Factory Service Repair Manual For Massey Ferguson 9695 9795 Rotary Combine. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

Number: 4283358M1

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Massey Ferguson 9695, 9795

Contents

- -GENERAL INFORMATION

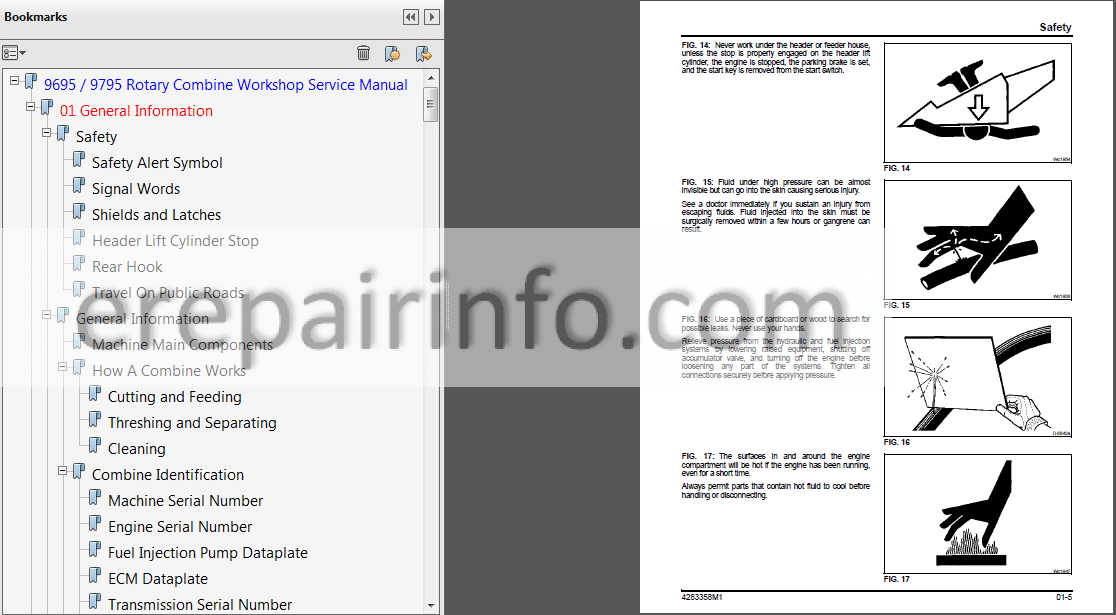

–SAFETY

Safety Alert Symbol

Signal Words

Shields and Latches

Header Lift Cylinder Stop

Rear Hook

Travel On Public Roads

–GENERAL INFORMATION

Machine Main Components

How A Combine Works

Cutting and Feeding

Threshing and Separating

Cleaning

Combine Identification

Machine Serial Number

Engine Serial Number

Fuel Injection Pump Dataplate5

ECM Dataplate5

Transmission Serial Number5

Final Drive Serial Number

Headers

Lubrication and Maintenance

Lubricants

Service Procedures

Service Periods

Lubrication and Maintenance

Lubrication Details

Front of Combine

Lefthand Side

Righthand Side

Rear Axle

Auto Lube

Auto Lube Intervals

Auto Lube Diagnosis

Engine

Type of Engine Oil

Viscosity

Oil Additives

Checking Oil Level

Changing Engine Oil and Filters

Rotor Gearbox

Transmission

Checking and Changing Lubricant

Brakes

Master Cylinder Oil Reservoir

Bleeding Brake System

Final Drive

Tires and Wheels

Tire Pressure

Dual Tires

Maintenance of Tires

Removing Wheel from Combine

Wheel Installation

Tire Dimensions

Drive Belts

Banded Drive Belt

Maintenance of Belts

Belt Changing Guides

Belt Sheave Alignment

Belt Run In Procedure

Belt Troubleshooting

Belt Problem and Wear Guide

Roller Chains

Inspection of Drive Chains and Sprockets

Drive Chain Adjustment and Tightening

Drive Chain Sprocket and Idler Alignment

Drive Chain Elongation and Sprocket Wear

Normal Tooth Wear

Not Normal Tooth Wear

Worn Chain on New Sprockets

Drive Chain Service Tips

Chain Replacement

Cleaning and Lubricating Chains

Drive Chain Lubrication

Drive Chain Lubricants

Good Drive Chain Lubrication

Roller Chain Drive Troubleshooting Guide

Speed of Components

Drives Listing and Specifications

Drives Speeds And Specifications

Engine Platform

Engine Platform Ladder

Engine Compartment

Fuel System

Fuel Handling

Fuel Vent Breather

Fuel Filter/Water Separator

Bleeding the Fuel System

Engine Cooling System

Coolant System Monitoring

Monitor Warnings

AntiFreeze Type

Coolant Change Period

Engine Cooling System Coolant

Checking Coolant Level

Radiator

Thermostat

Draining System

Filling System

Engine Air Cleaner

Outer Filter Element

Inner Filter Element

Hydraulics

Checking Oil Level

Hydraulic Oil Filter

Changing Hydraulic Oil

Removing Air From Hydraulic System

Hydraulic Pump

Steering Priority Valve

Main Hydraulic Control Valve

Unloader Auger Engagement Valve

Pump Drive Disconnect Valve

Accumulator

Hydrostatic Drives – A66

Hydrostatic Drives – A76

Hydraulic Oil Cooler

Rotor Speed Control

Air Conditioning System

Compressor

Condenser

Receiver-Drier

Cab Filters

Cab Filter – Primary

Cab Filter – Secondary

Recirculation Filter

Air Filter Cleaning Procedure

Windshield Washer Reservoir

Cleaning Windshield

Storage Preparation

Combine

Engine

Preparation For Use After Storage

Combine

Engine

Torque Charts

Standard Torque Specifications

Metric Capscrew Markings and Torque Values

Metric Conversions

Fractions, Decimals, and Millimeters Conversion Chart

Decimal Equivalents of 8ths, 16ths, 32nds, and 64ths

Decimal Equivalents Of Letter Size Drills

Decimal Equivalents of Number Size Drills

Tap Drill Sizes – SAE & Metric

American Standard Pipe Thread and Tap Drill Sizes

Electrical Formulas

Amperes (Current Flow)

Volts (Electromotive Force)

Ohms (Resistance)

Watts

Horsepower

Belt Speed Calculation Formulas

Geometrical Formulas

Circumference of a Circle

Area of a Circle

Volume of a Cylinder

Volume of a Sphere

Area of a Triangle

Metric to Imperial and Imperial to Metric Conversion Factors

Measures of Temperature

Measures of Power

Measures of Pressure

Measures of Length

Measures of Area

Measures of Volume (Dry)

Measures of Volume (Liquid)

Measures of Mass (Weight)

Measures of Effort (Torque)

