Factory Service Manual For Bomag Milling Machine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG

Pages: 792

Number: 00891036 (june 2006)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Bomag Cold Milling Machine

BM2000-60

S/N 821 836 13 ….

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

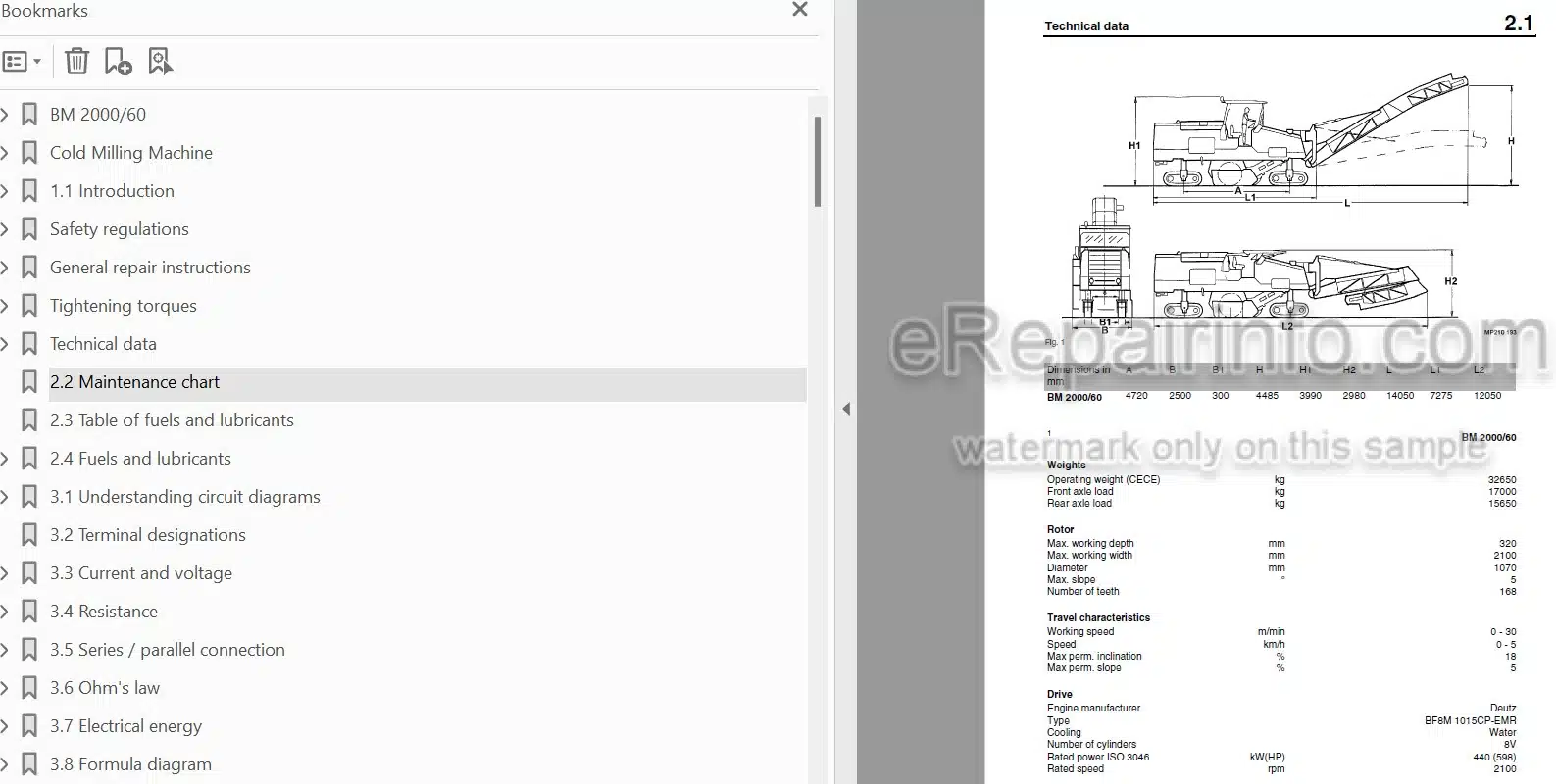

-TECHNICAL DATA

Technical Data

Maintenance Chart

Table Of Fuels And Lubricants

Fuels And Lubricants

-FUNDAMENTAL ELECTRICS

Understanding Circuit Diagrams

Terminal Designations

Current And Voltage

Resistance

Series / Parallel Connection

Ohm’s Law

Electrical Energy

Formula Diagram

Logical Base Gates

Metrology

Diodes, Relays, Fuses

Batteries

Three-Phase Generator

Electric Starter

-SPECIAL TOOLS, ELECTRICS

Special Tools, Electrics

-MACHINE RELATED ELECTRICS

Component Overview

Driver’s Stand

Control Console, Rear Right

Control Console, Rear Left

Control Console, Front Right

Control Console, Front Left

Control Console For Auxiliary Control

Engine Hood Control Console

Loading Conveyor Belt

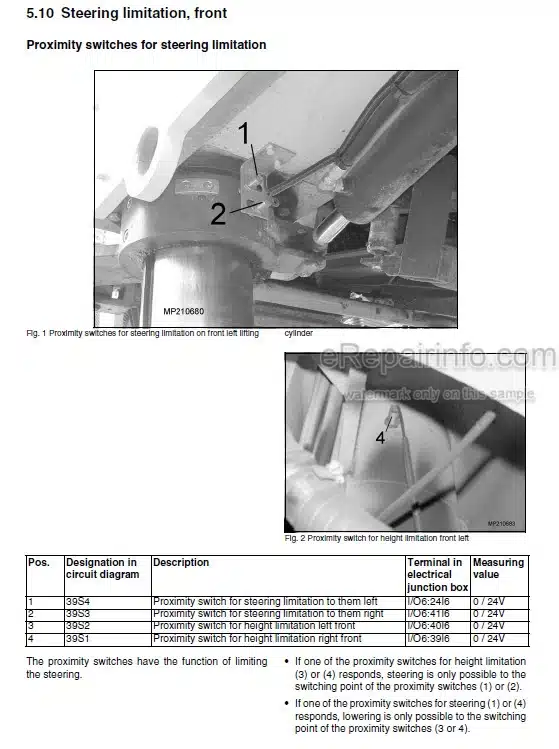

Steering Limitation, Front

Middle Position, Rear Steering

Operating Conditions For Rear Steering

Height Limitation, Rear

Operating Conditions For Rear Posts

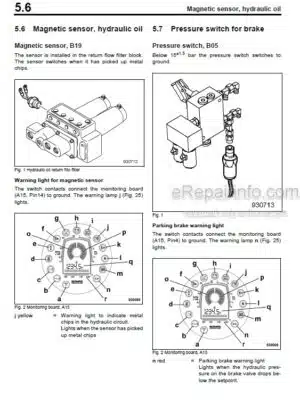

High Pressure Sensors For Travel/Conveyor Belt Pump

Pressure Sensor For Steering / Working Hydraulics

Pressure Sensor For Clutch Pressure

Pressure Sensor For Fan Circuit

Differential Pressure Switch For Hydraulic Oil Filter

Pressure Switch For Water Sprinkling System

Operating Condition For Sprinkling System

Limit Switch On Scraper

Operating Conditions For Scraper

Rope Sensors, Height Regulation

