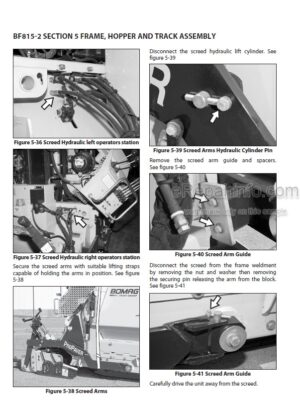

Factory Service Manual For Bomag Cold Milling Machine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG

Pages: 1090

Number: 00891597 (april 2010)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Bomag Cold Milling Machine

BM2000-60

S/N 821 836 16 ….>

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-TECHNICAL DATA

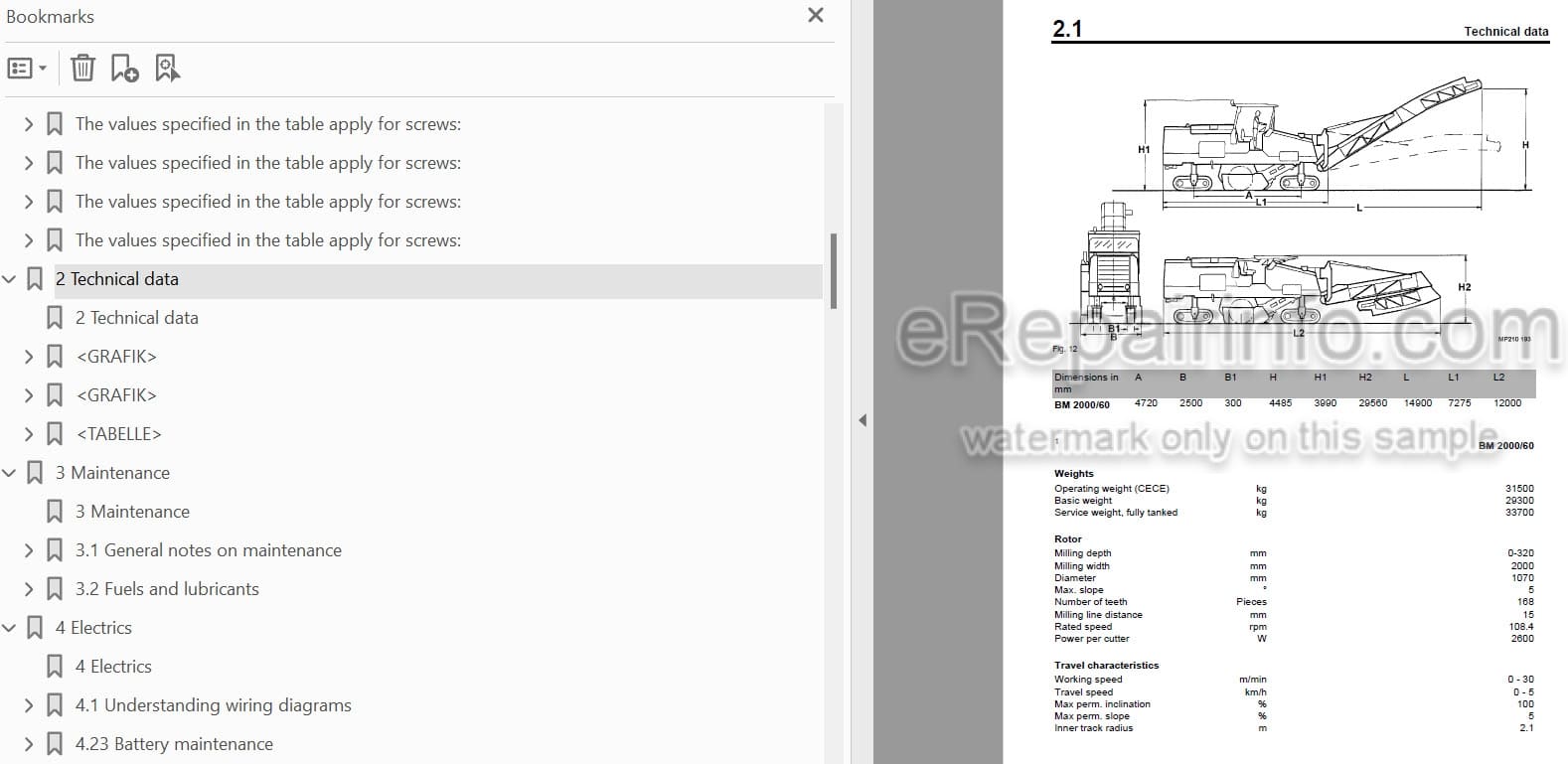

Technical Data

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

-ELECTRICS

Understanding Wiring Diagrams

Terminal Designations In Wiring Diagram

Circuit Symbols In The Circuit Diagram

Battery Ground And Analog Ground

Processor Signals

Current And Voltage

Pulse Width Modulation, PWM

Characteristic Of PWM Solenoid Valves

Resistance

Series / Parallel Connection

Ohm’s Law

Electrical Energy

Formula Diagram

Metrology

Diodes, Relays, Fuses

Inductive Proximity Switches

Plug Connectors

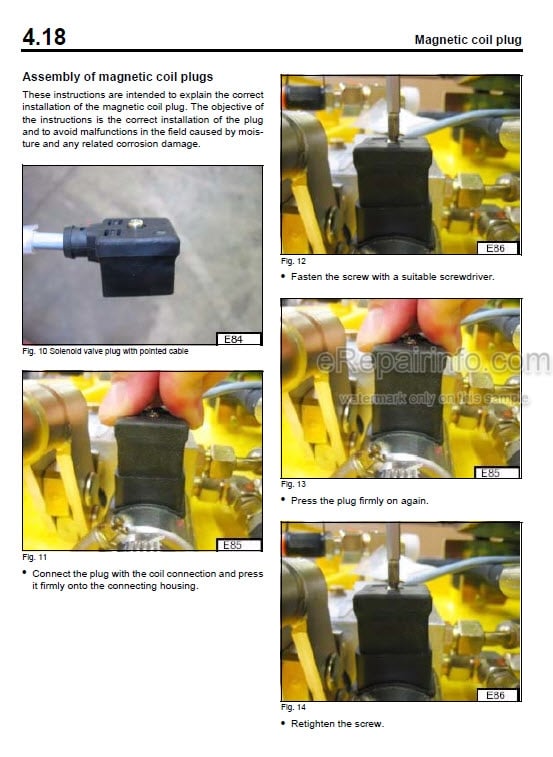

Magnetic Coil Plug

Deutsch Plug, Series DT And DTM

Telemechanique Switch

Plugs And Terminals In Spring Clamping Technology

Batteries

Battery Maintenance

Main Battery Switch, 150S1

Fuses In Battery Compartment

Can Bus Overview

Id Nodes, Overview And Fusing

Control Panels Operator’s Stand, 106B1, 106B2 And 106B3

Modules CR2012, Operating Consoles

Fuse, Multi-Function Display

Control Panel Contact Pressure, 100B10 And 100B11

Control Console For Auxiliary Control 100B5

Control Panel, 100B9

Control Panel Rear Right, 100B3 And 100B8

Control Panel Rear Left, 100B2 And 100B7

Control Panel Front Right, 100B4

Control Console Front Left, 100B1

Central Electrics, 106.1 B1

Modules CR2012, Central Electrics

Travel Pump High Pressure Sensor, 290.1 S2

Hydraulic Oil Temperature Sensor, 290.1 S1

Water Sprinkling System

Limit Switch On Scraper, 214.2S1 And 214.2S2

Rope Sensors For Height Control, 226.5R2 And 226.5R1

Rope Sensors For Steering, 264.6R1 And 264.6R.2

Proximity Switches, Height Limitation

Valve Block (Wording Valve)