Reference Tables - -SPECIFICATIONS

General Lubrication – A66/9695/660B

Combine – A66/9695/660B

General – A66/9695/660B

Main Body – A66/9695/660B

Feeder – A66/9695/660B

Front Beater – A66/9695/660B

Stone Trap – A66/9695/660B

Thresher-Separator – A66/9695/660B

Rotor – A66/9695/660B

Feeder Reverser – A66/9695/660B

Concave – A66/9695/660B

Concave Overlap – A66/9695/660B

Separator Area – A66/9695/660B

Separator Return Pan – A66/9695/660B

Cascade Chaffer Pan – A66/9695/660B

Cleaning Fan – A66/9695/660B

Shoe – A66/9695/660B

Chaffer – A66/9695/660B

Sieve – A66/9695/660B

Cleaning Area – A66/9695/660B

Elevators (Clean Grain And Return) – A66/9695/660B

Grain Tank – A66/9695/660B

Steering Axle – A66/9695/660B

Ground Drive – A66/9695/660B

Transmission – A66/9695/660B

Final Drive – A66/9695/660B

Brakes – A66/9695/660B

Wheel Bolt Torque – A66/9695/660B

Front Wheels

Rear Wheels

Crop Residue Disposal System – A66/9695/660B

Straw Chopper – A66/9695/660B

Straw Spreader – A66/9695/660B

Chaff Spreader – A66/9695/660B

Weights – A66/9695/660B

Capacities – A66/9695/660B

Engine – A66/9695/660B

Electrical System – A66/9695/660B

Batteries – Maintenance-Free – A66/9695/660B

Operator’S Cab – A66/9695/660B

Cab – A66/9695/660B

Air Conditioning – A66/9695/660B

Mirrors – A66/9695/660B

Lighting – A66/9695/660B

Machine Monitor – A66/9695/660B

Grain Loss Monitor – A66/9695/660B

Digital Display – A66/9695/660B

Hydraulic System – A66/9695/660B

Hydrostatic Rotor And Propulsion Drive – A66/9695/660B

Hydraulic Pressures – A66/9695/660B

Filters – A66/9695/660B

Hydraulic Pump – A66/9695/660B

Hydraulic Control Valves – A66/9695/660B

Unloader Swing In And Out Valve – A66/9695/660B

Auger Swing Check Valves – A66/9695/660B

Header Lift / Lower And Feeder Reverser Valve – A66/9695/660B

Reel Fore And Aft Valve (Ce Only) – A66/9695/660B

Chaff Spreader, Reel Lift / Lower, And Master Valve – A66/9695/660B

Reel Lift Raise Valve – A66/9695/660B

Reel Speed Valve – A66/9695/660B

Reel Speed Pressure Compensator – A66/9695/660B

Header Lowering Valve- A66/9695/660B

Chaff Spreader / Rotary Screen Pressure Compensator – A66/9695/660B

Pressure Compensated, Flow Regulator – A66/9695/660B

Chaff Spreader, Rotary Screen, Header Lift Load Sense, And Reel Speed Check Valves – A66/9695/660B

Reel Fore And Aft Check Valves (Ce Only) – A66/9695/660B

Header Lift And Feed Reverser Check Valves – A66/9695/660B

Unloader Swing Fast Valve

Header Lift Cylinder – A66/9695/660B

Accumulator – A66/9695/660B

Unloading Auger Tube Swing Cylinder -A66/9695/660B

Unloader Auger Engage Cylinder – A66/9695/660B

Unloader Auger Engage Valve – A66/9695/660B

Power Steering Cylinder – Standard Adjustable Axle – A66/9695/660B

Power Steering Cylinder – Rear Wheel Assist – A66/9695/660B

Steering Control Unit – A66/9695/660B

Rear Wheel Assist Motor – A66/9695/660B

Powered Rear Valve Assembly – A66/9695/660B

Steering Priority Valve Assembly – A66/9695/660B

Shuttle Valve – A66/9695/660B

Hydrostatic Rotor Drive – A66/9695/660B

Hydrostatic Propulsion Drive – A66/9695/660B

Hydraulic Rotary Screen Drive – A66/9695/660B

Feed Reverser Hydraulic Motor And Clutch Assembly – A66/9695/660B

Oil Cooler Bypass Check Valve -A66/9695/660B

Lateral Tilt Valve – A66/9695/660B

Lateral Tilt Cylinder – A66/9695/660B

Chaff Spreader Motors – A66/9695/660B

Variable Speed Header Drive Sheave Relief Valve – A66/9695/660B

General Lubrication – A76/9795/670B

Combine – A76/9795/670B

General – A76/9795/670B

Main Body – A76/9795/670B

Feeder – A76/9795/670B

Front Beater – A76/9795/670B

Stone Trap – A76/9795/670B

Thresher-Separator – A76/9795/670B

Feeder Reverser – A76/9795/670B

Rotor – A76/9795/670B

Concave – A76/9795/670B

Concave Overlap – A76/9795/670B

Separator Area – A76/9795/670B

Separator Return Pan – A76/9795/670B

Cascade Chaffer Pan – A76/9795/670B

Cleaning Fan – A76/9795/670B

Shoe – A76/9795/670B

Chaffer – A76/9795/670B

Sieve – A76/9795/670B

Cleaning Area – A76/9795/670B

Elevators (Clean Grain And Return) – A76/9795/670B

Grain Tank – A76/9795/670B

Steering Axle – A76/9795/670B

Ground Drive – A76/9795/670B

Transmission – A76/9795/670B

Final Drive – A76/9795/670B

Brakes – A76/9795/670B

Wheel Bolt Torque – A76/9795/670B

Front Wheels

Rear Wheels

Crop Residue Disposal System – A76/9795/670B

Straw Chopper – A76/9795/670B

Straw Spreader – A76/9795/670B

Chaff Spreader – A76/9795/670B

Weights – A76/9795/670B

Capacities – A76/9795/670B

Engine – A76/9795/670B

Electrical System – A76/9795/670B

Batteries – Maintenance-Free – A76/9795/670B

Operator’S Cab – A76/9795/670B

Cab – A76/9795/670B

Air Conditioning – A76/9795/670B

Mirrors – A76/9795/670B

Lighting – A76/9795/670B

Machine Monitor – A76/9795/670B

Grain Loss Monitor – A76/9795/670B

Digital Display – A76/9795/670B

Hydraulic System – A76/9795/670B

Hydrostatic Rotor And Propulsion Drive – A76/9795/670B

Hydraulic Pressures – A76/9795/670B

Filters – A76/9795/670B

Hydraulic Pump – A76/9795/670B

Hydraulic Control Valves – A76/9795/670B

Unloader Swing In And Out Valve – A76/9795/670B

Auger Swing Check Valves – A76/9795/670B

Header Lift / Lower And Feeder Reverser Valve – A76/9795/670B

Reel Fore And Aft Valve (Ce Only) – A76/9795/670B

Chaff Spreader, Reel Lift / Lower, And Master Valve – A76/9795/670B

Reel Lift Raise Valve – A76/9795/670B

Reel Speed Valve – A76/9795/670B

Reel Speed Pressure Compensator – A76/9795/670B

Header Lower Valve

Chaff Spreader / Rotary Screen Pressure Compensator – A76/9795/670B

Pressure Compensated, Flow Regulator – A76/9795/670B

Chaff Spreader, Rotary Screen, Header Lift Load Sense, And Reel Speed Check Valves – A76/9795/670B

