Factory Service Repair Manuals set For Hitachi Zaxis 210W Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1526

Number: KM-CDBE

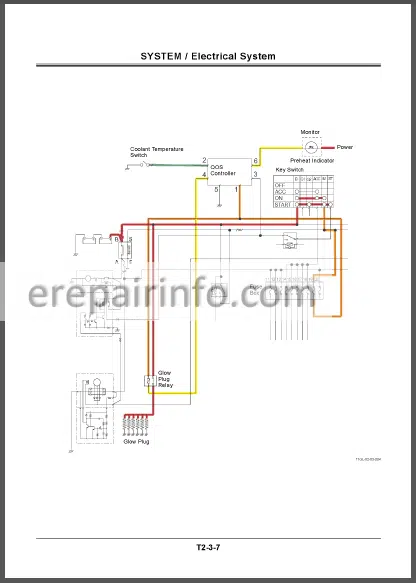

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi Zaxis 210W

Contents

1.Technical Manual

2.Workshop Manual

INTRODUCTION

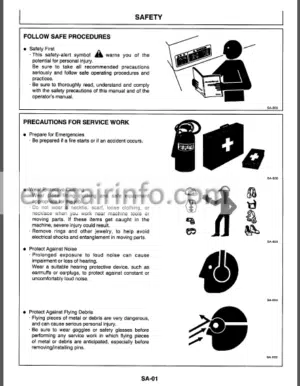

sAFETY

-GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING TORQUE

Tightening Torque Specification

Torque Chart

Piping Joint

Periodic Replacement of Parts

–PAINTING

Painting

–BLEEDING AIR FROM HYDRAULIC OIL TANK

Bleeding Air from Hydraulic Oil tank

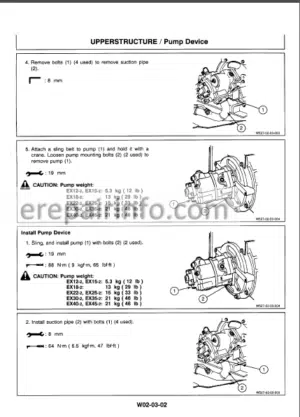

-UPPERSTRUCTURE

–CONTROL VALVE

Remove and Install Control Valve

Disassemble Control Valve (4-Spool Section)

Disassemble Control Valve (5-Spool Section)

Disassemble and Assemble 4-Spool and 5-Spool Sections

Assemble Control Valve (4-Spool Section)

Assemble Control Valve (5-Spool Section)

Remove and Install

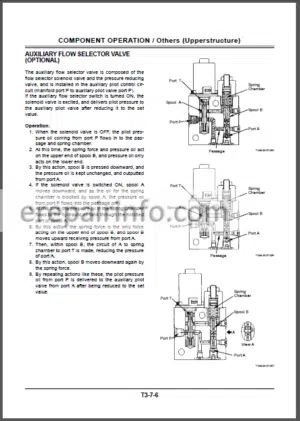

Auxiliary Control Valve

Disassemble Auxiliary Control Valve Assemble Auxiliary Control Valve

–SWING DEVICE

Remove and Install Swing Device

Disassemble Swing Reduction Gear

Assemble Swing Reduction Gear

Disassemble Swing Motor

Assemble Swing Motor

Maintenance Standard

–PILOT VALVE

Remove and Install Pilot Valve

Disassemble Front/Swing Pilot Valve

Assemble Front/Swing Pilot Valve

Disassemble Travel, PositionIng/Auxillary

Blade/Stabilizer Pilot Valve

Assemble Travel, Positioning/Auxiliary Blade/Stabilizer Pilot Valve

–PILOT SHUT-OFF VALVE

Remove and Install Pilot Shut-Off Valve

Disassemble Pilot Shut-Off Valve

Assemble Pilot Shut-Off Valve

–SIGNAL CONTROL VALVE

Remove and Install Signal Control Valve

–TRAVEL SHOCKLESS VALVE

Remove and Install Travel Shockless Valve

Construction of Travel Shockless Valve

–SOLENOID VALVE

Remove and Install 4-Unit Solenoid Valve Unit

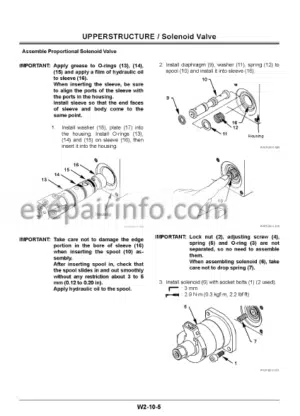

Disassemble Proportional Solenoid Valve

Assemble Proportional Solenoid Valve

Remove and Install 2-Unit Solenoid Valve (for Pump Control)

