brake Switch

Switch

System Test And Warm-Up

Telematics Repair Mode

Timed Purge Interval

Top Refueling

Track Drive Controls

Traveling, Boom Raised

USB Connection

Video Display, Camera

Warm-up Mode

Work And Service Lighting

Work Lights Switches

-LUBRICATION AND MAINTENANCE

Adding Engine Coolant

Aftertreatment System

Aftertreatment System (Denox 22 System, Tier 4F)

Air Cleaner Housing

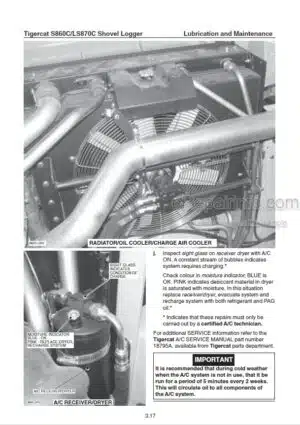

Air Conditioning System

Air Filters

Air Intake Clean Out Cover

Air Intake System

Anti-Corrosion Spray, Removal, If Applicable

Approved Anti-Seize Pastes For Exhaust/Aftertreatment Sensors

Approved Hydraulic Oils

Attachment Case Drain Filter

Battery Box Cover

Battery Care

Belt, Serpentine, Inspection/Replacement

Bottom Refuelling System (Optional)

Care Of Polycarbonate Windows

Care Of The Machine

Check Engine Coolant Level

Cleaning

Cleaning Cooler Package

Clean Out Cover

Commercial Wood-Weights

Cooler Package-Cleaning

DEF Flushing Test

Denox 22 Dosing System

Diagnostics Connection, Engine

Diesel Exhaust Fluid (DEF)

Diesel Exhaust Fluid (DEF) Handling And Storage

Diesel Exhaust Fluid (DEF) Tank

Diffusers

Diffusers/Strainers – Hydraulic Oil Return

Draining Engine Coolant

Draining Hydraulic Oil Tank

Draining The Hydraulic Oil Tank

Emergency Exits

Emergency Exits, Check Monthly

Engine Bottom Access Cover

Engine Coolant Heater Unit (Optional)

Engine Coolant Heater Unit Preventive Maintenance

Engine Diagnostics Connection

ER Boom System

Escape Hatch Replacement

Filling The DEF Tank

Filter And Lubrication Schedule

Filter/Breather

Filter Change Procedure

Filter Restriction Indicator

Filters

Fire Extinguisher Enclosure

Fire Prevention

Fire Suppression System Components

Fluid Analysis Program

Fluid Sampling Program

Front Door Prop Rod

Fuel Filter/Water Separator Draining Procedure

Fuel Heater

Fuel System

Fuel Tank

Fuses And Relays

Graffiti Removal

Heater Valve/Heated DEF Supply Lines

Hydraulic Adjustments Table

Hydraulic Oil Heater 120V, 1500W (Optional)

Hydraulic Oil Heater (Optional)

Hydraulic Oil Level Sight Gauges

Hydraulic Oil Operating Range

Hydraulic Oil Tank

Hydraulic Oil Tank Electric Fill Pump

Hydraulic Oil Tank Hand Fill Pump

Hydraulic Oil Tank Pressurization Instructions

Hydraulic Oil Tank Vacuum System (If Equipped)

Hydraulic System

Intake Tubing And Joints

Leveler Cylinder Locks

Lockout Reset Procedure

Low Voltage Disconnect Adjustment

Lubrication Schedule

Machine Parameters

Main Control Valve Bottom Access Cover

New Machine Maintenance

Oil Lost From Leakage

Pilot Filter

Power Roof

Power Unit

Pressure And Speed Settings

Pressure Washing

Preventive Maintenance Schedule

Pump Case Drain Filter

Pump Cover

Pump Cover Side Door

Pump-Hydraulic Oil Fill-Hand

Rear Door

Refilling The Hydraulic System

Remote Fuel Tank, Coolant Heater Unit (Optional)