02-92

Reel Fore And Aft Check Valves (Ce Only) – A76/9795/670B

Header Lift And Feed Reverser Check Valves – A76/9795/670B

Unloader Swing Fast Valve – A76/9795/670B

Header Lift Cylinder – A76/9795/670B

Accumulator – A76/9795/670B

Unloader Auger Tube Swing Cylinder – A76/9795/670B

Unloading Auger Engage Cylinder – A76/9795/670B

Unloader Auger Engage Valve – A76/9795/670B

Power Steering Cylinder – Standard Adjustable Axle – A76/9795/670B

Power Steering Cylinder – Rear Wheel Assist – A76/9795/670B

Rear Wheel Assist Motor – A76/9795/670B

Powered Rear Axle Valve Assembly – A76/9795/670B

Steering Control Unit – A76/9795/670B

Steering Priority Valve Assembly – A76/9795/670B

Shuttle Valve – A76/9795/670B

Hydrostatic Rotor Drive Pumps – A76/9795/670B

Hydrostatic Rotor Motor – A76/9795/670B

Hydrostatic Propulsion Drive – A76/9795/670B

Hydraulic Rotary Screen Drive – A76/9795/670B

Feed Reverser Hydraulic Motor And Clutch Assembly – A76/9795/670B

Oil Cooler Bypass Check Valve -A76/9795/670B

Lateral Tilt Valve – A76/9795/670B

Lateral Tilt Cylinder – A76/9795/670B

Chaff Spreader Motors – A76/9795/670B

Variable Speed Header Drive Sheave Relief Valve – A76/9795/670B

Torque Charts

Standard Torque Requirements

Metric Capscrew Markings And Torque Values

Special Torque Requirement

Dimensions

Metric Information - – ENGINE – DRIVES, COOLING AND FUEL

–ENGINE

Removal

Installation

Starting Procedure

–ENGINE OUTPUT SHAFT

General

Removal (From Engine)

