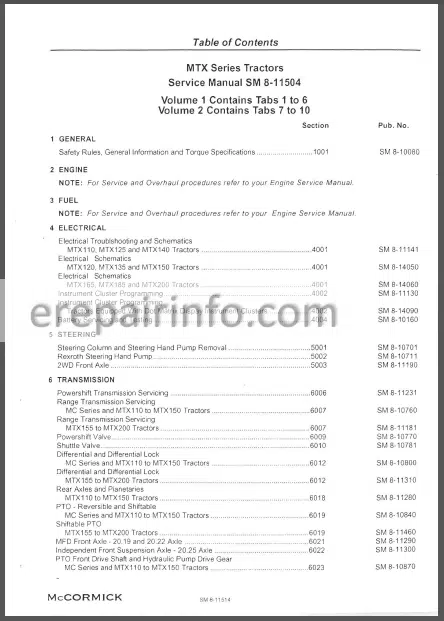

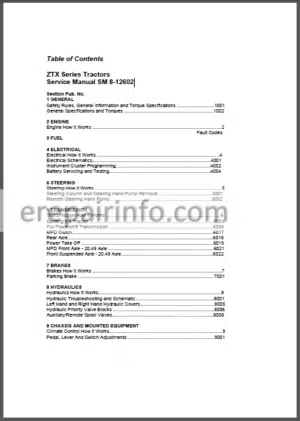

Factory Service Repair Manual For McCormick McCormick MTX Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1602

Bookmarks: Yes

Searchable: Yes

Number: SM 8-11504

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

McCormick

MTX110

MTX120

MTX125

MTX135

MTX140

MTX150

MTX155

MTX165

MTX185

MTX200

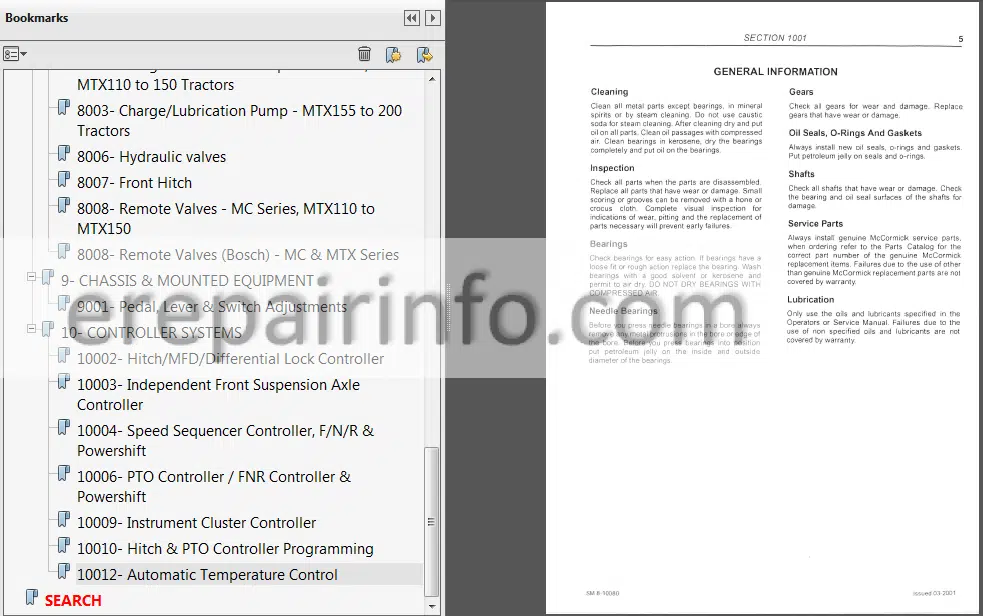

Contents

- GENERAL

- ELECTRICAL

- STEERING

- TRANSMISSION

- BRAKES

- HYDRAULICS

- CHASSIS AND MOUNTED EQUIPMENT

- CONTROLLER SYSTEMS

-GENERAL

–SAFETY, GENERAL INFORMATION AND STANDARD TORQUE SPECIFICATIONS

SAFETY

GENERAL INFORMATION

Cleaning

Inspection

Bearings

Needle Bearings

Gears

Oil Seals, O-Rings And Gaskets

Shafts

Service Parts

Lubrication

STANDARD TORQUE DATA FOR NUTS AND BOLTS

Chart 1 (Plain Nuts/Bolts)

Chart 2 (Phosphate Coated Nuts/Bolts)

Chart 3 (Zinc or Cadmium Plated Nuts/Bolts)

-ELECTRICAL

–ELECTRICAL TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

CIRCUIT TESTING

General Information

FUSE LOCATION AND IDENTIFICATION (European Specification Tractors)

FUSE LOCATION AND IDENTIFICATION (American Specification Tractors),

SWITCHES AND CONTROLS

Instrument Panel

Deluxe Cab Roof Controls (Operator Environment)

Right Hand Console

HARNESS LAYOUT AND CHASSIS GROUND LOCATIONS

Instrument Panel Harness and Components

Right Hand Console Harness Components (Tractors Without Speed Sequencer)

Right Hand Console Harness Components (Tractors with Speed Sequencer)

Engine Harness Components

MTX 110, MTX 125 and MTX 140 Transmission Harness Components

MTX 155, and MTX 175 Transmission Harness Components

Deluxe Cab Harness and Rear Fender Harness Components

Platform Harness and Rear Fender Harness Components,

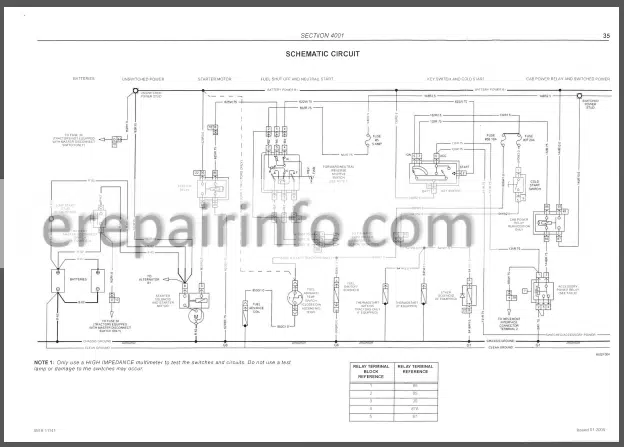

STARTER MOTOR, NEUTRAL START, FUEL SHUT-OFF

COLD START AND CAB POWER RELAY

INSTRUMENT CLUSTER WARNING LIGHTS AND GAUGES

FRONT PTO, ROTARY BEACON AND ELECTRIC MIRRORS

4TH AUXILIARY SOLENOIDS, IMPLEMENT INTERFACE CONNECTOR

AND 3 PIN AUXILIARY POWER CONNECTORS

HORN, CIGAR LIGHTER, SWITCHED FENDER AUXILIARY

POWER CONNECTOR, 7 POLE SOCKET AUXILIARY POWER

AND ELECTRIC AIR SEAT

RADIO AND INTERIOR LIGHT

BLOWER MOTORS AND AIR CONDITIONING

FRONT AND REAR WINDSCREEN WIPERIWASHER

BRAKE LIGHTS AND EUROPEAN SPECIFICATION AIR TRAILER BRAKE

–ELECTRICAL SCHEMATICS MTX 120, 135, 150

SPECIAL TOOLS

CIRCUIT TESTING

General Information

EUROPEAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (Tractors Without Dot Matrix Instrument Clusters)

EUROPEAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (Tractors With Dot Matrix Instrument Clusters)

AMERICAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (Tractors Without Dot Matrix Instrument Clusters)

AMERICAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (Tractors With Dot Matrix Instrument Clusters)

COMPONENT IDENTIFICATION

Hood Components

Engine Components

Transmission Components

Instrument Panel Component Identification (Tractors Without Dot Matrix Instrument Clusters)

Instrument Panel Component Identification (Tractors With Dot Matrix Instrument Clusters)

Right Hand Console Components (For Tractors Without Speed Sequencer or AutoSpeed)

Right Hand Console Components (For Tractors With Speed Sequencer or AutoSpeed)

Rear Fender Components

Cab Components

Cab Roof Panel Components

NEUTRAL START COLD START, KEY SWITCH, CAB POWER, FUEL SHUT-OFF, WATER IN FUEL AND FUEL HEATER

Neutral Start Circuit

Cold Start Circuit

Fuel Shut-off and Fuel Auto Advance Circuit

Water In Fuel Circuit

Fuel Heater Circuit

Accessory Power Relay Circuit

Cab Power Relay Circuit

Schematic Circuit

INSTRUMENT CLUSTER WARNING LAMPS AND GAUGES (For Tractors Without Dot Matrix Display Instrument Clusters Only)

Instrument Cluster Circuit

Charging Circuit

Schematic Circuit – Tractors Without Speed Sequencer or AutoSpeed

Schematic Circuit – Tractors With Speed Sequencer or AutoSpeed

4th AUXILIARY/REMOTE VALVE, IMPLEMENT INTERFACE CONNECTOR, AUXILIARY POWER

CONNECTORS AND BEACON LIGHT

4th Auxiliary/Remote Valve Circuit

Implement Interface Connector Circuit

Front and Rear 3 Pin Auxiliary Power Connector Circuit

Switched Fender Auxiliary Power Connector Circuit

Beacon Light

Schematic Circuit_

HORN, CIGAR LIGHTER AND SEAT

Horn Circuit

Cigar Lighter Circuit

Electric Air Seat Circuit

Schematic Circuit

RADIO AND INTERIOR LIGHT

Radio Circuit

Interior Light Circuit

Schematic Circuit

BLOWER AND AIR CONDITIONING (For Tractors Without Automatic Temperature Control)

Blower Circuit

Air Conditioning Circuit

Schematic Circuit

ELECTRIC MIRRORS AND WINDSHIELD WIPER WASHER

Electric Mirror Circuit

Front Windscreen WiperlWasher Circuit

Schematic Circuit

BRAKE LIGHTS, AIR TRAILER BRAKE AND FRONT PTO

Brake Light Circuit (European Specification Tractors Only)

Air Trailer Brake Solenoid Circuit (European Specification Tractors Only)

Front PTO Circuit

Schematic Circuit

SIDE/TAIL LIGHTS, NUMBER PLATE LIGHTS, RIGHT HAND

CONSOLE LIGHT, TURN SIGNAL AND HAZARD WARNING LIGHTS (European Specification Tractors Only)

Side/Tail Light, Number Plate Light and Right Hand Console Light Circuits

Turn Signal and Hazard Warning Light Circuits

Schematic Circuit – Tractors Without Dot Matrix Display Instrument Clusters

Schematic Circuit – Tractors With Dot Matrix Display Instrument Clusters

WARNING AND TURN SIGNAL LIGHTS (American SpeCification Tractors Only)

Turn Signal and Warning Light Circuits

Schematic Circuit – Tractors Without Dot Matrix Display Instrument Clusters

Schematic Circuit – Tractors Without Dot Matrix Display Instrument Clusters

GRILLE HEADLIGHTS, CAB MOUNTED HEADLIGHTS AND REAR FOG LIGHT (European Specification Tractors Without Dot Matrix Display Instrument Clusters Only)

Grille Headlights Circuit

Cab-Mounted Headlights Circuit

Rear Fog Light Circuit

Schematic Circuit

GRILLE HEADLIGHTS, CAB MOUNTED HEADLIGHTS AND REAR FOG LIGHT (European Specification Tractors With Dot Matrix Display Instrument Clusters Only)

Grille Headlights Circuit

Cab-Mounted Headlights Circuit

Rear Fog Light Circuit

Schematic Circuit

HEADLIGHTS, RIGHT HAND CONSOLE LIGHT AND TAIL LIGHTS (American Specification Tractors Without Dot Matrix Instrument Clusters Only)

Headlights Circuit

Right Hand Console Light Circuit

Rear Tail Light Circuits

Schematic Circuit

HEADLIGHTS, RIGHT HAND CONSOLE LIGHT AND TAIL LIGHTS (American Specification Tractors With Dot Matrix Display Instrument Clusters Only)

Headlights Circuit, Right Hand Console Light Circuit

Rear Tail Light Circuits,

Schematic Circuit

WORK LIGHTS (European Specification Tractors Without Dot Matrix Display Instrument Clusters Only)

Work Light Circuit

Schematic Circuit

MAIN CONNECTORS

–ELECTRICAL SCHEMATICS MTX165, MTX185 AND MTX200

SPECIAL TOOLS

CIRCUIT TESTING

General Information

Schematic Symbols

Schematic Legend

Wire Colour Code

EUROPEAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (MTX200 Tractors up to JJE3361242)

EUROPEAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (For All MTX165/185 and MTX200 Tractors from JJE3361243)

AMERICAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION(MTX200 Tractors up to JJE336124)

AMERICAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION (For All MTX165/185 and MTX200 Tractors from JJE3361243)

COMPONENT IDENTIFICATION

Hood Components

MTX165 and MTX185 Engine Components

MTX200 Engine Components

Transmission Components,

Instrument Panel Components

Right Hand Console Components (For Tractors Without Speed Sequencer or AutoSpeed)

Right Hand Console Components (For Tractors With Speed Sequencer or AutoSpeed)

Fender Components

Cab Components

Cab Roof Panel Components

NEUTRAL START, COLD START, KEY SWITCH, CAB POWER, FUEL HEATER AND FOOT THROTTLE (For MTX165 and MTX185 Tractors)

Neutral Start Circuit

Cold Start Circuit

Fuel Heater

Foot Throttle

Accessory Power Relay Circuit ,

Cab Power Relay Circuit

Schematic Circuit (For MTX165 and MTX185 tractors)

NEUTRAL START, COLD START, KEY SWITCH CAB POWER

WATER IN FUEL AND THROTTLE (For MTX200 Tractors)

