Factory technical manual and performance check and troubleshooting manual For Hitachi EX120-2 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 451

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX120-2

Contents

INTRODUCTION

SAFETY

-SPECIFICATIONS

–GENERAL INFORMATION

Foreword

Specifications

Working Range

Lifting Capacities

Service Refill Capacities

–DIMENSIONS AND WEIGHTS

Transportation

Weights

–FUELS AND LUBRICANTS

Fuel

Grease

Engine Oil

Gear Oil

Hydraulic Oil

Engine Coolant

–INTERCHANGEABILITY

Interchangeability

Installation of Attachments

-UPPERSTRUCTURE

–LAYOUT

Layout of Upperstructure

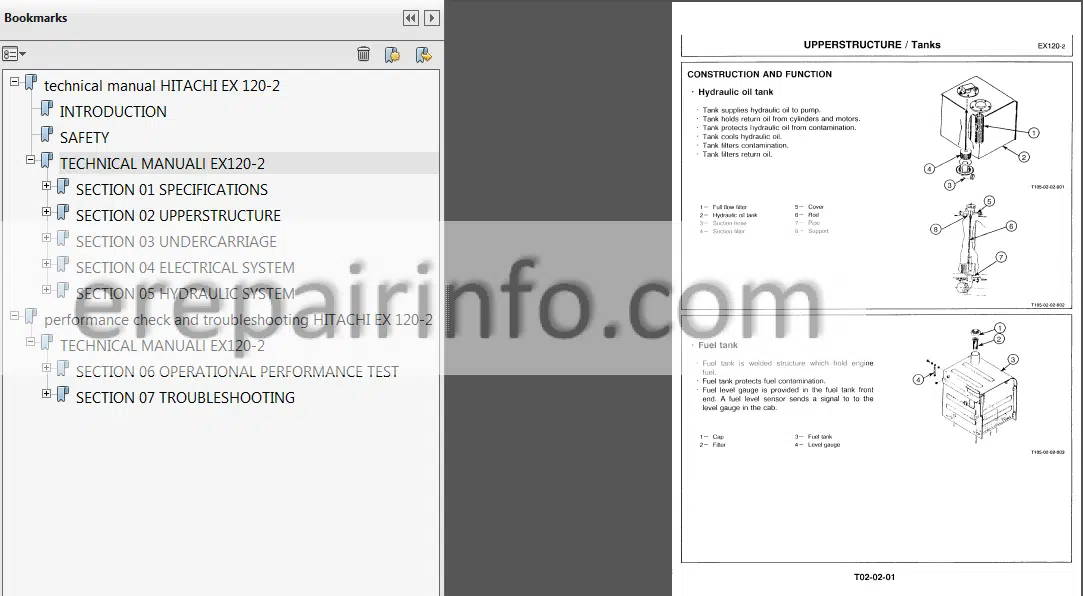

–TANKS

Construction and Function

Hydraulic Oil Tank

Fuel Tank

–PUMP DEVICE

Construction and Function

Main Pump

Regulator

Gear Pump

–SWING DEVICES

Construction and Function

Swing Motor

Brake Valve

Parking Brake

Swing Dampener Valve

Swing Reduction Device

–PIPINGS

Construction and Function

Main pipings

Pilot pipings

–CONTROL VALVE

Construction

No 1 Valve (Three spools side) No2 Valve (Four spools side)

System Pressure Regulator

Surge Relief Valve

Overload Relief Valve with Anti-Cavitation Feature

Variable Pressure Compensated

Valve

Shuttle Valve

Holding Valve

OperationfLever in Neutral)

Operation(Single)

Operation(Combined)