Disassembly

Assembly

Installation

–COOLING SYSTEM

Radiator

Removal

Installation

Filling the Radiator

Charge Air Cooler

Removal

Installation

–CONDENSER / COOLER ASSEMBLY

Removal

Installation

–FUEL TANK

Removal

Installation

–ENGINE DRIVES

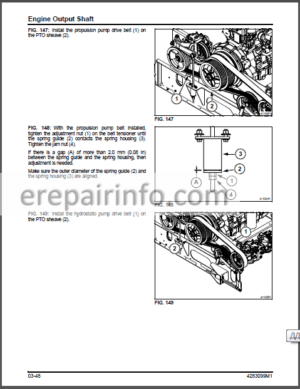

Propulsion Pump Drive

Belt Removal

Belt Installation

Propulsion pump Drive Sheave Removal

Propulsion Pump Drive Sheave Installation

Hydrostatic Pump Drive

Belt Removal

Belt Installation

Tandem Pump Drive Sheave Removal

Tandem Pump Drive Sheave Installation - – MATERIAL HANDLING

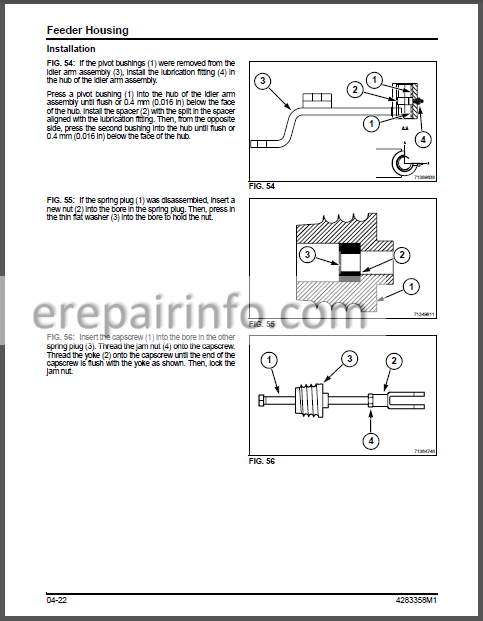

FEEDER HOUSING

General Information

Header Fixed Speed Countershaft Drive Belt

Removal

Installation

Drive Belt Idler SheaveHeader Fixed Speed Countershaft

Removal

Installation

Header Variable Speed Countershaft Drive Belt And Flat Idler

Removal

Installation

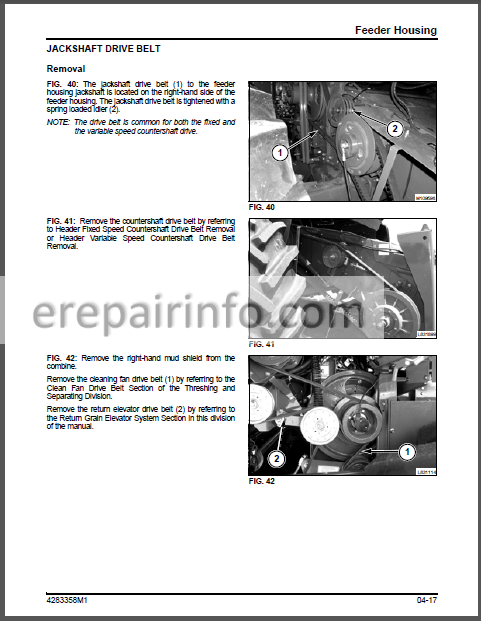

Jackshaft Drive Belt

Removal

Installation

Jackshaft Drive Belt Idler Sheave

General Information

Removal

Installation

Pivot Shaft Drive Belt

General Information

Removal

Installation

Pivot Shaft Drive Belt Idler Sheave

General Information

Removal

Installation

Feeder Conveyor Chain Slats

General Information

Removal

Installation

Feeder Conveyor Chain

General Information

Adding and Removing Chain Links

Adjustment

Check Feeder Chain Wear

Removal

Installation

Adjusting Position BlocksFeeder Drum Float

Front Feeder Drum And Shaft

Removal

Installation

Countershaft Variable Speed Header Drive

Removal

Disassembly

Inspection of Parts

Assembly

Installation

Countershaft Fixed Speed Header Drive

Removal

Installation

Feeder Housing Floors

Removal

Disassembly

Assembly

Installation

Seal

General Information

Removal

Installation

Feed Plate

Removal

Installation

Variable Speed Header Drive Jackshaft

General Information

Removal

Installation

Fixed Speed Header Drive Jackshaft

General Information

Removal

Installation

Feeder Housing

General Information

Removal

Installation

Lateral Tilt Assembly

General Information

Hydraulics

Electrical

Removal

Disassembly

Assembly

Installation

Pivot Shaft Slip Clutch

Removal

Disassembly

Assembly

Installation

Pivot Shaft

Removal

Installation

–CLEAN GRAIN SYSTEM

General Information

Clean Grain Elevator Drive Belt

Drive Belt Adjustment

Drive Belt Removal

Installation

Clean Grain Drive Belt Idler Sheaves

General Information

Idler Sheave Removal

Idler Sheave Installation

Clean Grain Elevator Conveyor Chain

Conveyor Chain Adjustment

Conveyor Chain Paddle Replacement

Conveyor Chain Removal

Installation

Clean Grain Cross Auger

Removal

Installation

Clean Grain Elevator

Removal

Installation

Grain Bin Loader

General Information

Grain Bin Loader Drive Chain

Upper Elevator Shaft

Bin Loader Auger Assembly

Bin Loader Drive Shaft

–RETURN GRAIN SYSTEM

General Information

Return Elevator Drive Belt

Drive Belt Adjustment

Removal

Installation

Drive Belt Idler Sheaves

Removal

Installation

Return Elevator Conveyor Chain

Conveyor Chain Adjustment

Conveyor Chain Paddle Replacement

Conveyor Chain Removal

Conveyor Chain Installation

Return Grain Cross Auger

Removal

Installation

Return Grain Elevator

Removal

Installation

Upper Elevator Shaft

Removal

Installation

Upper Return Auger

Removal

Installation

Upper Head Assembly

Removal

Installation

Return Grain Torque Limiter

Disassembly

Assembly

–UNLOADING AUGER SYSTEM

General Information

Unloader Auger System Shear Bolts

Angled Auger

Cross Auger

Unloader Drive Belt

Unloader Drive Adjustment

Drive Belt Removal

Drive Belt Installation

Drive Belt Idler SheavesUnloading Auger System

General Information

Removal

Installation

Unloader Jackshaft

Removal

Installation

Main Cross Auger

Removal

Disassembly

Assembly

Installation

Righthand U-Joint And Bearing Assembly

Removal

Disassembly

Assembly

Installation

Angled Unloader Auger

Removal

Disassembly

Assembly

Installation

Unloading Auger Tube

Removal

Installation

Unloading Auger Coupler And Pilot Ring

Removal

Installation

Unloading Auger Spill Reducer Assembly

Removal And Disassembly

Assembly And Installation

Unloading Auger Outer Bearing

Removal

Installation

Unloading Auger

Removal

Installation

–UNIVERSAL JOINT REPLACEMENT

Disassembly

Assembly

–POWER FOLD GRAIN TANK EXTENSIONS

Power Fold Grain Tank Extension Switch

Entering The Grain Tank

Grain Tank Seals

Push Rods And Rocker

Actuators

Removal

Installation - – MATERIAL DISCHARGE

–STRAW CHOPPER

General Information

Adjustments

Spread Width

Chopper Support Rails

Knife Replacement

Straw Chopper Secondary Drive Belt

Drive Belt Adjustment

Drive Speeds

Removal

Installation

Drive Belt Idler SheavesSecondary Drive

Removal

Installation

Straw Chopper Primary Drive Belt

Drive Belt Adjustment

Removal

Installation

Drive Belt Idler SheavePrimary Drive

Removal

Installation

Jackshaft

Removal

Disassembly

Assembly

Installation

Straw Chopper

Removal

Disassembly

Assembly

Installation

–CE STRAW CHOPPER

General Information

Windrow Converger

Fine Cut Knife

Adjustments

Fine Cut Knife

Spreader Board

Spreader Fins

Straw Chopper Knives

Knife Replacement

Straw Chopper Drive

Sheave Removal and Installation

Primary Drive Adjustment

Primary Drive Belt Replacement

Primary Drive Idler Arm and Sheave

Secondary Drive Adjustment

Secondary Drive Belt Replacement

Secondary Drive Idler Arm and Sheaves

Jackshaft

Straw Chopper

Removal

Disassembly

Assembly

Installation

–STRAW SPREADER

General Information

Straw Spreader Primary Drive

Adjustments

Drive Belt Replacement

Idler Arm and Sheave

Straw Spreader Secondary Drive

Adjustments

Drive Belt

Idler Arm and Sheave

Jackshaft

Removal

Disassembly

Assembly

Installation

Straw Spreader

Removal

Disassembly

Assembly

Installation

–CHAFF SPREADER

General Information

Adjustments

Positioning The Chaff Spreader

Adjustment Of Disc Speed

Removal

Disassembly

Assembly

Installation - -REAR AXLE

–STANDARD REAR AXLE

Adjustable Steering Axle – Standard

General Information

Standard Rear Axle Wheel Bolt Torque

Steering Cylinder Removal

Steering Cylinder Installation

Bleeding Steering Cylinder and Lines

Adjusting Rear Axle Wheel Tread Width

Adjusting Rear Wheel Toe-In

Axle Removal

Axle Installation

Rear Wheel Bearing Removal And Disassembly

Cleaning, Inspection, And Installation

Spindle Bushing Removal

Spindle Bushing Installation

Steering Stop Adjustment

Adjustable Steering Axle – If Equipped

General Information

Rear Wheel bolt Torque

Adjusting Rear Axle Wheel Tread (Width)

Adjusting Rear Wheel Toe-in

Axle Stop Adjustment

Rear Wheel Bearing Lubrication and Adjustment

Axle Removal and Disassembly

Axle Assembly and Installation

–POWER REAR AXLE

Power Rear Axle – Single Speed

General Information

Power Rear Axle Identification

Power Rear Axle Wheel Motor Identification

Power Rear Axle Performance

Power Rear Axle Electrical Components And Controls

Power Rear Axle Hydrostatic Circuits Description

Case Drain Return 0 to 2758 kPa (0 to 40 psi)

Power Rear Axle Operation Description

Steering Cylinder Operation

Steering Cylinder Removal

Steering Cylinder Installation

Bleeding Steering Cylinder and Lines

Rear Wheel Lug Nut Torque

Rear Wheel Motor Axle Bearings

Wheel Motor Steering Pin Bushings

Adjusting Rear Axle Wheel Tread Width

Adjusting Rear Wheel ToeIn

Checking And Tightening Rear Wheel Tie Rod Ends

Wheel Stop Adjustment

Axle Removal

Axle Installation

Power Rear Axle EquaTrac Ii Valve Components

Operation Of EquaTrac Ii Valve

Power Rear Axle Wheel Motor

Basic Motor Repair

Power Rear Axle Service Tools

Power Rear Axle Troubleshooting And Testing

Power Rear AxleTwo Speed

General Information

Power Rear Axle Identification

Power Rear Axle Wheel Motor Identification

Basic Motor Specifications

Power Rear Axle Performance

Power Rear Axle Electrical Components And Controls

Hydrostatic Circuitry Description

Case Drain Return

Operation Description

Rear Wheel Lug Bolt Torque

Rear Wheel Motor Axle Bearings

Wheel Motor Steering Pin Bushings

Adjusting Rear Axle Height

Wheel Motor CFrame Mounting Bolts

Adjusting Rear Axle Wheel Tread (Width)

Adjusting Rear Wheel ToeIn

Checking And Tightening Rear Wheel Tie Rod Ends

Wheel Stop Adjustment

Axle Removal

Axle Installation

Selector Valve

Selector Valve Principle Of Operation

Power Rear Axle Wheel Motor

Principle Of Operation (For The Route Of One Piston)

Removal

Steering CFrame Removal And Installation

Disassemble And Assemble Bushings

Installation

Wheel Motor Bleeding/StartUp Procedures

Bleeding And StartUp Procedures

Power Rear Axle Service Tools

Basic Motor Repair

Troubleshooting And Testing - – THRESHING AND SEPARATING

–BEATER

General Information

Drive Belt

Removal

Installation

Beater Drive Belt Idler Sheaves

Removal and Disassembly

Assembly and Installation

Beater and Shaft

Removal

Installation

Bearing Replacement

Lefthand Bearing

Righthand Bearing

Header Drive Clutch Assembly

Removal and Disassembly

Assembly and Installation

–STONE TRAP

General Information

Handle

Removal

Installation

Stone Trap Cover Plate (Accessory)

ROTOR

General

Cylinder Bars

Removal

Installation

Rotor Assembly

Removal

Installation

Front Stub Shaft

Removal

Installation

Front Bearing

Removal

Installation

Rear Drive Hub

Removal

Installation

Rotor Inlet Flighting

Removal

Repair

Installation

Knives

Removal

Installation

Sweeps (Paddles)