Starter Circuit

Cold Start Circuit

Wait to Start Light Circuit

Maintenance Light Circuit (Oil ChangeIWater in Fuel)

Foot Throttle Circuit

Accessory Power Relay

Cab Power Relay

Schematic Circuit (Tractors up to JJE3361242)

Schematic Circuit (Tractors from JJE3361243)

INSTRUMENT CLUSTER WARNING LIGHTS AND GAUGES (For MTX200 Tractors From JJE3361243)

Instrument Cluster Circuit

Charging Circuit

Schematic Circuit – MTX200 Tractors up to JJE3361242

Without Speed Sequencer or Autospeed

Schematic Circuit – MTX200 Tractors up to JJE3361242 With Speed Sequencer

4TH AUXILIARY/REMOTE VALVE IMPLEMENT INTERFACE CONNECTOR

AUXILIARY POWER CONNECTORS AND BEACON LIGHT Creeper Circuit

4TH Auxiliary/Remote Valve Circuit

Implement Interface Connector Circuit

Front and Rear 3 Pin Auxiliary Power Connector Circuit

Switched Fender Auxiliary Power Connector Circuit

Beacon Light

Schematic Circuit

HORN CIGAR LIGHTER AND SEAT

Horn Circuit

Cigar Lighter Circuit

Electric Air Seat Circuit

Schematic Circuit

RADIO AND INTERIOR LIGHT

Radio Circuit

Interior Light Circuit

Schematic Circuit

BLOWER AND AIR CONDITIONING (For Tractors Without Automatic Temperature Control)

Blower Circuit

Air Conditioning Circuit

Schematic Circuit

ELECTRIC MIRRORS AND WINDSHIELD WIPERIWASHERS

Electric Mirror Circuit

Front Windscreen WiperlWasher Circuit

Schematic Circuit

BRAKE LIGHTS, AIR TRAILER BRAKE AND FRONT PTO

Brake Light Circuit (European Specification Tractors Only)

Air Trailer Brake Solenoid Circuit (European Specification Tractors Only)

Front PTO Circuit

Schematic Circuit

SIDEn-AIL LIGHTS, NUMBER PLATE LIGHTS, RIGHT HAND CONSOLE LIGHT,

TURN SIGNAL AND HAZARD WARNING LIGHTS (European Specification Tractors Only)

Siden-ail Light, Number Plate Light and

Right Hand Console Light Circuits

Turn Signal and Hazard Warning Light Circuits

Schematic Circuit – MTX200 Tractors up to JJE3361242

Schematic Circuit – All MTX165/185 Tractors and MTX200 Tractors from JJE3361243

WARNING AND TURN SIGNAL LIGHTS (American Specification Tractors Only)

Turn Signal and Warning Light Circuits

Schematic Circuit

GRILLE HEADLIGHTS, CAB MOUNTED HEADLIGHTS

AND REAR FOG LIGHT (European Specification Tractors Only)

Grille Headlights Circuit

Cab Mounted Headlights Circuit

Rear Fog Light Circuit

Schematic Circuit – MTX200 Tractors up to JJE3361242

Schematic Circuit – All European Specification MTX165/185 Tractor

and MTX200 Tractors from JJE3361243

HEADLIGHTS, RIGHT HAND CONSOLE LIGHT

AND TAIL LIGHTS (American Specification Tractors Only)

Headlights Circuit

Right Hand Console Light Circuit

Rear Tail Light Circuits

Schematic Circuit – MTX200 Tractors up to JJE3361242

Schematic C ircu it – All American Specification MTX 165/185 Tractors

and MTX200 Tractors from JJE3361243

WORK LIGHTS (European Specification Tractors Only)

Schematic Circuit – MTX200 Tractors up to JJE3361242

Schematic Circuit – All MTX 165/185 Tractors and MTX200 Tractors from JJE3361243

WORK LIGHTS (American Specification Tractors Only)

Schematic Circuit – MTX200 Tractors up to JJE3361242

Schematic Circuit – All MTX165/185 Tractors and MTX200 Tractors from JJE3361243

MAIN CONNECTORS

–INSTRUMENT CLUSTER PROGRAMMING MTX SERIES

DIGITAL INSTRUMENT CLUSTER

GENERAL INFORMATION

PROGRAMMING THE DIGITAL INSTRUMENT CLUSTER (Programme Men’us 1 to 6),

Clock Programming (Menu Code 1)

MPH or km/h Speed Display Option Programming (Menu Code 2)

Ground Speed Tire Radius Programming (Menu Code 3)

Service Interval Programming (Menu Code 4)

Area Function Mode Programming (Menu Code 5)

Old Hours Programming (Menu Code 6)

PROGRAMMING THE DIGITAL INSTRUMENT CLUSTER (Programme Menu’s 7 to 14)

PTO Option Programming (Menu Code 7)

540 rpm PTO Programming (Menu Code 8)

750 rpm PTO Programming (Menu Code 9)

1000 rpm PTO Programming (Menu Code 10)

Engine rpm Programming (Menu Code 11)

Axle Ratio (Wheel Speed)

Programming (Menu Code 12)

True Ground Speed (Radar) Programming (Menu Code 13)

Powershift Speed Display Programming (Menu Code 14)

ANALOG INSTRUMENT CLUSTER

GENERAL INFORMATION

PROGRAMMING THE ANALOG INSTRUMENT CLUSTER

Tachometer Programming

Speedometer Programming

–INSTRUMENT CLUSTER PROGRAMMING – TRACTORS EQUIPPED WITH DOT MATRIX DISPLAY INSTRUMENT CLUSTERS

GENERAL INFORMATION

Standard (Analogue) Instrument Cluster (If Equipped)

Deluxe (Digital) Instrument Cluster (If Equipped)

INDICATOR LAMPS

Critical Indicator Lamps

MAIN DIGITAL DISPLAY

CLOCK SETTINGS

To Change Display To Read 12 Or 24 Hours

To Change The Time Setting:

CLUSTER CONTRAST/BRIGHTNESS ADJUSTMENT

UNIVERSAL DATA DISPLAY

IGNITION ON/RUN MODE

During normal operation ,

Entering The Programming Mode

Area Function (Menu 1)

Distance Function (Menu 2)

Percentage Wheel Slip (Menu 3)

Fuel Remaining Timer (Menu 4)

Electrical System Voltage (Menu 5)

Cluster Hitch Position Display Calibration (Menu 6)

Dynamic Calibration (Menu 7)

Cab Suspension Calibration (Menu 8)

ACCESSORY MODE – (One position counterclockwise from OFF)

Entering The Programming Mode

Programming MPH or km/h (Menu 1)

Programming Tyre Radius (Menu 2) – (Both Analogue and Digital Cluster)

Programming the Service Intervals (Menu 3)

Service Reminders (Menu 4)

Programming Implement Width (Menu 5)

Programming the “OLd” Instrument Cluster Hours (Menu 6)

Programming the PTO Constants (ALL PTO options) (Menu 7)

Programming A True Ground Speed Sensor (Radar) Constant (Menu 8)

