Factory Operating Maintenance Instructions For Bomag Cold Milling Machine. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 174

Number: 00806061 (august 2011)

Searchable: Yes

Model

Bomag Cold Milling Machine

BM2000-60

S/N 821 836 26 ….>

S/N 821 836 31 ….>

Contents

TECHNICAL DATA

SAFETY REGULATIONS

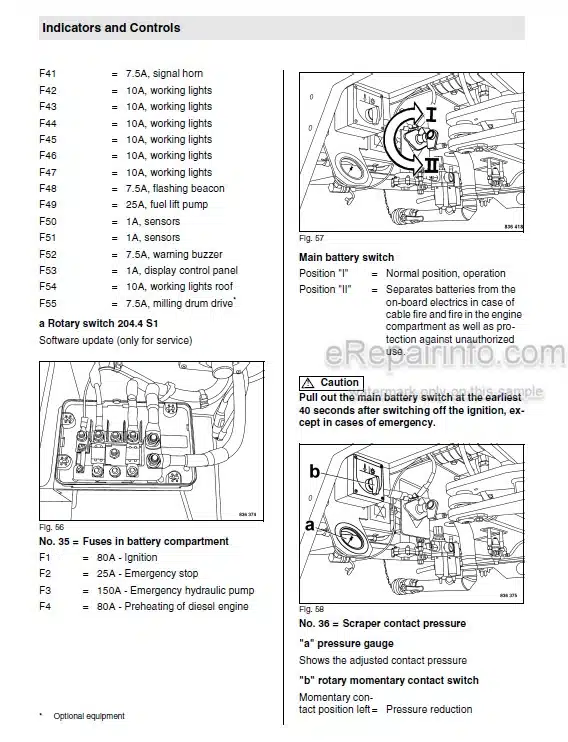

-INDICATORS AND CONTROLS

View Of Operating Console Left, Middle, Right

General Notes

Display And Control Elements Operator’s Stand

View Rear Right Hand Control Panel

Control Elements On Rear Right Hand Control Panel

View Rear Left Hand Control Panel

Description Of Rear Left Hand Control Panel

View Front Right Hand Control Panel

Description Of Front Right Hand Control Panel

View Front Left Hand Control Panel

Description Of Front Left Hand Control Panel

Automatic Levelling Control

Description Of Levelling Control

View Of Ultrasonic Levelling System

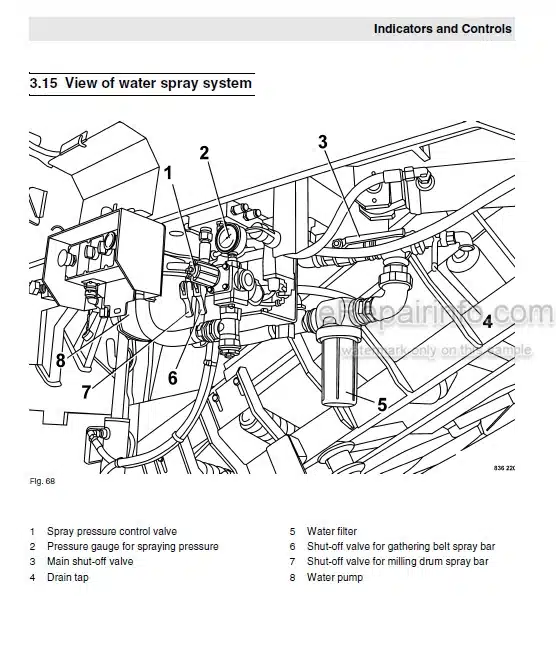

View Of Water Spray System

-OPERATION

General Notes

Tests Before Taking Into Operation

Starting The Engine

Starting With Jump Wires

Shutting Down The Engine

Steering

Lifting / Lowering The Machine

Switching The Milling Drum On/Off

Operating The Scraper

Operation Of Loading And Gathering Conveyor Belt

Driving The Machine

Preparing For Work

Work Operation, Setting The Cutting Depth

Automatic Milling Depth Control

Milling Depth Control By Means Of Ultrasound

Stopping/Finishing Work

Adjusting The Seat

Operating The Engine Hood

Operating The Protection Roof On The Operator’s Stand

In Events Of Emergency

Preparing The Machine For A Longer Rest

Operating The Water Spray System

Folding / Unfolding The Loading Conveyor Belt

Loading, Transport

Multi-Function Display

Scrapping The Machine

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

Check The Engine Oil Level

Check, Clean The Water Separator

Check The Fuel Level

Checking The Hydraulic Oil Level

Check Water Level, Spray Nozzles

Check/Replace Cutting Tools, Scraper

Checking The Track Plates

Check, Tighten The Conveyor Belts

Checking The Safety Ropes

Lubricate The Machine

Check The Coolant Level

Check The Oil Level In The Pump Drive Gear

Retightening The Track Shoe Fastening Screws

Lubricate The Machine

Clean The Cooling Fins On Engine And Hydraulic Oil Cooler

Cleaning The Engine

Changing Engine Oil And Oil Filter Cartridges

Checking, Replacing The Generator V-Belt

Checking, Replacing The Milling Drum V-Belt

Checking The Track Drive

Lubricate The Machine

Check, Adjust The Valve Clearance

Change The Fuel Pre-Filter Cartridge

Change The Fuel Filter Cartridge

Check Fastening Of Engine / Turbocharger / Combustion Air Hoses

Checking The Crankcase Pressure

Intercooler, Draining Oil And Condensation Water

Change The Hydraulic Oil

Changing The Hydraulic Oil Filter

Change The Oil In The Pump Drive Gear

Change The Oil In The Milling Drum Reduction Gear

Oil Change In Milling Drum Bearing

Oil Change In Track Drive Gear

Drain The Sludge From The Fuel Tank

Battery Maintenance

Changing The Coolant

Changing The Injection Valve

Changing The Coolant Pump

Changing The Pressure Retaining Valve On Te Injection Pump

Changing The Crankcase Ventilation Valve

Service The Combustion Air Filter

Clean Water Tank And Water Filter

Water Spray System, Maintenance In Case Of Frost

Clean The Pressure Cleaner Water Filter

Tightening Torques

Engine Conservation

-TROUBLESHOOTING

General Notes

Engine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.