Discharge Sweeps

Separator Sweeps

Rotor Repair

Skin Dents

Static Balancing

ROTOR GEARBOX

General Information

Rotor Drive

Lubrication

Rotor Gearbox Shift Lever

Removal

Disassembly

Inspection

Assembly

Installation

–CONCAVES

General Information

Adjustment

Calibrations

Removal

Installation

Concave Adjustments

Concave Alignment

Leveling and Indexing Concave

Concave Overlaps

Solid

Perforated

Concave Blanks

–SEPARATOR GRATES

General Information

Removal

Installation

–ROTOR GUIDE VANES / GUIDE VANE SHELL

Rotor Guide Vanes

Removal

Installation

Rotor Guide Vane Shell

Removal

Installation

–SEPARATOR RETURN PAN

General Information

Rear Separator Pan Seal

Removal

Installation

Separator Return Pan Side Frame Seals

Removal

Installation

Separator Return Pan Support Bearings

Removal

Installation

Rear Support Shaft Bearings

Removal

Installation

Front Support Shaft Bearings

Removal

Installation

Separator Return Pan

Removal

Installation

–CHAFFER / CLEANING SHOE / SHAKER SHAFT

General Information

Cleaning (Shaker) Shoe

Adjustable Chaffer (Upper Cleaning Screen)

Fixed Air Foil Chaffer (Upper Cleaning Screen)

Adjustable Sieve (Lower Cleaning Screen)

Chaffer (Top Screen)

Removal

Installation

Sieve (Lower Screen)

Removal

Installation

Cleaning Shoe Frame Assembly

Removal

Installation

Cleaning Shoe Frame Front Support Bearing

Removal

Installation

Cleaning Shoe Frame Hanger Arm BearingsUpper

Removal

Installation

Cleaning Shoe Frame Rear Support Shaft Bearing

Removal

Installation

Cleaning Shoe Frame Front Sea-lUpper

Removal

Installation

Cleaning Shoe Frame Front Seal-Lower

Removal

Installation

Cleaning Shoe Side Frame Seals

Removal

Installation

Cleaning Shoe Corner Seals

Removal

Installation

Lower Separator Pan

Removal

Installation

Lower Separator Pan Front Support Bearings

Removal

Installation

Lower Separator Pan Rear Support Shaft Bearings-Upper

Removal

Installation

Lower Separator Pan Rear Support Shaft Bearings-Lower

Removal

Installation

Lower Separator Pan Side Frame Seals

Removal

Installation

Shaker Shaft

Removal

Installation

Shaker Shaft Righthand Support Bearing

Removal

Installation

Shaker Shaft LeftHand Support Bearing

Removal

Installation

CLEANING SHOE PITMAN

Drive Belt

Removal

Installation

Drive Belt Tensioning Idler

Disassembly

Assembly

Idler Sheave Alignment

Pitman Shaft

Removal and Disassembly

Assembly and Installation

CLEANING FAN

General Information

Fan Speed Adjustment

Fan Speed Ranges

Cleaning Fan Accessory

Drive Belt

Removal

Installation

Variable Speed Driven Sheave

Removal

Installation

RightHand Bearing

Removal

Installation

LeftHand Bearing

Removal

Installation

Fan Assembly

Removal

Disassembly

Assembly

Balancing

Installation

–THRESHER DRIVE MAIN COUNTERSHAFT

General Information

Drive Belts

Removal

Installation

Drive Belt Idler

Removal And Disassembly

Assembly And Installation

Alignment And Adjustment

Main Countershaft

Removal And Disassembly

Assembly And Installation - – FRONT AXLE

–BRAKES

General Information

Brakes

Basic Operating Principles

Drum Brakes

Brake Inspections

Brake Lines and Hoses

Master Cylinder Operation

Checking Brake Fluid Level

Master Cylinder

Removal

Disassembly

Inspection and Cleaning

Assembly

Bench Bleeding Master Cylinder

Installation and Adjustment

Brake Wheel Cylinder

Removal

Installation

Disassembly And Assembly Of The Wheel Cylinder

Replacing The Shoe And Lining Assemblies

Removal Of Brake Drums

Removal Of Brake Assembly

Removal Of Shoe And Lining Assemblies

Removal Of Brake Parking Lever

Cleaning And Inspection Of Parts

Installation Of Adjuster Cable

Parking Brake Assembly

Installation Of Shoes To Backing Plate

Installation Of Brake Assembly

Installation Of Brake Drum

Brake Shoe To Drum Adjustment

Used Or New Brake Drums

New Brake Drums

In Combine

Parking Brake Adjustments

Minor Adjustment

Major Adjustment

Parking Brake Adjustment Procedure

Bleeding Brake System

Manual Bleeding

–FINAL DRIVE

General Information

Identification

Final Drive Capscrew Torques

Removal

Disassembly

Assembly

Installation

Oil Level

Final Drive Riser

General Information

Installation

–TRANSMISSION

General Information

Transmission Identification

Combine Transmission Capscrew Torque

Transmission Maintenance

Transmission Lubrication Pump

General Information

Testing

Replacement

Transmission

Removal

Installation

Transmission Shifter

Transmission Shifter Assembly Adjustment

Transmission Shifter Cable Adjustment

Transmission Shifter Assembly

Shift Rails, Forks, and Top Cover

Bearing Adjustment Procedures

All Shafts And Differential

Differential

Removal

Output Shaft and Differential Carrier

Differential Assembly

Installation

Input Shaft

Seal Replacement With The Transmission Installed

Input Shaft Removal

Input Shaft Installation

Main Pinion Shaft

Removal

Installation

Countershaft

Countershaft Removal

Countershaft Installation

Transmission Troubleshooting

Transmission Troubleshooting Table - -HYDRAULICS

–GENERAL INFORMATION

General Information

Hydraulic Schematic (Pressure And Flow Compensated Load Sense System)

Axial Piston Pump (Load Sense Compensator)

Filter Screen

Oil Filters

Priority And Shuttle Valve

MonoBlock Main Control Valve

Lateral Tilt Valve

Hydraulic Load Sensing System

During Low Pressure Standby Mode (No Steering Demand)

During Activation Of Load Sense (Pressure And Flow Compensated) Functions

During High Pressure Standby Mode (Flow Compensated Functions)

–HYDRAULIC RESERVOIR

General

Draining

Removal

Cleaning The Strainer Assembly

Removal

Screen Cleaning

Installation

Disassemble And Clean The Hydraulic Reservoir

Installation

RESERVOIR STRAINER SCREEN HYDRAULIC

Removal

Screen Cleaning

Installation

–OIL FILTER

General

Removal

Installation

–HYDRAULIC CONTROL VALVE

General

Hydraulic Control Valve

Valve Locations

Main Control Valve Port Location

Hydraulic Lines

Valve Adjustments

Hydraulic Valves

O-Rings And Backup Rings

Unloader Swing In And Out Valve

Reel Fore And Aft Valve (Optional)

Feeder Reverser Valve

Chaff Spreader, Reel Lift Lower, And Master Valve

Reel Lift Raise Valve

Reel Speed Valve And Header Lift / Lower

Reel Speed Pressure Compensator

Chaff Spreader / Rotary Screen Pressure Compensated Flow Regulator

Load Sense Pressure Regulator

Auger Swing Check Valves

Reel Fore And Aft Check Valves (Option)