Programming the Axle Ratio Constants (Menu 9)

Programming The Speed/Gear Display Constants (Menu 10)

–BATTERY SERVICING AND TESTING

SPECIFICATIONS

SPECIAL TOOLS

SAFETY PROCEDURES

MAlNTENANCE

Electrolyte Level

Inspecting and Cleaning the Battery Cables and Terminals

BA TIERY TESTING

Method One – Five Step Battery Test

Method Two – Using Heavy Duty Battery Tester

CHARGING THE BATTERY

PREPARING A DRY CHARGED BATTERY FOR USE

BOOSTER BATTERY CONNECTIONS

-STEERING

–STEERING COLUMN AND STEERING HAND PUMP REMOVAL

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

STEERING COLUMN

Removal and Installation

Disassembly and Assembly

STEERING HAND PUMP

Removal

Installation

–REXROTH STEERING HAND PUMP

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

STEERING HAND PUMP (MC Series, MTX110, 125 and 140 European 2WD Tractors, MTX110, 125 and 140 North American Tractors and MTX155 and 175 North American 2WD Tractors)

Disassembly

Inspection

Assembly

STEERING HAND PUMP (MTX110, 125 and 140 European MFD Tractors)

Disassembly

Inspection

Assembly

STEERING HAND PUMP (MTX155 and 175 European Tractors and MTX155 and 175 North America MFD Tractors)

Disassembly

Inspection

Assembly

–2WD FRONT AXLE

SPECIAL TORQUES

SPECIFICATIONS

SPECIAL TOOLS

WHEEL BEARING, HUB AND KING PIN

Wheel Bearing and Hub Disassembly

Wheel Bearing and Hub Assembly

King Pin and Bushings Disassembly

King Pin and Bushings Assembly

STEERING CYLINDER

Removal and Installation

Disassembly and Assembly

FRONT AXLE

Removal and Installation

Disassembly and Assembly

-TRANSMISSION

–POWERSHIFT TRANSMISSION SERVICING

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TRANSMISSION FRONT COVER

Removal and Installation

Front Cover Oil Seal

INPUT SHAFT AND DROPSHAFT

Removal

Installation

INPUT SHAFT

Disassembly:

Assembly

Cross Sectional Drawing of the Input Shaft

DROPSHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Dropshaft

Cross Sectional Drawing of the Powershift Transmission

–RANGE TRANSMISSION SERVICING

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

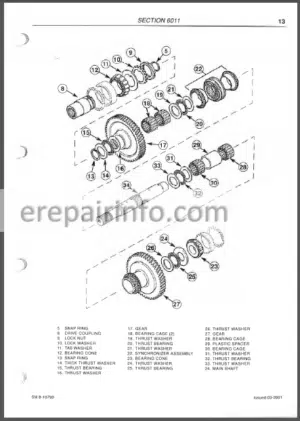

PICTORIAL INDEX

BEARING CARRIER HOUSING

Removal

Installation

GEAR SHIFTERS

Selector Forks

Pivot Shafts and Bushings

INTERMEDIATE SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Intermediate Shaft

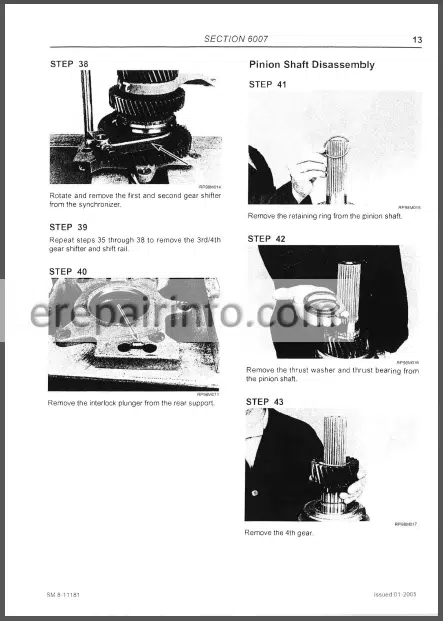

PINION SHAFT AND SHUTTLE SHAFT

Removal

Installation

Cross Sectional Drawing of the Pinion Shaft

SHUTTLE SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Shuttle Shaft

PINION SHAFT MOUNTING DISTANCE

PINION BEARING PRELOAD SETTING

–SERVICING THE RANGE TRANSMISSION

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

RANGE TRANSMISSION

Removal and Disassembly

Intermediate Shaft Disassembly

Range Shift Rails Disassembly

Pinion Shaft Disassembly

Synchronizer Disassembly

Shuttle Shaft Disassembly

Assembly and Installation

Shuttle Shaft Assembly

Shuttle Shaft Cross Section

Synchronizer Assembly

Pinion Shaft Assembly

Pinion Shaft Cross Section

Range Shift Rails Assembly

Intermediate Shaft Assembly

Gear Shifter Installation

Range Transmission Assembly

Shaft Bearing Adjustments

Pinion Shaft

Pinion Shaft Mounting Distance

Pinion Bearing Preload

Shuttle Shaft

Intermediate Shaft

–POWERSHIFT VALVE

SPECiFiCATIONS

SPECIAL TORQUES

POWERSHIFT VALVE

Removal and Installation

Disassembly and Assembly

Cross Sectional Drawing of the Powershift Valve

–SHUTTLE VALVE

SPECIFICATIONS

SPECIAL TORQUES

SHUTTLE VALVE

Removal and Installation

Disassembly and Assembly

Cross Sectional Drawing of the Shuttle Valve

–DIFFERENTIAL AND DIFFERENTIAL LOCK MC SERIES, MTX110 TO MTX150 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DIFFERENTIAL AND DIFFERENTIAL LOCK

Disassembly

Assembly,

Installation

Setting the Differential Bearing Pre-load

Setting the Ring Gear and Pinion Shaft Backlash

RING GEAR TO PINION SHAFT TOOTH PATTERN

Correct Tooth Pattern

Incorrect Tooth Pattern

CROSS SECTIONAL DRAWING OF THE DIFFERENTIAL

–DIFFERENTIAL AND DIFFERENTIAL LOCK MTX155 TO MTX200 TRACTORS

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DIFFERENTIAL AND DIFFERENTIAL LOCK

Removal

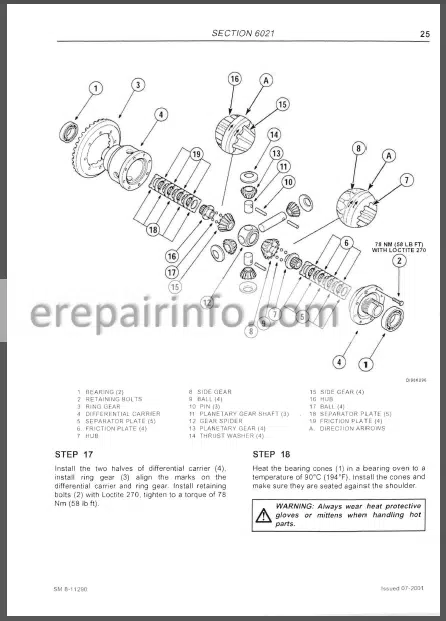

Disassembly

Assembly

Differential and Differential Lock Cross Section

Installation

ADJUSTING DIFFERENTIAL BEARING PRELOAD

ADJUSTING RING AND PINION BACKLASH

CHECKING FOR CORRECT PINION AND RING GEAR TOOTH CONTACT

–REAR AXLES AND PLANETARIES

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

REAR AXLE

Removal and Installation

Disassembly

Assembly – Flange Axle

Assembly – Bar Axle

–PTO – REVERSIBLE/SHIFTABLE

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

PTO HOUSING

Removal and Installation

PTO CLUTCH

Removal and Installation

Disassembly and Assembly

Cross Sectional Drawing of the PTO Clutch

SHIFTABLE PTO (If Equipped)