Hydraulic Pilot Warm Up Circuit

Auxiliary Spool Speed Adjustment

–PILOT VALVE

Construction and Function

Pilot Valve

Shuttle Valve

–LOCK VALVE

Construction and Function

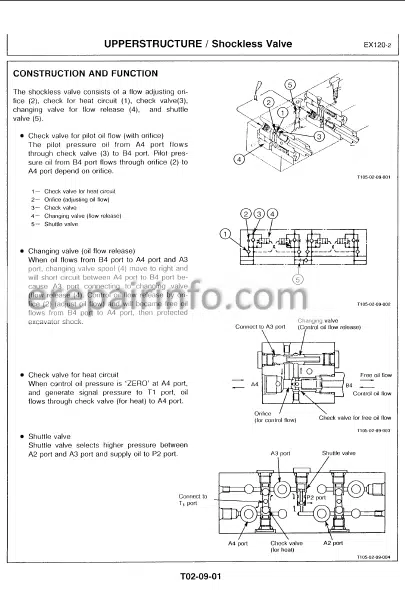

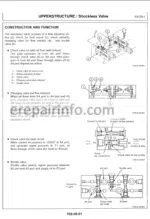

–SHOCKLESS VALVE

Construction and Function

–ACCUMULATOR

Construction

Function

Cautions for Handling

–SOLENOID VALVE

Construction and Function

Solenoid Valve

Solenoid Valve Assembly

–COMPONENT LOCATION

Component Location

–SWING BEARING

Construction and Operation

–CENTER JOINT

Construction and Operation

–TRAVEL DEVICE

Construction and Operation

Travel Reduction Device

Travel Motor

Travel Brake Valve

Parking Brake

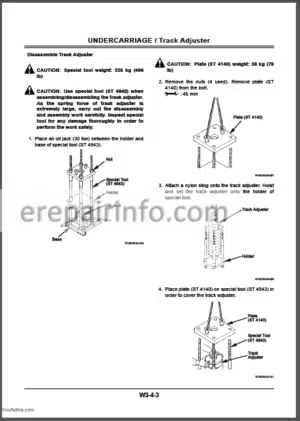

–ADJUSTER

Construction and Operation

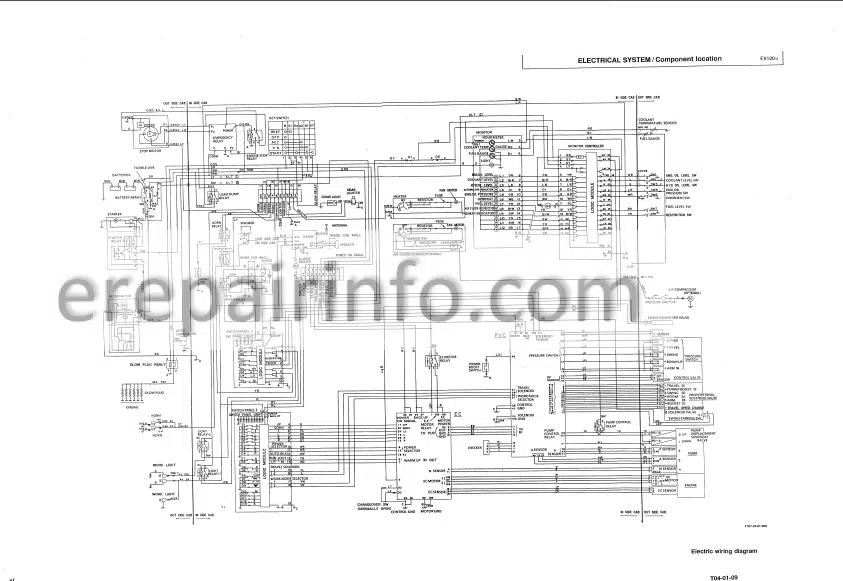

-ELECTRICAL SYSTEM

–COMPONENT LOCATION

Component Location

Monitor and Switch Panel

Monitor Panel

Switch Panel (1)

Switch Panel (2)