Inclination Sensor For Height Regulation

Operating Conditions For Height Regulation

Levelling Control Panel

Speed Sensor

Operating Conditions For Travel Drive

Terminal Box

Pin Assignment, Id4 Id6

Battery Compartment

Battery Maintenance

Multi-Function Display, Inputs/Outputs

Tuning PID Parameter

Digital Inputs And Outputs In The Electric Circuit Diagram

Switching States, Compact (ID4)

Switching States, Compact (ID5)

Switching States, Compact (ID6)

Switching States, CGC Matrix

Operating Conditions For Conveyor Belt

Operating Conditions For Gathering Foot

Operating Conditions For Grade Shoes

Operating Condition For Milling Rotor Operation

-ENGINE

General Information On Diesel Engine

Engine Attachment Parts

Lubrication Oil Schematic

Electronic Engine Control EMR

Sensor Data EMR

Plug Assignment EMR

Connection Diagram EMR Engine Control

Engine

Fault Lamp

Diagnostics Button

Overview Of Fault Flashing Codes

Possible Diagnostics With The Serida Software

Checking The Engine Speed

Disassembling And Assembling The Injection Valves

Checking And Adjusting The Start Of Commencement

Replacement Of Radial Seal On Flywheel Side

Replacement Of Radial Seal On Pump Carrier

Replacing The Thermostats

Replacing The Coolant Pump

Sealing / Replacing The Oil Cooler

Replacing The Cylinder Head Gasket

Check, Adjust The Valve Clearance

Checking, Replacing The Generator V-Belt

Service The Combustion Air Filter

Check The Coolant Level

Change The Coolant

Check The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridges

Check Fastening Of Engine / Turbocharger / Combustion Air Hoses

Engine Conservation

Cleaning The Engine

Fuel Pre-Filter / Water Separator (Separ Filter)