Disassembly

Assembly

Cross Sectional Drawing of the Shiftable PTO

REVERSIBLE PTO (If Equipped)

Disassembly

Assembly

Cross Sectional Drawing of the Reversible PTO

–SHIFTABLE PTO

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

PTO HOUSING REMOVAL AND DISASSEMBLY

Removal

Disassembly

PTO INPUT SHAFT DISASSEMBLY AND ASSEMBLY

Disassembly

Assembly

PTO OUTPUT SHAFT DISASSEMBLY AND ASSEMBLy

Disassembly

Assembly

PTO CLUTCH DISASSEMBLY AND ASSEMBLy

Disassembly

Assembly

PTO HOUSING ASSEMBLY AND INSTALLATION

Assembly

Installation

PTO OUTPUT SHAFT OIL SEAL INSTALLATION

–MFD FRONT AXLE 20.19 AND 20.22 AXLE

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

GENERAL INFORMATION

PLANETARY GEARS

Removal and Installation

Disassembly and Assembly

WHEEL HUB

Disassembly and Assembly

Cross Sectional Drawing of the Planetary Gear Assembly and Wheel Hub

SWIVEL HOUSING

Removal and Installation

Disassembly and Assembly

Cross Sectional Drawing of the Swivel Housing

DRIVE SHAFT

Removal and Installation

Disassembly and Assembly

MFD AXLE

Removal and Installation ,

Disassembly and Assembly

DIFFERENTIAL HOUSING

Disassembly

Ball Type Differential (if equipped)

Disassembly 2022 Axle

Assembly 20,22 Axle

Disassembly 2019 Axle

Assembly 2019 Axle

Cross Sectional Drawing of the Ball Type Differential

2022 Axle

2019 Axle

Limited Slip Differential (if equipped)

Disassembly 2022 Axle

Assembly 2022 Axle

Disassembly 20 19 Axle

Assembly 2019 Axle

Cross Sectional Drawing of the Limited Slip Differential

2022 Axle

2019 Axle

Setting the Position of the Pinion Shaft

Pinion Shaft Assembly

Differential Installation

Ring Gear Backlash Adjustment

Differential Bearing Preload Adjustment

–INDEPENDENT FRONT SUSPENSION AXLE

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

GENERAL INFORMATION

PLANETARY GEARS

Removal and Installation

Disassembly and Assembly

WHEEL HUB

Disassembly and Assembly

Cross Sectional Drawing of the Planetary Gear Assembly and Wheel Hub

SWIVEL HOUSING

Removal and Installation

Disassembly and Assembly

KING PIN HOUSING

Removal and Installation

Disassembly

Cross Sectional Drawing of the Swivel Housing and King Pin Housing

DRIVE SHAFTS

Disassembly and Assembly

MFD AXLE

Removal and Installation

Disassembly

Assembly

Setting the Torsion Bars

DIFFERENTIAL HOUSING

Disassembly

Differential Lock

Disassembly

Assembly

Cross Sectional Drawing of the Differential

Setting the Position of the Pinion Shaft

Pinion Shaft Assembly

Differential Installation

Ring Gear Backlash Adjustment

Differential Bearing Preload Adjustment

–PTO DRIVE SHAFT GEAR AND HYDRAULIC PUMP DRIVE GEAR

SPECIFICATIONS

SPECIAL TORQUES

PTO DRIVE SHAFT GEAR AND HYDRAULIC PUMP DRIVE GEAR

Removal

Installation

Cross Sectional Drawing of the PTO Drive Shaft Gear and Hydraulic Pump Drive Gear

-BRAKES

–SERVICE BRAKES

SERVICE BRAKES MTX110, 125 AND 140 TRACTORS

Removal

Installation

SERVICE BRAKES MTX155 AND 175 TRACTORS

Removal

Installation

–HYDRAULIC TRAILER BRAKE VALVE

TRAILER BRAKE VALVE

Removal and Installation

Disassembly and Assembly

Cross Sectional Drawing of the Trailer Brake Valve

-HYDRAULICS

–HYDRAULIC TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

HYDRAULIC SYSTEM TROUBLESHOOTING

PFC Pump Problems

Rear Hitch Problems

Signal Circuit Problems

Remote Valve Circuit Problems

Steering Problems

Brake Problems

Hydraulic Trailer Brake Problems (If Equipped)

PTO Problems

Differential Lock Problems

MFD Problems

Hydraulic System Cooling Problems

Independent Front Suspension Axle Problems

HYDRAULIC SYSTEM DIAGNOSTIC TESTING

Test 1 – Regulated Circuit Leakage Test

Test 2 – Charge Pump Pressure Test

Test 3 – Charge Pump Flow Test

Test 4 – Low Pressure Standby Test

Test 5 – Maximum Pressure Test

Test 6 – Remote Flow Test

Test 7 – Pump Flow Test

Test 8 – Steering Function and Pressure Test

Test 9 – Regulated Pressure Test and Adjustment

Test 10 – Powershift Valve Pressure Test

Test 11 – MFD Pressure Test

Test 12 – PTO Supply Pressure Test

Test 13 – Differential Lock Pressure Test

Test 14 – Forward and Reverse Clutch Pressure Test

Test 15 – Rear Hitch Pressure Test

Test 16 – Forward and Reverse Lubrication Pressure Test MTX11 0/120/125/135/140/150 Tractors Only

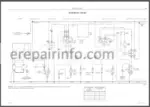

HYDRAULIC SCHEMATIC (MTX110/120/125/135/140/150 Tractors)

Hydraulic Circuit Components

–HYDRAULIC TROUBLESHOOTING AND SCHEMATICS MTX110 TO MTX150 TRACTORS MTX155 to MTX200

SPECIAL TOOLS

HYDRAULIC SYSTEM TROUBLESHOOTING

PFC Pump Problems

Rear Hitch Problems

Signal Circuit Problems

Remote Valve Circuit Problems

Steering Problems

Brake Problems

Hydraulic Trailer Brake Problems (If Equipped)