Construction of 2-Unit Solenoid Valve (for Pump Control)

Remove and Install 2-Unit Solenoid Valve (for Blade/Stabilizer)

Construction of 2-Unit Solenoid Valve (for Blade/Stabilizer)

–PILOT RELIEF VALVE

Remove and Install Pilot Relief Valve

Construction of Pilot Relief Valve

–STEERING VALVE

Remove and Install Steering Valve

Disassemble Steering Valve

Assemble Steering Valve

–BRAKE VALVE

Remove and Install Brake Valve

Disassemble Brake Valve

Assemble Brake Valve

–ACCUMULATOR CHARGING VALVE

Remove and Install

Accumulator Charging Valve

Constructton of

Accumulator Charging Valve

–TRANSMISSION CONTROL VALVE

Remove and Install

Transmission Control Valve

Construction of

Transmission Control Valve

-UNDERCARRIAGE

–SWING BEARING

Remove and Install Swing Bearing

Disassemble Swing Bearing

Assemble Swing Bearing

–TRAVEL MOTOR

Remove and Install Travel Motor

Disassemble Travel Motor

Assemble Travel Motor

Disa sse тџе Bra ke Va Ive

Assemble Brake Valve

–CENTER JOINT

Remove and Install Center Joint

Disassemble Center Joint

Assemble Center Joint

Maintenance Standard

–TRANSMISSION

Rernuve and Inslall Tiarisrnission

Disassemble Transmission

Disassemble Final Drive and Differential

Assemble Final Drive and Differential

Assemble Transmission

Adjusting Gear Clearance

–AXLE

Remove and Install Axle

Disassemble Front Axle

Assemble Front Axle

Disassemble Rear Axle

Assemble Rear Axle

Disassemble Differential

Assemble Differential

Disassemble Steering Cylinder

Assemble Steering Cylinder

–AXLE LOCK CYLINDER

Remove and Install Axle Lock Cylinder

Disassemble and Assemble

Axle Lock Cylinder

–OPERATE-CHECK VALVE

Remove and Install Operate-Check Vatve (for Axle Lock Cylinder)

Construction of Operate-Check

Valve (for Axle Lock Cylinder)

–PROPELLER SHAFT

Remove and Install Propeller Shaft

-FRONT ATTACHMENT

–FRONT ATTACHMENT

Hydraulic Circuit Pressure Release Procedure

Remove and Install Mono block Boom Front Attachment

Remove and Install 2-Piece Boom Front Attachment

Maintenance Standard

Standard Dimensions for Arm and Bucket Connection

Standard Dimensions for Arm and Boom Connection

–CYLINDER

Remove and Install Cylinder(Monoblock Boom, 2-Piece Boom)

Disassemble Cylinder (Boom (ћопоџоск/2-Piece),Positioning, Bucket)

Assemble Cylinder (Boom (ћопоџоск/2-Piece), Positioning, Bucket)

Disassemble Cylinder (Arm)

Assemble Cylinder (Arm)

Disassemble Cylinder (Stabilizer, Blade)

Assemble Cylinder (Stabilizer, Blade)

Maintenance Standard

–HOSE-RUPTURE SAFETY VALVE

Remove and Install

Hose-Rupture Safety Valve

Construction of

Hose-Rupture Safety Valve

–OPERATE-CHECK VALVE

Remove and Install Operate-Check Valve (for Blade/Stabilizer)

Construction of Operate-Check Valve (for Blade/Stabilizer)