Remote Fuel Tank Filling

Rotary Manifold Seal Lubrication

Scheduled Maintenance

Serpentine Belt, Inspection/Replacement

Service And Lubrication Schedule

Service And Maintenance Access Doors And Covers

Strainer/Diffuser, Case Drain

Strainer-Fuel Tank

Swing Drive Gearbox

Swing Drive Lubrication

Telematics System

Telematics System Components

Temperature Sender

Timed Purge Interval

Torque Chart

Torque, Fluid Connections

Track Chain

Track Components

Track Drive Gearbox

Track Drive Gearbox Grease Seal, Tigercat

Track Motor Cover

Track Operation And Wear Prevention

Track Sag Adjustment

Warm Air Intake Cover

Weights Of Commercial Wood

Windows

Wire Colour Code Chart

Wood, Weights Of Commercial Wood

-HYDRAULIC SYSTEM

Case Drain Strainer

Cracking Pressure

Hydraulic Fundamentals

Hydraulic Oil Tank

Hydraulic System Overview

Load Sense Relief Pressure Setting

Load Sensing

Margin Pressure

Test Main Hydraulic Pump Wear

-PILOT SYSTEM

Circuit Diagram

Controls

Hydraulic Schematic

Pilot Supply Pressure Setting

Pilot System

Pilot System Components

Pilot System Electrical Circuits

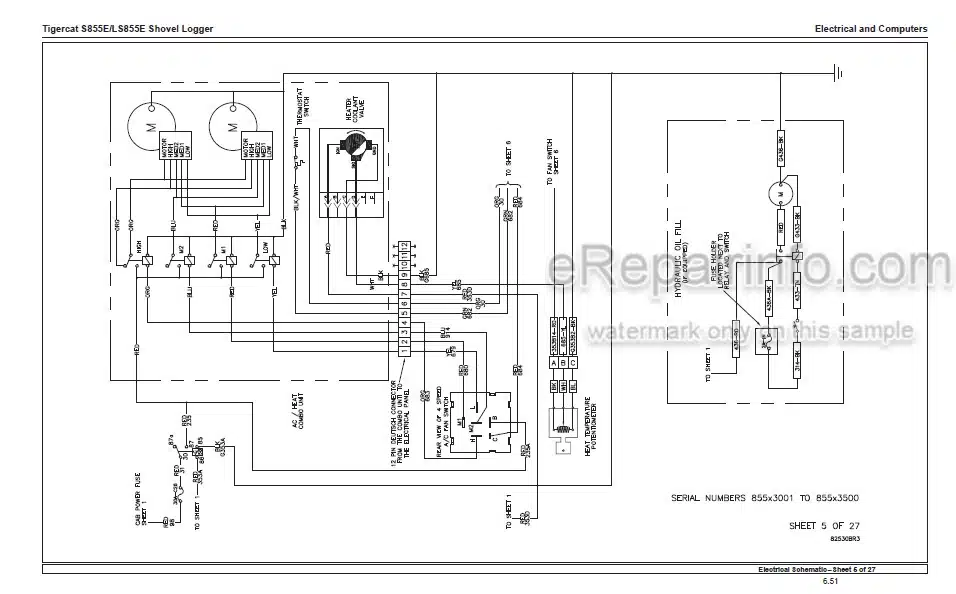

-ELECTRICAL AND COMPUTERS

Cab Electrical Installation

Computer Control System

Electrical Schematic

Electrical Service And Diagnostic Kit

Electrical System Overview

Machine Program Updates

Upper Structure Electrical Installation

-ENGINE AND ANTI-STALL

Circuit Diagram

Electrical Schematic

Engine Anti-Stall System

Engine Diagnostic Connector

Flex Drive Coupling

Hydraulic Schematic

Load Sense

Starting And Stopping The Engine

-COOLING SYSTEM

A/C Condenser And A/C System

Charge Air Cooler

Coolant Pre-Heating System (Optional)