PTO Problems

Differential Lock Problems

MFD Problems

Hydraulic System Cooling Problems

Independent Front Suspension Axle Problems

HYDRAULIC SYSTEM DIAGNOSTIC TESTING

Test 1 – Regulated Circuit Leakage Test

Test 2 – Charge Pump Pressure Test

Test 3 – Charge Pump Flow Test

Test 4 – Low Pressure Standby Test

Test 5 – Maximum Pressure Test

Test 6 – Remote Flow Test

Test 7 – Pump Flow Test

Test 8 – Steering Function and Pressure Test

Test 9 – Regulated Pressure Test

Test 10 – Powershift Valve Pressure Test

Test 11 – MFD Pressure Test

Test 12 – PTO Supply Pressure Test

Test 13 – Differential Lock Pressure Test

Test 14 – Forward and Reverse Clutch Pressure Test

Test 15 – Rear Hitch Pressure Test

Test 16 – Forward and Reverse Lubrication Pressure Test MTX110/120/125/135/140/150 Tractors Only

HYDRAULIC SCHEMATIC (MTX Tractors)

Hydraulic Circuit Components

–CHARGE LUBRICATION PUMP MC SERIES, MTX110 TO MTX150·TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

CHARGE/LUBRICATION PUMP

Disassembly

Assembly

Cross Sectional Drawing of the Charge/Lubrication Pump

–CHARGE/LUBRICATION PUMP MTX155 TO MTX200 TRACTORS

REMOVAL AND DISASSEMBLY

ASSEMBLY AND INSTALLATION

–HYDRAULIC VALVES

SPECIFICATIONS

SPECIAL TORQUES

HITCH VALVE

Removal and Installation

Disassembly and Assembly

PRIORITY REGULATOR VALVE (Racine)

Removal and Installation

Disassembly and Assembly

PRIORITY REGULATOR VALVE (Bosch)

Removal and Installation

Disassembly and Assembly

–FRONT HITCH

SPECIAL TORQUES

SPECIAL TOOLS

FRONT HITCH

Removal and Installation

LIFT CYLINDER

Disassembly and Assembly

Cross Sectional Drawing of the Lift Cylinder

–REMOTE VALVES MC SERIES, MTX110 TO MTX150 TRACTORS

SPECiFiCATIONS

REMOTE VALVES

Removal and Installation

REMOTE VALVE WITHCHECK VALVE AND PRIORITY OR CHECK VALVE

Disassembly and Assembly

REMOTE VALVE WITHCHECK VALVES OR BYPASS PLUGS

Disassembly and Assembly

DISASSEMBLY AND ASSEMBLY OF CHECK VALVE

DISASSEMBLY AND ASSEMBLY OF CHECK VALVES OR BYPASS PLUGS

REMOTE VALVE WITHOUT CHECK VALVE

Disassembly and Assembly

POWER BEYOND MANIFOLD

Disassembly and Assembly

SINGLE ACTING REMOTE VALVE

Disassembly and Assembly

–REMOTE VALVES (BOSCH) MC AND MTX SERIES TRACTORS

SPECIAL TORQUES

REMOTE VALVES

Removal and Installation

REMOTE VALVE

Disassembly and Assembly

REMOTE VALVE (ELECTRONIC)

Disassembly and Assembly

POWER BEYOND MANIFOLD

Disassembly and Assembly

REMOTE VALVE END PLATE

Disassembly and Assembly

REMOTE VALVE END PLATE WITH FORTH REMOTE VALVE

Disassembly and Assembly

CHECK VALVE

Disassembly and Assembly

Check valve pin

-CHASSIS & MOUNTED EQUIPMENT

–PEDAL, LEVER AND SWITCH ADJUSTMENTS

SPECIAL TORQUES

SPECIAL TOOLS

HAND AND FOOT THROTTLE ADJUSTMENT

BRAKE PEDAL

Brake Pedal Stop Adjustment

Master Cylinder Rod Adjustment

Brake Pedal Maximum Travel Adjustment

Brake Light Switch Adjustment

INCHING PEDAL

Inching Pedal Cable Adjustment

Interlock Cable Adjustment

INCHING PEDAL (Tractors with Auto Speed)

Inching Pedal Cable Adjustment

Interlock Cable Adjustment

DROMONE AUTO HITCH ADJUSTMENT (if Equipped)

Cable Adjustment

Lift Rod Adjustment

CBM AXLA AUTO HITCH ADJUSTMENT (if Equipped)

Cable Adjustment

Lift Rod Adjustment

CREEP CONTROL

Cable Adjustment

Creep Switch Adjustment MTX155 to 200 Tractors Only

PARKING BRAKE ADJUSTMENT

SHIFTABLE PTO ADJUSTMENT MTX 11 0 to MTX 150 Tractors

SHIFTABLE PTO ADJUSTMENT MTX 155 to MTX200 Tractors

REMOTE CONTROL VALVE LINKAGE

RANGE SELECTOR LINKAGE (Tractors Without Speed Sequencer or Auto Speed)

RANGE SELECTOR LINKAGE (Tractors With Speed Sequencer or Auto Speed)

REMOVING AIR FROM THE BRAKE SYSTEM MTX 11 0 to MTX 150 Tractors Equipped With Standard Brakes

REMOVING AIR FROM THE BRAKE SYSTEM MTX 11 0 to MTX 150 Tractors Equipped With Booster Brakes

REMOVING AIR FROM THE BRAKE SYSTEM MTX155 to 200 Tractors Equipped With Booster Brakes

-CONTROLLER SYSTEMS

–HITCH/MFD/DIFFERENTIAL LOCK CONTROLLER

SPECIAL TOOLS

TOOLS TO BE MADE

DELUXE HITCH CALIBRATION

Tire Size Calibration and Ride Control Enabling/Disabling

GENERAL INFORMATION FOR HITCH ERROR CODES

Normal Operation

No Error Codes Displayed But Hitch Is Not Working Correctly

Controller LED

Failure Modes

General Notes

Error Codes That Disable Hitch Motion

Other Possible Error Indications

Error Codes That Allow Hitch Operation

Failures That Are Checked Once

Double Failures Involving The UP/DOWN Switch

CALIBRATION ERROR CODE CHART

READING AND ERASING ERROR CODES

HITCH SYSTEM PERFORMANCE CODE CHART

CIRCUIT TESTING

Hitch Operating Circuit

Test 1 – No Power to Controller (Power and Clean Ground)

Test 2 – Circuit Shorted to Ground

Test 3 – Hitch Up/Down Switch and Hitch Enable Lamp (Tractors Without Speed Sequencer)

Test 4 – Hitch Up/Down Switch Circuit (Tractors Without Speed Sequencer)

Test 5 – Multi-Function Lever Hitch Circuit (Tractors With Speed Sequencer)