Chaff Spreader, Rotary Screen, Header Lift, Load Sense, And Reel Speed Check Valves

Header Lift And Feed Reverser Check Valves

Unloader Swing Fast Valve

Troubleshooting

Main Control Valve Assembly

Chaff Spreader Valve

Rotary Screen Valve

Reel/Pickup Speed Valve

Header Lift

Auger Swing

Feed Reverser

Reel Lift

Reel Fore And Aft (Ce)

Solenoid Troubleshooting

Solenoid Torque Values

Removal And Installation Of Hydraulic Control Valve

Removal

Installation

–LATERAL TILT VALVE

General

ORings And Backup Rings

Removal

Disassembly

Inspection

Assembly

Installation

Troubleshooting

Solenoid Troubleshooting (Directional Control Valve Solenoids)

Solenoid Troubleshooting (Float Solenoid Valves)

Lateral Tilt Valve Assembly

–PRIORITY VALVE

General

Operating Modes

Normal Operation (No Steering Demand)

Steering Demand Mode

Steering Relief Mode

Priority Valve Troubleshooting

Priority Valve Disassembly And Assembly

Disassembly

Assembly

–UNLOADER ENGAGE AND ROTOR DISCONNECT VALVE

General

Operating Modes

Disengaged

Engaged

Troubleshooting

Disassembly

Inspection

Assembly

–SHUTTLE VALVE

General

Removal

Installation

–VARIABLE SPEED RELIEF VALVE

General Information

Testing The Relief Valve On The Combine

Testing The Relief Valve Off The Machine

Servicing the Relief Valve

OIL COOLER BYPASS VALVE

General Information

Servicing of Oil Cooler Bypass Valve

Testing

–CHAFF SPREADER FLOW DIVIDER

General Information

Flow Divider Cartridge

ORings And Backup Rings

Removal

Disassembly And Inspection

Assembly

Installation

Troubleshooting

Chaff Spreader Flow Divider

–SINGLE POINT FIXED CONNECTOR

General Information

Single Point Fixed Connector

Single Point Mobile Connector (Header)

Connecting the Single Point Couplers

Cartridge Removal and Installation

Fixed Plate (Machine)

Removal

Disassembly

Assembly

Installation

Single Point Mobile Connector (Header)

Removal

Disassembly

Assembly

Installation

–HEADER LIFT CYLINDERS

General

Removal

Disassembly

Inspection

Reassembly

Installation

–REEL LIFT CYLINDERS

Reel Lift Master Cylinder

Removal From Header

Installation On Header

Disassembly

Inspection

Reassembly

Reel Lift Slave Cylinder

Removal From Header

Installation On Header

Disassembly

Inspection

Reassembly

–UNLOADING AUGER TUBE SWING CYLINDER

General

Operation

Extend (Out)

Retract (In)

Removal

Disassembly

Inspection

Reassembly

Installation

Bleeding Unloading Auger Tube Swing Cylinder and Lines

–STEERING CYLINDERS

Standard Rear Axle

General

Operation

Removal

Disassembly

Inspection

Reassembly

Installation

RWA Rear Axle (Class 6 and 7)

General

Operation

Removal

Disassembly

Inspection

Reassembly

Installation

Bleeding Steering Cylinders and Lines (One Double Acting)

RWA Rear Axle (Class 8 On Class 7)

General

Removal

Disassembly

Inspection

Reassembly

Installation

Bleeding Steering Cylinders and Lines (Two Double Acting)

–UNLOADING AUGER ENGAGE CYLINDER

General

Operation

Removal

Disassembly

Inspection

Reassembly

Installation

Bleeding Unloader Engage Cylinder and Line

–HEADER LATERAL TILT CYLINDER

General

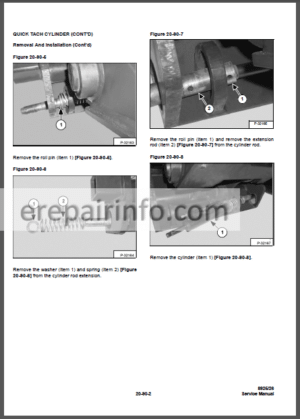

Disassembly

Inspection

Reassembly

–HYDRAULIC ACCUMULATOR

General

Special Tools

To Lock Out The Accumulator

Removal

Installation

Discharging The Accumulator

Charging The Accumulator

To Check The Charge At Any Time

Accumulator Disassembly

Inspection

Accumulator Assembly

–HYDROSTATIC DRIVE SYSTEMS

General

Model A66, 660B And 9695

Models A76, 670B And 9795

Rotor And Propel Pump Hydraulic Schematic

Principle Of Operation Of A Hydrostatic Motor

Principle Of Operation Of A Hydrostatic Pump

Operation

Neutral Position

Stroked (Forward) Position

Stroked (Reverse) Position

Multi-Function Valve

System Check Valve

Pressure Limiter Operation

High-Pressure Relief Operation

–PRIMING, FLUSHING, CLEANING, AND START-UP OF HYDRAULIC SYSTEM

General

Class 6

Class 7

Priming The Suction Line For The Main Hydraulic Pump

Priming The Hydrostatic Charge Pump Suction Filters And Lines

Suction Filters

CHarge Pump Suction Lines

Flushing And Cleaning

Hydraulic System Start-Up Procedures

After Servicing Of The Suction Lines, Suction Screen, Or Suction Filter(S)

Starting-Up A New/Repaired Hydraulic Pump

Hydrostatic Propulsion Drive Start-Up Procedures (New/Repaired Pump/Motor)

Hydrostatic Rotor Drive Start-Up Procedures (New/Repaired Pump/Motor)

–HYDROSTATIC ROTOR DRIVE SYSTEM

General

Rotor Drive Motor

Removal

Installation (Models A66, 660B and 9695)

Installation (Models A76, 670B and 9795)

Rotor Pump (Models A66, 660B and 9695)

Removal

Disassembly

Reassembly

Installation

Rotor Drive Tandem Pump (Models A76, 670B and 9795)

Removal

Disassembly

Reassembly

Installation

Hydrostatic Rotor Drive System Adjustments

Electric Displacement Control (Edc) And Hydraulic Displacement Control (Hdc) Neutral Adjustment

Multi-Function Valve Adjustment (Pressure Limit & High Pressure Relief Valve)

Pump Charge Pressure Relief Valve Adjustment

Motor Charge Pressure Relief Valve Non-Adjustable (Forward)

Hydrostatic Rotor Drive System – Test Port Locations

Hydrostatic Rotor Drive Troubleshooting Tables

Neutral – Difficult or Impossible to Find

System Operating Hot

Transmission Operates Normally in One Direction Only

System Will Not Operate in Either Direction

Low Motor Output Torque

Improper Motor Output Speed

Excessive Noise and/or Vibration

System Response is Sluggish

Hydrostatic Rotor Drive Electronic Speed Control Module/Reversing Switch

Thresher (Rotor) Engage Switch

Rotor Speed (Control Console)

HYDROSTATIC PROPULSION DRIVE SYSTEM

General Information

Pump

Motor

Transmission Components

Manual Displacement Control (MDC)

Multi-Function Valve (Pressure Limiter and High Pressure Relief)