Checking, Cleaning The Water Separator

Changing The Fuel Prefilter Element

Change The Fuel Filter Cartridge

Special Tools, Deutz Engine (Bf8M 10T5C)

Explanation Of Symbols

-MILLING DRIVE, MECHANICS

Milling Drive

Checking, Replacing The Milling Drum V-Belt

Change The Oil In The Milling Drum Reduction Gear

Oil Change In Milling Drum Bearing

Checking/Replacing Cutting Tools, Scraper

Replacing Bases/Holders

Lubricating The Milling Drum

Lubricating The Dry Clutch

Checking The Wear Of The Friction Lining

Friction Lining / Replacing The Outer Discs

-CONVEYOR BELTS, MECHANICS

Conveyor Belts

Checking, Tightening The Conveyor Belts

Checking The Safety Ropes

Lubricating The Conveyor Belts

Folding / Unfolding The Loading Conveyor Belt

-TRAVEL DRIVE, MECHANICS

Travel Drive

Checking The Track Plates

Retightening The Track Shoe Fastening Screws

Checking The Track Drive

Lubricating The Travel Drive

Lubricating The Steering System

Oil Change In Track Drive Gear

-PUMP TRANSFER CASE

Transfer Case

Check The Oil Level In The Pump Drive Gear

Change The Oil In The Pump Drive Gear

-HYDRAULICS

Service Training Hydraulics

-HYDRAULIC CYLINDER

Repairing Hydraulic Cylinders

-SUPPLIERS DOCUMENTATION

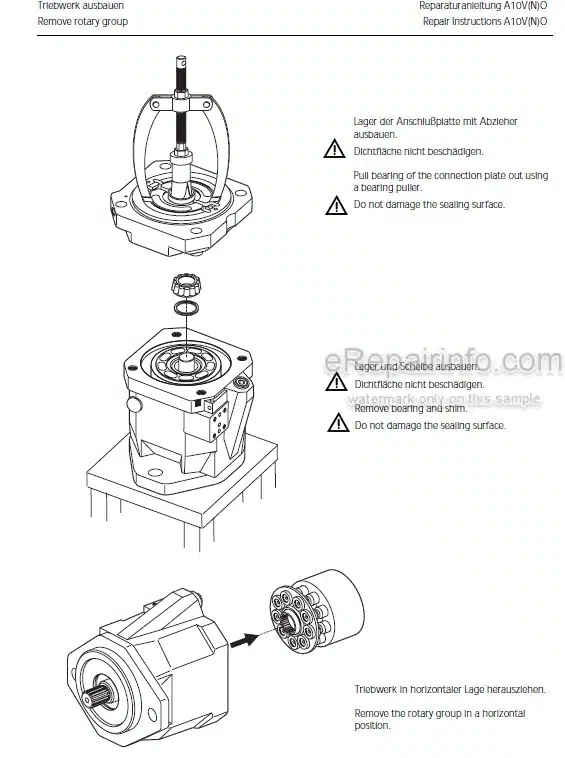

Steering And Working Pump A10V…..

Travel Pump A4VG 71 … 180

Conveyor Belt Pump A10VG 28 … 56

Travel Motor A6VM/VE

Travel Gear 705C3H10C80

Conveyor Belt Motor OMT

Sprinkling Pump

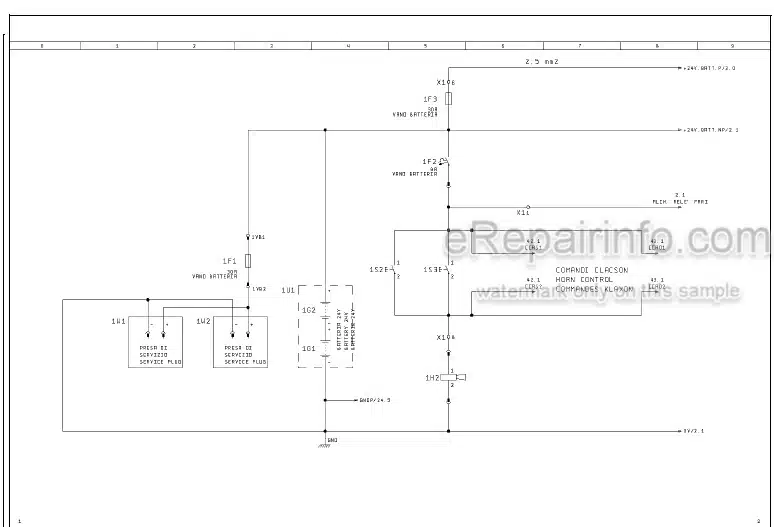

-CIRCUIT DIAGRAMS

Wiring Diagram

Hydraulic Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.