Factory Technical Manual and Workshop Manual For Hitachi EX45 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 568

Bookmarks: Yes

Searchable: Yes

Number: KM510E-01

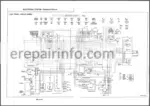

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX45

Contents

1.Technical Manual

INTRODUCTION

SAFETY

-SPECIFICATIONS

–GENERAL INFORMATION

Outline

Specifications

Working Range

Lifting Capacities

Service Refill Capacities

–DIMENSIONS AND WEIGHTS

Transportation

Weight

–FUELS AND LUBRICANTS

Fuel

Engine Oil

Hydraulic Oil

Gear Oil

Grease

Engine Coolant

–INTERCHANGEABILITY

Interchangeability

-UPPERSTRUCTURE

–OUTLINE

Upperstructure Outline

–TANKS

Construction

–PUMP DEVICE

Construction and Function

–SWING DEVICES

Construction and Function

Swing Reduction Device

Swing Motor

Swing Brake Valve

Overload Relief Valve

–PIPINGS

General

–CONTROL VALVE

General

Switch Valve

Main Relief Valve

Overload Relief Valve

–PILOT VALVE

Construction

Function

–PILOT SHUT-OFF VALVE

Construction and Function

–SOLENOID VALVE

Construction and Function

–ENGINE

Construction and Function

Radiator

Air Cleaner

Maintenance and Adjustment

-UNDERCARRIAGE

–OUTLINE

Undercarriage Outline

–SWING BEARING

Construction and Function

–CENTER JOINT

Construction and Function

–TRAVEL DEVICE

Construction and Function

Travel Reduction Gear

Travel Motor

Travel Brake Valve

Travel Speed Change Valve

Counterbalance Valve Operation

Overload Relief Valve Operation

–ADJUSTER

Construction and Function

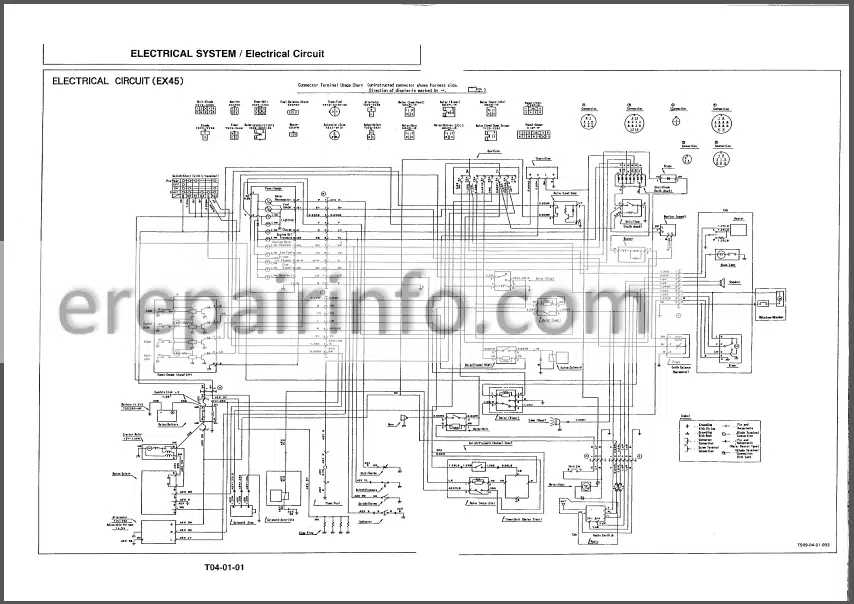

-ELECTRICAL SYSTEM

–ELECTRICAL CIRCUIT

Electric Wiring Diagram

-HYDRAULIC SYSTEM

–HYDRAULIC CIRCUIT

Hydraulic Circuit Diagram

-OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Purpose

Terminology

Preparation For Performance Tests

–ENGINE TEST

Engine Speed

Engine Compression Pressure

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Motor Leak Check

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever And Pedal Stroke

–HYDRAULIC COMPONENT TEST

Pilot Secondary Pressure

Main Relief Valve Pressure Setting

Overload Relief Valve Pressure Setting

Swing Motor Overload Relief Valve Pressure Test

-TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

How to read the troubleshooting flow charts

Check Battery Voltage

–HYDRAULIC SYSTEM

Actuators

Front Attachments

Swing

Travel

–ELECTRICAL SYSTEM

Monitor Panel and Electrical Parts

Engine

Fuse Fails

Monitor Panel

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Alternator

Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Air Filter Restriction Indicator