Test 6 – Hitch Solenoids Circuit,

Test 7 – R/H Hitch Remote Switch

Test 8 – LlH Hitch Remote Switch

Hitch Position Control Circuit

Test 9 – Hitch Position Potentiometer

Test 10 – Hitch Position Command Potentiometer

Test 11 – Hitch Drop Speed Potentiometer,

Test 12 – Hitch Upper Height Potentiometer

Hitch Load Control Circuit

Test 13 – Load Pins

Test 14 – Hitch Load Command Potentiometer

Test 15 – Hitch Travel Potentiometer

Test 16 – Wheel Speed Sensor

Slip Limit Control Circuit

Test 17 – Slip Control Switch

Test 18 – Slip Control Switch Circuit

Test 19 – Radar

Ride Control Circuit

Test 20 – Ride Control Switch

Differential Lock Circuit

Test 21 – Differential Lock Solenoid

Test 22 – Differential Lock Switch, Auto Differential and Auto Indicator Lamp

Test 23 – Differential Lock Indicator Lamp

MFD Circuit

Test 24 – MFD Solenoid

Test 25 – MFD Switch and Auto MFD Circuit

Test 26 – MFD Relay Circuit

Test 27 – MFD Indicator Lamp

Brake Switches

Test 28 – Brake Switch Circuit

HARNESS LAYOUT, SCHEMATICS AND CONNECTORS

Instrument Panel Harness Components

Right Hand Console Harness Components (For Tractors Without Speed Sequencer)

Right Hand Console Harness Components (For Tractors With Speed Sequencer)

MC Series, MTX 11 0/120/125/135/140/150 Transmission Harness and Fender Harness Components

MTX 155/165/175/185 Transmission Harness and Fender Harness Components

Hitch Control Schematic Circuit(For Tractors Without Speed Sequencer)

Hitch Control Schematic Circuit(For Tractors With Speed Sequencer)

Differential Lock and MFD Schematic Circuit(For Tractors Without Speed Sequencer)

Differential Lock and MFD Schematic Circu(For Tractors With Speed Sequencer)

Schematic Legend

Wire Colour Code

MAIN CONNECTORS AND SPLICE PACKS

TIRE RADIUS CONSTANT TABLE

–INDEDENDENT FRONT SUSPENSION AXLE CONTROLLER

SPECIAL TOOLS

GENERAL INFORMATION AXLE CONTROL

CALIBRATION

General Information

Calibration Procedure

AXLE POTENTIOMETERS

Potentiometer Check

Potentiometer Adjustment

MANUAL LOWERING OF THE FRONT AXLE

ERROR CODES

Identifying Error Codes

ERROR CODE FAULT GUIDE

No Error Code – Axle Suspension Does Not Operate

No Error Code – Axle Will Not Operate in Manual Override Mode

No Error Code – Axle Will Not Raise to Mid Position in Suspension Mode

Only Right Hand Side of Axle Raises in Manual Override Mode

No Error Code – Axle Will Not Raise to Mid Position in Suspension Mode

Only Left Hand Side of Axle Raises in Manual Override Mode

No Error Code – Axle Will Not Remain at Lowest Position in the Manual Override Mode

No Error Code – Axle Will Not Remain at Highest Position in the Manual Override Mode

No Error Code – Indicator Light Flashes Continually

No Error Code – Axle Will Not Automatically Go into Suspension Mode Above 14 Km/h

Error Code 21

Error Code 22

Error Code 31

Error Code 32

CIRCUIT TESTING

General Information

AXLE CONTROLLER CIRCUIT TESTS

Test 1 – No Switched Power to Controller

Test 2 – Switched Power Circuit Shorted to Ground

Test 3 – No Unswitched Power to Controller

Test 4 – Unswitched Power Circuit Shorted to Ground

Test 5 – Switched Power Chassis Ground Circuit

Test 6 – Unswitched Power Chassis Ground Circuits

Test 7 – Suspension Mode Switch and Indicator Lamp Circuits

Test 8 – Manual Override Switch Circuit

Test 9 – Right Hand Solenoid

Test 10 – Left Hand Solenoid

Test 11 – Pilot Solenoid

Test 12 – Potentiometer C ircu its

Test 14 – Wheel Speed Sensor Circuit

INDEPENDENT FRONT SUSPENSION AXLE HARNESS LAYOUT, SCHEMATIC AND CONNECTORS

Independent Front Suspension Axle Harness Layout

Independent Front Suspension Axle Schematic Circuit

Schematic Legend

Wire Colour Code

MAIN CONNECTORS AND SPLICE PACKS

–SPEED SEQUENCER CONTROLLER, F/N/R AND POWERSHIFT

SPECIAL TOOLS

TOOLS TO BE MADE

SPEED SEQUENCER GENERAL INFORMATION

Gear Selection

Soft Shift

Range Skip

Gear Display

SPEED SEQUENCER CALIBRATION

SPEED SEQUENCER NEUTRAL SELECTION

ERROR CODES

General Information

Retrieving Speed Sequencer Error Codes

Identifying Speed Sequencer Error Codes

Erasing Speed Sequencer Error Codes

SPEED SEQUENCER ERROR CODE QUICK REFERENCE GUIDE

SPEED SEQUENCER ERROR CODE FAULT GUiDE

FORWARD/NEUTRAL/REVERSE ERROR CODE FAULT GUIDE

CIRCUIT TESTING

General Information

Test 1- Chassis Ground Circuit

Test 2 – No Switched Power to PTO Controller, Speed Sequencer

Control Module (SSCM) and Multi-Function Lever (MFL)

Test 3 – Speed Sequencer Control Module (SSCM) Power

and Chassis Ground Circuit

Test 4 – Switched Power Circuit Shorted to Ground

Test 5 – Speed Sequencer Control Module (SSCM) Battery Power

Circuit Shorted to Ground

Speed Sequencer Circuit Test

Test 6 – Speed Sequencer 1st Range Solenoid

Test 7 – Speed Sequencer 2nd Range Solenoid

Test 8 – Speed Sequencer 3rd Range Solenoid

Test 9 – Speed Sequencer 4th Range Solenoid

Test 10- 1 st/2nd Range Potentiometers

Test 11 – 3rd/4th Range Potentiometers

Test 12 – Multi-Function Lever

Forward/Neutral/Reverse Circuit Test

Test 13 – Forward Solenoid

Test 14 – Reverse Solenoid

Test 15 – Forward/Neutral/Reverse Switch

Test 16 – Operator Seat Switch

Test 17 – Wheel Speed Sensor

Test 18 – Alternator Speed Signal

Powershift Circuit Test

Test 19 – S1 and S2 Speed Solenoids

Test 20 – Powershift S1 and S2 Relay Circuit

HARNESS LAYOUTS, SCHEMATICS AND CONNECTORS

Instrument Panel Harness Components

Right Hand Console Harness Components

MC Series, MTX110, MTX125 and MTX140 Transmission Harness, Fender Harness and Components

MTX155 and MTX175 Transmission Harness, Fender Harness and Components

Forward/Neutral/Reverse, Speed Sequencer and Powershift

Schematic Circuit

Schematic Symbols

Schematic Legend

Wire Colour Code

MAIN CONNECTORS

–PTO CONTROLLER FOR TRACTORS WITH OR WITHOUT SPEED SEQUENCER

SPECIAL TOOLS

GENERAL INFORMATION FOR ELECTRONIC PTO CONTROL

PTO Control Functions

FNR Control Functions

Controller LED

Error Codes

Operators Seat Switch Monitor and Alarm

Programming the PTO controller

PTO CONFIGURATION

Configuration Set Up

Configuration Procedure

ERROR CODES

General Information

Retrieving Error Codes

Identifying Error Codes

Erasing Error Codes

ERROR CODE QUICK REFERENCE CHART

ERROR CODE FAULT GUiDE

No Error Code – No PTO or F/N /R (Tractor Stops)