Cooling System

Diesel Exhaust Fluid (DEF) System

Fan Control System

Fan Drive System

Fan Hub Installation

Fan System Testing

Heater System

Hydraulic Oil Cooler Circuit

POR Pressure Setting

Radiator

-TRACK DRIVE

Circuit Diagram

Hydraulic Drive System

Hydraulic Schematic

Important Track Drive Information

Measure Track Sag

Parking Brake Disc Replacement (Tigercat)

Parking Brake Disc Replacement (Type A)

Pressure And Speed Settings Type B

Pressure And Speed Settings Type C

Rotary Manifold

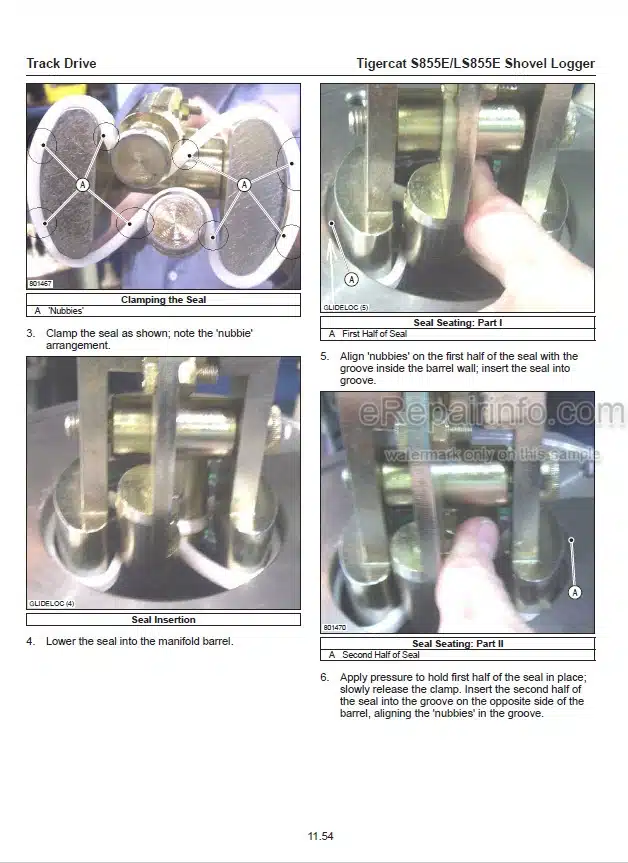

Rotary Manifold Seal Installation

Summary Of Track Speed Adjustment Procedure

Torquing Undercarriage Bolts

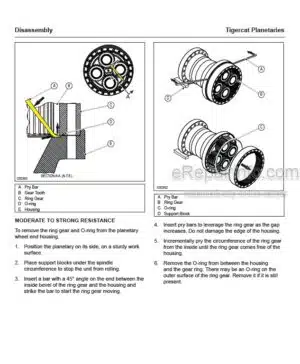

Track Drive Gearbox Identification

Track Drive Motor

Undercarriage Components

Wear Limits

-BOOM FUNCTIONS

Adjust Flow Cycle Times

ER Boom System Description

ER Boom Valve

ER/Cooler Bypass Valve

Hoist And Stick Control Valve

Hoist And Stick Functions (ER Boom System)