Pressure Sensor For Conveyor Belt Drive, 290.1 S3

Temperature Control Valve For Fan Circuit, 216Y1

Fan Circuit Pressure Sensor, 290.1S4

Clutch Pressure Sensor, 290.2S1

Pressure Sensor For The Scraper Flap, 290.2S4

Pressure Sensor For Hold-Down, 290.2S3

Pressure Sensor For Wording Hydraulics, 290.2S2

Hydraulic Temperature Switch, 290S4

Hydraulic Oil Filter Differential Pressure Switch, 290S1 To 290S3

Coolant Level Sensors, 170.1S2 And 170.1S4

Travel Speed Sensor 206.7S1

Solenoid Valve Travel Pump, 206.7Y1

Solenoid Valve Differential Lock, 206.6Y2

Solenoid Valve Brake, 206.6Y3

Solenoid Valve Speed Range Selection, 206.6Y1

Solenoid Valve Conveyor Belt Pump, 238.9Y1

Modules In Engine Compartment, CR2031

Module, CR2031

Module CR2012

Electronic Control Units

Machine Control CR0505

-CAN-BUS, PARAMETER AND DIAGNOSE

Can Bus Overview

Id Nodes, Overview And Fusing

Id-Nodes, Inputs

Id-Nodes, Outputs

Multi-Function Display

Error Messages, Multi-Function Display

Multi-Function Display, Setup

Adjustment Parameters Overview

Menu Option, Tuning Parameters

Menu Option, Check Input Output

Menu Option, Display Adjustment

Menu Option, Can-Bus

Menu Option, Machine States

Menu Option, Rs232

Side Doors, Setup

Milling Drum

Steering, Joysticks

Steering, Pistons

Steering, Adjust Potentiometer

Steering, Central Position Calibration

Steering, Pistons Position Limit

Steering, Front-Rear Link

Steering, Front Prop. Solenoid Valve

Traveling, Joysticks Potentiometer

Traveling, Softgear

Traveling, Engine Load Manager

Traveling, Time Ramps

Traveling, Var. Displ. Pump

Traveling, Var. Displ. Motor

Pause, Time In Sequence

Pause, Time Out Sequence

Columns, Levelling Wire Sensor

Columns, Levelling Slope Sensor

Columns, Speed

Columns, Calibration Levelling Sensor

Columns, Left Column Prop. Valve

Columns, Right Column Prop. Valve

Conveyor, Potentiometer

Conveyor, Var. Displ. Pump

Backdoor, Set-Up

Backdoor, Solenoid Valve

Fan

Fan, Solenoid Valve

Check Input Output

Can Bus, Scan

Can Bus, Change Node Id

ID Nodes, Overview And Fusing

Machine States

-ENGINE ELECTRICS

Engine Control Unit

Pin Assignment

Diagnose With Serdia

Can Bus Overview

Diagnose With Can-Bus

Error Messages, Multi-Function Display

Diagnostic Interface, XMB

Emr3 List Of Fault Codes

Sensors

Oil Pressure Sensor

Fuel Temperature Sensor

Charge Air Temperature – Charge Air Pressure Sensor

Coolant Temperature Sensor

Coolant Level Sensors, 170.1 S2 And 170.1S4

Speed Sensor For Diesel Engine

Preheating System

Sensor, Water In Fuel, 170.1 S3

Air Filter Vacuum Switch, 170.1S1

Generator

Replacing The Voltage Regulator

Electric Starter

-ENGINE

Diesel Engine

Engine Description TCD 2015 V 8 Cylinder

Lubrication Oil Circuit TCD 2015

Coolant Circuit TCD 2015

Fuel Circuit TCD 2015

Injection System (MVS) TCD 2015

Exhaust Gas Recirculation TCD 2015

Wastegate – Charge Pressure Controller On TCD-Engines

Adjusting The Valve Clearance

Check The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridges

Check The Coolant Level

Change The Coolant

Checking The Thermostat In Disassembled State

Cleaning The Engine

Check, Clean The Water Separator

Change The Fuel Pre-Filter Cartridge

Change The Fuel Filter Cartridge

Checking, Replacing The Generator V-Belt

Service The Combustion Air Filter

Intercooler, Draining Oil And Condensation Water

Check Fastening Of Engine / Turbocharger / Combustion Air Hoses

Engine Conservation

General Trouble Shooting Chart TCD 2015

Special Tools, Deutz Engine (TCD 2015)