Pressure Limiter Operation

High-Pressure Relief Operation

Motor Operation

Hydrostatic Propulsion Motor

Removal

Installation

Propel Pump (Models A66, 660B and 9695)

Removal

Disassembly

Reassembly

Installation

Propel Pump (Models A76, 670B and 9795)

Removal

Installation

Hydrostatic Propulsion Drive System Adjustments

Multi-Function Valve Adjustment (Pressure Limiter and High Pressure Relief Valve)

Pump Charge Pressure Relief Valve Adjustment

Motor (Forward/Reverse) Charge Pressure Relief Valve Non-Adjustable

Hydrostatic Propulsion Drive Troubleshooting Tables

Neutral – Difficult or Impossible to Find

System Operating Hot

Transmission Operates Normally in One Direction Only

System Will Not Operate in Either Direction

Low Motor Output Torque

Improper Motor Output Speed

Excessive Noise and/or Vibration

System Response is Sluggish

Test Port Locations

Series 90 Pump

Series 90 Motor

HYDROSTATIC PUMP AND MOTOR REPAIR

General

Series 90 Pump (Rotor and Propulsion Drive)

Input Shaft Seal

Multi-Function Valve Cartridges (High Pressure Relief Valves)

Charge Pressure Relief Valve

Charge Pump

Auxiliary Pad Installation

Displacement Control Valve (Propel Pump)

Pressure Control Pilot Valve (PCP) (Rotor Pump Only)

Disassembly

Clutch Disassembly

Clutch Assembly

Motor Disassembly

Inspection Of Gerotor Motor Components

Motor Assembly Procedure

Assembly Of Gerotor Hydraulic Motor

Assembly Of Clutch Housing To Gerotor Hydraulic Motor

–HYDRAULIC CHAFF SPREADER MOTOR

General Information

Hydraulic Chaff Spread Motor Components

Removal

Disassembly

Inspection

Installation

–HYDRAULIC ROTARY SCREEN DRIVE

General

Hydraulic Schematic

Adjustment of Flow Control

Removal and Disassembly

Inspect Parts For Wear

Assembly and Installation

Placing System Back Into Service

Troubleshooting Drive System

–ROTOR DISCONNECT CYLINDER (CLASS 7)

Operation

Removal

Disassembly

Assembly

Installation - -ELECTRICAL

–GENERAL INFORMATION

Introduction

Basic Troubleshooting Procedures

Tools

General Testing Procedures

Visual Inspection

Continuity Check

Voltage Check

Testing For Open Circuits

Finding An Open Circuit

Testing For Short Circuits

Testing For High Resistance

–CONSOLE II TERMINAL

Console Ii Terminal

Gauges

Work Screen

Unloading Auger

Header Position

Percentage Of Header Used

Digital And Analog Display

Header Screen

Reel Control

Header Control

Combine Screen

Engine Screen

Miscellaneous Screen

Setup

System Setup

Maintenance

Calibrations

Vmm Diagnostics

Mvec Diagnostics

Engine Alarms

Alarms

Software Version

Symbols And Alarms

1St Message And Alarm Area

2Nd Message And Alarm Area

3Rd Message And Alarm Area

4Th Message And Alarm Area

5Th Message And Alarm Area

6Th Message And Alarm Area

7Th Message And Alarm Area

8Th Message And Alarm Area

Engine Diagnostics

Engine Trouble Code List

–CAB ELECTRICAL COMPONENT LOCATIONS

Electronic Modules

Steering Column

Seat and Console

Right-hand Seat Mounted Console

Right-hand Armrest Switches

Seat

Park Brake

Overhead Console

Lights and Wiper Switches

Heating and Air Conditioning

Electric Mirrors (Optional)

Windshield Wiper

Radio

Power Outlets

CHASSIS SENSOR LOCATION

Adjusting Switches

Adjusting Inductive Sensors

Sensors, Switches, Electrical Components

Miscellaneous Electrical Components

ELECTRICAL CIRCUITS

Fuse and Relay Panel

Relay Locations

Fuse Location and Amperage

Fuses and Relays Outside of Cab

Primary Circuit Breaker

MVEC Relay Boxes

Location

Relay/Fuse Location

VMM Inputs/Outputs

VMM1

VMM2

VMM3

VMM4

VMM5

VMM6

Testing

Fuse Testing

Relay Testing

Diode Test

Machine Grounds

Cab Frame Grounds

Under Cab Grounds

Main Machine and Battery Grounds

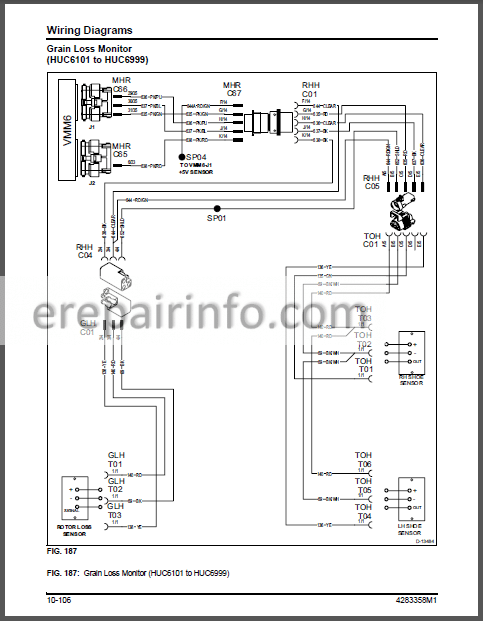

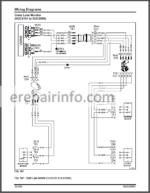

–WIRING DIAGRAMS

General Information

Harness Abbreviations

Splice Cross Reference

Wiring Diagrams

Air Conditioner and Blower

AutoGuide

Beacon Light

Clutch and Feeder Reverse

Concave and Separator Fan Control

Grain Loss Monitor

(HUC6101 to HUC6999)

Grain Loss Monitor(Huc7101 To Huc7999)