Malfunction of Buzzer

Malfunction of Hour Meter

Wiring Hamess Test

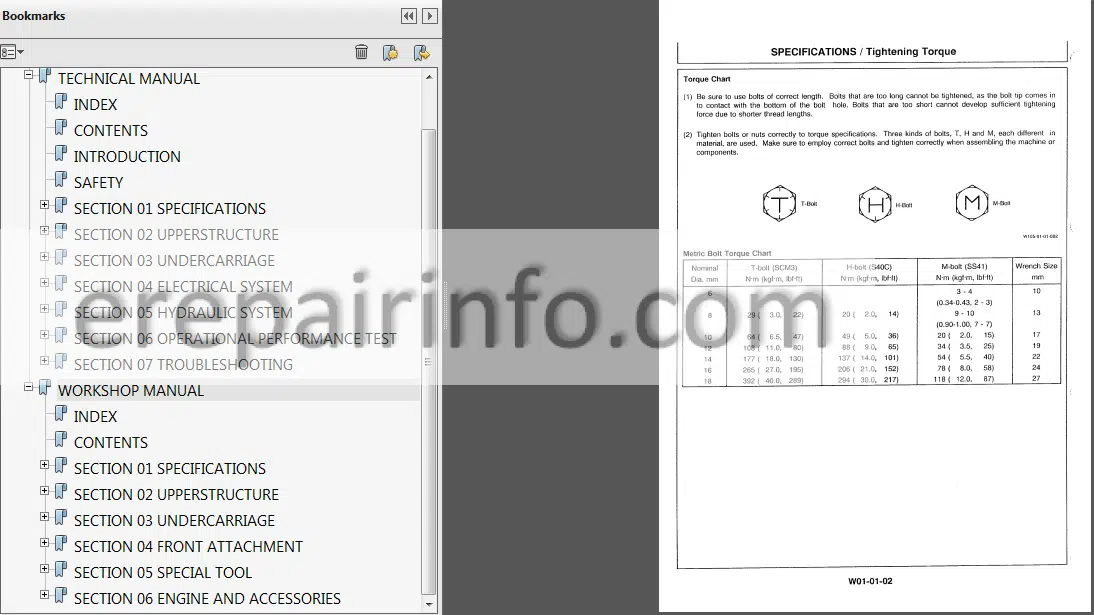

2.Workshop Manual

-SPECIFICATIONS

–TIGHTENING TORQUE

Tightening Torque

–LABELS

Label Location

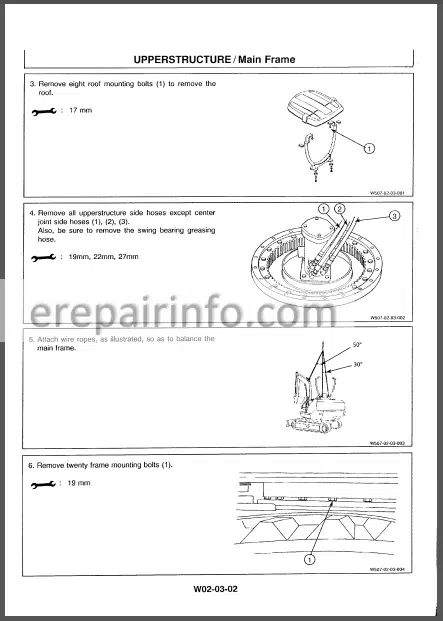

-UPPERSTRUCTURE

–CAB

Removal and Installation

–COUNTERWEIGHT

Removal and Installation

–MAIN FRAME

Removal and Installation

–PUMP DEVICE

Removal and Installation of Pump Device

Disassembly and Assembly of Pump Device

Maintenance Standard

–CONTROL VALVE

Removal and Installation of Control Valve

Disassembly and Assembly of Control Valve

–SWING DEVICE

Removal and Installation of Swing Device

Disassembly and Assembly of Swing Device

Maintenance Standard

–PILOT VALVE

Removal and Installation of Pilot Valve

Disassembly and Assembly of Pilot Valve

–SOLENOID VALVE

Disassembly and Assembly of Solenoid Valve

-UNDERCARRIAGE

–SWING BEARING

Removal and Installation

–TRAVEL DEVICE

Removal and Installation of Travel Device

Disassembly and Assembly of Travel Device

Maintenance Standard

–CENTER JOINT

Removal and Installation of Center Joint

Disassembly and Assembly of Center Joint

–TRACK ADJUSTER

Removal and Installation of Track Adjuster

–FRONT IDLER

Removal and Installation of Front Idler

Maintenance Standard

–CARRIER AND TRACK ROLLER

Removal and Installation of Carrier Roller

Removal and Installation of Track Roller

Maintenance Standard

–TRACK LINK

Removal and Installation of Track Link Assembly

Maintenance Standard

-FRONT ATTACHMENT

–FRONT ATTACHMENT

Removal and Installation of Front Attachment

Maintenance Standard

–CYLINDER

Removal and Installation of Cylinder

Disassembly and Assembly of Cylinder

Maintenance Standard

-SPECIAL TOOL

–SPECIAL TOOL

Drawing Of Special Tool