-MILLING DRIVE, MECHANICS

Milling Drive

Checking, Replacing The Milling Drum V-Belt

Change The Oil In The Milling Drum Reduction Gear

Oil Change In Milling Drum Bearing

Checking/Replacing Cutting Tools, Scraper

Replacing Bases/Holders

Lubricating The Milling Drum

Lubricating The Dry Clutch

Checking The Wear Of The Friction Lining

Friction Lining / Replacing The Outer Discs

-CONVEYOR BELTS, MECHANICS

Conveyor Belts

Checking, Tightening The Conveyor Belts

Checking The Safety Ropes

Lubricating The Conveyor Belts

Folding / Unfolding The Loading Conveyor Belt

-TRAVEL DRIVE, MECHANICS

Travel Drive

Checking The Track Plates

Retightening The Track Shoe Fastening Screws

Checking The Track Drive

Lubricating The Travel Drive

Lubricating The Steering System

Oil Change In Track Drive Gear

-PUMP TRANSFER CASE

Transfer Case

Check The Oil Level In The Pump Drive Gear

Change The Oil In The Pump Drive Gear

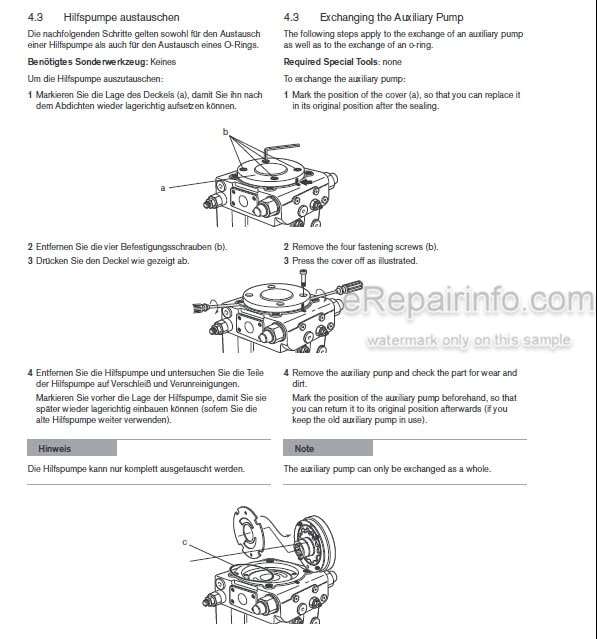

-HYDRAULICS

Service Training Bomag Road Milling Machines – Hydraulics

Fault Display

Travel System – Service Training

Conveyor Belt Drive

Working Hydraulics

Fan Drive

Electric Pump For Auxiliary Control (Additional Valves)

-SUPPLIERS DOCUMENTATION

Steering And Working Pump

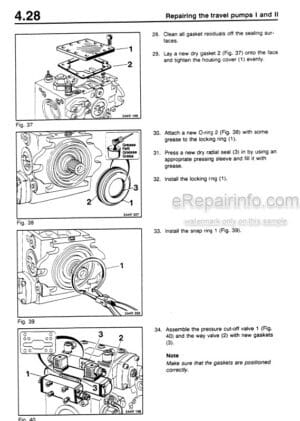

Travel Pump

Conveyor Belt Pump

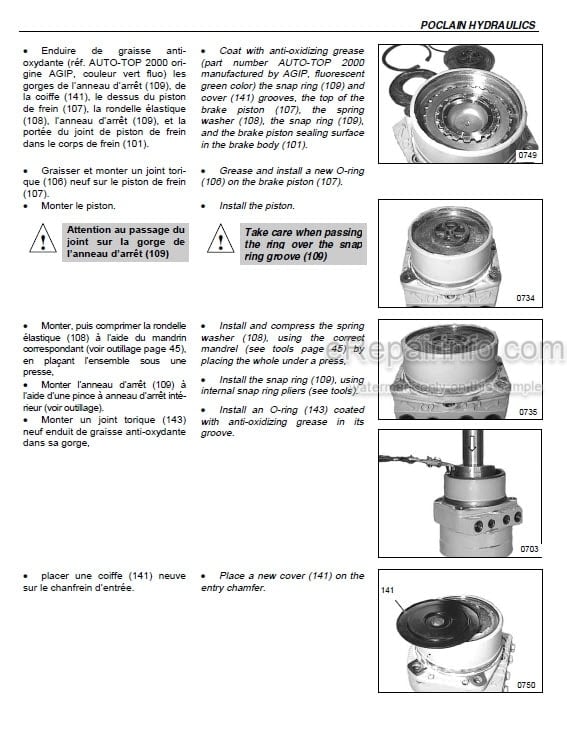

Travel Motor

Travel Gear

Conveyor Belt Motor

Sprinkling Pump

-CIRCUIT DIAGRAMS

Hydraulic Diagram

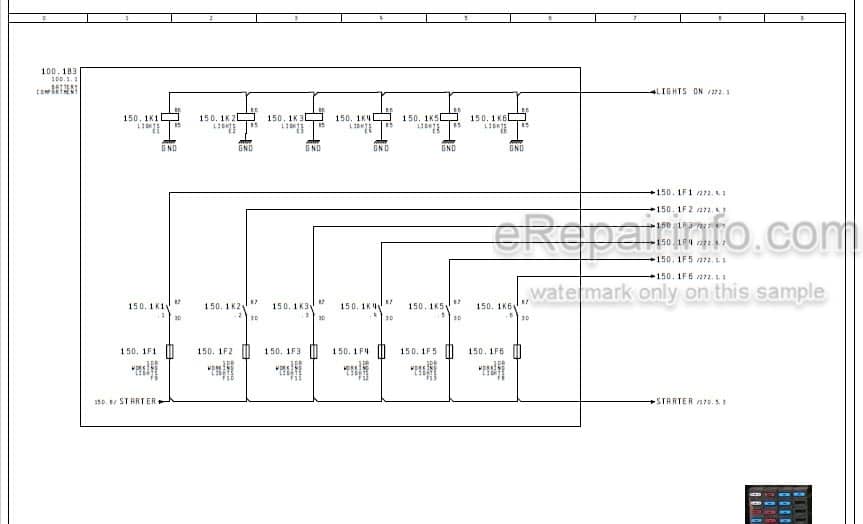

Wiring Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.