No Error Code (PTO Indicator Lamp is Continuously Flashing)

No Error Code – PTO Operates But PTO Indicator Lamp Does Not Illuminate

Error Code 11

Error Code 14

Error Code 15

Error Code 16

Error Code 22

Error Code 23

Error Codes 24, 25 and 26

Error Code 27

Error Code 31

Error Code 32

Error Code 33

Error Code 34

Error Code 35

Error Code 36

Error Code 37

Error Code 41

Error Code 42

Error Code 43

Error Code 44

Error Code 45

Error Code 46

Error Code 47

Error Code 51

Error Code 52

Error Code 53

Error Code 54

Error Code 55

Error Code 56

Error Code 57

Error Code 61

Error Code 62

Error Code 63

Error Code 64

Error Code 65

Error Code 66

Error Code 67

Error Code 71

Error Code 72

Error Code 73

Error Code 74

Error Code 75

Error Code 76

Error Code 77

Error Code 81

Error Code 82

Error Code 83

CIRCUIT TESTING

General Information

PTa Controller Clean Ground Test

Test 1

PTa Controller Power Circuit Tests

Test 2 – No Power to Controller

Test 3 – No Power to Controller

Test 4 – Circuit Shorted to Ground

Test 5 – PTa Control Switch

Test 6 – PTa Indicator Lamp

Test 7 – PTa Solenoid

Test 8 – PTa Speed Sensor

Test 9 – PTa Speed Switch (European Specification)

Test 10 – PTa Speed Switch (American Specification)

Auto and Remote PTa Circuit Test

Test 11 – Auto PTa Indicator Lamp

Test 12 – Auto PTa Switch

Test 13 – R/H Remote PTa Switch

Test 14 – L/H Remote PTa Switch

Test 15· Jumper Harness

Alternator Circuit Test

Test 16 – Alternator

Test 17· Alternator Speed Signal

Operator Seat Switch, Audible Alarm and Parking Brake Circuit Tests

Test 18 – Operator Seat Switch

Test 19· Audible Alarm

Test 20 – Parking Brake Switch

Forward/Neutral/Reverse Circuit Test

Test 21 – Forward/Reverse Solenoid Power

Test 22 – Forward Solenoid

Test 23 – Reverse Solenoid

Test 24 – Forward/Neutral/Reverse Switch

Test 25 – F/N/R Neutral Lamp

Test 26 – Reverse Indicator Lamp

Test 27 – 4th Range Switch

Test 28 – Wheel Speed Sensor

Powershift Circuit Test

Test 29 – S1 and S2 Speed Solenoids

Test 30 – Powershift Switch

Test 31 – Powershift S1 Relay

Test 32 – Powershift S2 Relay

Test 33 – Soft Shift Switch

Test 34 – Powershift Speed Indicators

HARNESS LAYOUTS, SCHEMATICS AND CONNECTORS

Instrument Panel Harness Components

Right Hand Console Harness Components (For Tractors With Speed Sequencer)

Right Hand Console Harness Components (For Tractors Without Speed Sequencer)

MC Series, MTX110, MTX125 and MTX140 Transmission Harness, Fender Harness and Components

MTX155 and MTX175 Transmission Harness, Fender Harness and Components

Forward/Neutral/Reverse and PTO Schematic Circuit

Auto and Remote PTO Schematic Circuit

Powershift Schematic Circuit.

Schematic Symbols

Schematic Legend

Wire Colour Code

MAIN CONNECTORS AND SPLICE PACKS

–INSTRUMENT CLUSTER CONTROLLER

SPECIAL TOOLS

INSTRUMENT CLUSTER GENERAL INFORMATION

CAN Bus Communication

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

INSTRUMENT CLUSTER PROGRAMMING

INSTRUMENT CLUSTER CONFIGURATION

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Error Code 100

Error Code 101

Error Code 102

Error Code 103

Error Code 106

Error Code 200

Error Code 201

Error Code 202

Error Code 300

Error Code 301 (MTX165 and Tractors Only)

Error Code 30 (MTX200 Tractors Only)

COMPONENT IDENTIFICATION

Engine Components – MTX120, MTX135 and MTX150 Tractors

Engine Components – MTX165 and MTX185 Tractors

Engine Components – MT200 Tractors

Transmission Components – MTX120, MTX135 and MT150 Tractors

Transmission Components – MTX 165 , MTX 185 and MT200 Tractors

Instrument Panel Components.

SCHEMATIC CIRCUITS

Schematic Circuit – MTX120, MTX135 and MTX150 – Tractors Without Speed Sequencer or Autospeed

Schematic Circuit· MTX120, MTX135 and MTX150 · Tractors With Speed Sequencer or Autospeed

Schematic Circuit – MTX165, MTX185 and MTX200 – Tractors Without Speed Sequencer or Autospeed

Schematic Circuit – MTX165. MTX185 and MTX200 – Tractors With Speed Sequencer or Autospeed

CAN Bus Schematic Circuit

MAIN CONNECTORS

–HITCH AND PTO CONTROLLER PROGRAMMING

SPECIAL TOOLS

GENERAL INFORMATION

CONTROLLER PROGRAMMING

–AUTOMATIC TEMPERATURE CONTROL

SPECIAL TOOLS

AUTOMATIC TEMPERATURE CONTROL GENERAL INFORMATION

SYSTEM OPERATION

CENTIGRADE/FAHRENHEIT DISPLAY

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Temperature Control Module Error Codes

Error Code 01

Error Code 02

Error Code 03

Error Code 04

Error Code 05

Error Code 06

Error Code 07

Error Code 08

Error Code 10

COMPONENT IDENTIFICATION

Air Conditioning Components (Cab Front)

Air Conditioning Components (Rear and Left Hand Side of Cab).

Automatic Temperature Control Schematic Circuit (MTX120, MTX135, MTX150. MTX165 and MTX185 Tractors)

Automatic Temperature Control Schematic Circuit (MTX200 Tractors up to JJE3361242)

Automatic Temperature Control Schematic Circuit (MTX200 Tractors from JJE3361243)

MAIN CONNECTORS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

It us not much information

Just a waist of money

Admin eRepair (store manager) –

Thank you for reaching out to us. We’re sorry to hear that you feel that the manual you purchased was not worth the money. We always strive to provide high-quality and informative manuals to our customers, and we’re disappointed to hear that we fell short in your case. That being said, we’d like to let you know that at the moment, the manual we suggested is the only one available for your particular McCormick model. We understand that this may not be the answer you were hoping for, but we hope this information helps. Please let us know if you have any other questions or concerns.