Relays

Electric Wiring Diagram

Connector

Engine Harness

Cab Harness

–ENGINE CONTROL SYSTEM

Outline of the Control System Summary of Control Circuits

Outline of the Engine Control System

Operation of the Engine Control Motor

Engine Control Circuit

Setting Engine Mode Speeds and Engine Speed Programing

Engine Stop Double Function

Function of the Main Electrical Equipment

–MONITOR

Outline of the Monitor

Monitor Panel

Monitor Function

Monitor Check Procedure

–CIRCUIT OPERATION

Characteristics of the Electrical System

Power Circuit

Preheat Circuit

Engine Start Circuit

Charging Circuit

Operation of the Regulator

Voltage Adjustment

How to Troubleshoot Malfunction in the Charging Circuit

Surge Voltage Prevention Circuit

Accessory Circuit

EC Motor Engine Stop

Slop Motor Engine Stop

Key Switch Engine Stop

Emergency Engine Stop

Auto Idle Function

–INSPECTION AND MAINTENANCE

Precautions for Inspection and Maintenance

Fuse Continuity Test

Taking Apart Connector

Inspection and Replacement of Fusible Link

Installation and Adjustment of the A – Sensor

Positioning the EC Sensor

-HYDRAULIC SYSTEM

–GENERAL

General

Main Circuit

Suction Circuit

Delivery Circuit

Return Circuit

Drain CircuitT

Systerm Pressure Regulate Control

Pilot Circuit

Suction Circuit

Delivery Circuit

Return Circuit

Control System

Control Systern Layout

–CONTROL SYSTEM

Pump Control System

Load Sensing System

Speed Sensing System

Valve Control System

Flow Dividing Control System

Job Mode Selector

Propel Speed Control System

3-Speed Propel Control

Ollier Control System

Swing Parking Brake

Warming-Up Control

–MAIN HYDRAULIC CIRCUIT

Neutral Circuit

Swing Operation

Arm In Circuit

Swing Circuit

Combined Operation

Combined Boom and Swing Circuit

Relief Circuit

-OPERATIONAL PERFORMANCE TEST

–STANDARD

Operational Performance Standard

–INTRODUCTION

Purpose

Terminology

Preparation For Performance Tests

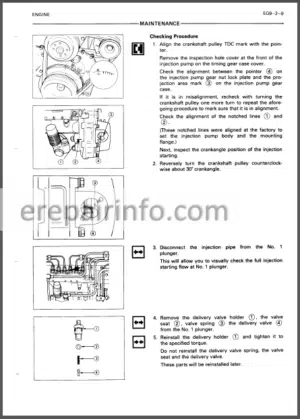

–ENGINE TEST

Engine Speed

Engine Compression Pressure

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack

Travel Parking Function Check

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Combined Boom Raise1 Arm Roll-In Functions Check

Combined Boom RaiseSwing Functions Check

Combined Boom Raise/Arm Roll-Out /Swing Functions Check

–HYDRAULIC COMPONENT TEST

Pilot Primary Pressure

Adjustment

Pilot Secondary Pressure

Proportional Solenoid Valve Pressure ( PC Pressure)

Adjustment

Swing Parking Brake Releasing Pressure

Reducing Valve Pressure Setting (PI Pressure)

Adjustment

Main Pump Delivere Pressure

System Pressure Regulator

Relief Setting

Adjustment

Overload Relief Valve

Pressure Setting

Adjustment

Main Pump Row Test

(Reference) Pump PQ Curve

Swing Motor Drainage

Travel Motor Drainage

–BASIC PERFORMANCE CHECK

Basic Performance Check

With the Dr EX

Pressure (P) switch

In the Neutral Position, and at Relief Pressure

A sensor (Pump Displacement Angle Sensor)

Single Operation

Combined Operation

Combmed Boom raise and Arm roll-in

Combined Bucket roll-in relief and Boom raise

Combinod Bucket roll-in and Boom raise

Combined Travel and Arm roll-in relief

Swing Check with Precision mode (M4)

-TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

Operation Procedure of DrEX

Self-diagnosis Function

Clearing self-diagnosis function

DrFX Monitor Function

Chock Battery Voltage and Fuses

Check Fusible Link

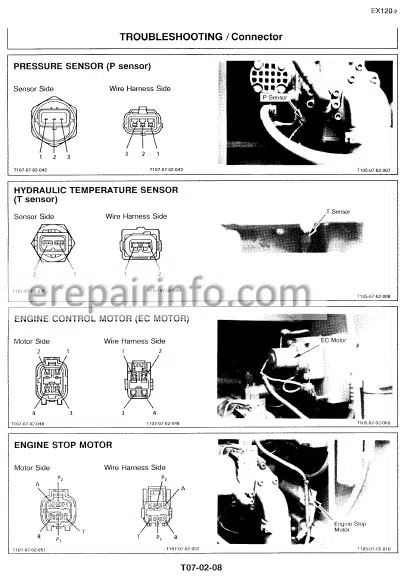

–CONNECTOR

Connector Location

Types of Each Connector

–TROUBLESHOOTING A

List of EC Relating Fault Codes List of PVC Relating Fault Codes

Fault Codes 01,020304 and 06

Fault Code 05

Fault Codes 09 and 10

Fault Code 13

Fault Codes 171819 and 21

Fault Code 20

Fault Codes 22

Fault Codes 25 and 26

Fault Codes 27 and 28

Fault Codes 29 and 30

Fault Codes 31 and 32

–TROUBLESHOOTING B

Outline

Effect of Electronic Component Malfunctions on Machine Operations

Machine Malfunctions and Possible Causes

ENGINE

E-1 Starter does not Rotate

E-2 Starter Rotates but Engine does not Fire

E-3 Hard to Start when Temperature is low

E-4 Engine Stalls when I ighl Load is Applied

E-5 Engine Stalls within about 10 Second After Engine Start

E-678 Auto-kile does not Function

E-91011 Abnormal Engine Speed

E-12 Engine does not Stop

ACTUATORS

A-1 Cylinder and Monitor Speed are Slow

A-2 Cylinder and Monitor do not Move

A-3 Cylinder and Monitor do not Stop Working

A -4 Poor Combined Operation

Front Attachments

F-1 Cylinder Speeds are Slow (Motor Speed are Normal)

F-2 Cylinder Moves Slowly or Docs Not Move

F-3 Front Attachment Drops Noticably

F-4 Front Attachment Drops Briefly then Begins to Move when Operating the Lever

Swing

S-1 Slow Speed or Weak Power in Swing Operation

S-3 Big Shock is Fell when Swing is Slopped

S-2 Swing Coasts Excessively when Swing Lever is Returned to Neutral

S-4 Swing Drifts Excessively on a Slope

S-5 Superstructure does not Swing

Travel

T-1 Travel Speed is Slower than Specified Ranges

T-2 Travel Speed does not Change

T-3 The Excavator Mistracks

T-4 Travel Motor do not Rotate

T-5 Travel Power is Weak

Others

0-1 Work Mode Selector Switch docs not Operate

0-2 Slow Response in Operation Control

0-3 Excessive Noise and/or Vibration from the Pump

0-4 Wiper does not Function

0-5 Fuse Fails

–TROUBLESHOOING C

Monitor Panel, Switch and Sensor Location

Malfunction of Coolant

Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Level Check Switch

Malfunction of Engine Oil Level Indicator

Malfunction ol Coolant Level Indicator

Malfunction of Hydraulic Oil Level Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Air Tilter Restriction Indicator

Malfunction of Buzzer

Malfunction of Hour Meter

–HARNESS CHECK

Wiring Harness Test

lest 1 Battery Circuit Test

Test 2 5 Volt Sensor Circuit Test Test 3 Branchless Harness Test

Test 4 Test Harnesses Between Switch Panel 2 and PVC EC

Test 5 T sensor Harness lest

Test 6 Pressure Switch Harness Test

Test 7 Proportional solenoid Valve Hamess Test

Test 8 Pump Displacement Solenoid Valve Harness Test

Test 9 Swing Dampener Solenoid Valve Harness Test

Test 10 Directional Solenoid Valve Harness lest

Test 11 EC motor

Harness Test

Test 12 Engine stop motor Harness Test

Test 13 Emergency Relay Activation Test

Test 14 Relay Circuit test

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Great service.

Anonymous (verified owner) –

Happy