Hydraulic Circuit Diagram

Hydraulic Schematic

Pressure Settings

Tilt Function

-LEVELING

Check Leveling Speed

Circuit Diagram

Hydraulic Schematic

Leveling Circuit Description

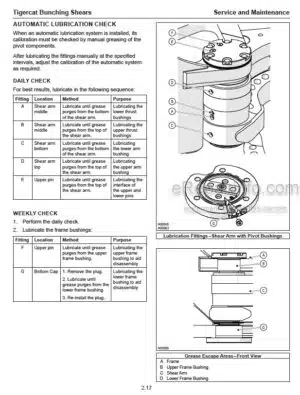

Leveling Component Lubrication

Leveling Control Valve

Leveling Cylinder Counterbalance Valves

Leveling Cylinder Tapered Lock Pins

Leveling Electronic Adjustment

Side Pivot Axis Bearings

-SWING

Adjust Swing Bearing Backlash

Hydraulic Schematic

Swing Bearing Identification

Swing Bearing Lower Seal Replacement-Kaydon

Swing Bearing Replacement

Swing Bearing Seal Replacement-Galperti

Swing Bearing Seal Replacement-Liebherr

Swing Bearing Wear Limits

Swing Drive System

Swing Pressure And Speed Settings

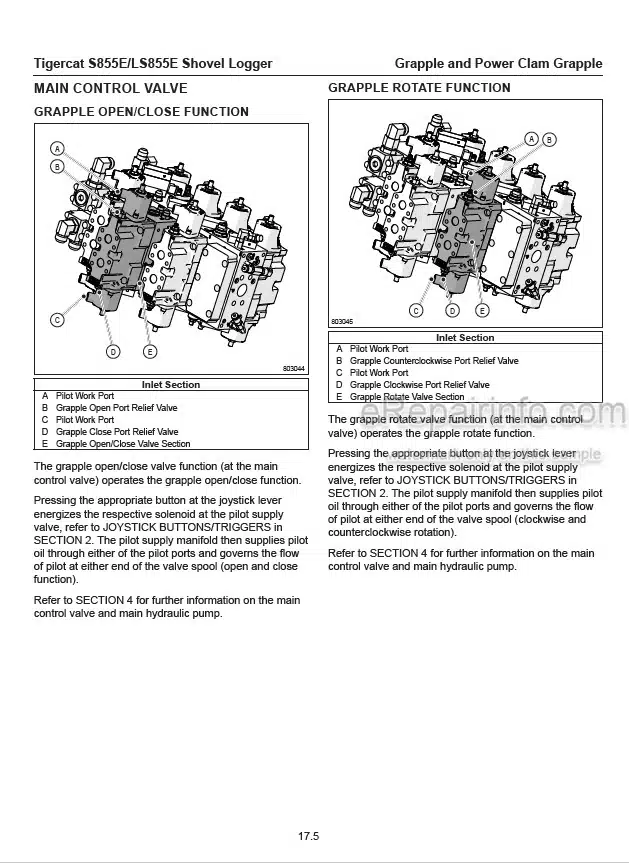

-GRAPPLE AND POWER CLAM GRAPPLE

Adjust Flow Cycle Times

Attachment Electronic Adjustment

Circuit Description, Grapple

Circuit Description, Power Clam

Grapple Electrical Circuit Diagram

Grapple Hydraulic Circuit Diagram

Grapple Open/Close Relief Valve Pressure Settings

Grapple Open/Close Function Speed Settings

Grapple Rotate Relief Valve Pressure Settings

Grapple Rotate Function Speed Settings

Hydraulic Schematic, Grapple

Hydraulic Schematic, Power Clam Grapple

Main Control Valve

Power Clam Grapple Electrical Circuit Diagram

Power Clam Grapple Hydraulic Circuit Diagram

Power Clam Grapple Open/Close Function Speed Settings

Power Clam Grapple Open/Close Relief Valve Pressure Settings

Priority Grapple Open/Close Plate Por Setting

Priority Grapple Open/Close Plate Por Setting

-LIVE HEEL

Adjust Flow Cycle Times

Live Heel Circuit Description

Live Heel Control Valve Section

Live Heel Function

Live Heel Function Speed Settings

Live Heel Hydraulic Circuit

Live Heel Hydraulic Schematic

Live Heel Relief Valve Pressure Settings

-FELLER DIRECTOR (BAR SAW)

Auxiliary Supply Valve

Bar Saw Summary And Electrical Circuits

Circuit Diagrams

Feller Director Attachment

Hydraulic Schematics

Main Control Valve

Main Pump Operation

Pilot Manifold Operation

Tilt Float Valve

-MISCELLANEOUS

Power Roof

Power Roof Electrical Schematic

Power Roof Hydraulic Circuit Diagram

Power Roof Hydraulic Schematic

Power Roof Pressure Settings

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.