-ENGINE AND ACCESSORY

–GENERAL INFORMATION

General Repair Instructions

Notes on the Format of This Manual

Main Data and Specifications

Performance Curve

External View

Tightening Torque Specifications

Angular Nut and Bolt Tightening Method

Major Parts Fixing Nuts and Bolts

Identifications

–MAINTENANCE

Lubricating System

Fuel System

Cooling System

Valve Clearance Adjustment

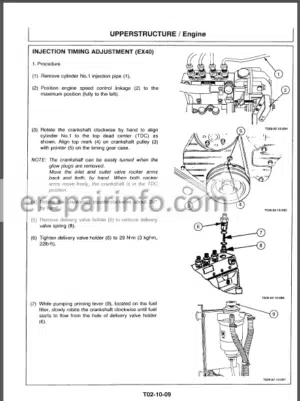

Injection Timing

Compression Pressure Measurement

TnrhrvhargAr IrHSportinn

Engine Repair Kit

Recommended Lubricants

Engine Oil Viscosity Chart

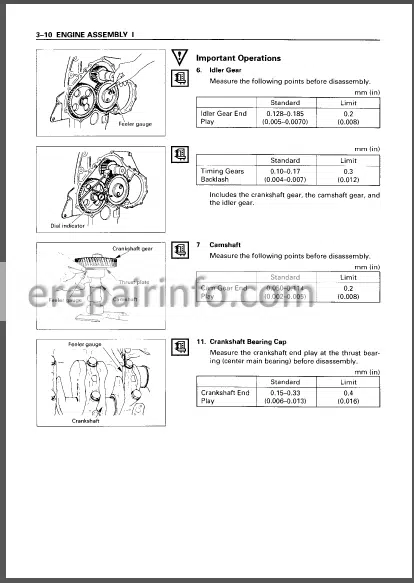

–ENGINE ASSEMBLY 1 (DISASSEMBLY)

External Parts Disassembly Steps

Major Components

Rocker Arm and Rocker Arm Shaft

Disassembly Steps

Cylinder Head Disassembly Steps

Piston and Connecting Rod

Disassembly Steps

–ENGINE ASSEMBLY 2 (INSPECTION AND REPAIR)

Cylinder Head

Valve Guide

Valve Spring

Tappet

Push Rod

Rocker Arm Shaft and Rocker Arm

Idler Gear and Idler Gear Shaft

Camshaft

Cylinder Body and Liner

Piston and Piston Ring

Piston Pin

Connecting Rod

Crankshaft

Flywheel

Timing Gear Case Cover

–ENGINE ASSEMBLY 3 (REASSEMBLY)

Piston and Connecting Rod

Reassembly Steps

Cylinder Head Reassembly Steps

Rocker Arm and Rocker Arm Shaft

Reassembly Steps

Major Component Reassembly Steps 1

Major Component Reassembly Steps 2

External Parts Reassembly Steps (Left-Hand Side)

External Parts Reassembly Steps (Right-Hand Side)

Engine Tuning Operation

–LUBRICATING SYSTEM

General Description

Oil Pump

Oil Cooler

–COOLING SYSTEM

General Description

Thermostat

–FUEL SYSTEM

General Description

Injection Nozzle

Injection Pump Calibration Data

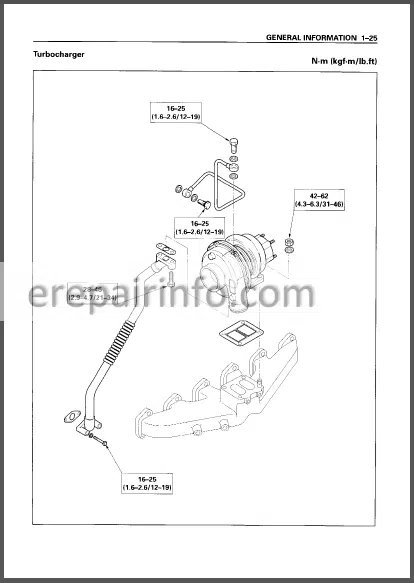

–TURBOCHARGER

General Description

Turbocharger Identification

Troubleshooting

Inspection and Repair

–ENGINE ELECTRICALS

Starter Identification

Starter Main Data and Specifications

Starter Sectional View

Performance

Disassembly

Inspection and Repair

Reassembly

Adjustment

Performance Test

Alternator Identification

Main Data and Specifications

Alternator Sectional View

Charging Circuit

Structure

Disassembly

Inspections

Reassembly

Bench Test

Current Output Test

Fault Finding

Specifications

–TROUBLESHOOTING

Hard Starting

1)Starter Inoperative

2)Starter Operates but

Engine does not Turn Over

3)Engine Turns Over but does not Start

Fuel is Being Delivered to the Injection Pump

4)Engine Turns Over but does not Start

Unstable Low Idling

Insufficient Power

Excessive Fuel Consumption

Excessive Oil Consumption

Overheating

Whity Exhaust Smoke

Dark Exhaust Smoke

Oil Pressure does not Rise

Abnormal Engine Noise

–SPECIAL TOOL LIST

Special Tool List

–REPAIR STANDARDS

Repair Standards

–CONVERSION TABLE

Length

Area

Volume

Mass

Pressure

Torque

Temperature

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.