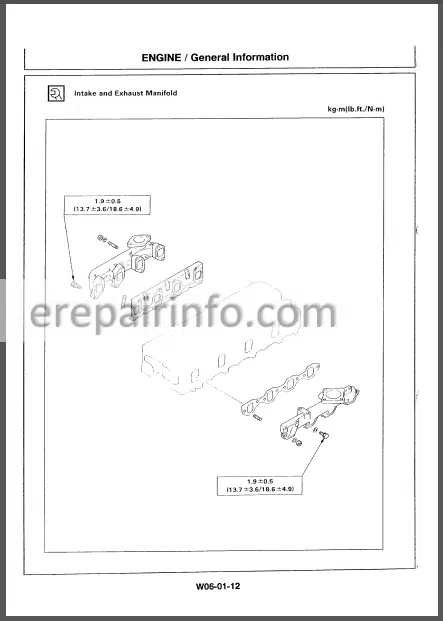

-ENGINE AND ACCESSORIES – EX45(ISUZU 4JC1)

–GENERAL INFORMATION

General Repair Instruction

Notes On The Format Of This Manual

Main Data And Specifications

Tightening Torque Specifications

–MAINTENANCE

Model Identification

Injection Pump Identification

Lubricating System

Fuel System

Cooling System

Valve Clearance Adjustment

Injection Timing

Compression Pressure Measurement

Recommended Lubricants

Repair Kit

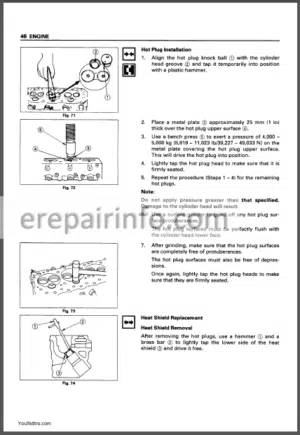

–ASSEMBLY I

General Description

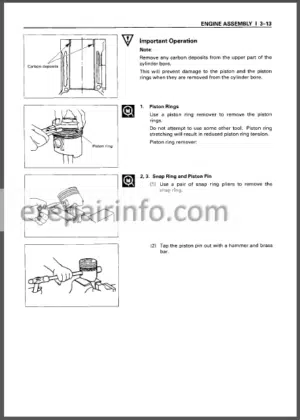

Disassembly Steps-1

Disassembly Steps-2

Disassembly Steps-3

Disassembly Single Unit

–ASSEMBLY II

Inspection And Repair

Cylinder Head

Valve Guide

Valve And Valve Seat Insert

Valve Spring

Rocker Arm Shaft And

Rocker Arm

Cylinder Body

Tappet And Push Rod

Camshaft

Crankshaft And Bearing

Crankshaft Pilot Bearing

Flywheel And Ring Gear

Piston Ring

Piston Pin

Connecting Rod

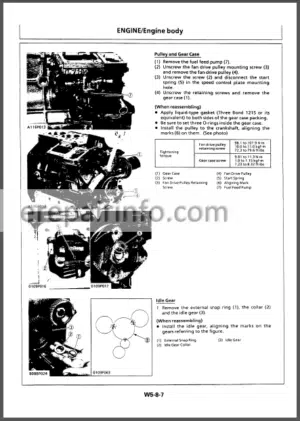

Idler Gear Shaft And Idler Gear

–ASSEMBLY III

Reassembly Single Unit

Reassembly Steps-1

Reassembly Steps-2

Reassembly Steps-3

–LUBRICATING SYSTEM

Main Data And Specifications

General Description

Oil Pump

Oil Filter With Built-In Oil Cooler

–COOLING SYSTEM

Main Data And Specifications

General Description

Water Pump

Thermostat

–FUEL SYSTEM

Main Data And Specifications

General Description

Injection Nozzle

Injection Pump Data

–TROUBLESHOOTING

Hard Starling

Unstable Idling

Insufficient Power

Excessive Fuel Consumption

Excessive Oil Consumption

Overheating

White Exhaust Smoke

Dark Exhaust Smoke

Oil Pressure Doos Not Rise

Abnormal Engine Noise

–SPECIAL TOOL

Special Tool List

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.