Lighter And Power Receptacles

Power Ladder

Rear Work And Service Lights

Rotor Speed Control

Sieve And Chaffer Control

Switch Circuits

Unloading Auger And Swing

Windshield Wiper, Seat Switch, And Power Mirrors

Header Height And Tilt

Rear Wheel Assist

Reel Position And Reel Speed

Headlights

Switch Backlighting

Steering Column

Radio And Horn

Power Distribution

Engine Start/Run

Fieldstar And Moisture Sensor

Sensor Circuits

Speed Sensors

Grain Bin Switch Circuits

Taillights, Backup Lights, And Alarm

Unloader, Exit, And Row Finder Lights

Field Lights

Data Bus And Auto Guide Roof

Smv And Turn Signals

Vertical Knife

ELECTRICAL TROUBLESHOOTING

Thresher, Header and Unloading Electromagnetic Clutch

General

Seat Interlock Switch

Electrical Header and Separator Clutch Troubleshooting

Ignition Key Turned to ON Position and Header and Thresher Switches Toggled ON

Clutch Removal and Installation

Clutch Magnet and Armature Inspection

Testing Clutch Magnet

Clutch Brush holder

Continuity Test

Diode Test

Brush Holder Servicing

Brush holder Installation

Bin Unloading Clutch Circuit

Troubleshooting

–BATTERIES

Safety Precautions

General

Battery Connections

Battery Disconnect Switch

Battery Connections

Starting Engine With Booster Battery

–STARTING SYSTEM

General Information

Ignition Switch

System Operation

Battery Condition

–CHARGING SYSTEM

Introduction

Operating Principles

Trouble Shooting

Charging Systems

Systems With Voltmeter

No output

Alternator Bench Test - -ELECTRONICS

–GENERAL INFORMATION

General

Electrical System

Batteries

Cleaning

–INPUTS AND OUTPUTS

Inputs and Outputs

Console

Combine Cab

Combine Speed Inputs

Control Handle Inputs

Righthand Console Switches

Wiring Diagram

Operating Specifications

Seat Interlock Switch

Thresher and Header Switch

Exit Light

Flasher/Hazard Lights

–ROTOR SPEED CONTROL

General Information

General

Rotor Speed Control / Reversing Switch

Operator Interface

Thresher On Mode

Thresher Off (Unplug) Mode

Electrical Circuit

Test Procedure

–CONSOLE CONTROLS

Reel Drive Electronic Speed Control

General

Calibration

Operating Specifications

Manual Mode

Automatic Mode

Automatic Header Height Control System

General Information

Manual Mode

Automatic Mode

Manual Override

AHHC Default (Manual) Mode

System Components

Header Height Control Operation

Automatic Header Height Control

Automatic Header Sensitivity and Height Control Adjustments

Return To Cut (RTC)

Float

Auto Header Tilt Control

General

Automatic Mode

Adjustments

Manual Mode

Standby

Calibration

Hydraulic System

Hydraulic Accumulator

Sensors

Sensor Operation

Sensor Setup

Flex Header Cutter Bar Linkage Adjustment

Ground Pressure

Cutterbar Angle

Sensor Linkage Settings

Header Diagnostic Fault Parameters

Fault Codes

Unloader Swing Automatic Mode

General

Manual Mode

Automatic Mode

Unloader Tube

System

Input Description

Output Description - – CAB AND HVAC

–REMOTE ELECTRIC ADJUST CAB MIRRORS

Components

Cab Mirror

Removal

Installation

–OPERATOR SEAT

Operator SeatEarly Production

General Information

Operation

Lubrication

Cushion Removal and Installation

Lumbar Support

Seat Back and Armrest

Seat Switch

Seat Angle and Seat Depth Adjuster

Seat and Slide Rails

Suspension Troubleshooting

Horizontal Shock Absorber

Vertical Shock Absorber

Vertical Shock Absorber Adjustment Cable

Compressor

Fore and Aft Isolation Unit

Height Control Component

Pneumatic Spring

Upper Part of the Suspension System

Lower Part of the Suspension System

Scissor Linkage

Operator SeatLate Production

Late Production

–STEERING COLUMN

General Information

Steering Column Adjustment

Turn Signal Switch

Ignition Switch

Steering Column Components

Steering Wheel

Removal

Installation

Steering Column

Removal

Disassembly

Assembly

Installation

–WINDSHIELD WIPER MOTOR

Windshield Wiper Motor

Removal

Installation

–HEADLINER

Front Headliner

Removal

Installation

Main Headliner

Removal

Installation

–CAB GLASS

Windshield

Installation

Rear Window

Installation

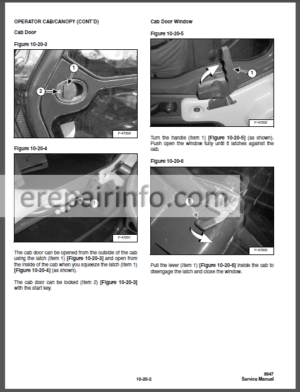

LeftHand Door Assembly

Components

Removal

Disassembly

Assembly

Installation

RightHand Door Assembly

Components

Removal

Disassembly

Assembly

Installation

–AIR CONDITIONING AND HEATING

Safety Precautions

Personal Injury Can Result if These Precautions Are Not Followed

Operation Information

System Operation

Efficient Operating Tips and Maintenance

Components and Operation of System

General Information

Pressure Temperature Relationship

Air Conditioning System Components

Compressor

System Protection Switches

Condenser

Receiver Drier

Thermal Expansion Valve

Evaporator

Blower Fan and Motor

Lines and Connections

Ra Refrigerant

Heat And Air Conditioning Controls

Compressor Refrigeration Oil

Check The Condition Of The Oil:

System Oil Level

Determining Oil Charge

Checking Oil Level

Compressor Mounting Angle (Degrees) Correct Dipstick Oil Level Units

Check the condition of the oil:

Service Tools

Manifold Gauge Set

Service Tools and Equipment

Moisture In A Refrigerant System

Single Drop Of Water

Moisture To Ice Crystals

Moisture To Acids

Increasing Acid Because Of Heat

Acid Results On Metals

Moisture Removal

Servicing Refrigeration System

Preliminary Checks

Drive Belt

Compressor Service Valves

Gauge Manifold Set

Fastening The Manifold Gauge Set

Leak Testing Procedure

Compressor Clutch Testing

Testing The System

Purging The Manifold Set (Hoses, Gauges, And Manifold)

Stabilizing The System

Performance Testing

Refrigerant Recovery (Discharging)

Evacuating The System

Charging The System

Diagnosis

Check The Easy Items First

Evaporator

Condenser

Compressor

Receiver Drier

Expansion Valve

Refrigerant Line Restrictions And Leaks

Electrical Checks

Troubleshooting Indicators

Procedure

False Compressor Seizure

Compressor And Fan Belt Test

Compressor Function Test

Expansion Valve Function Test

Troubleshooting Chart

System Fault Finding

Procedure

Pressure Reading Diagnosis

Procedure

Pressure Problem Chart

Test Condition 1

Test Condition 2

Test Condition 3

Test Condition 4

Test Condition 5

Test Condition 6

Test Condition 7

Test Condition 8

Test Condition 9

Test Condition 10

Test Condition 11

Test Condition 12

Air Conditioning Test Data Log Sheet:

Compressor Clutch

Electrical Check

Removal And Replacement

Disassembly

Pulley Bearing

Assembly

Air Conditioning Compressor

Contents

Removal

Installation

Service Valves

Lubrication

Evaporator And Condenser Core Repairs

Condenser

Removal

Installation

General

Evaporator And Expansion Valve

Removal

Installation

Receiver Drier

Removal

Installation

High And Low Pressure Switches

Replacement

Troubleshooting High Pressure Switch

Troubleshooting Low Pressure Switch

AntiIcing Temperature Sensor

Removal

Installation

Troubleshooting The AntiIcing Temperature Sensor

Internal Air Temperature Sensor

Troubleshooting The Internal Air Temperature Sensor

External Air Temperature Sensor

Troubleshooting The External Air Temperature Sensor

Mixed Air Temperature Sensor

Troubleshooting The Mixed Air Temperature Sensor

Blower Motor

Removal

Installation

Hose Replacement

Procedure

SpecificationsRefrigeration ORing Fitting Torque Chart

Cab Air Filter

Cab FilterPrimary

Cab FilterSecondary

Recirculation Filter

Cab Filters

Heater Core

Removal

Installation

Electronically Controlled Water Valve

Removal

Installation

Heating And Air Conditioning Controls

Removal

Installation

Troubleshooting Automatic Temperature Control

Sensor Malfunctions

Air Conditioning And Blower Relays

Control Panel Connectors

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

It was great thank you so much